Patents

Literature

32results about How to "Achieve stable operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

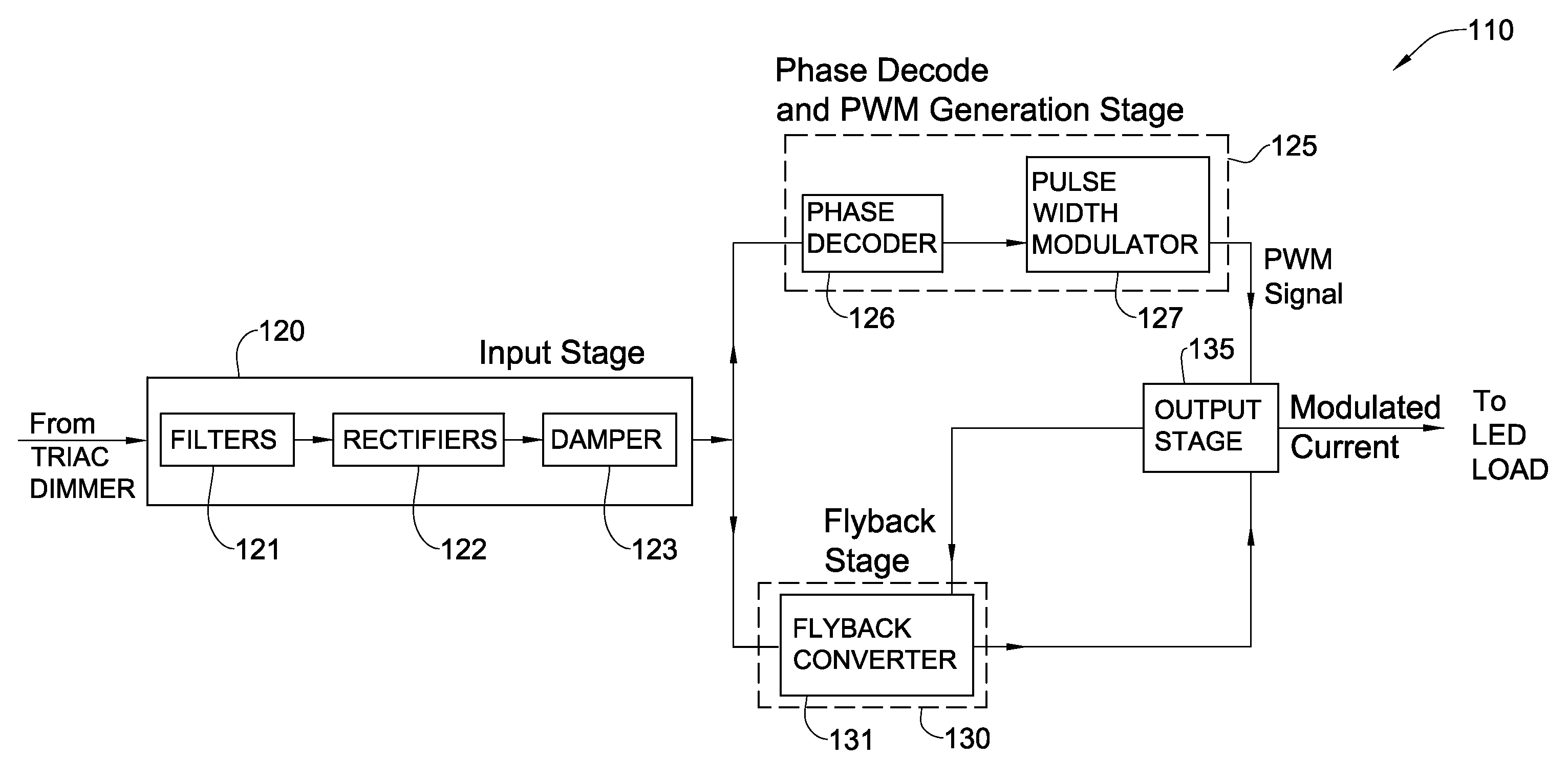

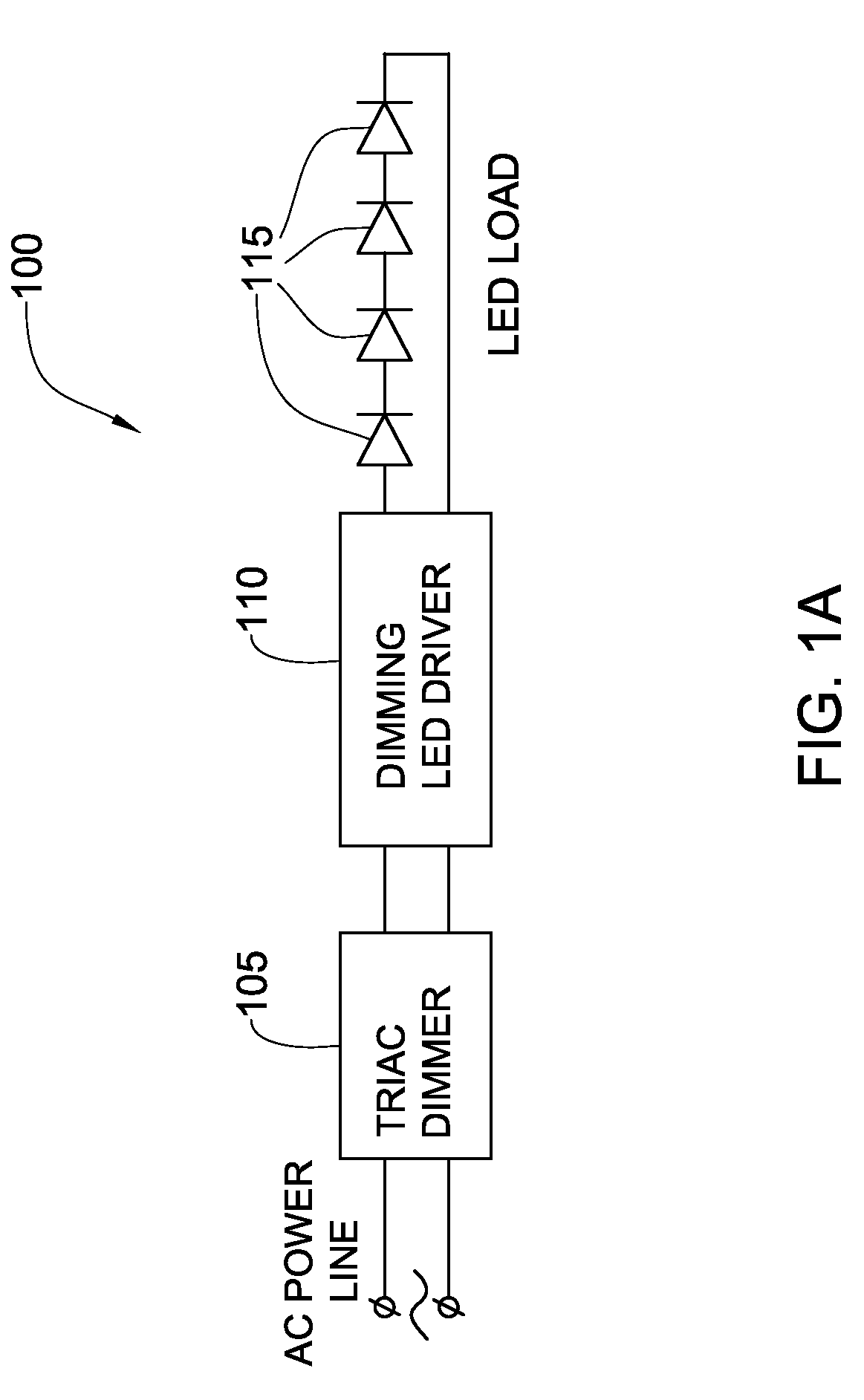

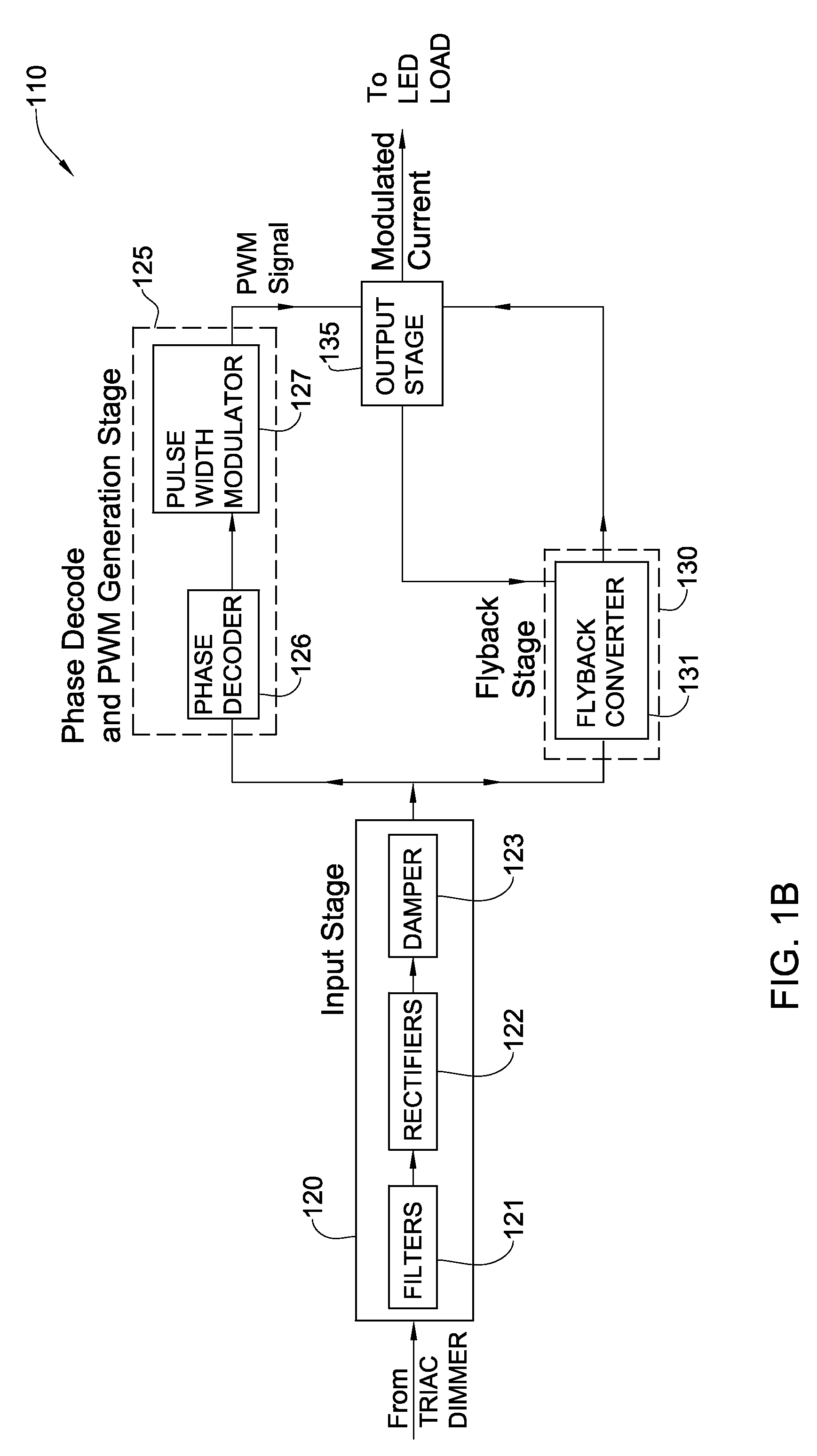

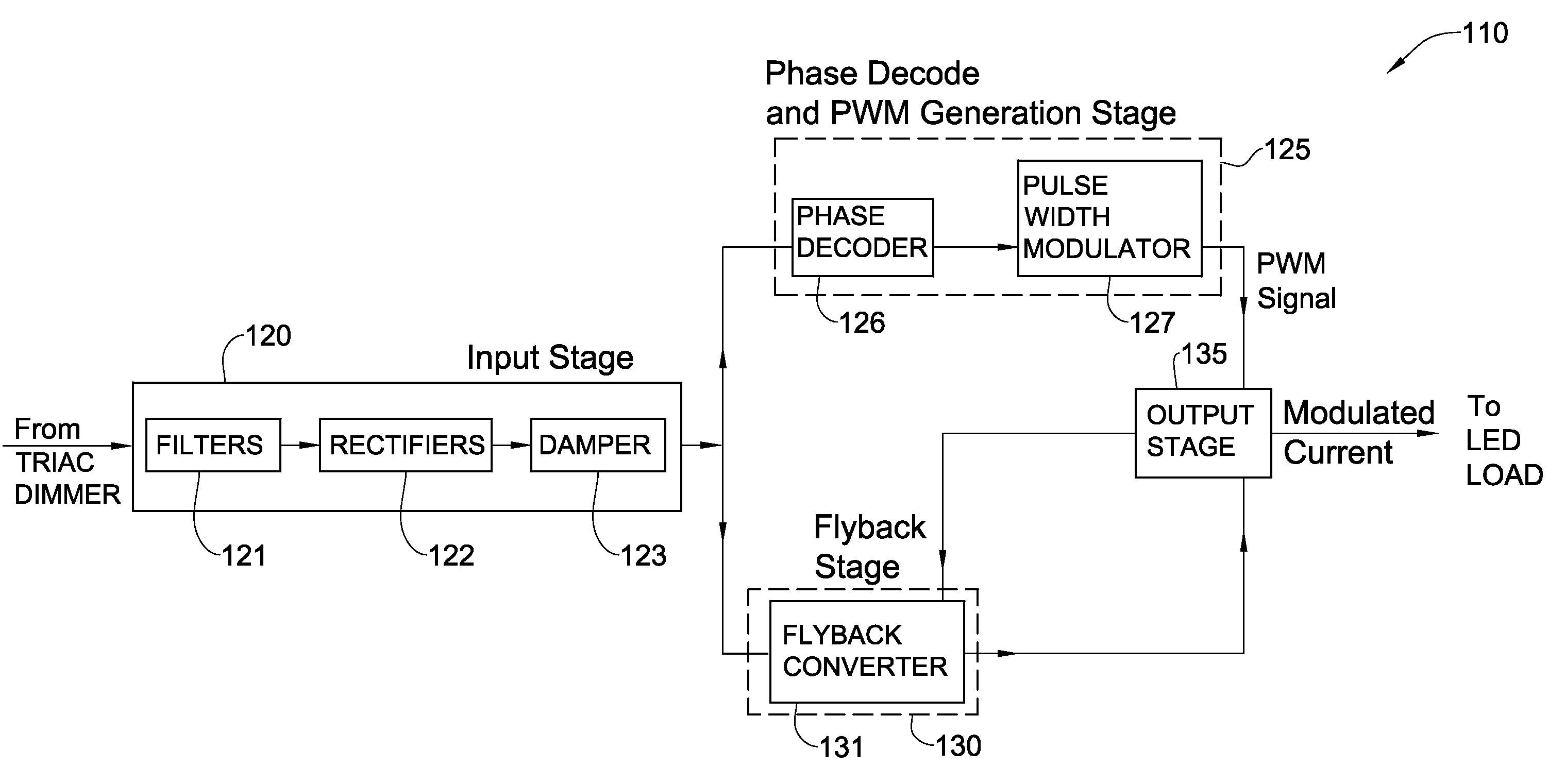

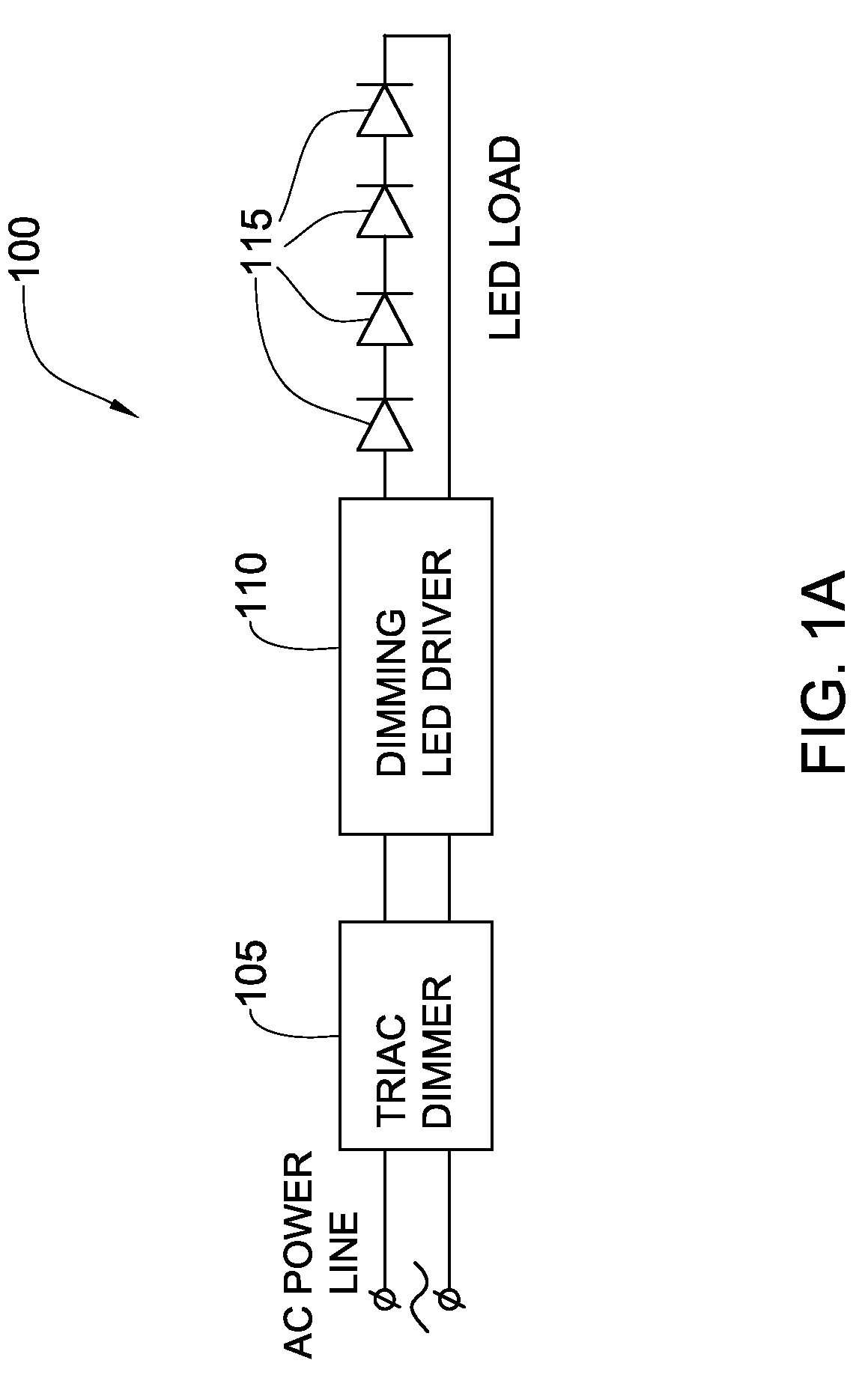

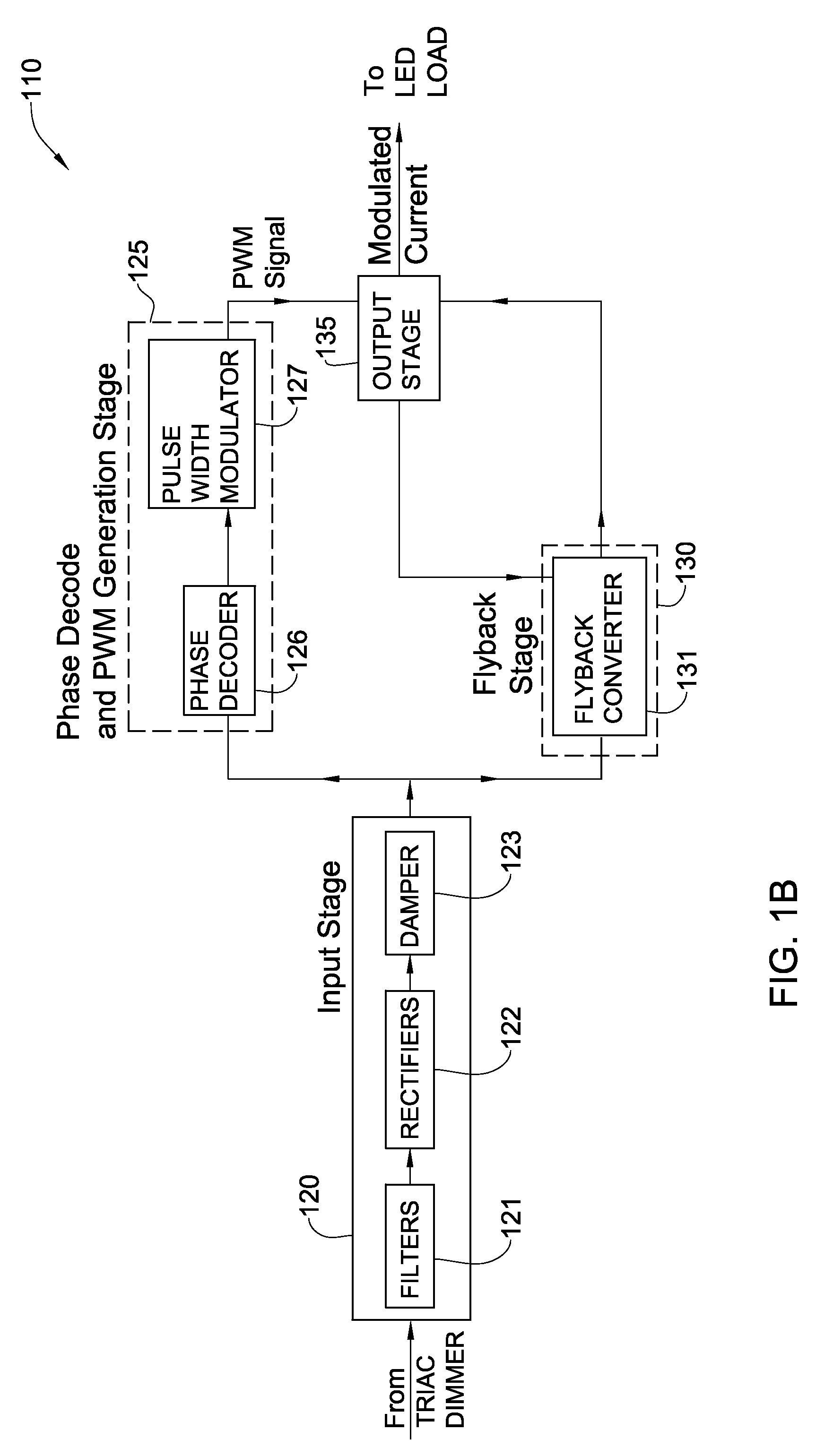

Phase controlled dimming LED driver system and method thereof

ActiveUS20100134038A1Guaranteed uptimeAchieve stable operationElectroluminescent light sourcesElectric light circuit arrangementDimmerEngineering

The present invention relates to providing an improved phase controlled dimming LED driver circuitry, system and a method thereof, which is configured to enable dimming intensity of light generated by a light source, said phase controlled dimming driver circuitry being connected to a phase control dimmer that provides to it a regulated alternating current (AC) signal, wherein said phase controlled dimming driver circuitry does not include a microprocessor and pulse width modulates its output current, provided to said light source, at a frequency unrelated to the AC signal frequency. Further, the phase controlled dimming driver circuitry applies amplitude modulation (AM) and pulse width modulation (PWM) substantially simultaneously to the output current provided to the light source.

Owner:SAVANT TECH LLC

Phase controlled dimming LED driver system and method thereof

ActiveUS8203276B2Guaranteed uptimeAchieve stable operationElectroluminescent light sourcesElectric light circuit arrangementDimmerEngineering

The present invention relates to providing an improved phase controlled dimming LED driver circuitry, system and a method thereof, which is configured to enable dimming intensity of light generated by a light source, said phase controlled dimming driver circuitry being connected to a phase control dimmer that provides to it a regulated alternating current (AC) signal, wherein said phase controlled dimming driver circuitry does not include a microprocessor and pulse width modulates its output current, provided to said light source, at a frequency unrelated to the AC signal frequency. Further, the phase controlled dimming driver circuitry applies amplitude modulation (AM) and pulse width modulation (PWM) substantially simultaneously to the output current provided to the light source.

Owner:SAVANT TECH LLC

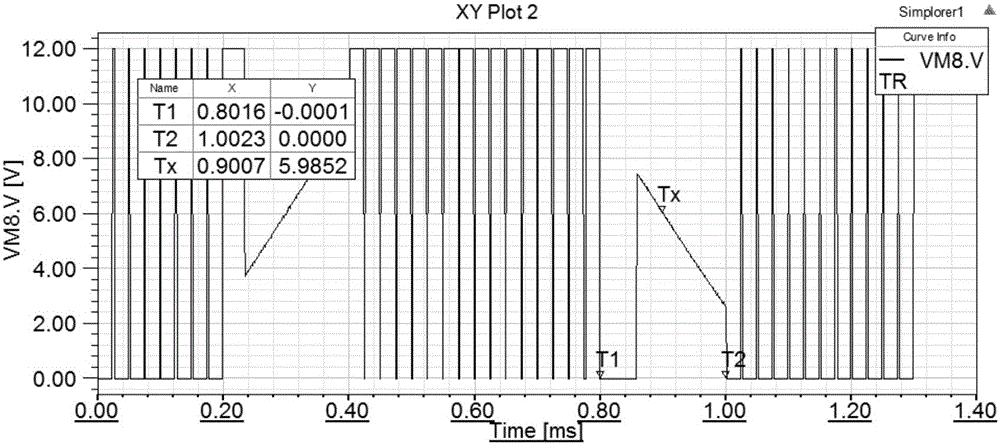

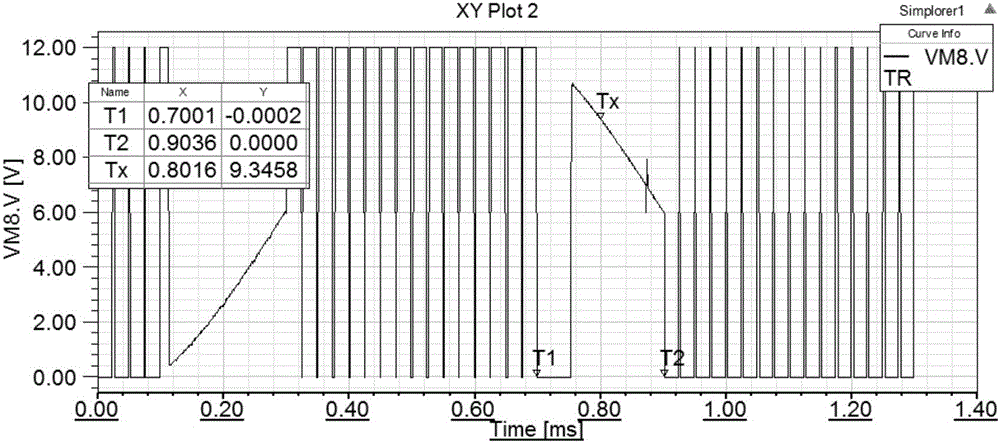

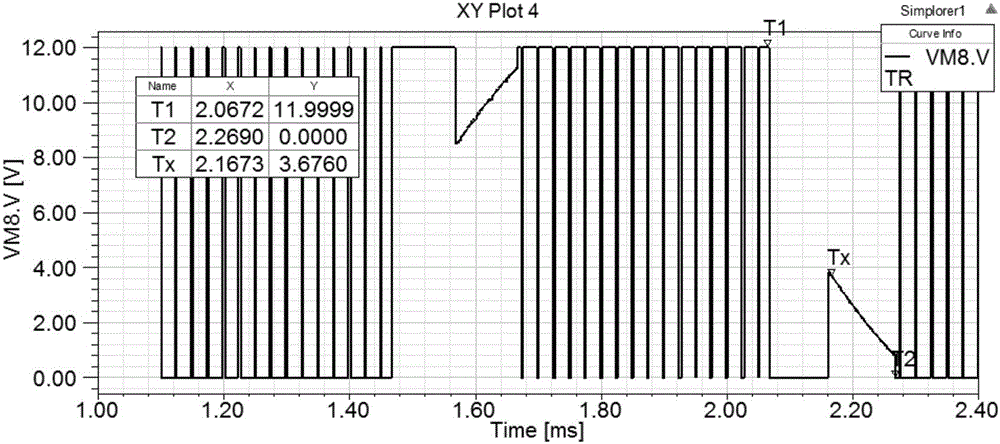

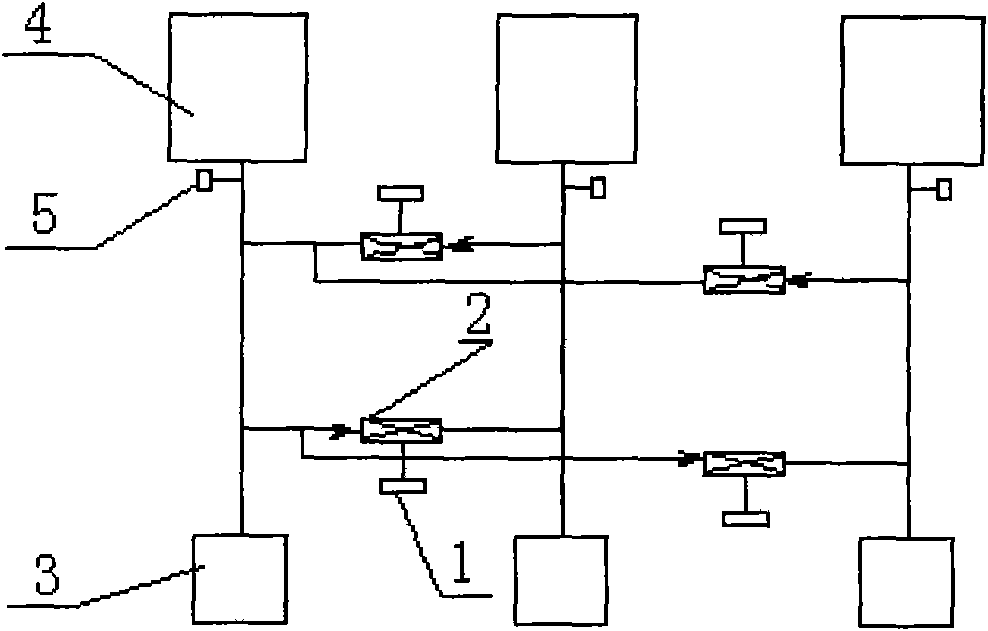

Real-time correction system and method for commutation phase of sensorless brushless DC motor

InactiveCN106452225AAchieve stable operationGuaranteed uptimeElectronic commutation motor controlDriver circuitClosed loop

The invention discloses a real-time correction system and method for a commutation phase of a sensorless brushless DC motor. A set of winding terminal voltage component voltage detection circuit is added to a drive circuit adopting complementary type PWM control on the basis of a traditional back electromotive force sensorless detection circuit; corresponding output voltage of a turn-off phase component voltage detection circuit is sampled at a middle moment tx of each on state of the brushless motor; whether an on state commutation phase is leading or lagging can be judged according to the voltage; and the on state commutation phase is taken as a feedback signal corrected by the commutation phase and closed-loop regulation of the commutation phase is completed through PI regulation, so that optimal commutation of the brushless motor at any rotating speed and in any load condition is ensured and sensorless stable operation of the brushless motor is achieved.

Owner:SHANDONG UNIV

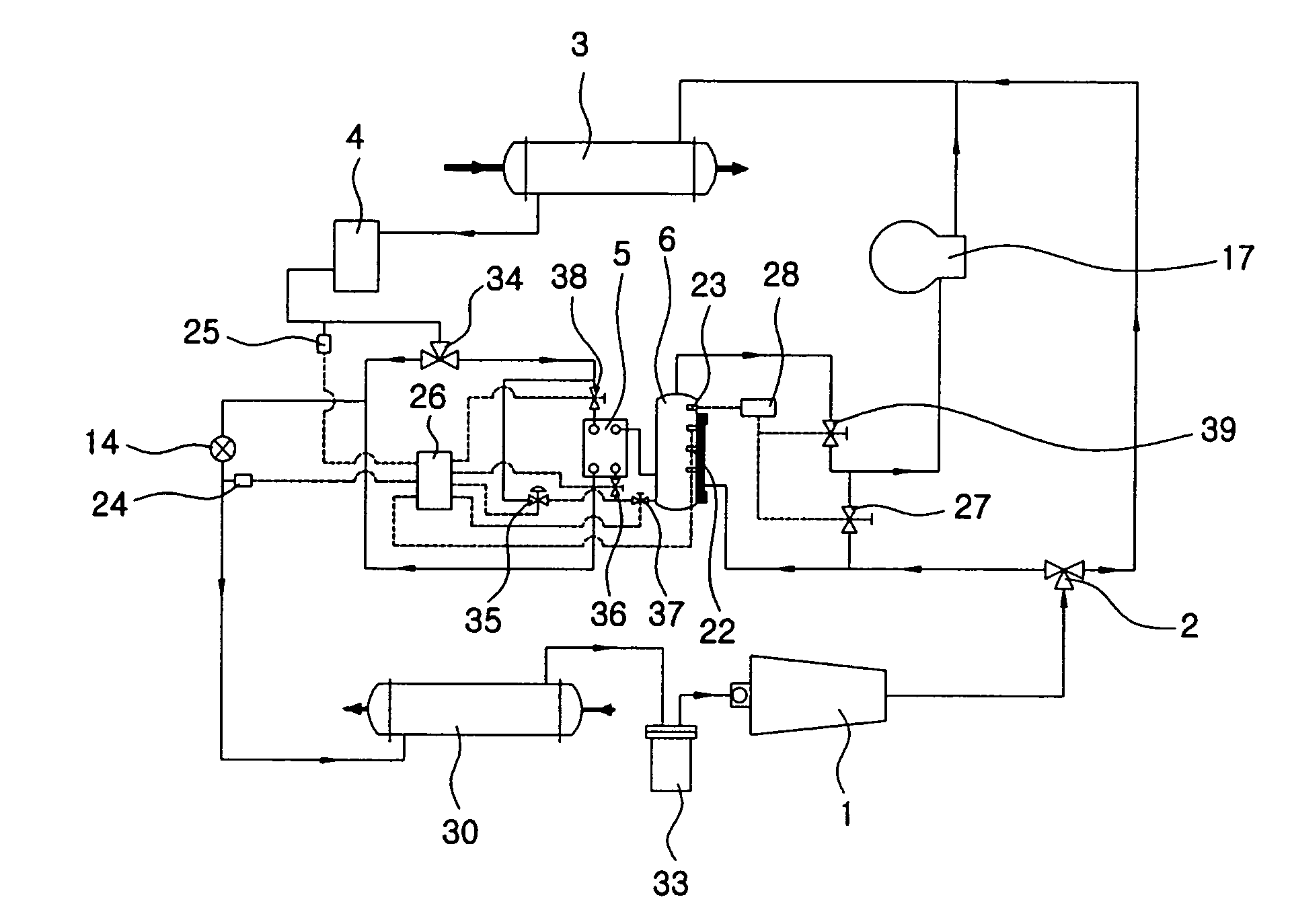

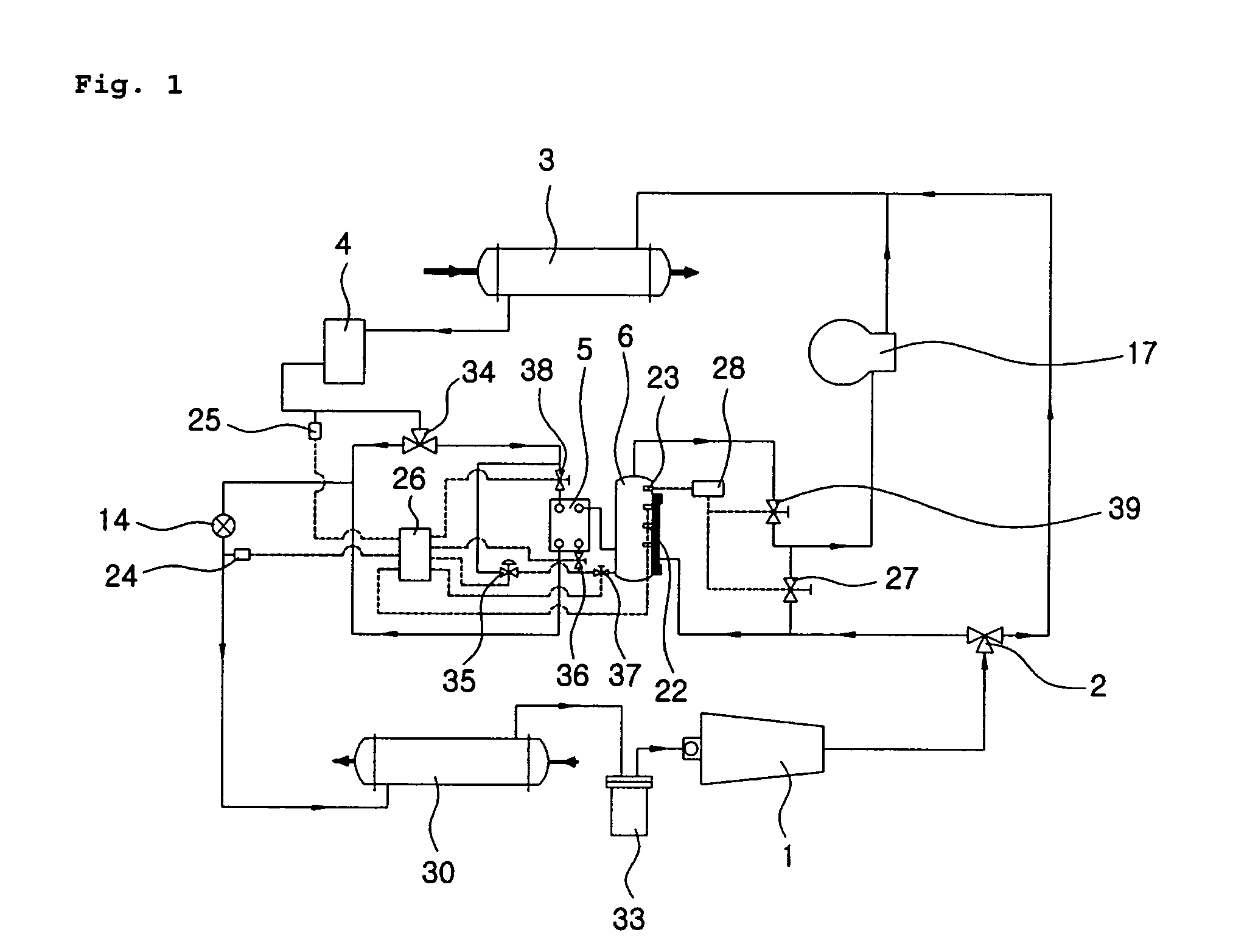

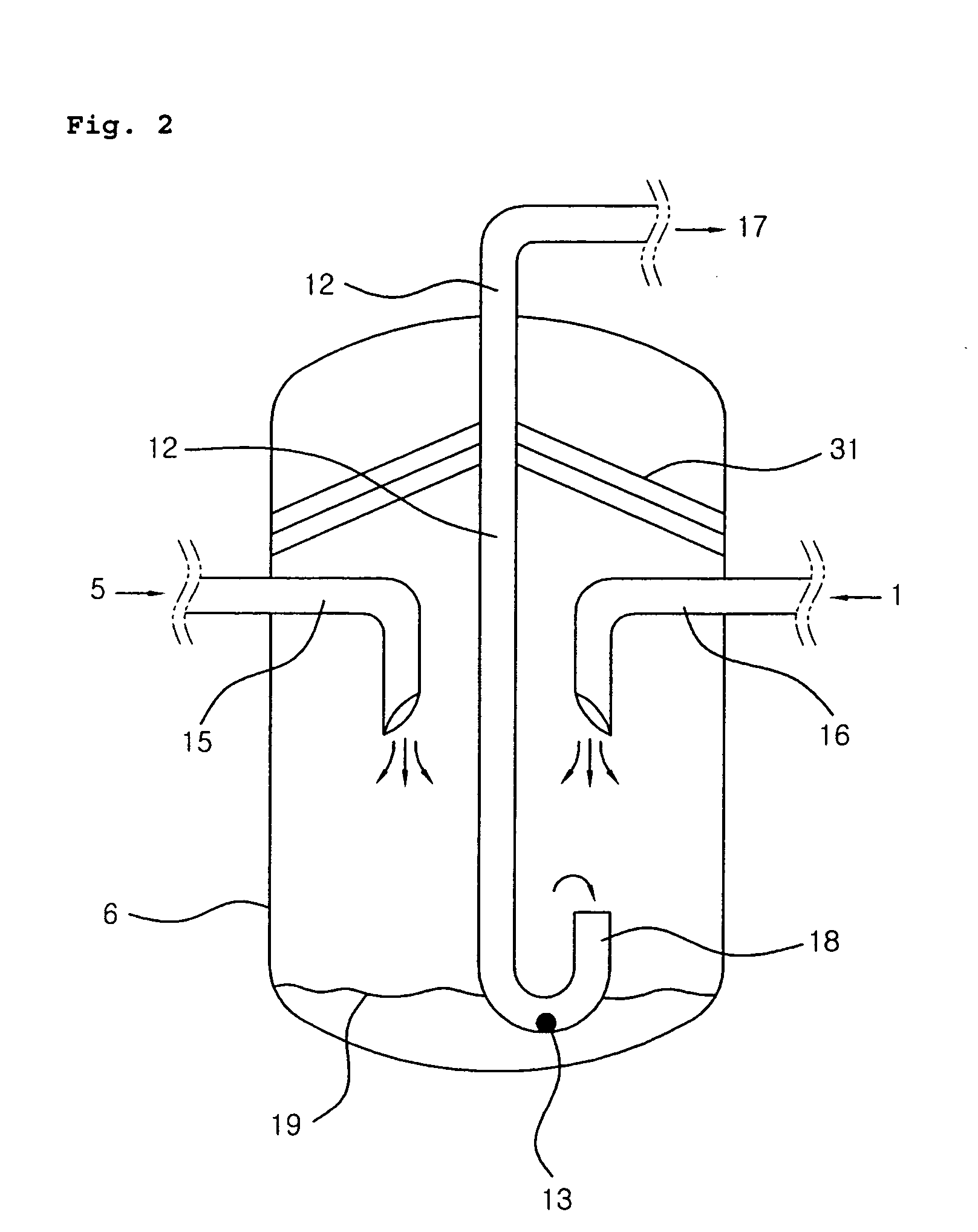

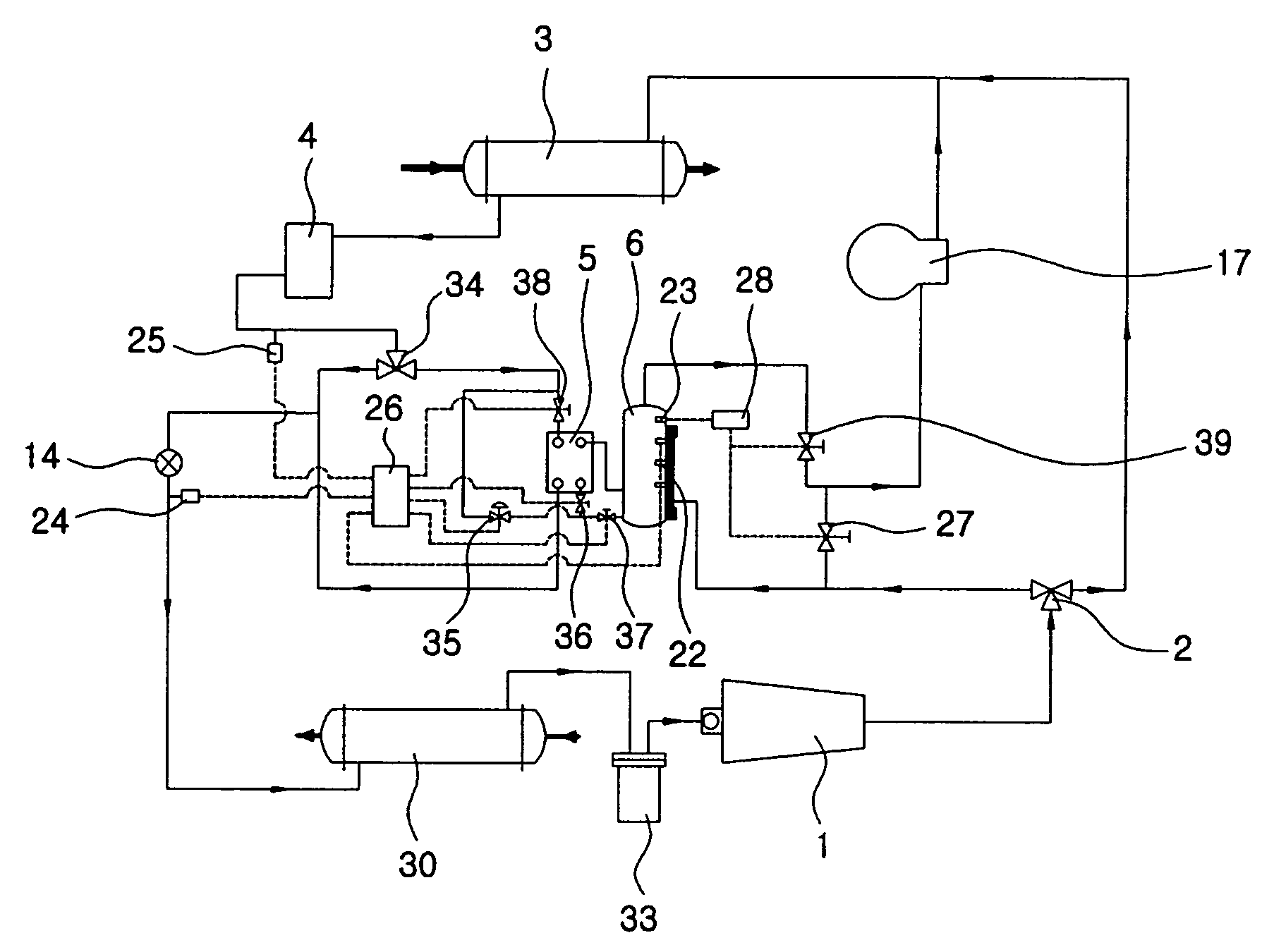

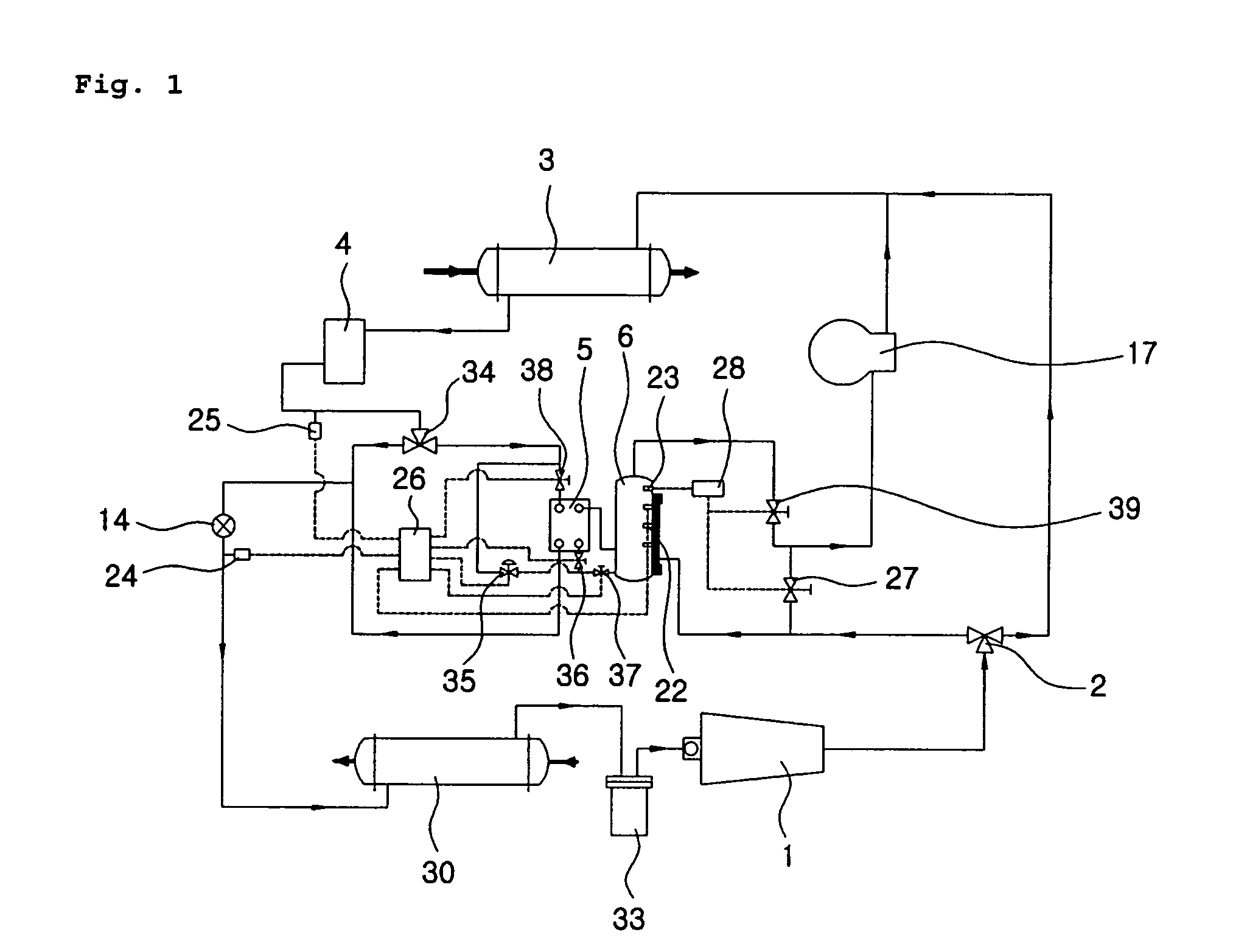

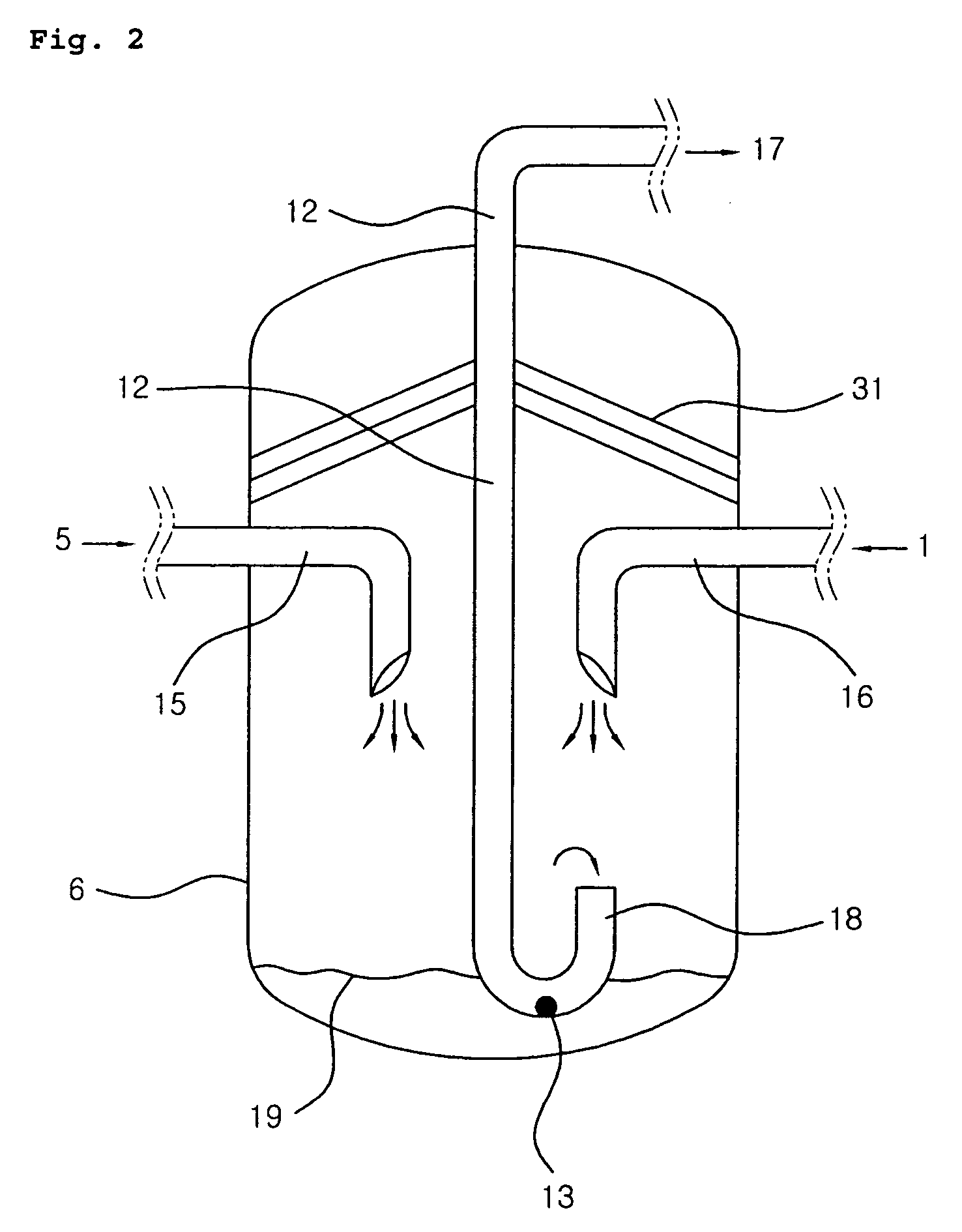

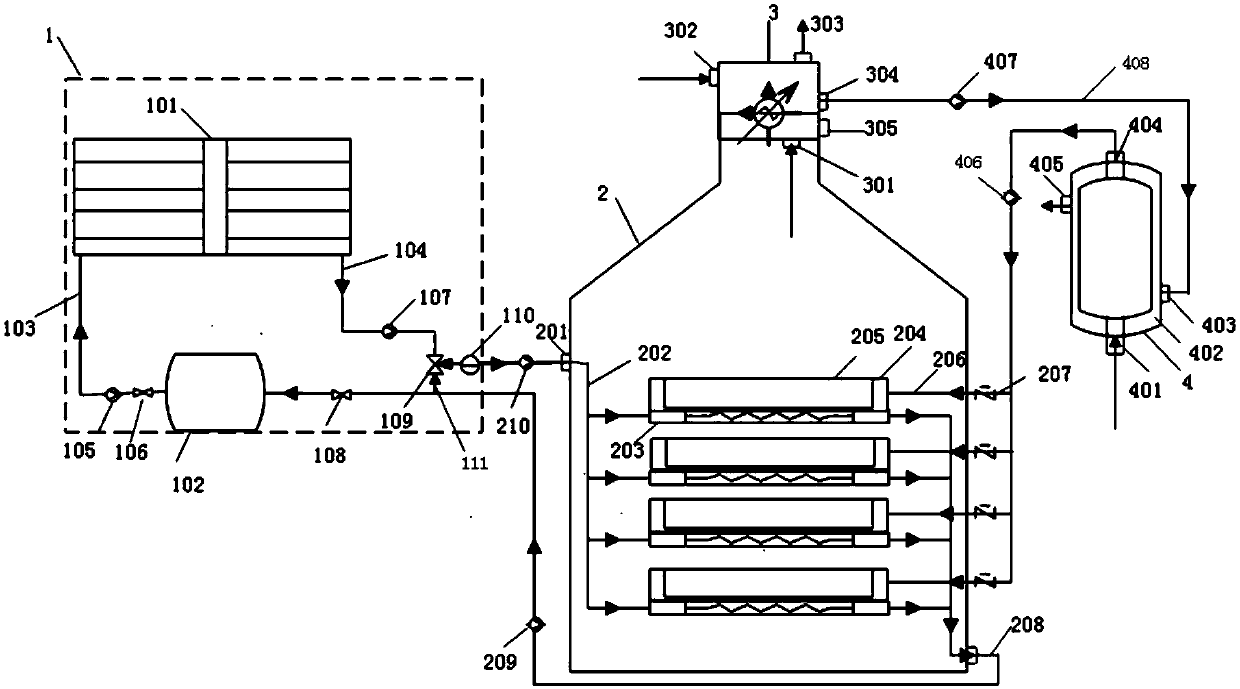

Flash tank of two-stage compression heat pump system for heating and cooling

ActiveUS20060174639A1Liquid compression can be preventedEasy to collectCompressorHeat pumpsEngineeringIntercooler

Disclosed herein is a flash tank of a two-stage compression heat pump system that can perform cooling and heating with a separate type intercooler and a high-stage compressor protecting device. The system comprises a fluid-level detecting sensor for detecting the fluid-level of the refrigerant, an alarm sensor for notifying the saturated state of the refrigerant filled in the flash tank, an evaporator pressure sensor for measuring and notifying the pressure of the refrigerant flowing into the evaporator, a condenser pressure sensor for measuring and notifying the pressure of the refrigerant flowing out of the condenser, a flash tank fluid-level controller for receiving signals from the above sensors and controlling intermediate pressure and the fluid-level of the flash tank, and a bypass valve controller for controlling a bypass valve that receives signals from the alarm sensor and allowing a refrigerant to directly flow from the low-stage compressor to the high-stage compressor.

Owner:KOREA INST OF ENERGY RES

Flash tank of two-stage compression heat pump system for heating and cooling

ActiveUS7356998B2Achieve stable operationImprove cooling effectCompressorHeat pumpsIntercoolerEngineering

Disclosed herein is a flash tank of a two-stage compression heat pump system that can perform cooling and heating with a separate type intercooler and a high-stage compressor protecting device. The system comprises a fluid-level detecting sensor for detecting the fluid-level of the refrigerant, an alarm sensor for notifying the saturated state of the refrigerant filled in the flash tank, an evaporator pressure sensor for measuring and notifying the pressure of the refrigerant flowing into the evaporator, a condenser pressure sensor for measuring and notifying the pressure of the refrigerant flowing out of the condenser, a flash tank fluid-level controller for receiving signals from the above sensors and controlling intermediate pressure and the fluid-level of the flash tank, and a bypass valve controller for controlling a bypass valve that receives signals from the alarm sensor and allowing a refrigerant to directly flow from the low-stage compressor to the high-stage compressor.

Owner:KOREA INST OF ENERGY RES

Two-speed wind distributing method for blast furnace blower

InactiveCN101880741AAlleviate wind pressure lossAchieve stable operationBlast furnace detailsHeating stovesSlagProgrammable logic controller

The invention discloses a two-speed wind distributing method for a blast furnace blower. The method adopts a running way combining a DCS (Distributed Control System) with a PLC (Programmable Logic Controller) system, and is characterized by adopting multi-machine interconnection, automatic judgment after failure, and automatic wind distributing and carrying out two-speed wind distributing on the blower. In the double-speed wind distributing method, the angle of a wind distributing valve is opened by sections, and in the opening method, the opening time is 3-5 seconds in first 20 degrees to ensure that the flow quantity reaches 30%-40% of the total flow quantity of the valve; and the opening time is 30-40 seconds in last 70 degrees so as to ensure that the throttling valve reaches maximum flow quantity in the time period. By adopting the measure of carrying out two-speed controlled wind distributing on the failed blast furnace blower, the invention stably increases the loads on the blast furnace blower subjected to wind distributing, ensures the pressure of the blast furnace to slowly and stably fluctuate, reduces the economic loss of accidents, effectively ensures the failed blast furnace not to run with slag pouring, and eliminates the slag pouring accident of the failed blast furnace, caused by delayed artificial operation.

Owner:ANGANG STEEL CO LTD

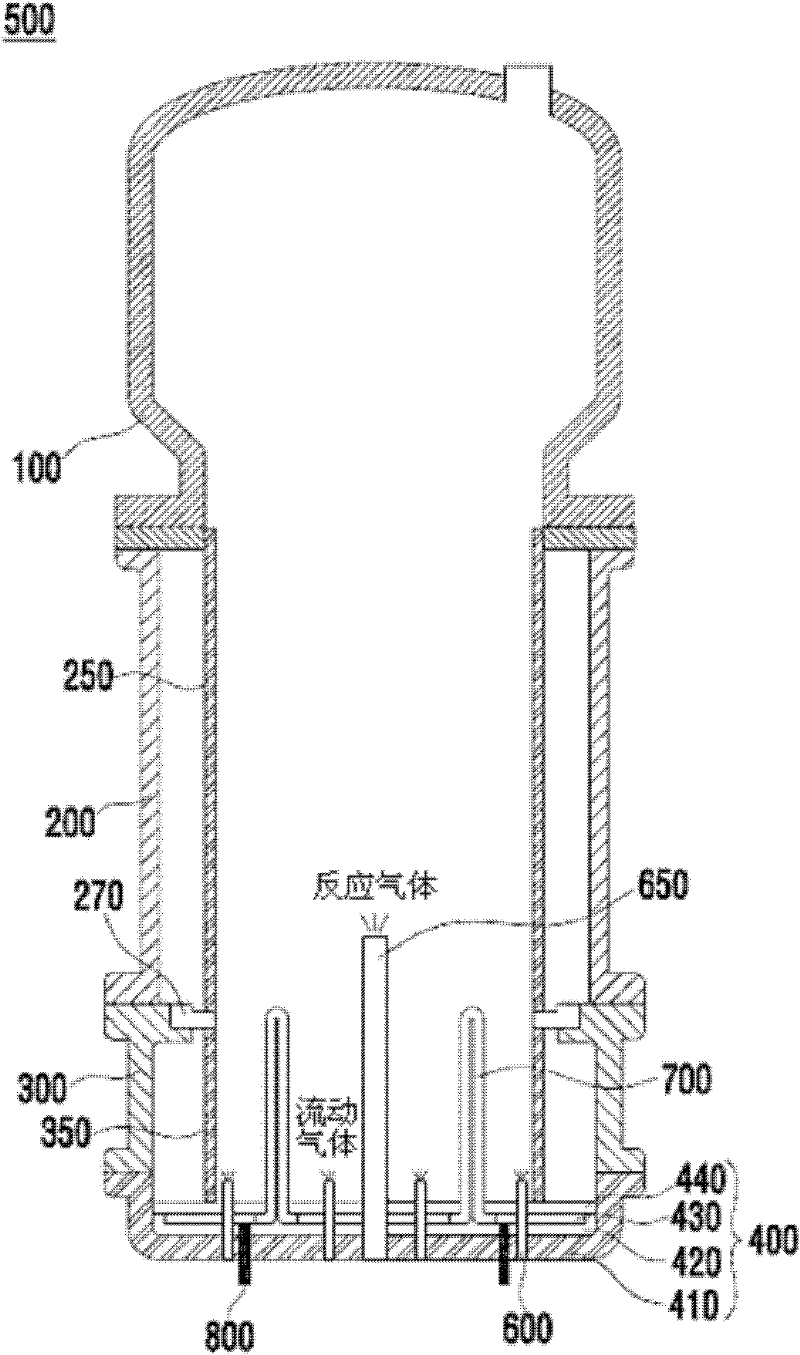

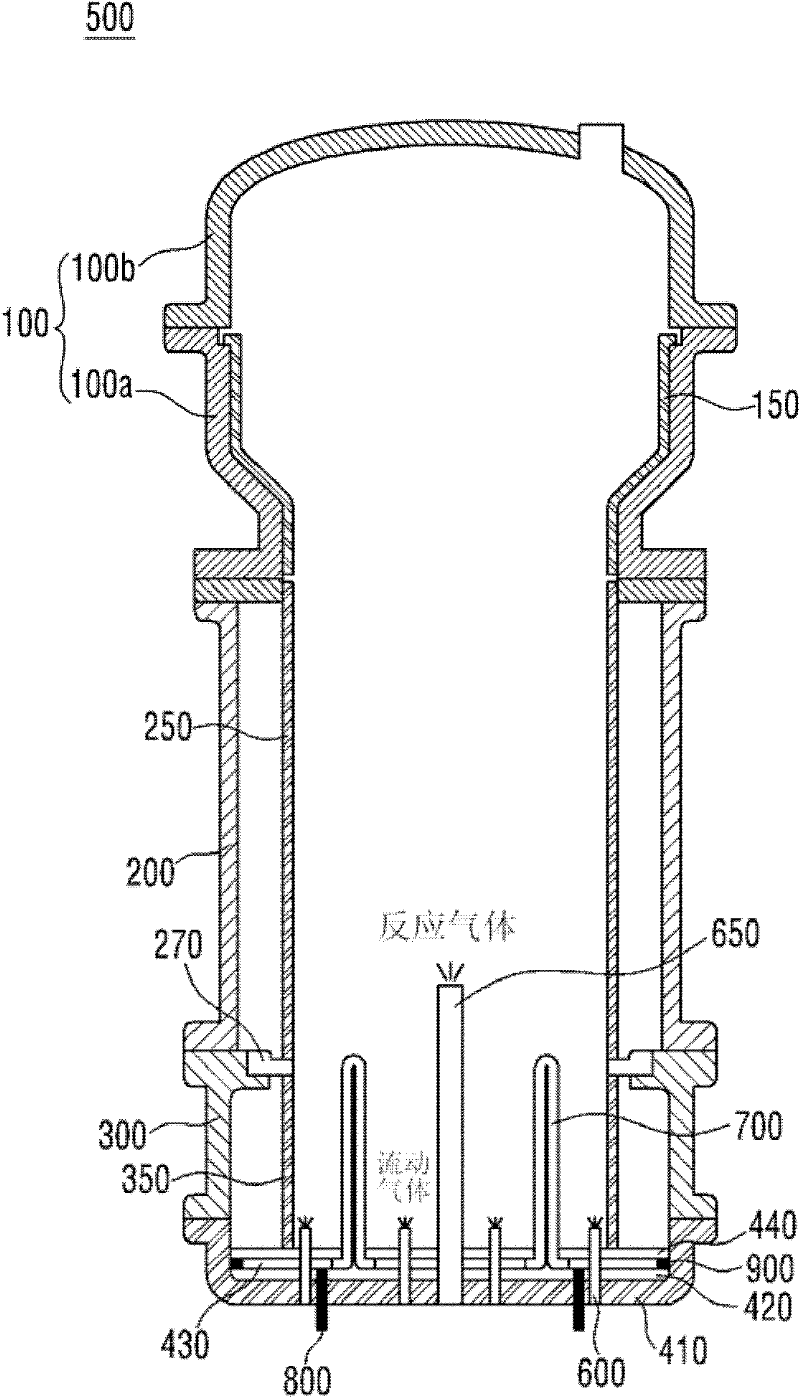

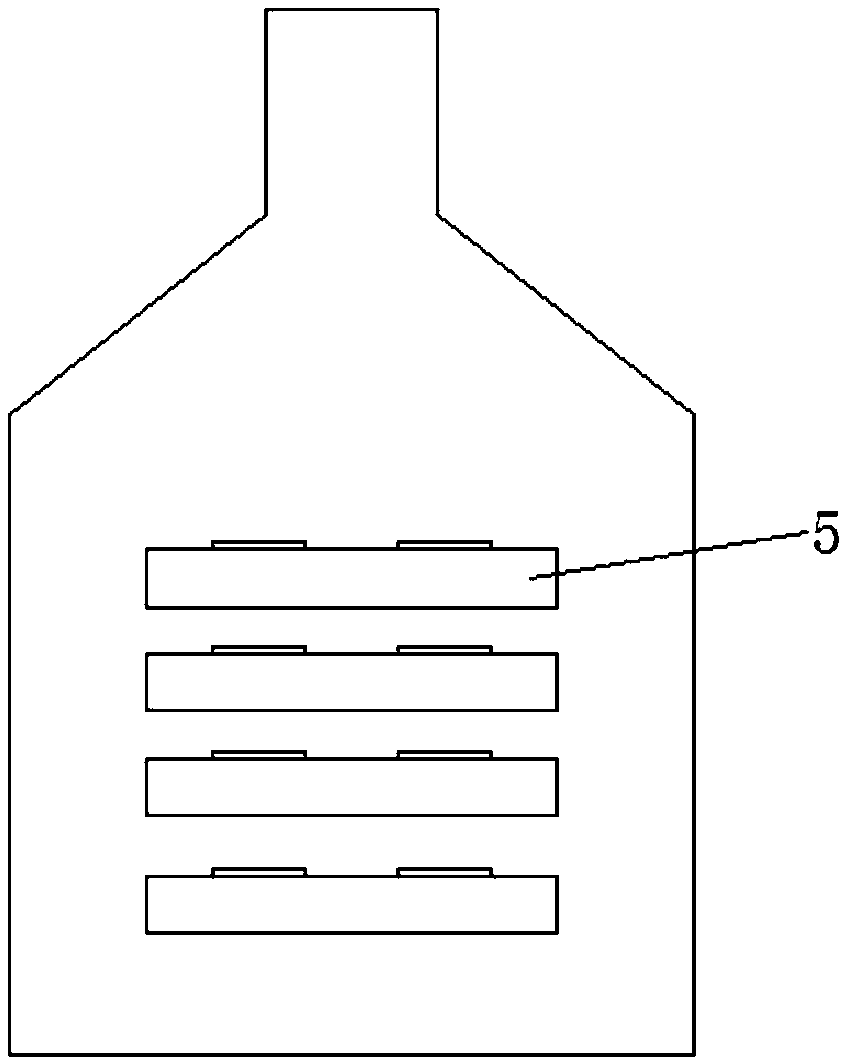

Fluidized bed reactor

InactiveCN102442669AEasy to assembleEasy to installSiliconChemical/physical/physico-chemical processesFluidized bedBiomedical engineering

Fluidized bed reactor is disclosed. The fluidized bed reactor includes a head; a first body part connected with the head, located under the head, the first body part having a first reaction pipe, with a diameter smaller than a diameter of the head, provided therein; a second body part connected with the first body part, located under the first body part, the second body part having a second reaction pipe, with a diameter substantially identical to the diameter of the first reaction pipe, provided therein; and a bottom part connected with the second body part, wherein the first body part and the second body part are able to be assembled to or disassemble from each other.

Owner:SILICONVALUE +1

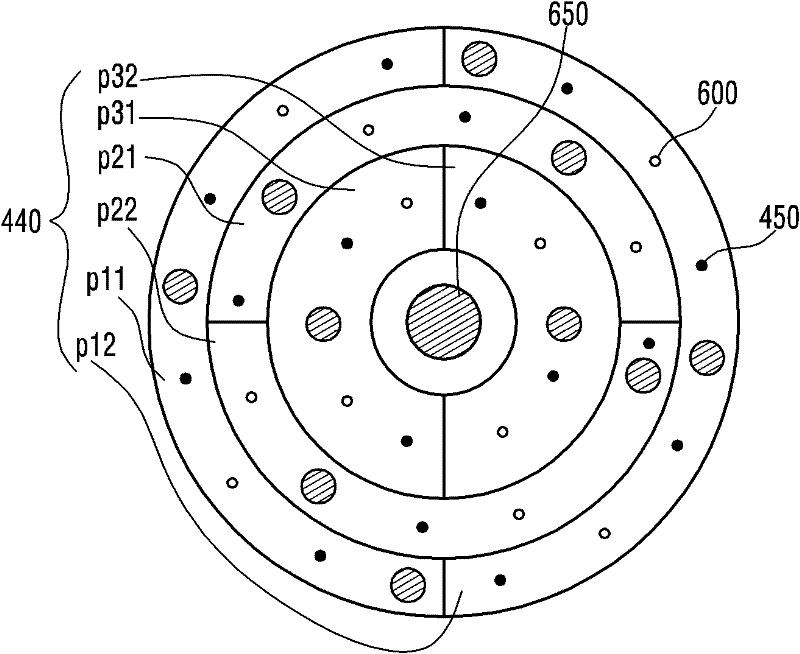

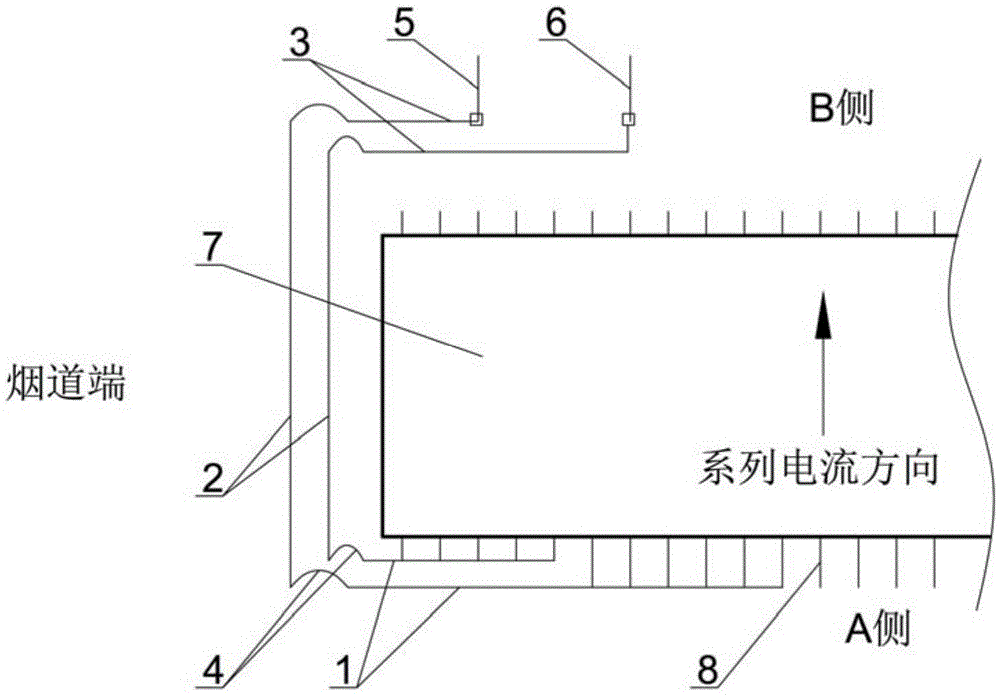

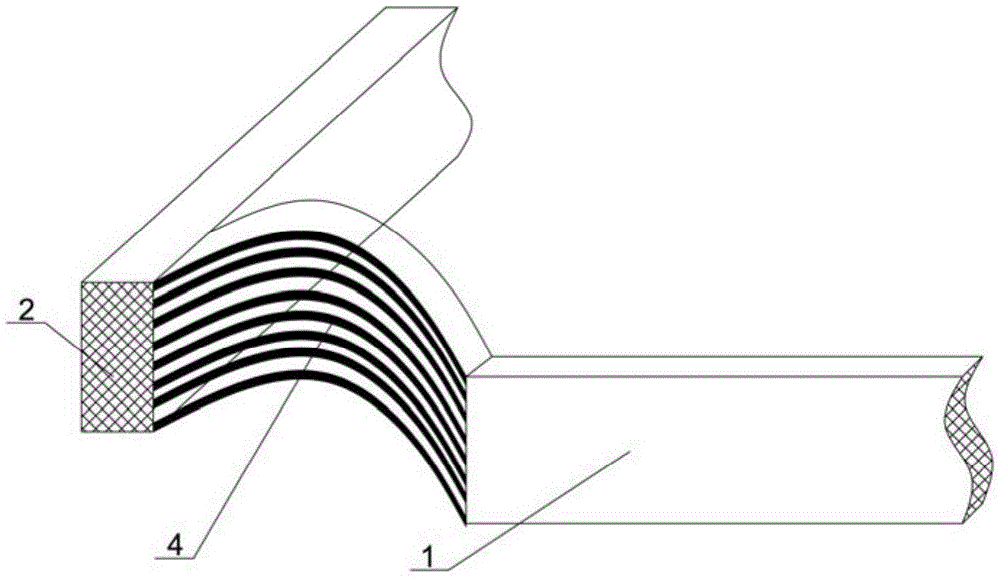

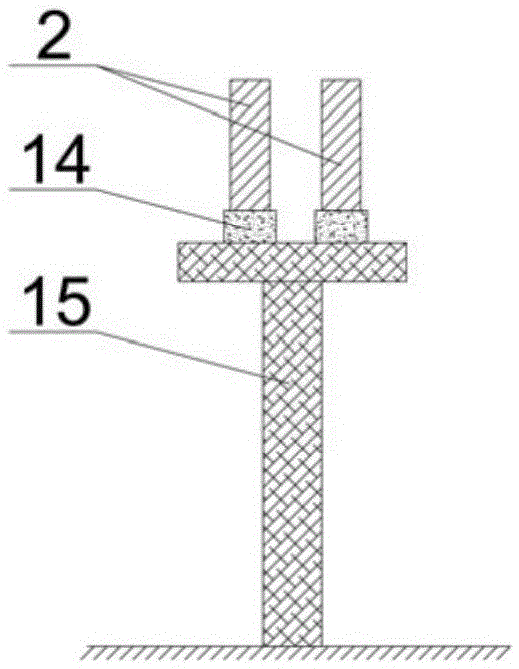

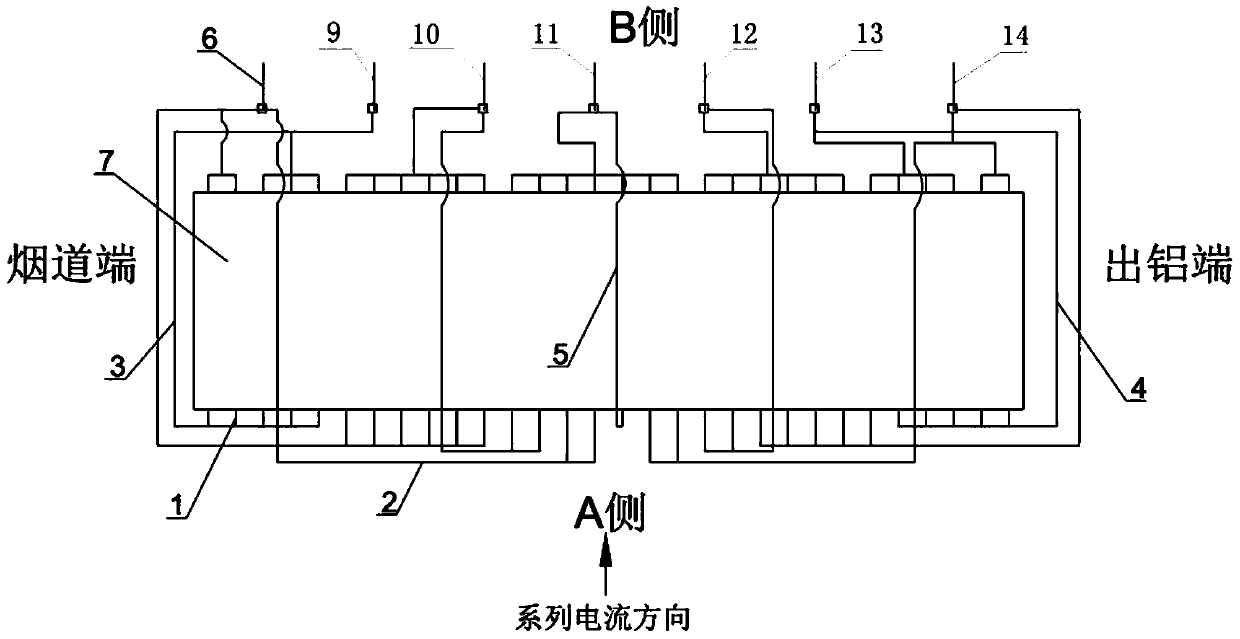

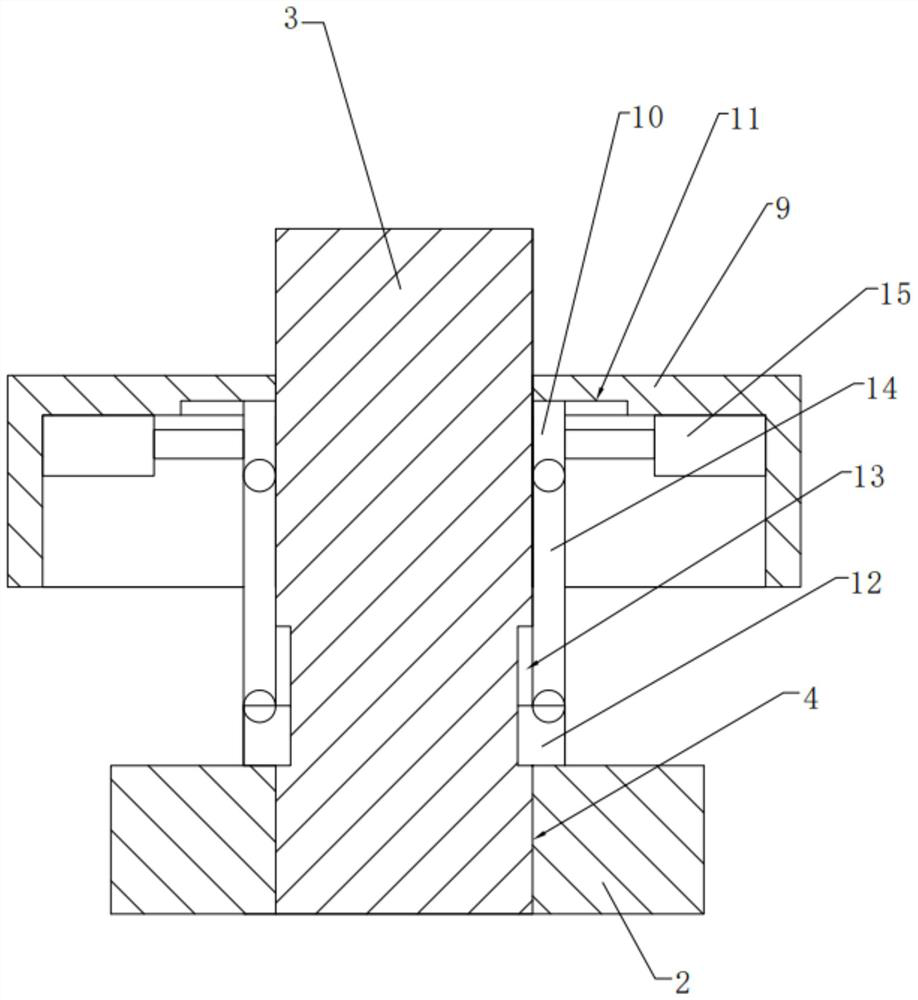

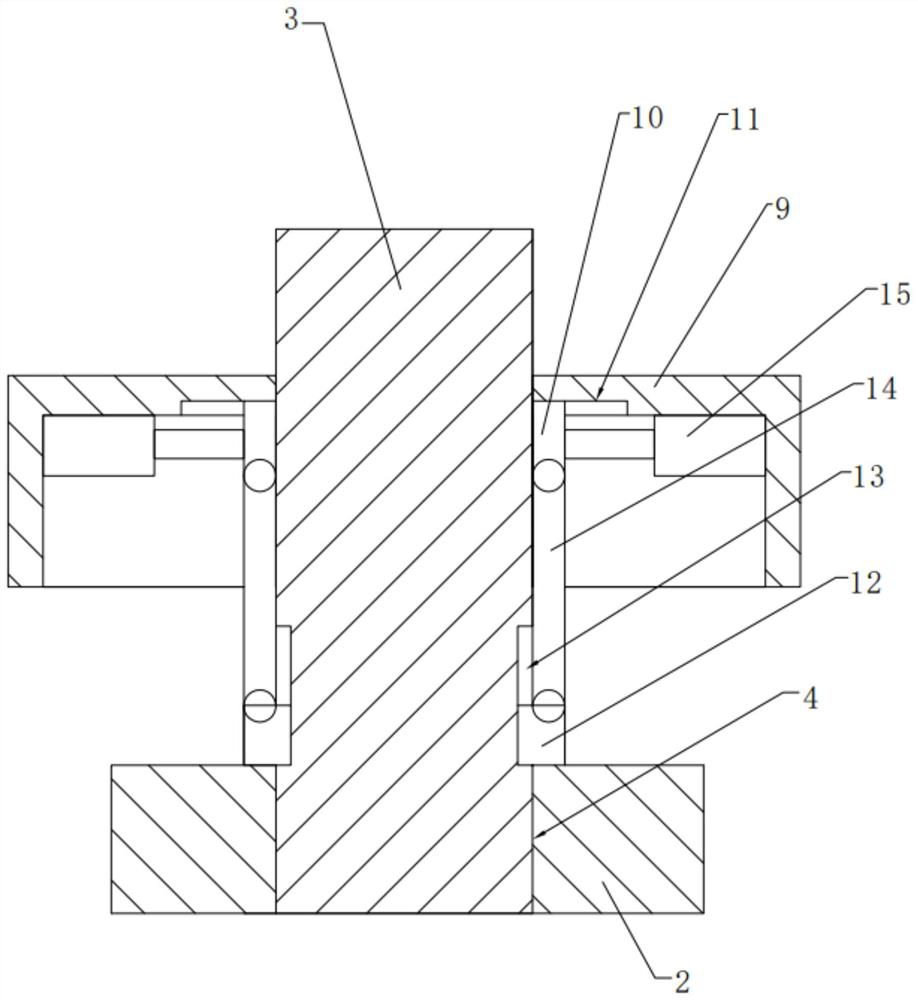

Configuration method for cathode buses of electrolytic baths with controllably adjustable vertical magnetic fields and structure adopting method

The invention discloses a configuration method for cathode buses of electrolytic baths with controllably adjustable vertical magnetic fields and a structure adopting the method. Each cathode bus flowing through an aluminum outlet end and a flue end is divided into an end bus electricity supply side part, an end bus tip part and an end bus electricity discharge side part which are connected through vertical magnetic field adjusting soft buses. The end bus tip parts can move in the vertical direction and the horizontal direction as needed, and dynamic adjustment of the most important end compensation buses of the aluminum electrolytic baths is achieved. The method is simple and efficient. The designed buses can not only meet the requirement for stable operation of magnetic fluid of the large aluminum electrolytic baths but also achieve configuration of the magnetic fields of the electrolytic baths according to demands in a series, and therefore the overall stability index of the electrolytic baths is greatly improved.

Owner:CENT SOUTH UNIV

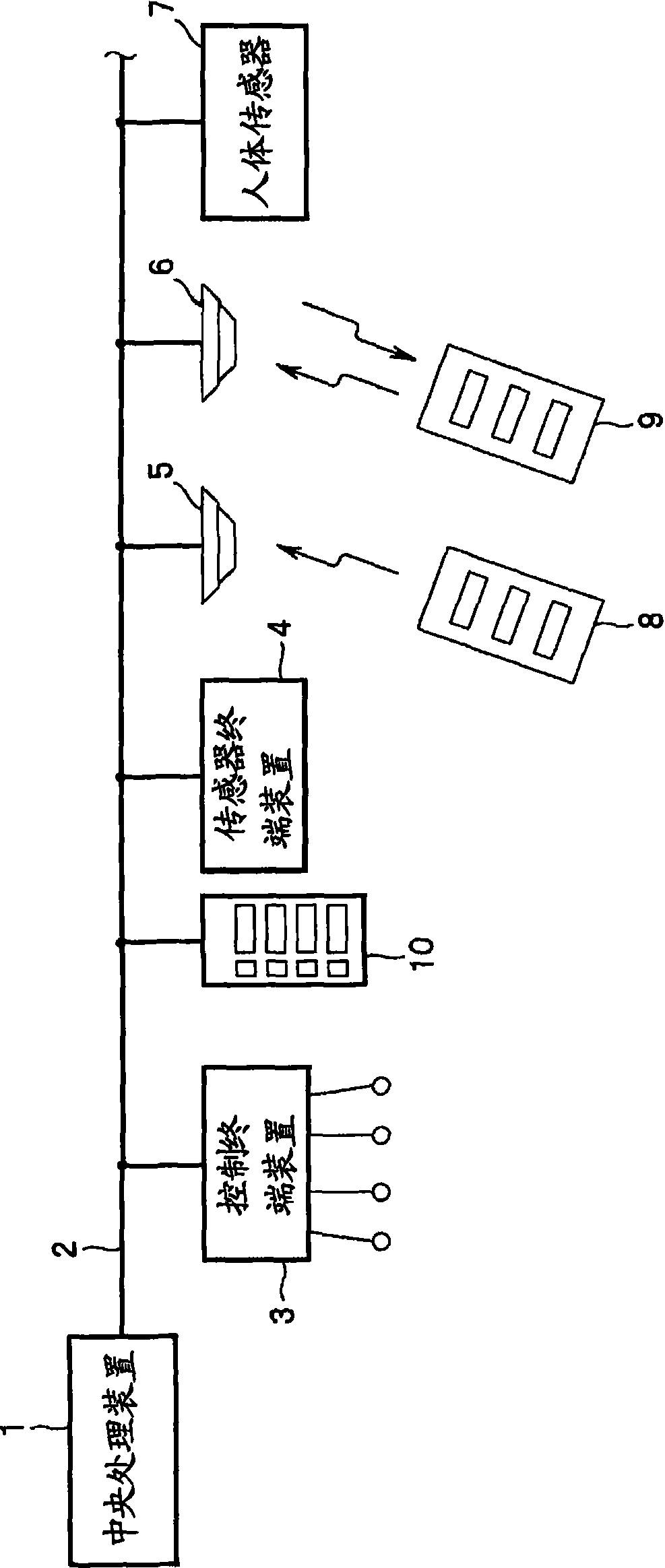

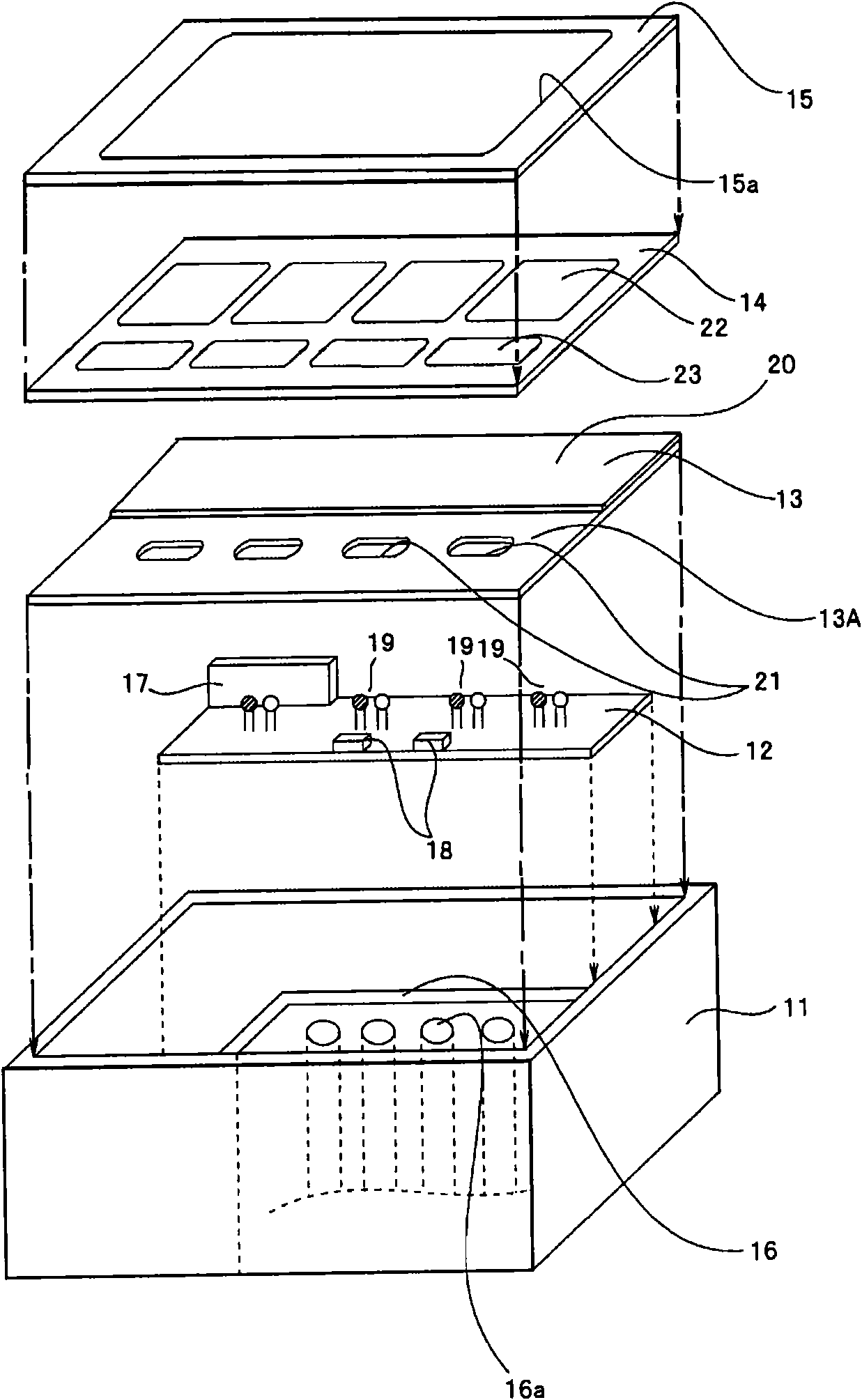

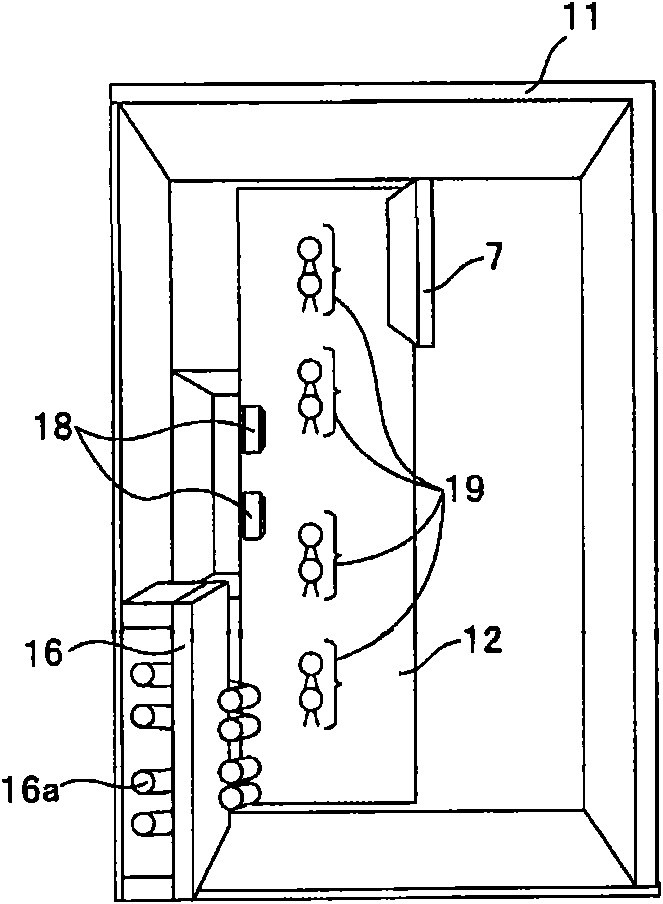

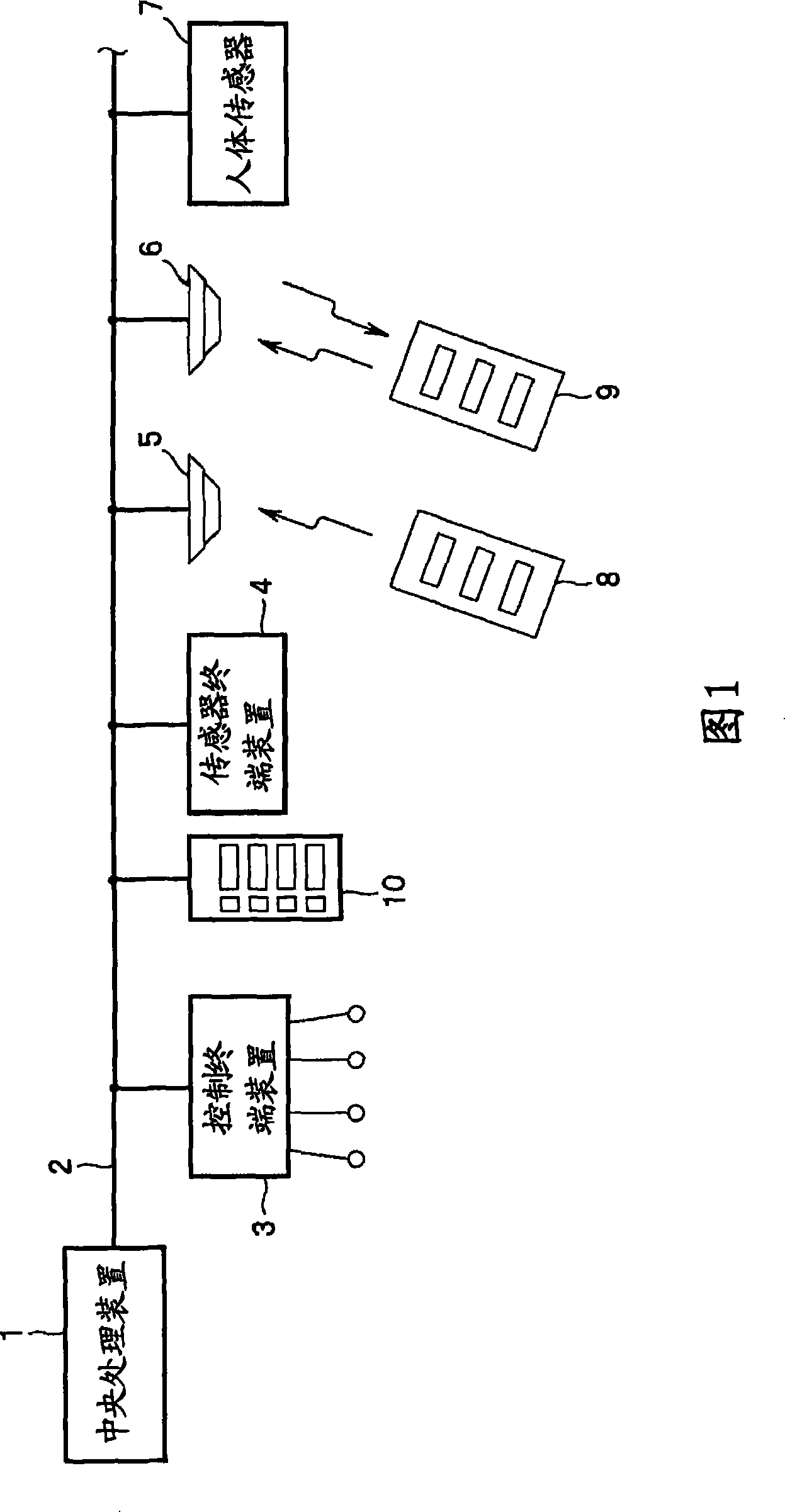

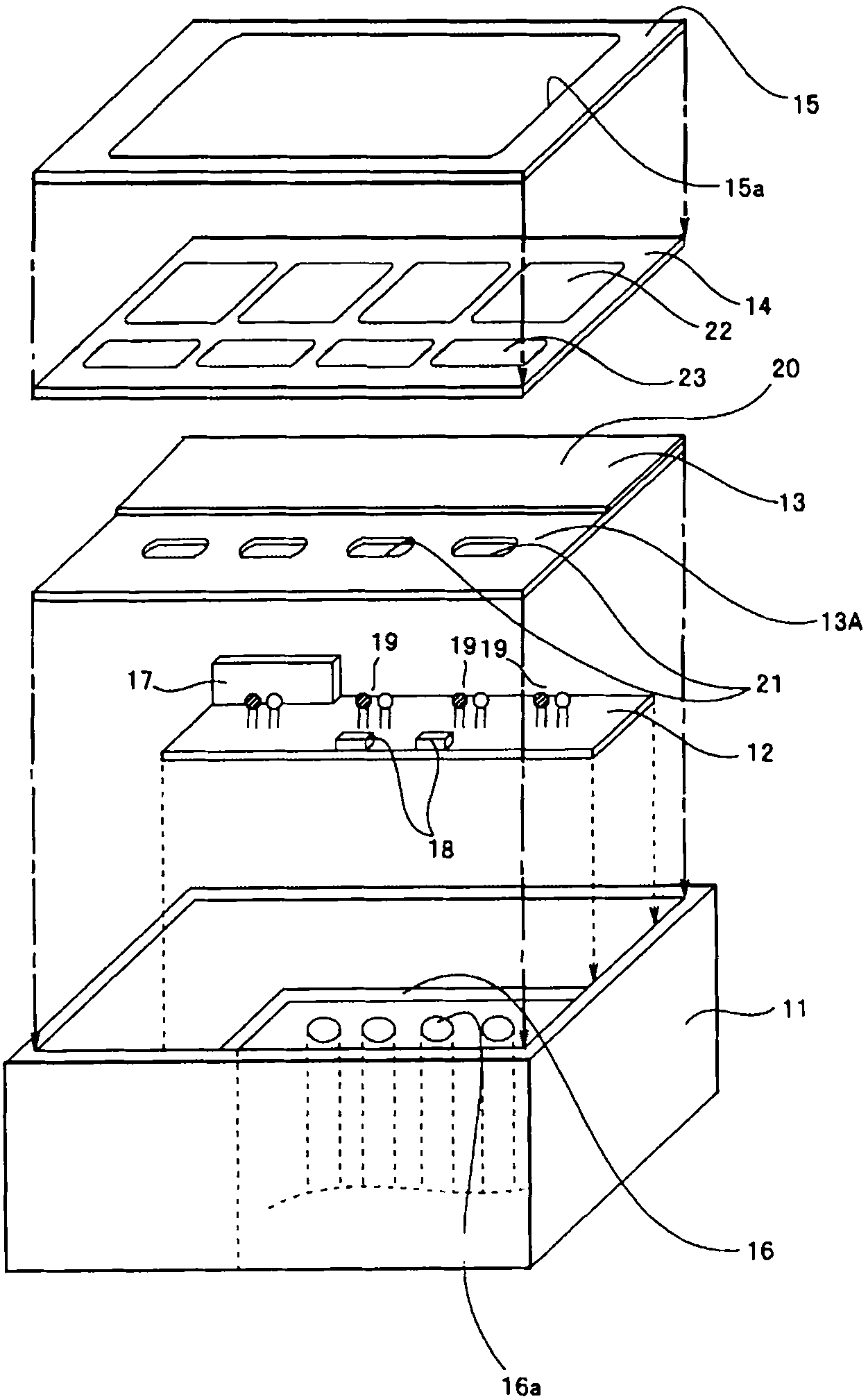

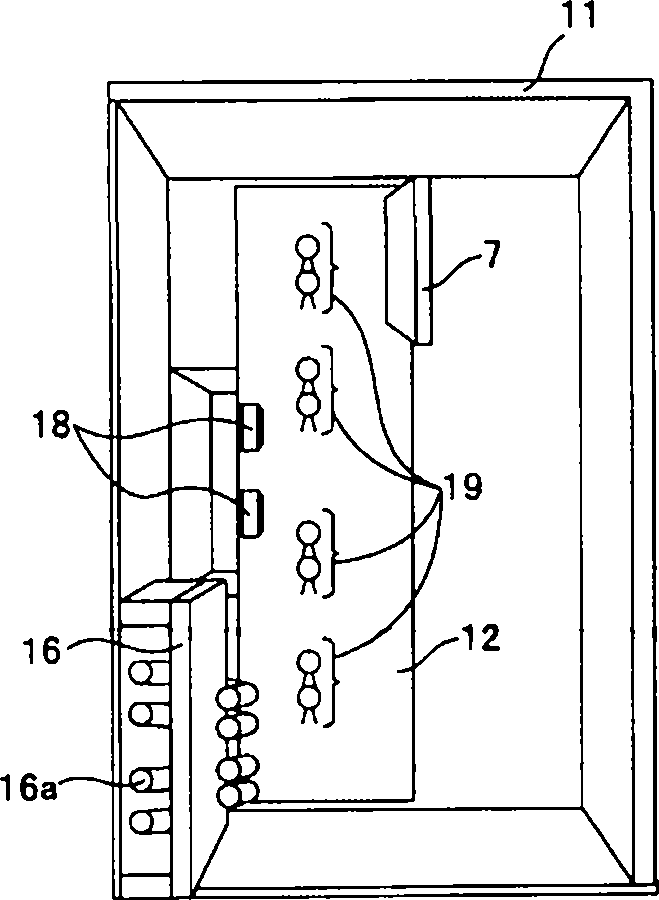

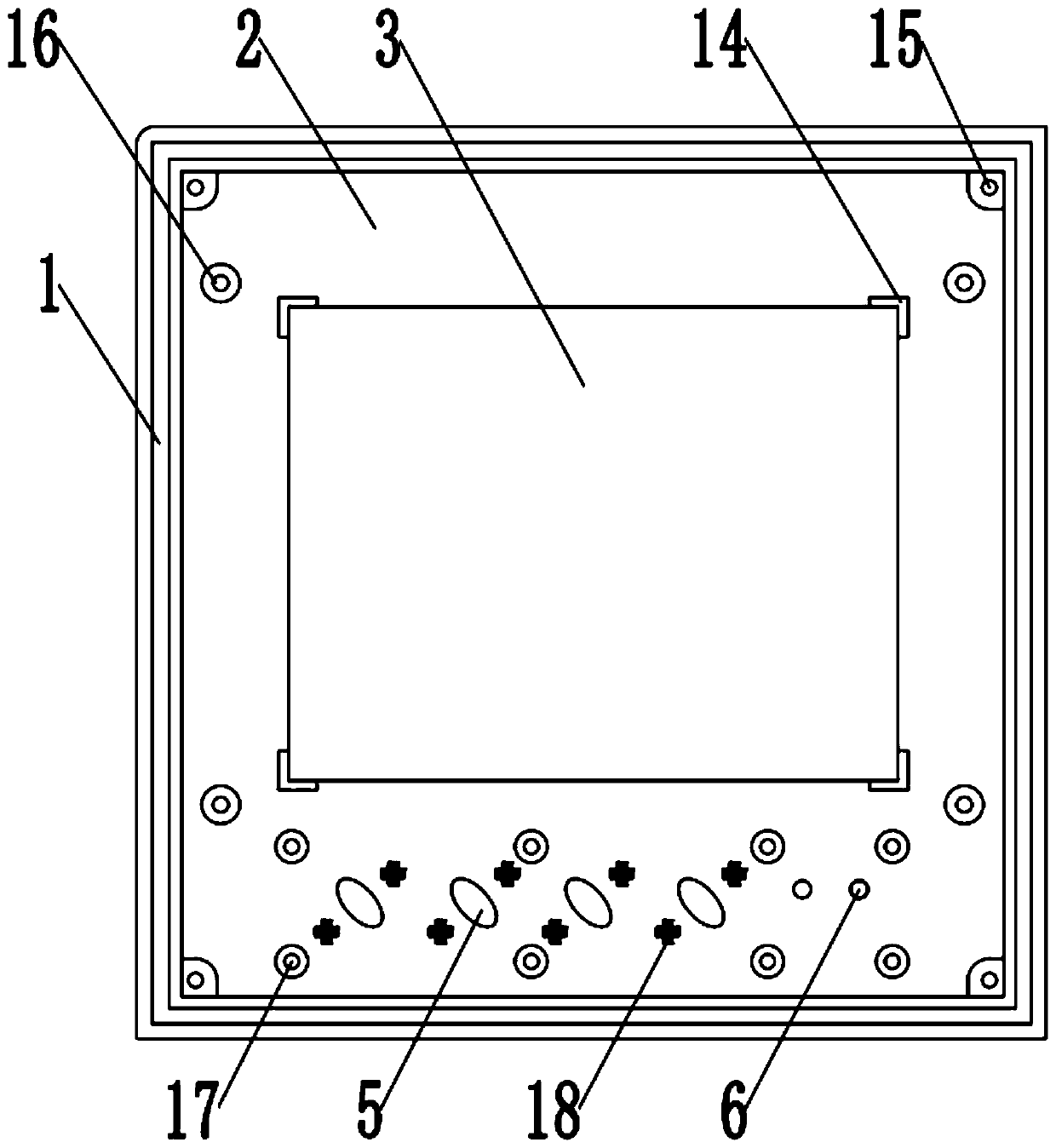

A monitor terminal device for remote control

InactiveCN101553067ALow costIncreased durabilityTelemetry/telecontrol selection arrangementsElectric circuit arrangementsOperating pointSurface plate

The invention provides a monitor terminal device for remote control, which can select and set a plurality of operating modes of a lighting fixture, thereby improving the sharing performance of the parts and lowering cost. The monitor terminal device for remote control 10 comprises a casing main body 11, an operating panel 14 provided with a plurality of operating parts 22, a substrate 13a, a plurality of touch operating parts 20, a detection area, and a transmission substrate 12; wherein a plurality of touch operating parts 20 which are arranged on the casing main body 11 and on the back of the operating panel 14 can be pressed and sensed through the operating panel 14; the detection area can be arranged according to the position of the operating parts 22 and is formed by at least more than one touch operating parts 20; the transmission substrate 12 is the transmission part, which is electrically connected with the substrate 13a; and when the touch operating parts 20 are pressed and sensed, the transmission substrate outputs operating signal.

Owner:TOSHIBA LIGHTING & TECH CORP

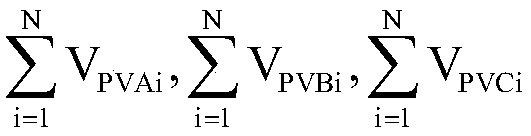

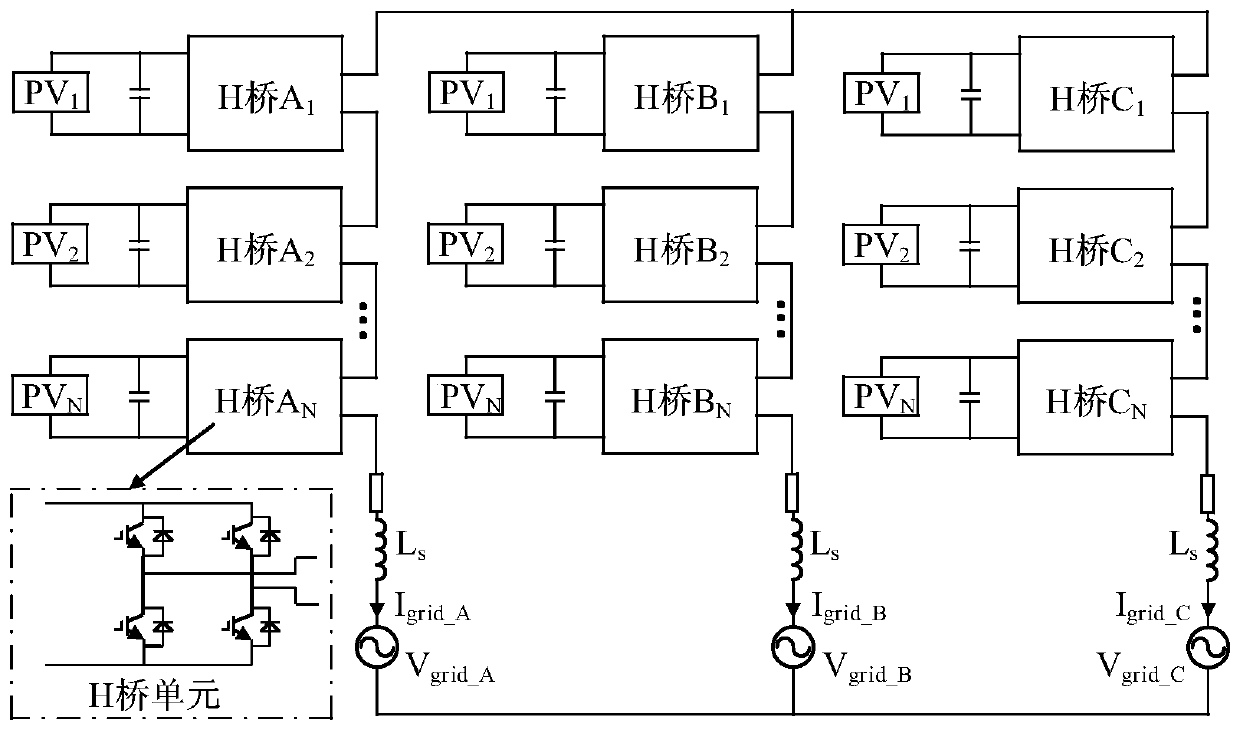

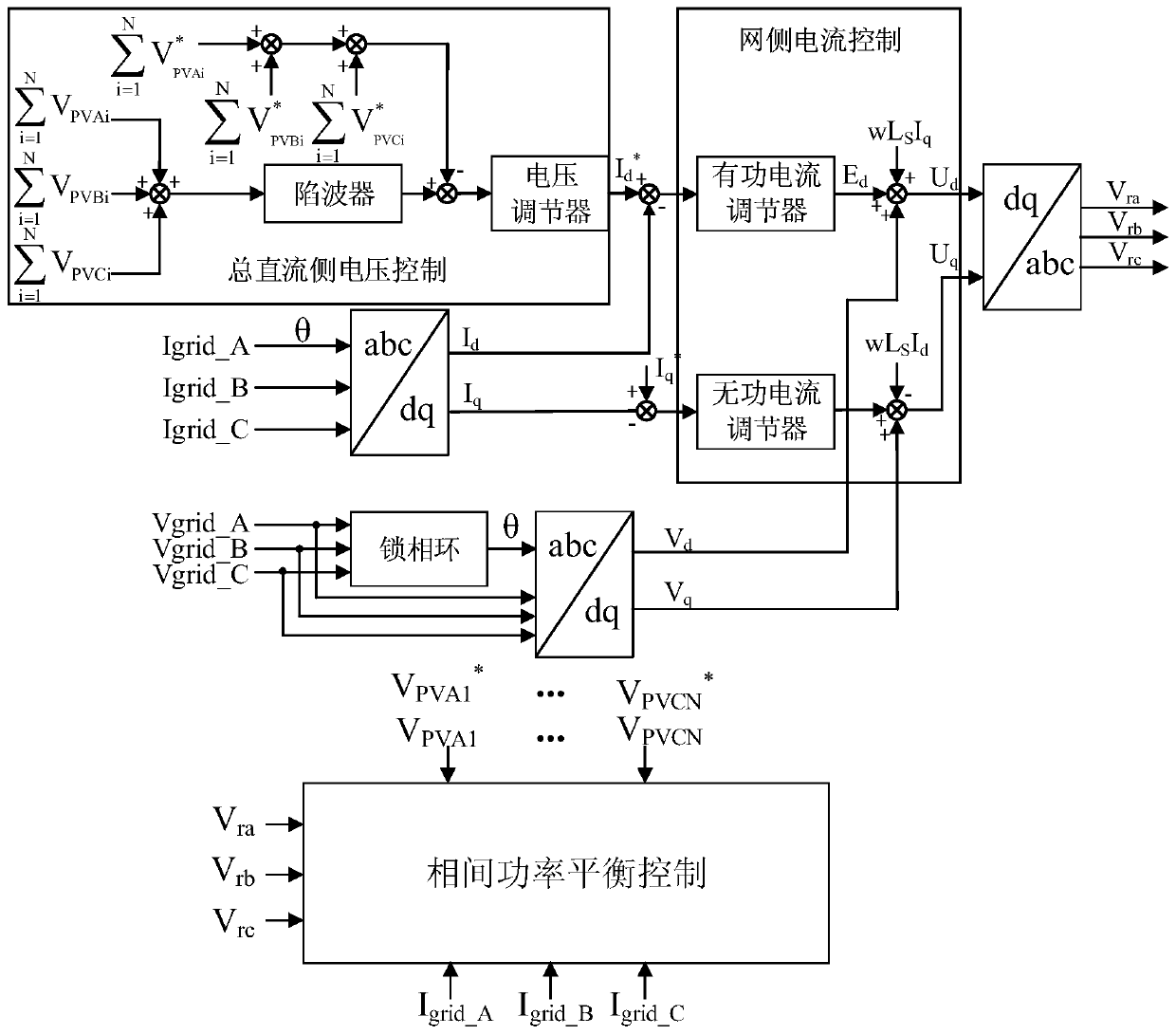

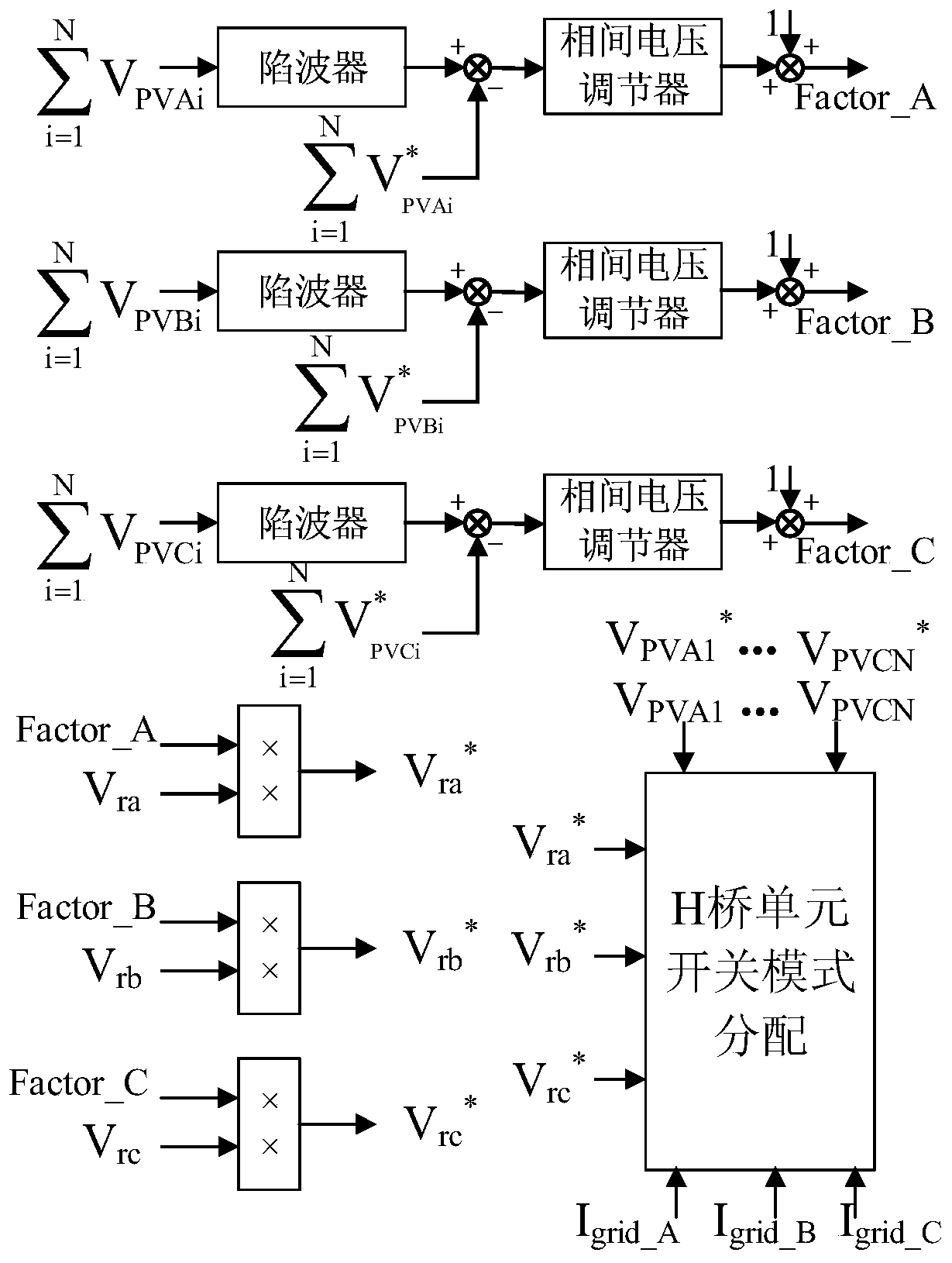

Control method for expanding operation range of three-phase cascade photovoltaic grid-connected inverter

ActiveCN109286203AMeet and adapt to various unbalanced working conditionsLarge adjustment rangeSingle network parallel feeding arrangementsPhotovoltaic energy generationVoltage regulationPower balancing

The invention discloses a control method for expanding the operation range of a three-phase cascade photovoltaic grid-connected inverter, which aims to solve a problem that the system cannot operate stably because of the grid-connected current distortion caused by unbalanced input power of a DC side photovoltaic panel of the three-phase cascade photovoltaic grid-connected inverter. The control method comprises the steps of (1) total DC side voltage control which is used for enabling the total DC side voltage of each H-bridge unit to track the total maximum power point voltage and obtaining anactive current instruction value of the system; (2) network side current control which can realize independent control for active current and reactive current and generate three phase inverter modulation wave signals at the same time; and (3) inter-phase power balance control in which the actual value of the total voltage of each phase is enabled to track the instruction voltage through an inter-phase voltage regulator, a regulation factor of the total voltage of each phase is obtained so as to modify the three phase inverter modulation wave signals, the H-bridge unit output mode is distributed according to the modified modulation wave signals, and thus the inter-phase power balance control is realized.

Owner:HEFEI UNIV OF TECH

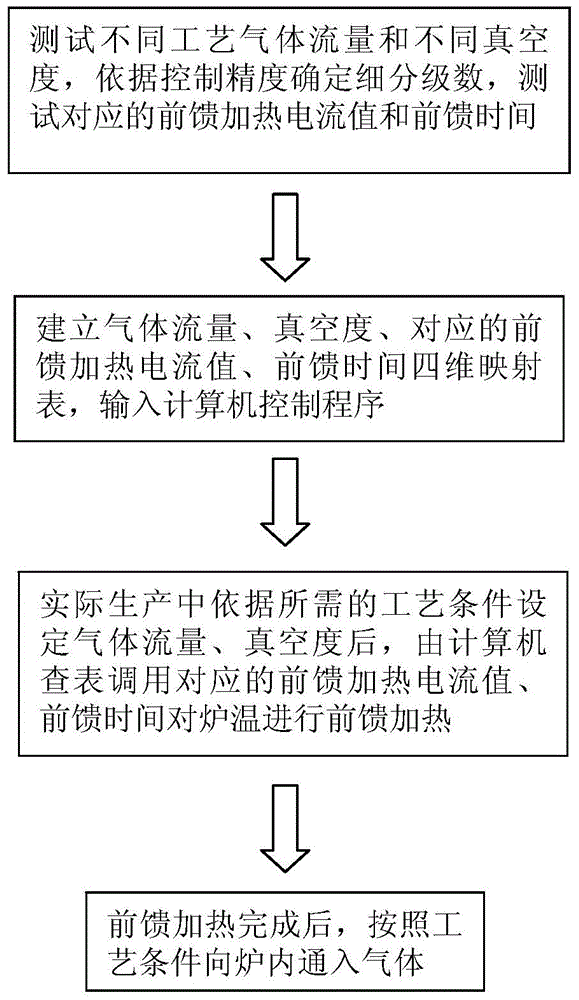

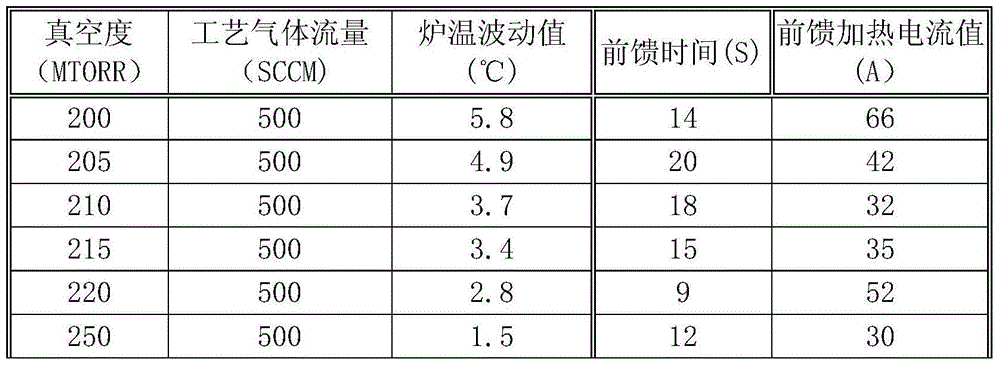

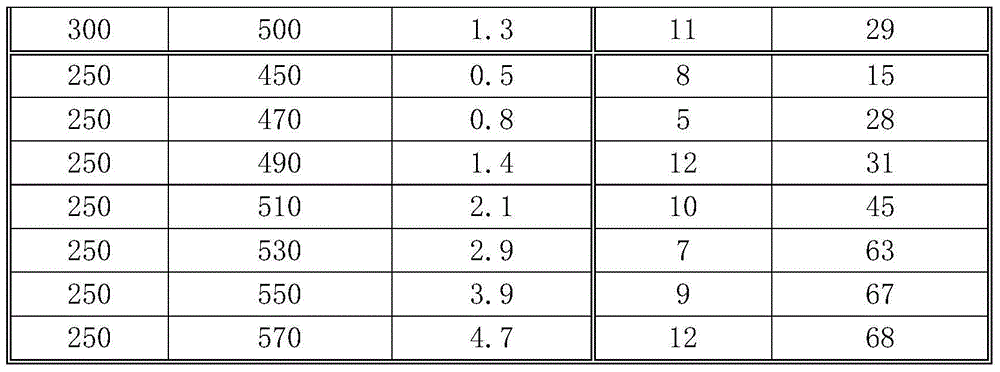

LPCVD initial-deposition furnace temperature accurate control method

ActiveCN104532212AAvoid fluctuations in furnace temperatureAchieve stable operationChemical vapor deposition coatingTemperature dropFurnace temperature

The invention discloses an LPCVD initial-deposition furnace temperature accurate control method. When gas enters, According to the flow and the vacuum degree of the gas which enters, the lowering range of temperature and the time for a furnace body to be heated to constant temperature are predicted, feedforward feeding is carried out so that constant furnace temperature during gas entering can be guaranteed, fluctuation is avoided, LPCVD furnace temperature can be controlled in real time, LPCVD furnace temperature is controlled stably, furnace temperature fluctuation is avoided, stable operation of an LPCVD furnace is achieved, and accordingly the consistency of an LPCVD initial-deposition film is guaranteed.

Owner:SHANGHAI MICRO SEMI WORLD

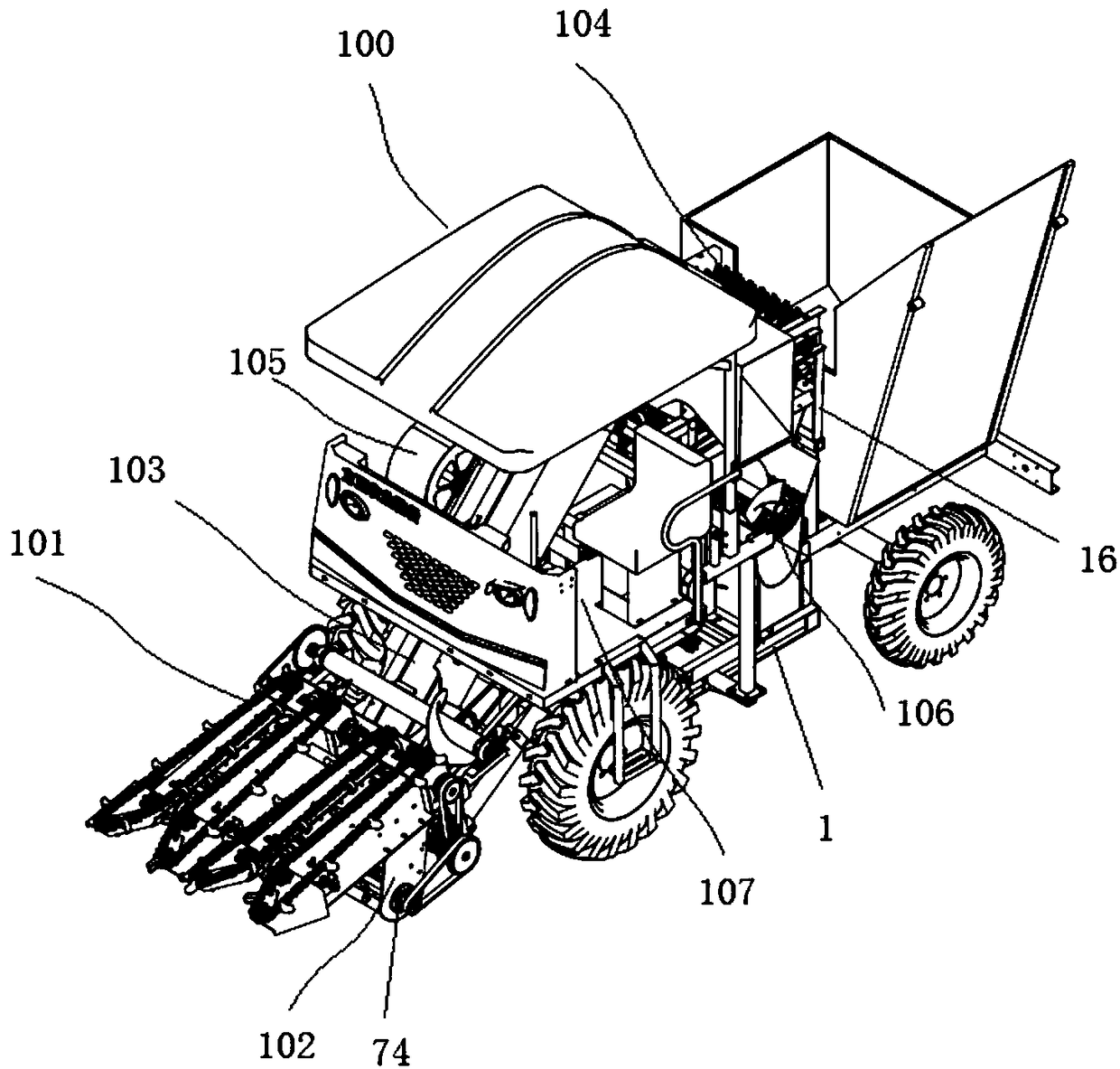

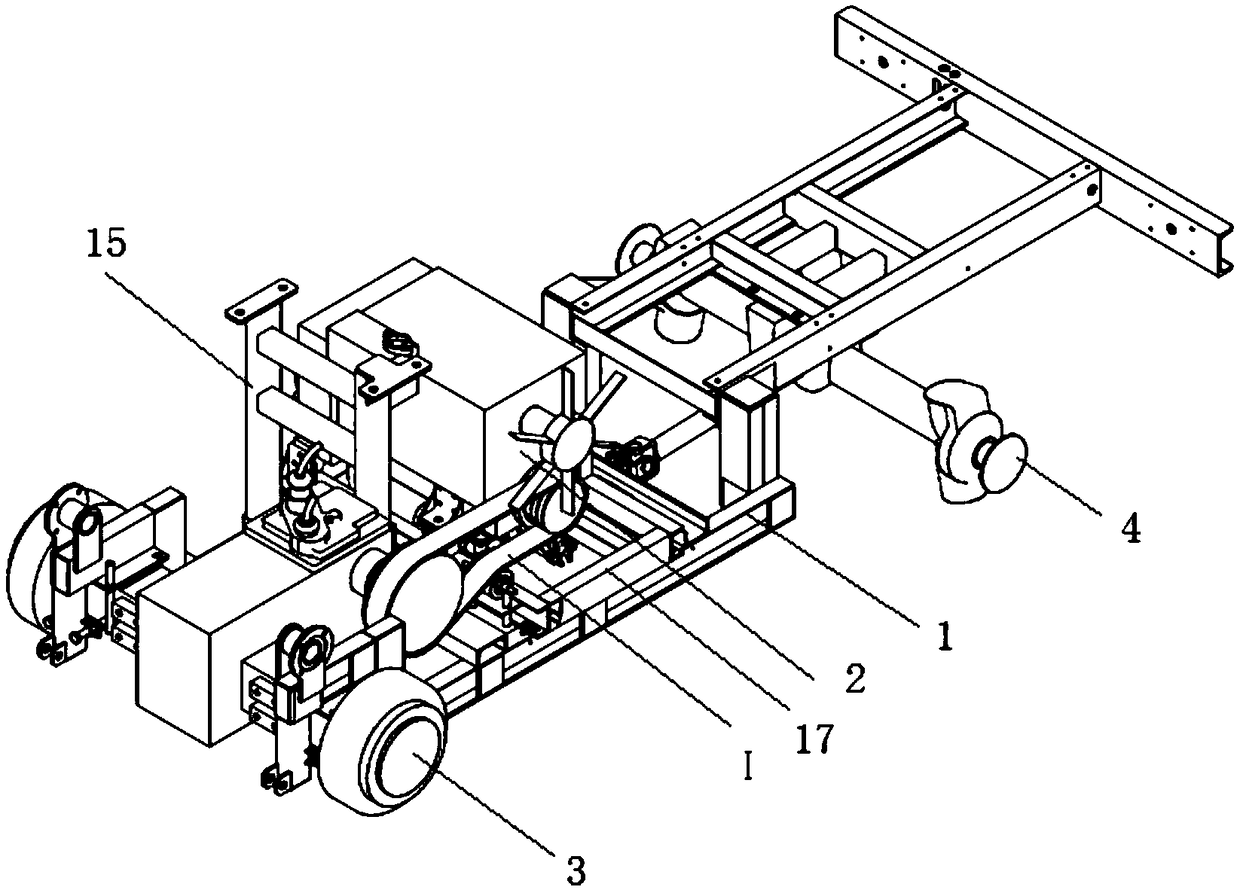

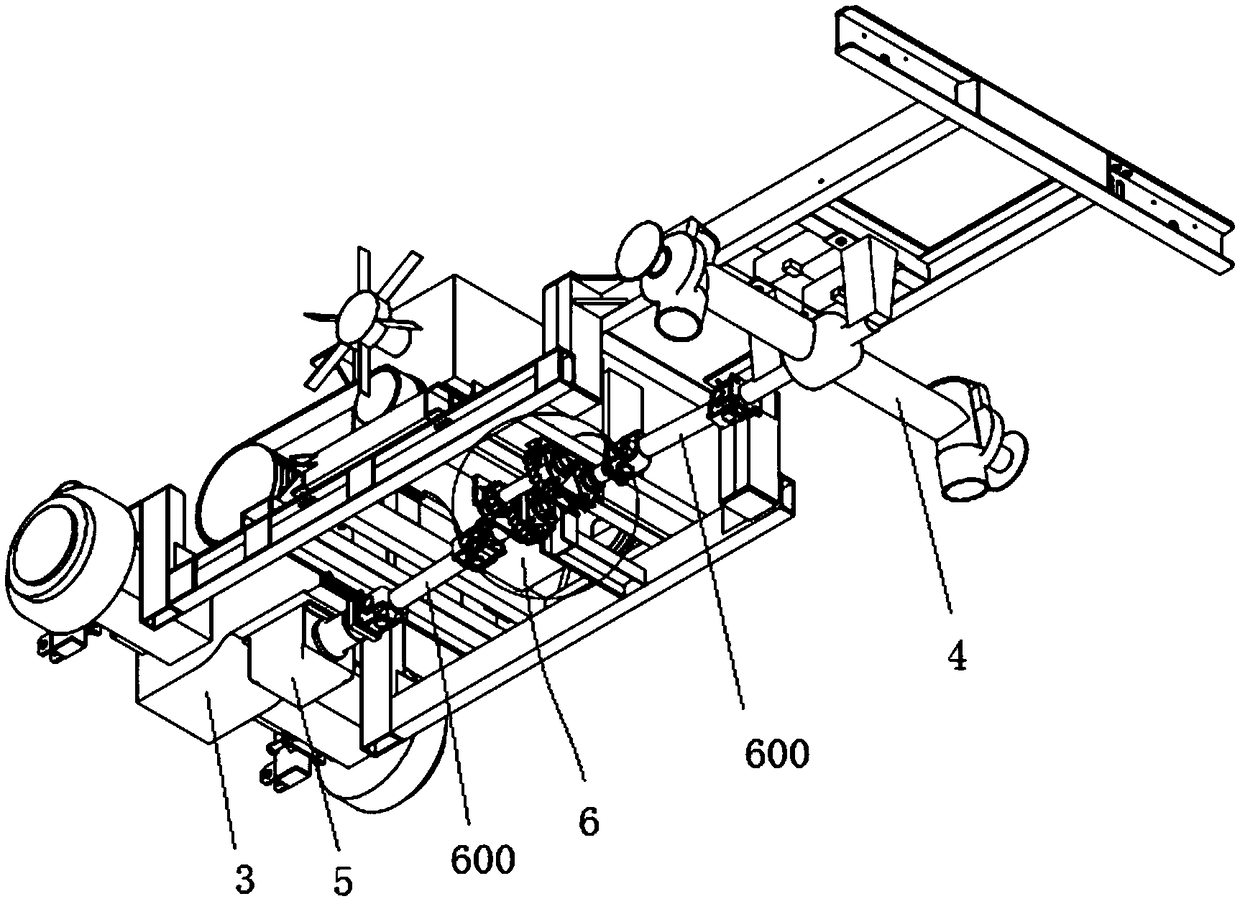

Power transmission system of corn harvester

PendingCN109496564ASmall footprintGuaranteed reliabilityHarvestersSaving energy measuresTransfer caseFour-wheel drive

The invention discloses a power transmission system of a corn harvester, wherein the power transmission system comprises a walking power transmission unit and a working power transmission unit arranged on a chassis frame; the walking power transmission unit comprises an engine, a driving axle, a steering axle, a four-wheel-drive gear box and a transmission mechanism; a first output shaft of the engine is connected with the driving axle through a first transmission assembly, the four-wheel-drive gear box is arranged at the bottom of the driving axle, and the output end of the four-wheel-drive gear box is connected with the input end of the steering axle through the transmission mechanism in a transmission manner. The working power transmission unit comprises a cutting table and field returning transmission mechanism, a lifter transmission shaft, a main transmission second shaft, a main transmission first shaft and a peeling machine transmission mechanism; the cutting table and field returning transmission mechanism comprises a transfer case group, filed returning cutter shafts distributed on the bottom of the front side of the transfer case group, a cutting table and field returningvariable speed device distributed below one side of the transfer case group, and a cutting table packing auger shaft distributed behind the transfer case group. The peeling machine transmission mechanism comprises a spike peeling input transverse shaft, a peeling roller shaft group and a spike dialing shaft group.

Owner:敦化市方正农业机械装备制造有限责任公司

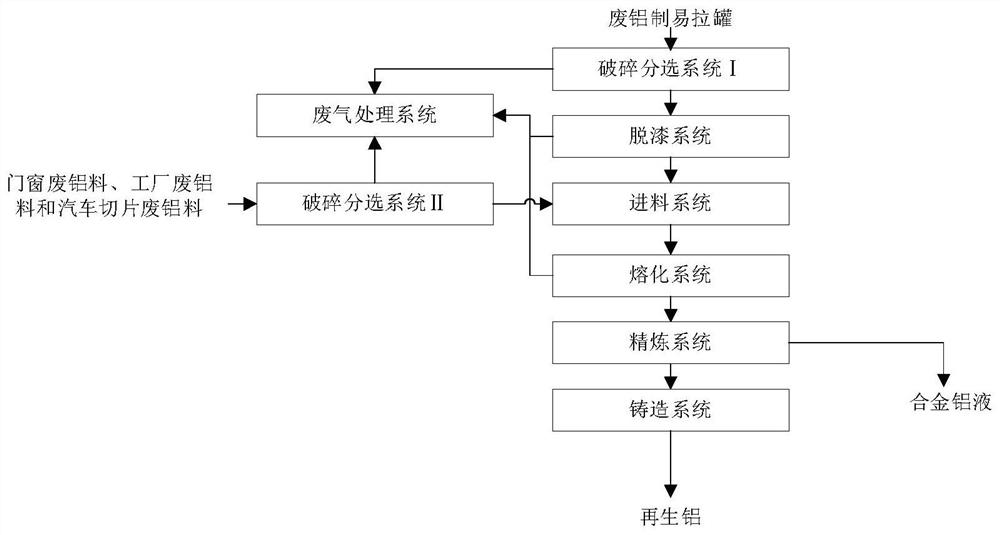

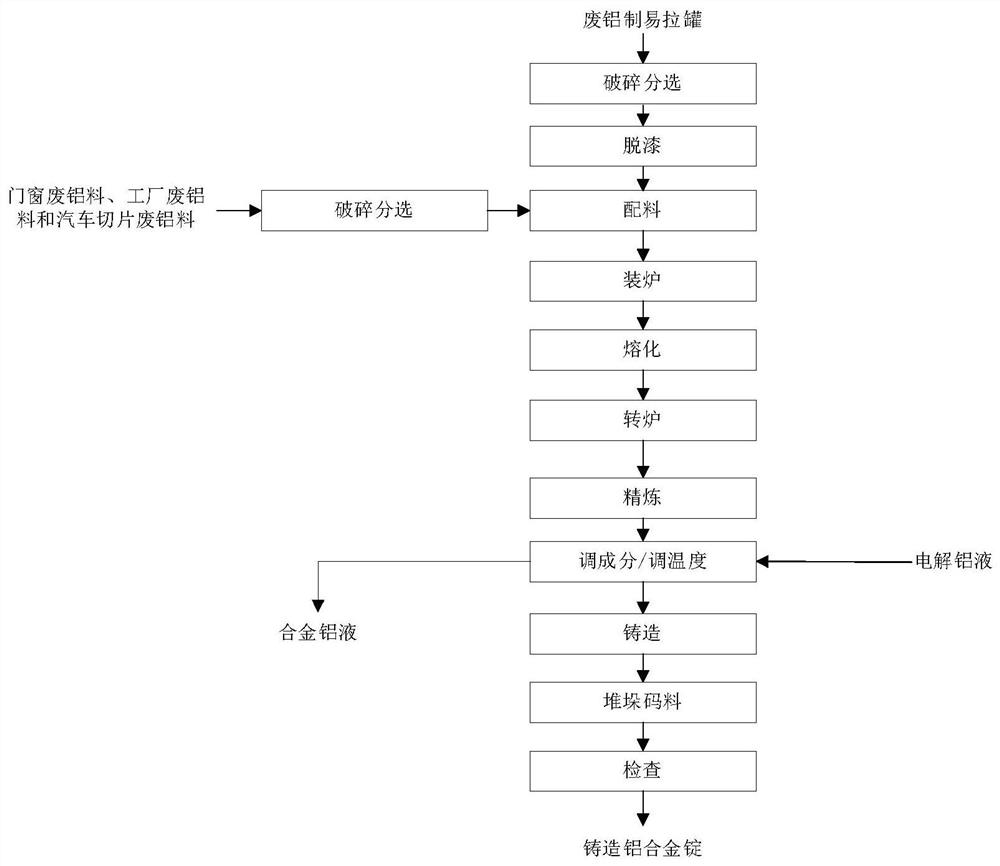

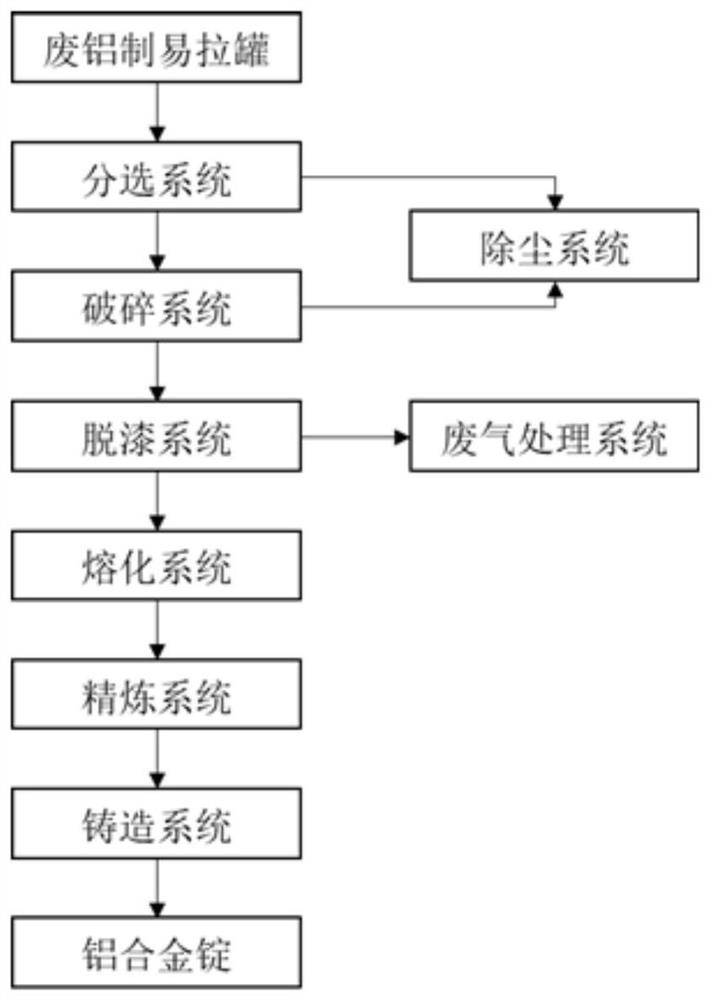

Secondary aluminum production system and method

PendingCN113897487AReduce usageReasonable configurationMagnetic separationGrain treatmentsProcess engineeringIndustrial engineering

The invention discloses a secondary aluminum production system and method. The secondary aluminum production system comprises a crushing and sorting system I, a crushing and sorting system II, a paint removal system, a feeding system, a melting system, a refining system, a casting system and a waste gas treatment system. The crushing and sorting system I is connected with the paint removing system, the paint removing system is connected with the feeding system, the crushing and sorting system II is connected with the feeding system, the feeding system is connected with the melting system, the melting system is connected with the refining system, and the refining system is connected with the casting system. The waste gas treatment system is respectively connected with the crushing and sorting system I, the crushing and sorting system II, the paint removing system and the melting system; the removal rate of the surface coating of the waste aluminum is greater than 99%; the use of waste aluminum ring-pull cans is not reduced; the recovery rate of the waste aluminum ring-pull cans is greater than 96%; and the purity of the sorted waste aluminum ring-pull cans is greater than 98%. According to the secondary aluminum production system and method, the secondary aluminum production system and method is safe, environment-friendly and reasonable in configuration, and continuous and stable operation can be realized; and through the advanced crushing technology, continuous operation of the device can be achieved, and meanwhile the service life of the device is prolonged.

Owner:顺尔茨环保(北京)有限公司

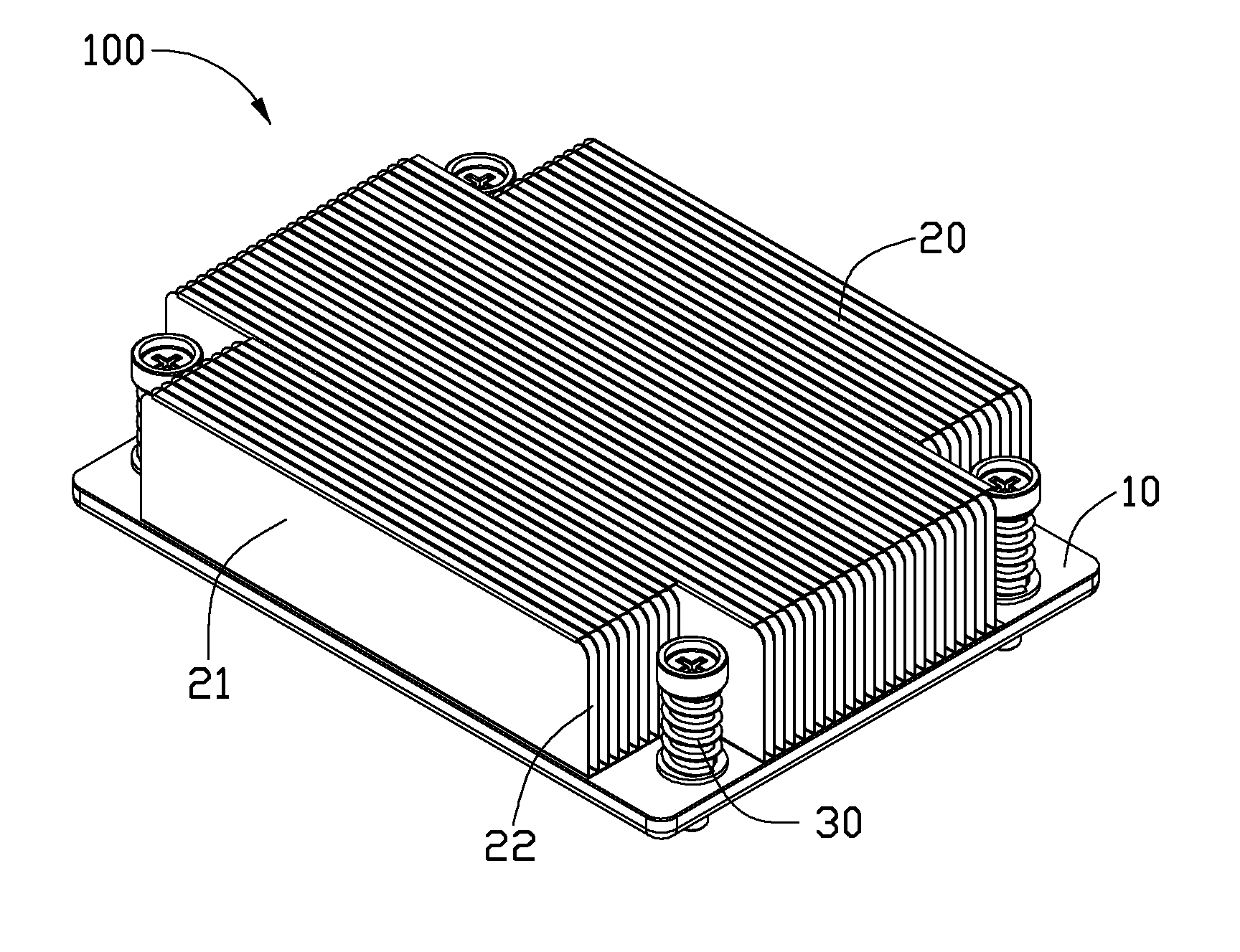

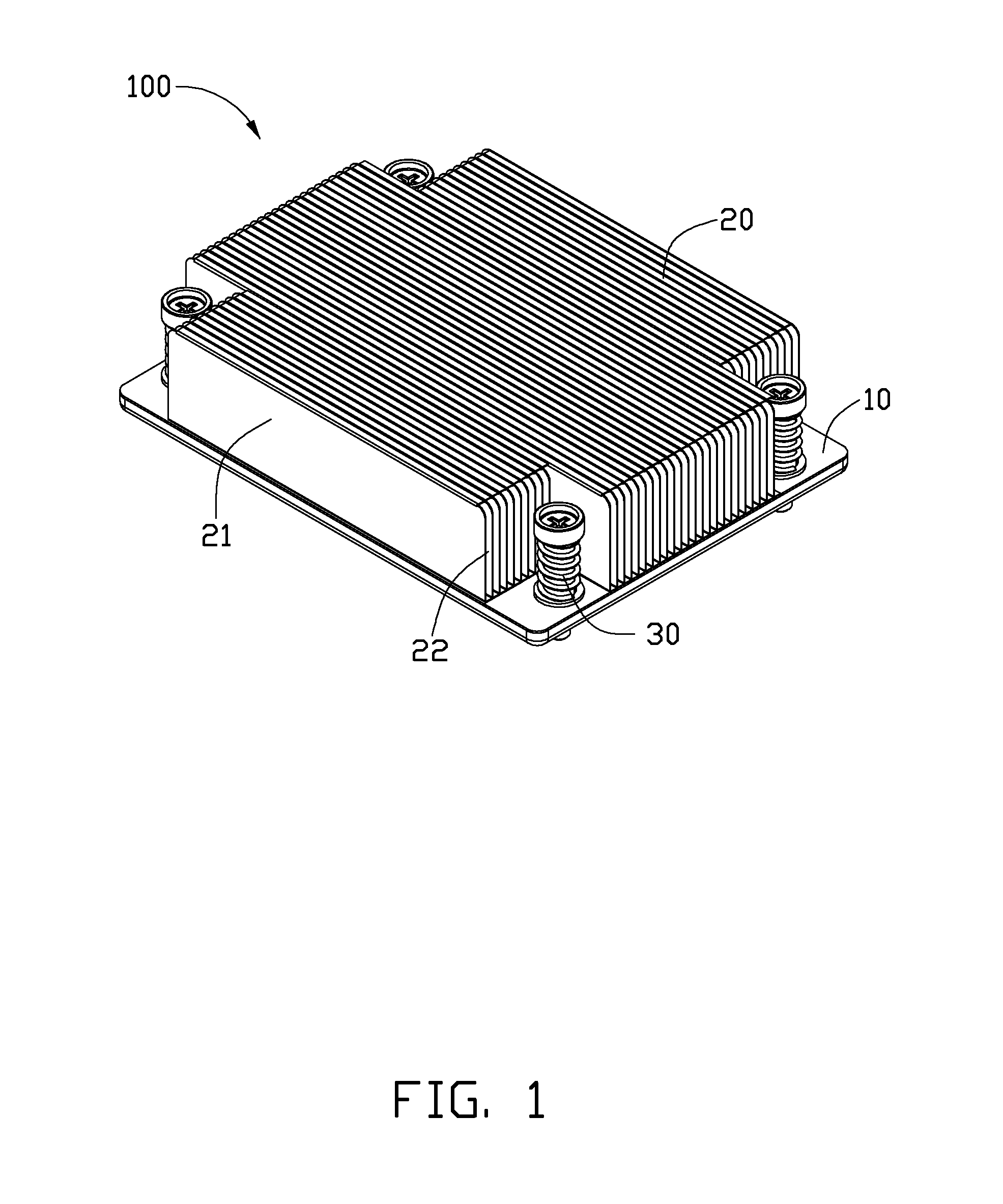

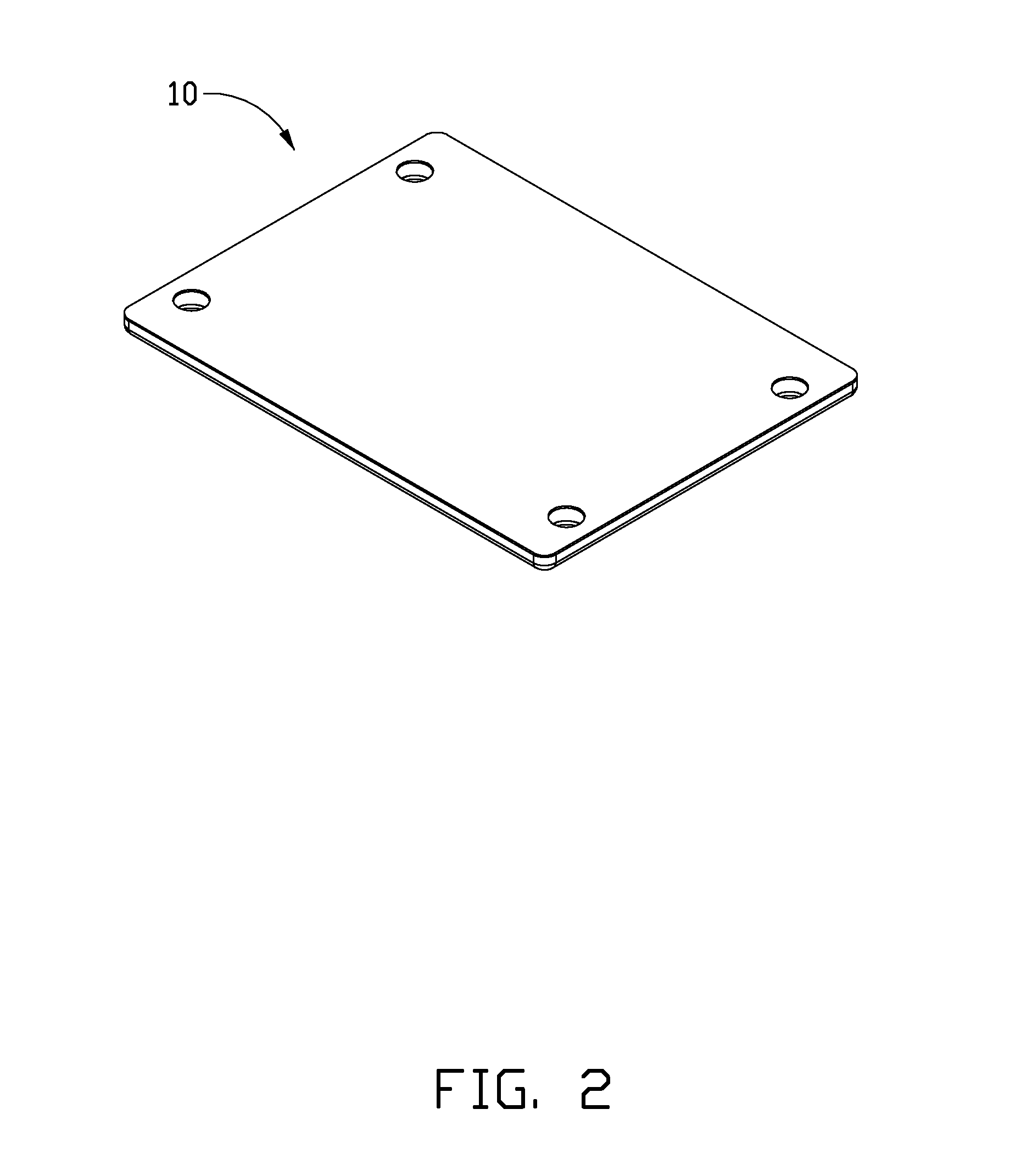

Heat dissipation device

InactiveUS20130020056A1Guaranteed uptimeAchieve stable operationSemiconductor/solid-state device detailsSolid-state devicesHOLDING CHAMBERHeat pipe

A heat dissipation device includes a base and a fin group fixed on the base. The base includes a container, a flattened heat pipe and a solid supporting member. The container includes a baffle plate and a cover engaging with the baffle plate to define a receiving chamber therebetween. The heat pipe and the supporting member are housed in the receiving chamber. Opposite sides of the heat pipe and the supporting member respectively abut against the baffle plate and the cover of the container.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

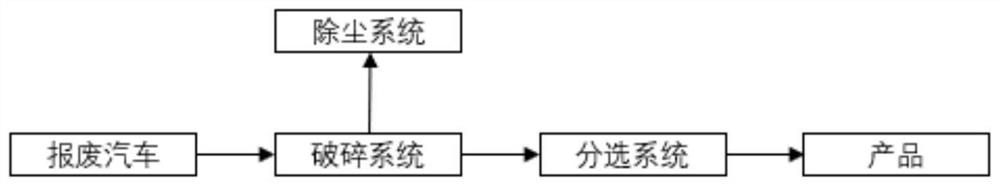

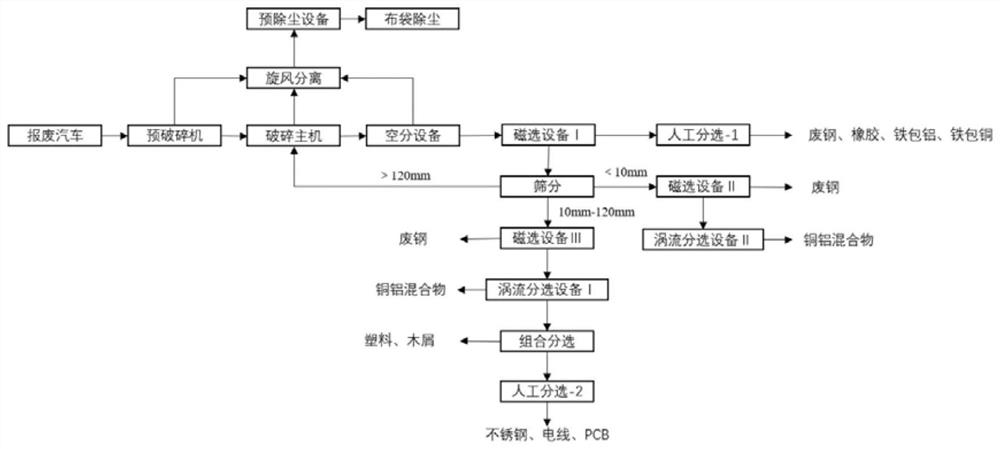

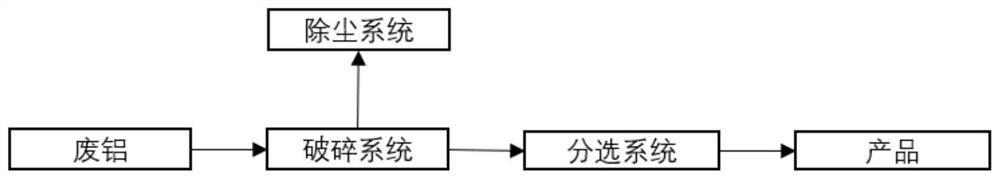

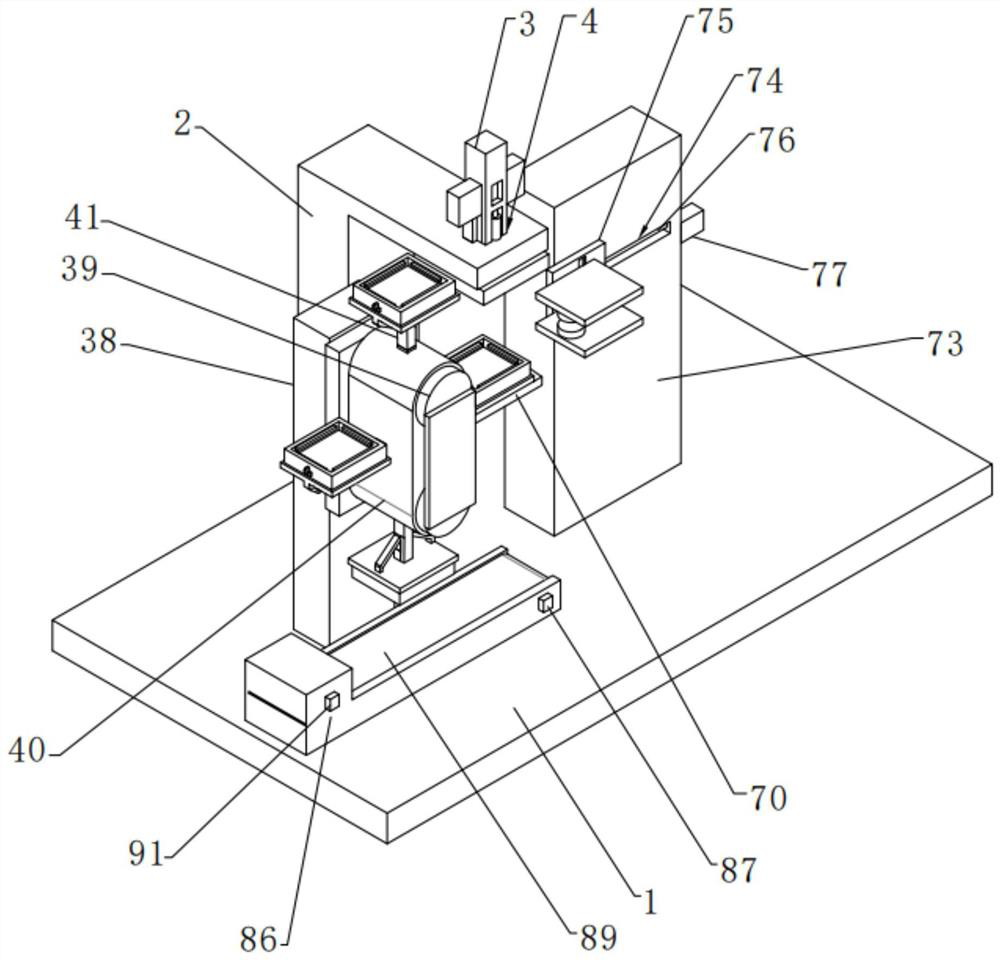

Efficient crushing and sorting system and method for scraped cars

PendingCN113182319AChange the situation that sorting mainly relies on manual workQuality assuranceSolid waste disposalGrain treatmentsDust controlMetallic materials

The invention discloses an efficient crushing and sorting system and method for scraped cars. The system comprises a crushing system, a sorting system and a dust removal system, wherein the crushing system is connected with the dust removal system and the sorting system respectively; the crushing system is used for crushing the scraped cars, and crushed materials enter the sorting system; the sorting system is used for sorting the crushed materials and finally sorting out waste steel, a copper-aluminum mixture, iron-clad aluminum, iron-clad copper, plastic, stainless steel, electric wires, PCBs, wood chips, rubber and the like; and the dust removal system is used for removing dust generated in the crushing system. The metal sorting automation degree reaches the international leading level, the situation that in China, waste metal sorting mainly depends on manpower is thoroughly changed, efficient crushing and sorting are achieved, the quality and purity of regenerated materials are guaranteed, and the recovery rate is increased to 97% or above. The recovery rate of metal materials in fine residues after crushing is larger than 99%. The device is safe, environment-friendly, reasonable in configuration and capable of realizing continuous and stable operation.

Owner:顺尔茨环保(北京)有限公司

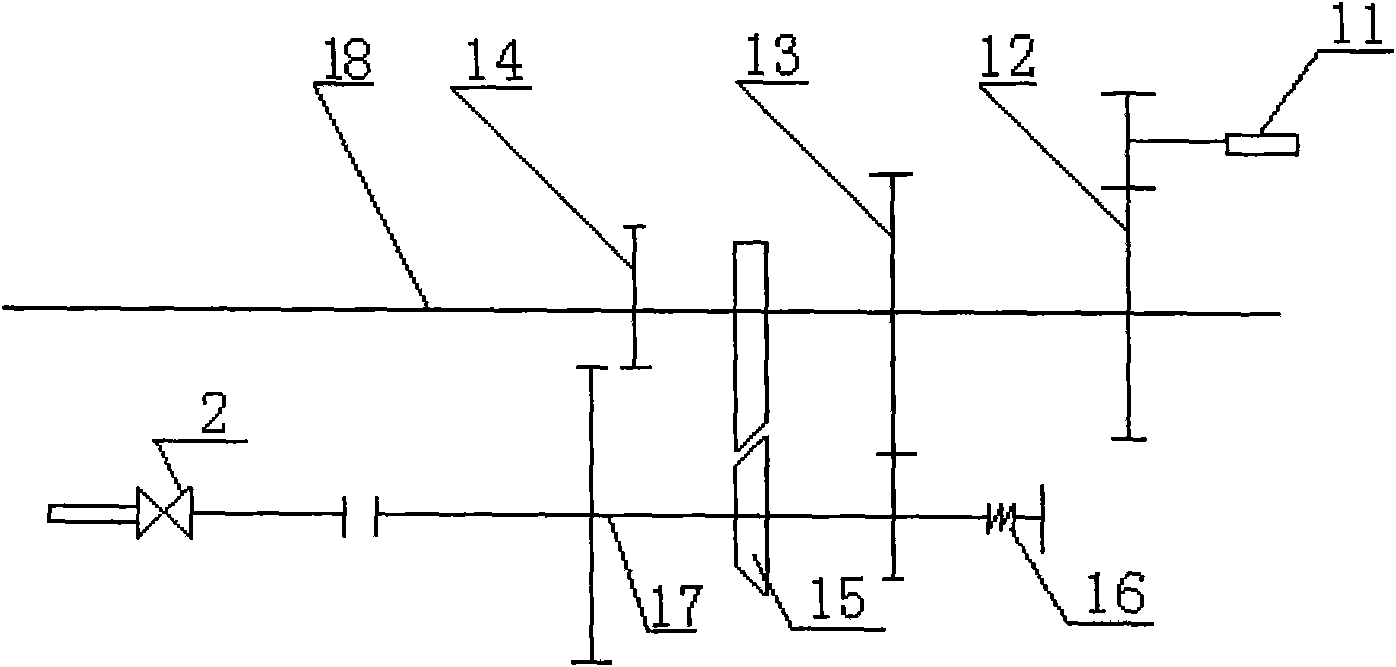

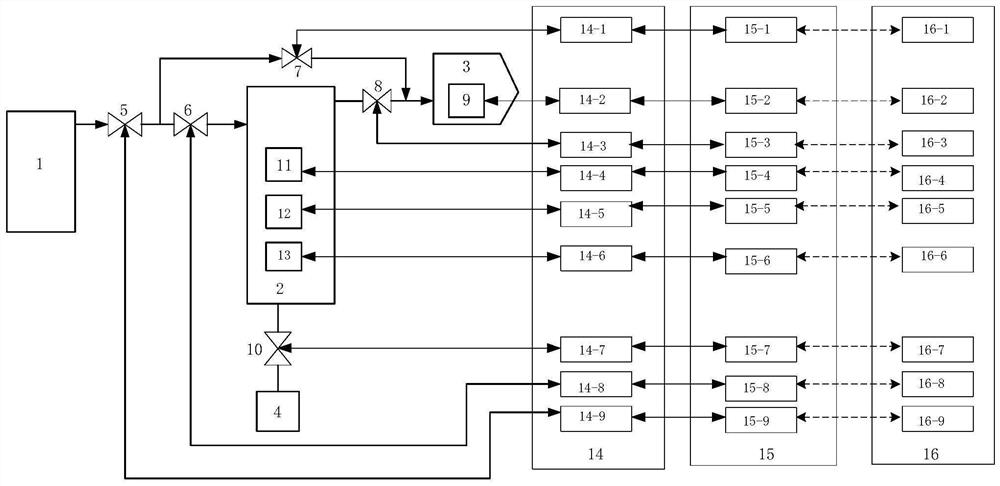

Device and method for testing control logic of start-stop system of high-temperature gas cooled reactor

PendingCN113270216AAchieve stable operationImprove reliabilityPower plant safety arrangementNuclear energy generationProcess engineeringTest set

A device for testing control logic of a start-stop system of a high-temperature gas cooled reactor comprises a steam generator, the steam generator is connected with a steam-water separator inlet regulating valve, the steam-water separator inlet regulating valve is divided into two paths, one path is connected with a steam-water separator inlet isolating valve, the steam-water separator inlet isolating valve is connected with a steam-water separator, and the steam-water separator first outlet is connected with a steam-water separator outlet isolating valve; the other path is connected with a steam-water separator bypass regulating valve, and the steam-water separator outlet isolating valve and an outlet of the steam-water separator bypass regulating valve are converged and then are connected into a main steam collecting pipe; and a second outlet of the steam-water separator is connected with a steam-water separator drain regulating valve, and an outlet of the steam-water separator drain regulating valve is connected with a drain tank. And the steam-water separator internal monitoring device and each valve of the steam-water separator are respectively connected with a simulation modeling server through a start-stop reactor system DCS cabinet via a PXI data acquisition cabinet. According to the invention, the actual functions of the start-stop reactor system can be verified in advance, and the test efficiency is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD

Control method for expanding the operating range of three-phase cascaded photovoltaic grid-connected inverters

ActiveCN109286203BMeet and adapt to various unbalanced working conditionsLarge adjustment rangeSingle network parallel feeding arrangementsPhotovoltaic energy generationVoltage regulationPower balancing

The invention discloses a control method for expanding the operation range of a three-phase cascade photovoltaic grid-connected inverter, which aims to solve a problem that the system cannot operate stably because of the grid-connected current distortion caused by unbalanced input power of a DC side photovoltaic panel of the three-phase cascade photovoltaic grid-connected inverter. The control method comprises the steps of (1) total DC side voltage control which is used for enabling the total DC side voltage of each H-bridge unit to track the total maximum power point voltage and obtaining anactive current instruction value of the system; (2) network side current control which can realize independent control for active current and reactive current and generate three phase inverter modulation wave signals at the same time; and (3) inter-phase power balance control in which the actual value of the total voltage of each phase is enabled to track the instruction voltage through an inter-phase voltage regulator, a regulation factor of the total voltage of each phase is obtained so as to modify the three phase inverter modulation wave signals, the H-bridge unit output mode is distributed according to the modified modulation wave signals, and thus the inter-phase power balance control is realized.

Owner:HEFEI UNIV OF TECH

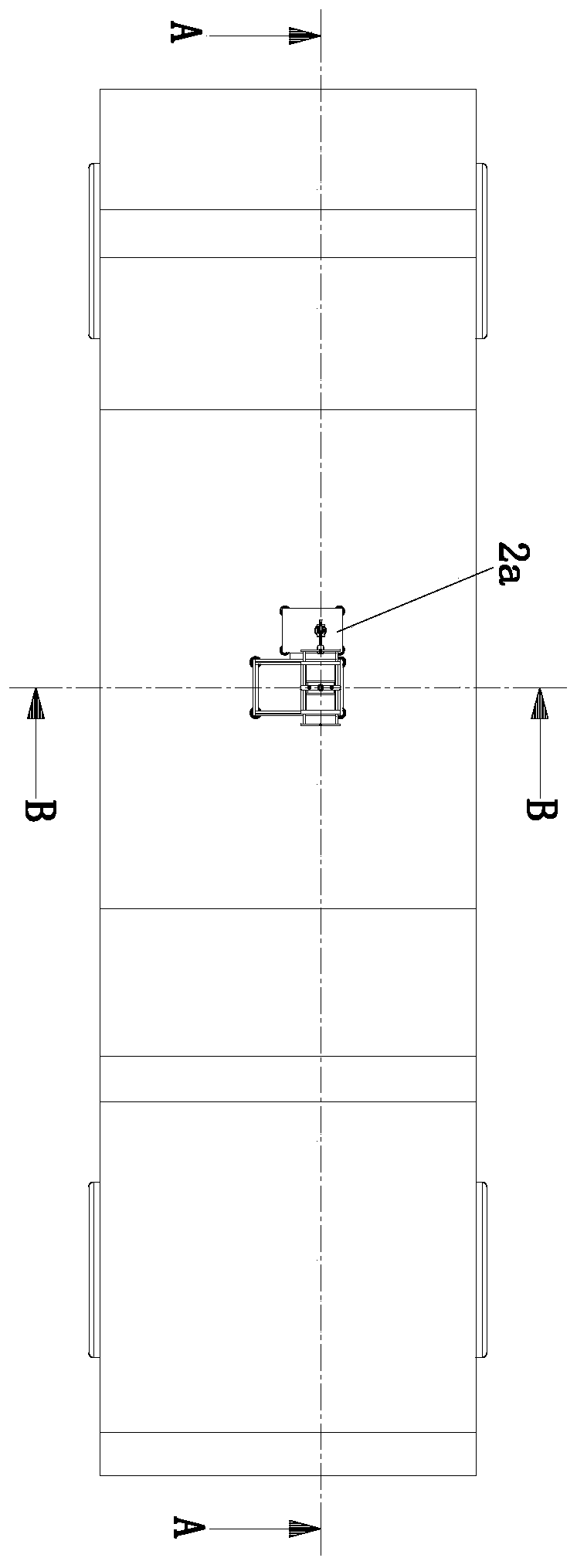

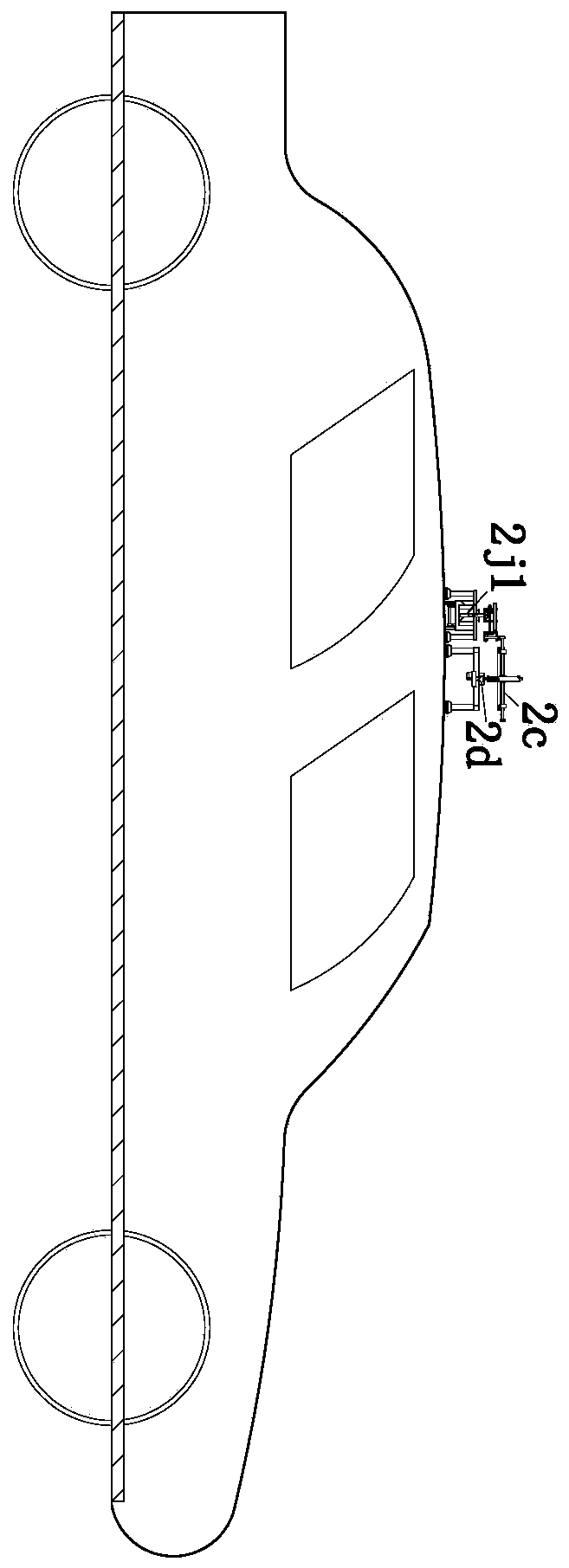

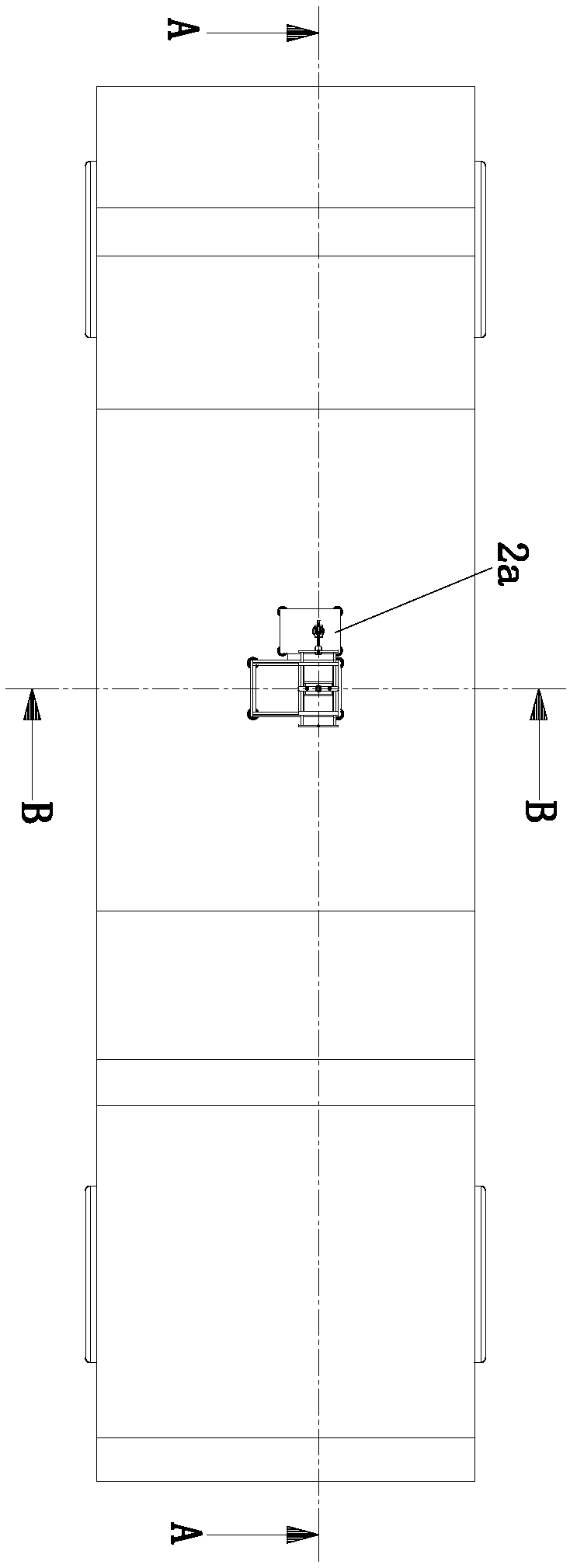

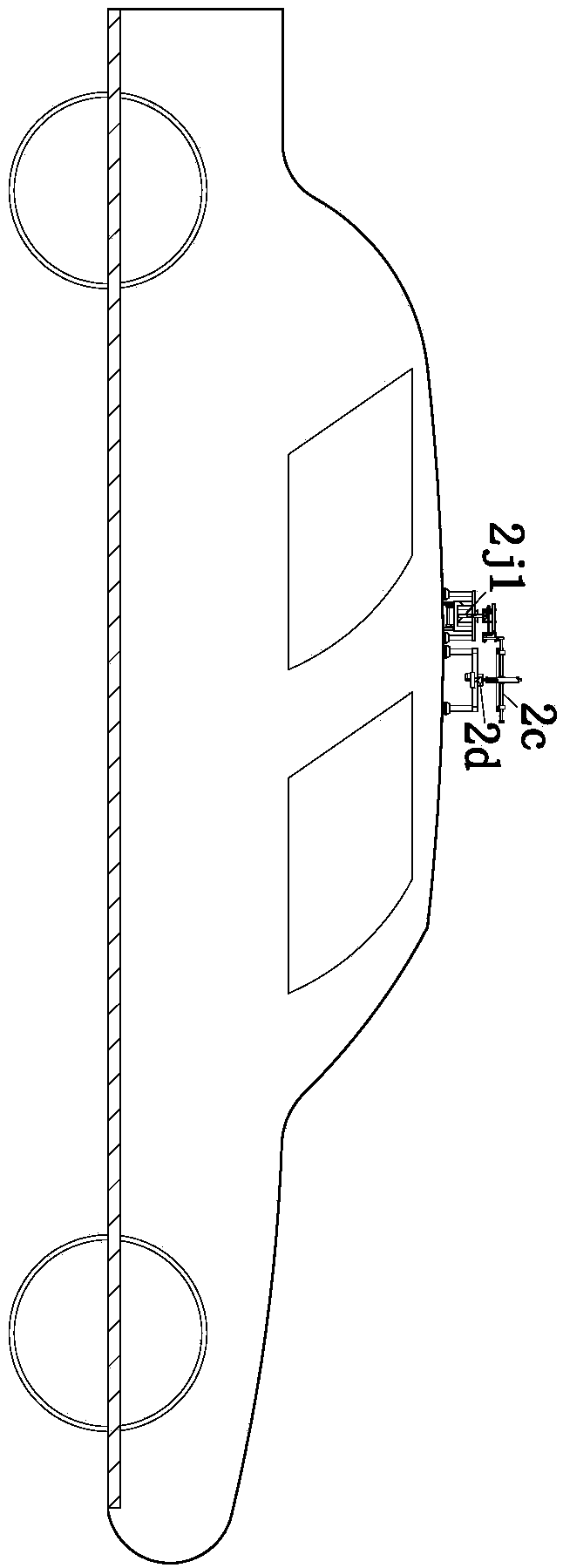

A family passenger car

InactiveCN109573470BRealize maintenance workAchieve stable operationToothed gearingsMechanical conveyorsWhole bodyCar passenger

The invention discloses a household passenger car, and belongs to the technical field of passenger car equipment. The household passenger car comprises a passenger car body and a movable carrying device. The movable carrying device comprises a positioning bearing component, a bearing driving component, a scraping output component and a limiting scraping component, and the limiting scraping component includes a limiting bearing frame, a sliding positioning assembly and a driving scraping assembly. The driving scraping assembly is disposed in a vertical state. According to the household passenger car, the entire device is firstly driven by the bearing driving component installed at the bottom of the positioning bearing component to move on the outer surface of a passenger car when the passenger car needs to be maintained, the position movement operation of the whole car body is completed, when the passenger car moves to a certain position which needs to be maintained, the entire positioning bearing component is fixedly attached to the outer side wall of the passenger car, the premise of stable operation is achieved, the limiting scraping component is driven by the scraping output component to rotate, and the maintenance operation of a coating can be completed at the position to be maintained.

Owner:台州市荣创电子有限公司

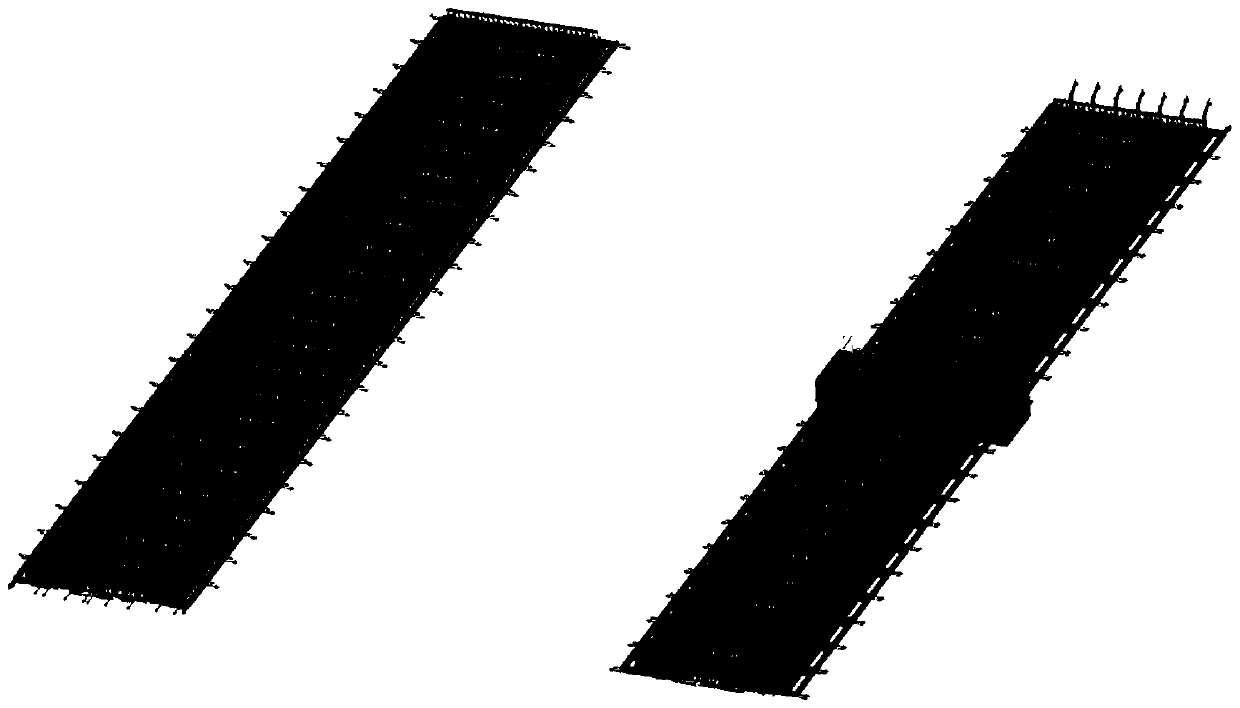

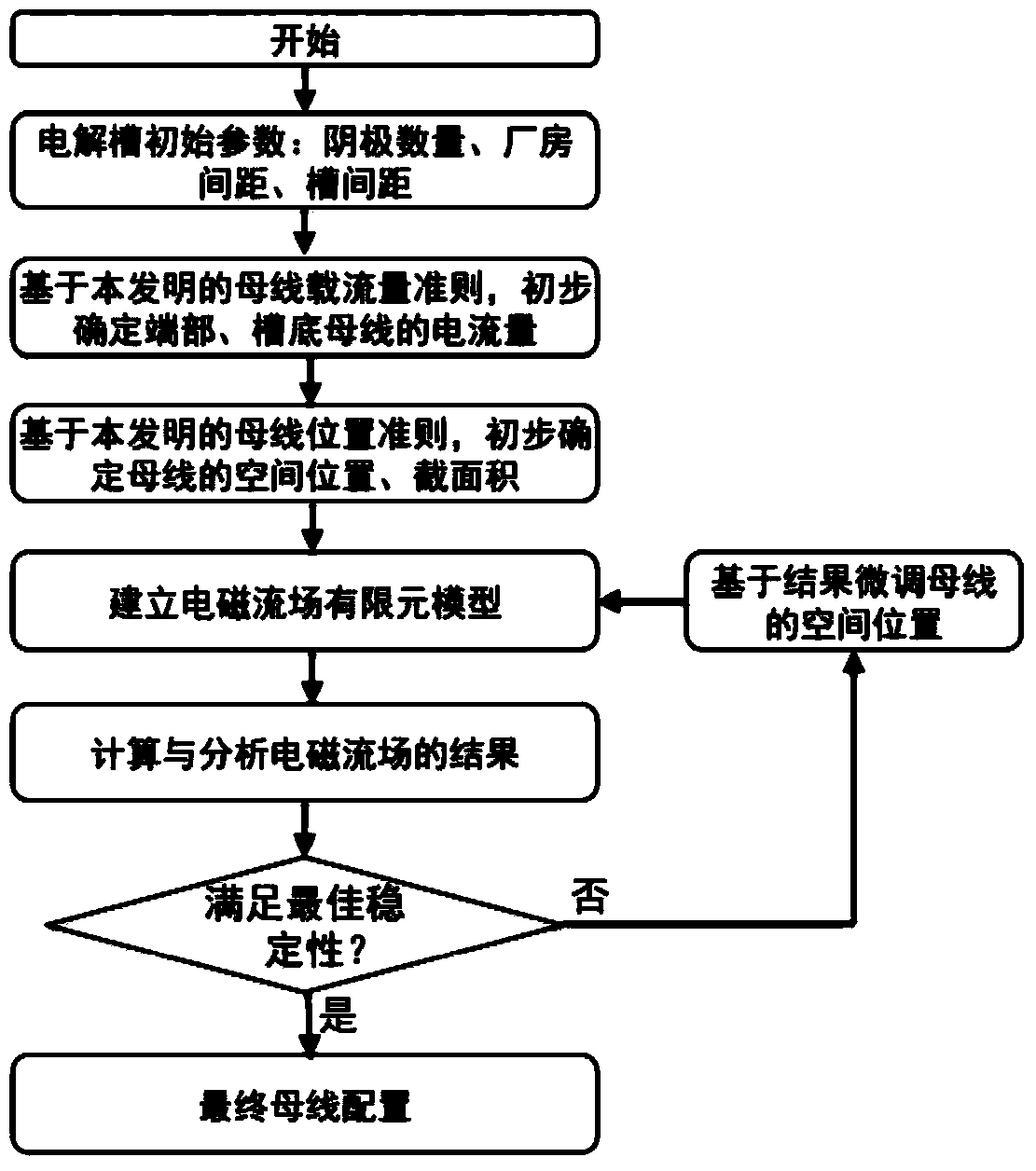

A cathode busbar configuration method for a super-large aluminum electrolytic cell

The invention discloses a cathode bus-bar configuration method of an ultra-large aluminum electrolytic cell. The total quantity of end compensating current is rated and cell bottom bus-bars adopt alternate compensation for offset, that is, the total current quantity flowing through a flue end is controlled within 100-150 kA, the current quantity of an aluminum discharge end is controlled within 80-120 kA, and the rest current on the A side bypasses the multiple cell bottom bus-bars. The routing manner of cathode bus-bars is designed accordingly, and specific parameters of cathode bus-bars of the electrolytic cell, independent compensation bus-bars, cell spacing and plant spacing are determined according to the calculated result of a magnetic fluid model. With the adoption of the cathode bus-bar configuration method of the ultra-large aluminum electrolytic cell, basic configuration of the bus-bars of the ultra-large aluminum electrolytic cell can be determined quickly, the vertical magnetic field and the horizontal magnetic field of melt can be effectively reduced, uniform distribution of the magnetic fields in the long axis direction of the cell is realized, stable operation of the aluminum electrolytic cell is realized, and the current efficiency of the electrolytic cell is improved.

Owner:CENT SOUTH UNIV

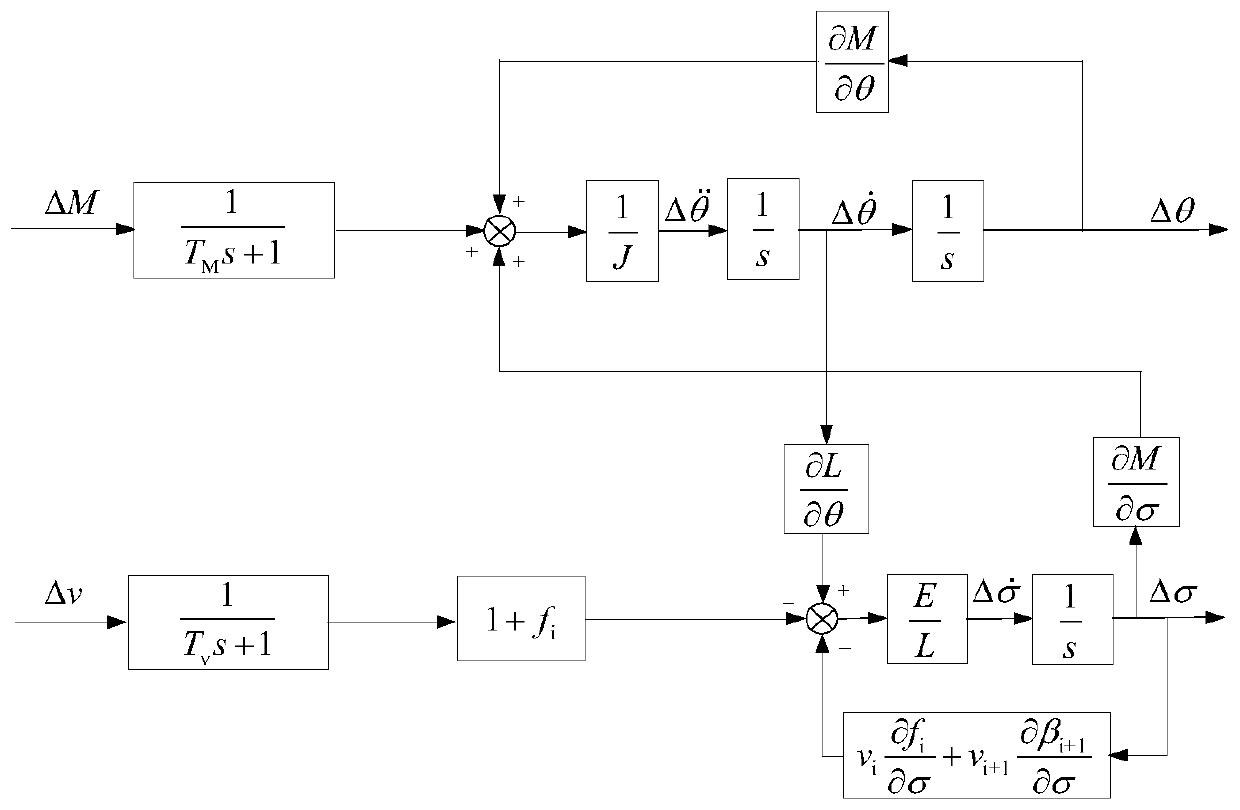

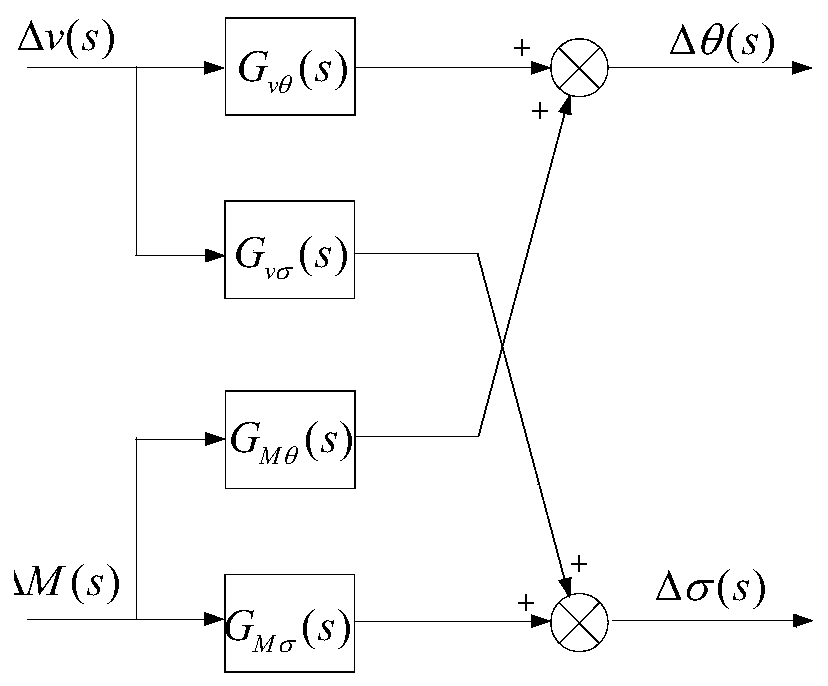

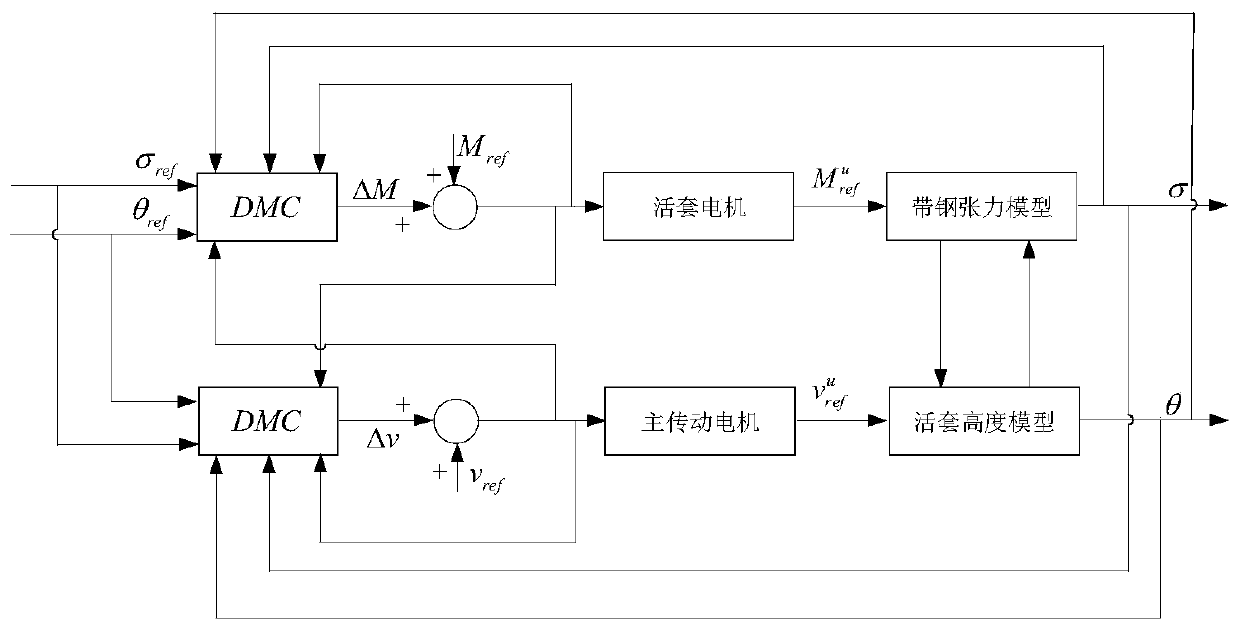

Hot continuous rolling loop system control method based on dynamic matrix controller

InactiveCN110639962AAchieve stable operationHigh dimensional accuracyFlexible work arrangmentsTension/compression control deviceDynamic couplingDimensional precision

The invention relates to a hot continuous rolling loop system control method based on a dynamic matrix controller, which realizes cooperative optimal control on a hot continuous rolling loop angle andtension dual-input dual-output coupling system. The method comprises the following steps that a dual-input double-output coupling transfer function model of a loop system is established through analysis of the dynamic coupling process of the loop system; the dual-input dual-output coupling transfer function model is decomposed into two dual-input single-output systems, and the two dual-input single-output systems are discretized; and a controller of the loop system is designed by adopting a dynamic matrix control algorithm (DMC), and by selecting a proper quadratic performance index function,the cooperative optimal control on the loop height and the strip steel tension is achieved. According to the technical scheme, the cooperative optimal control of angle and tension of any one hot continuous rolling loop system can be achieved, and stable operation of the loop system is realized, so that the dimensional precision of a strip steel is improved.

Owner:HUAQIAO UNIVERSITY

A monitor terminal device for remote control

InactiveCN101553067BLow costIncreased durabilityTelemetry/telecontrol selection arrangementsElectric circuit arrangementsComputer hardwareRemote control

PURPOSE: A monitoring terminal for remote control is provided to correct a reverse value so as to be optimized, automatically, although noises are generated according to the installation environment. CONSTITUTION: A monitoring terminal for remote control comprises a case body(11), an operation panel(14), a touch substrate(13) and a transmission unit(12). The operation panel includes a plurality of manipulation units(22). The touch substrate is arranged on the case body and in the rear side of the operation panel into which a plurality of touch manipulation parts(20) are inserted. The transmission unit is electrically connected to the touch substrate to output a manipulation signal when the pressing of the touch manipulation parts is detected.

Owner:TOSHIBA LIGHTING & TECH CORP

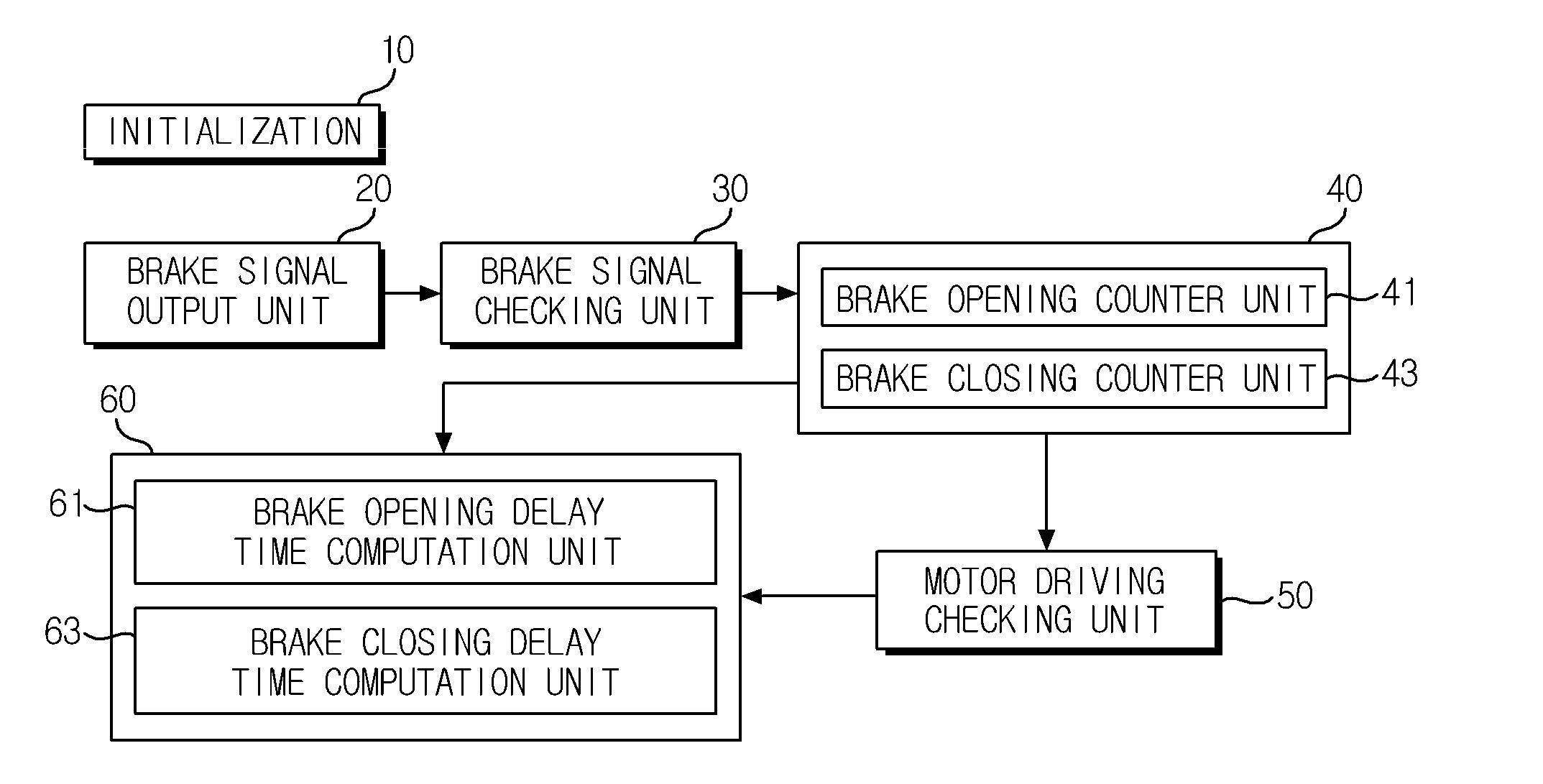

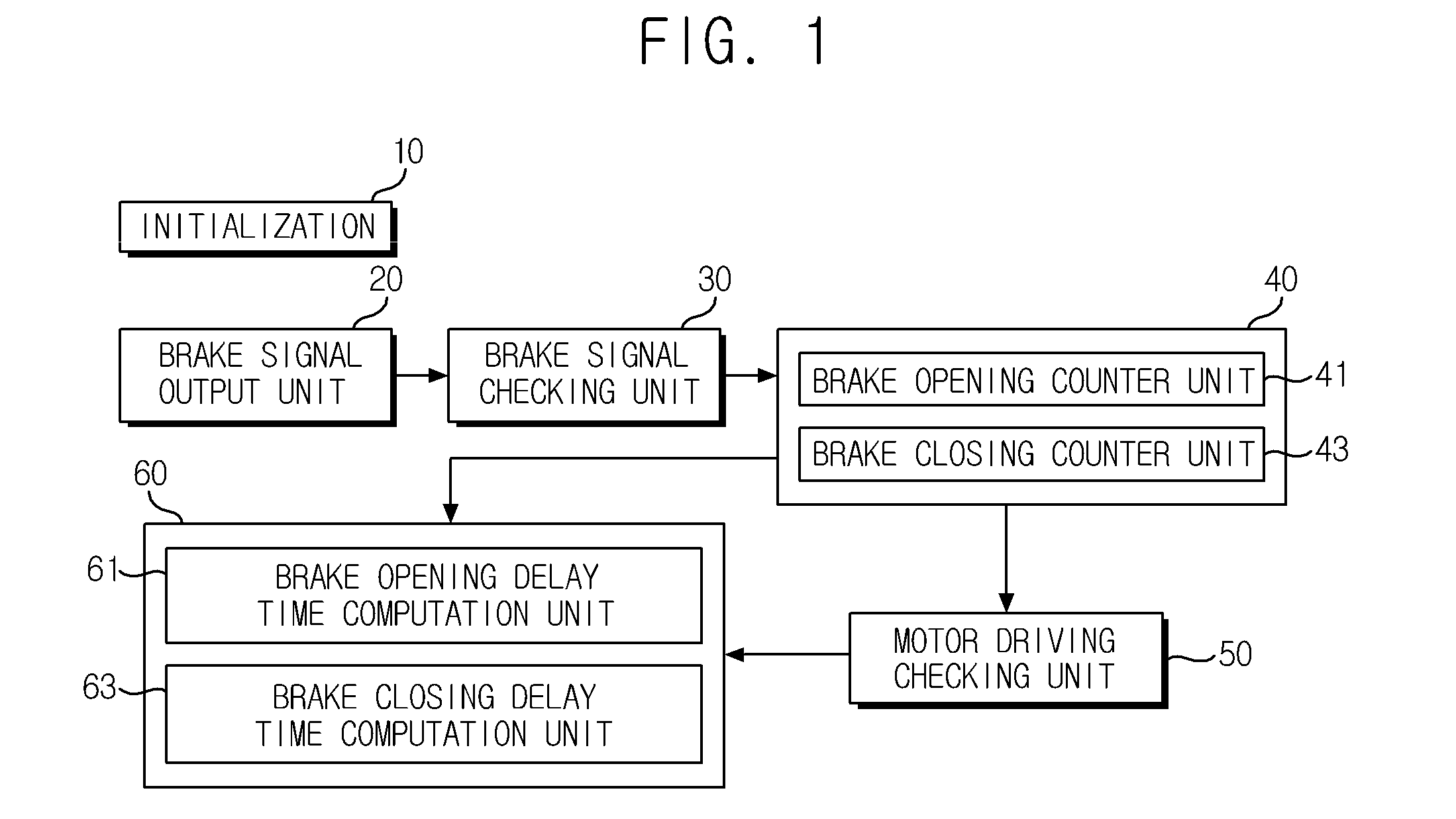

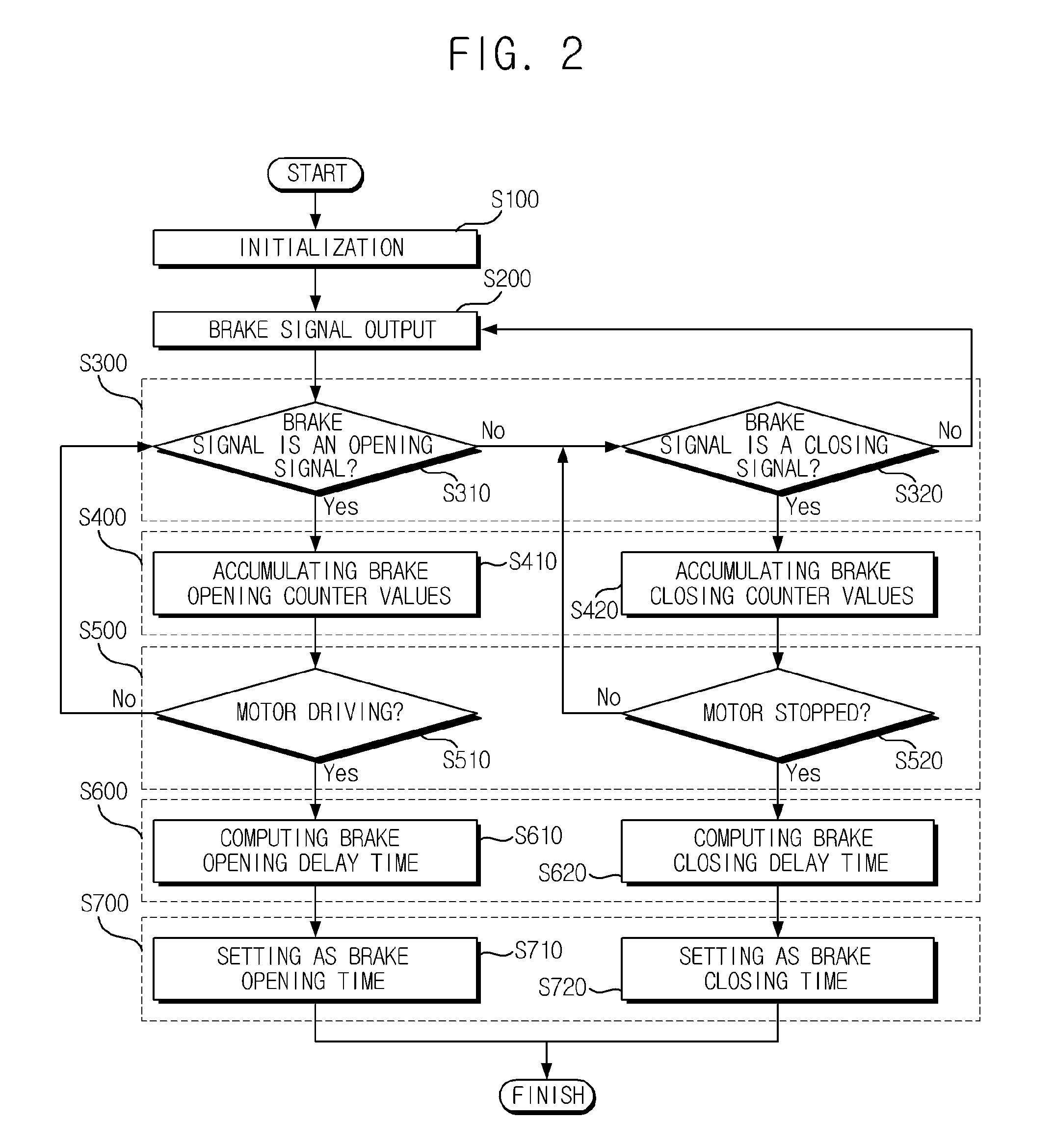

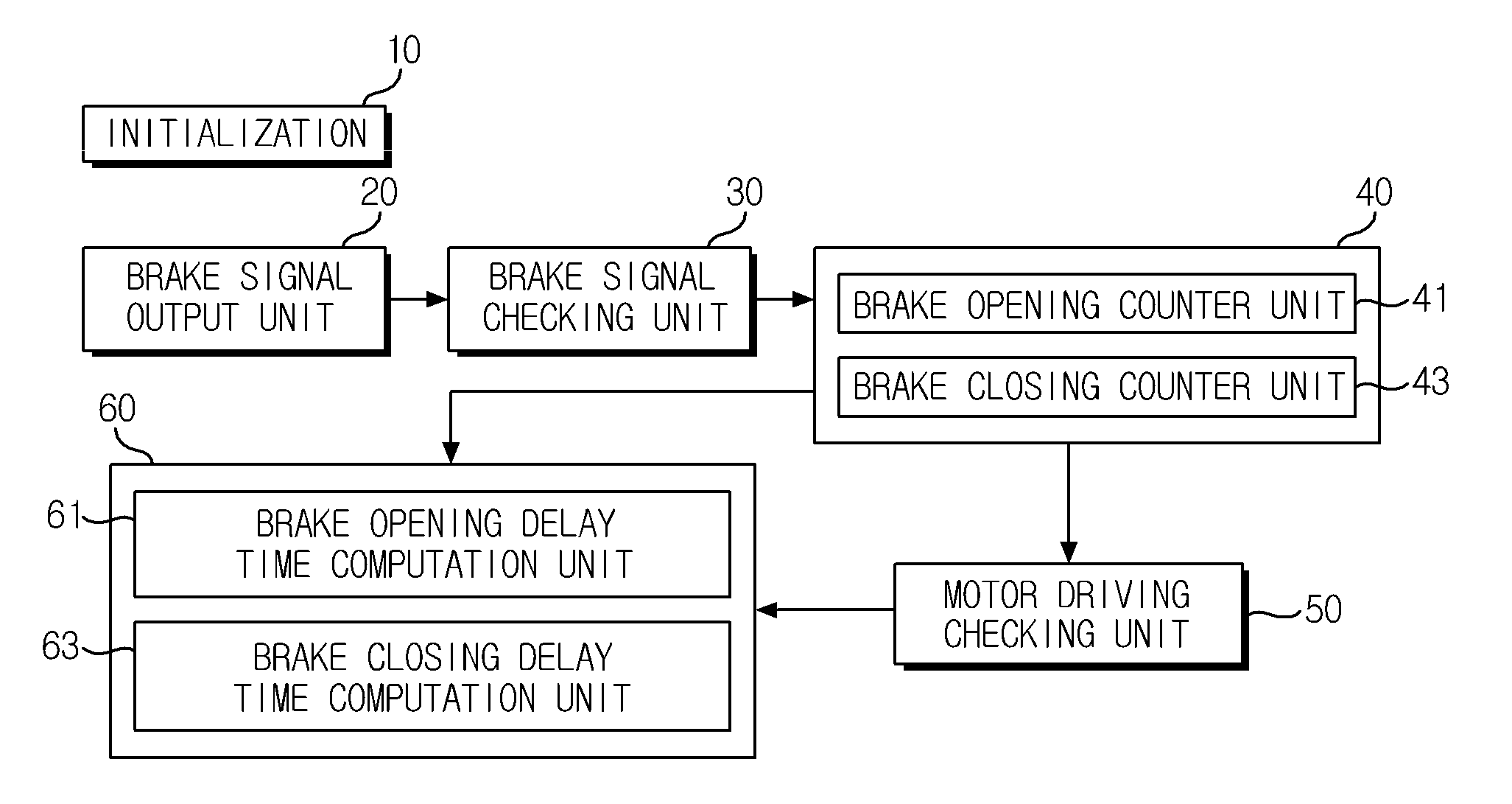

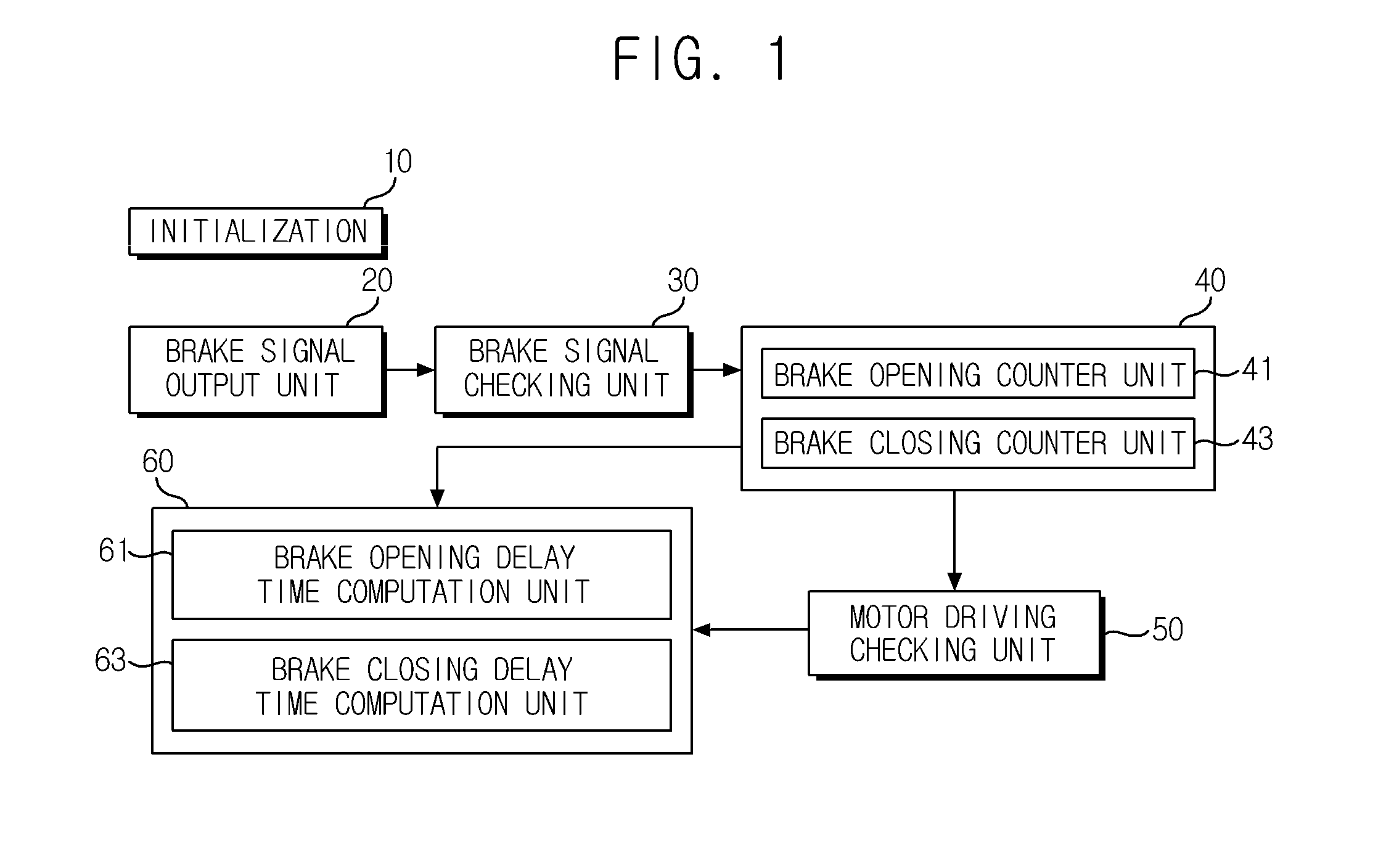

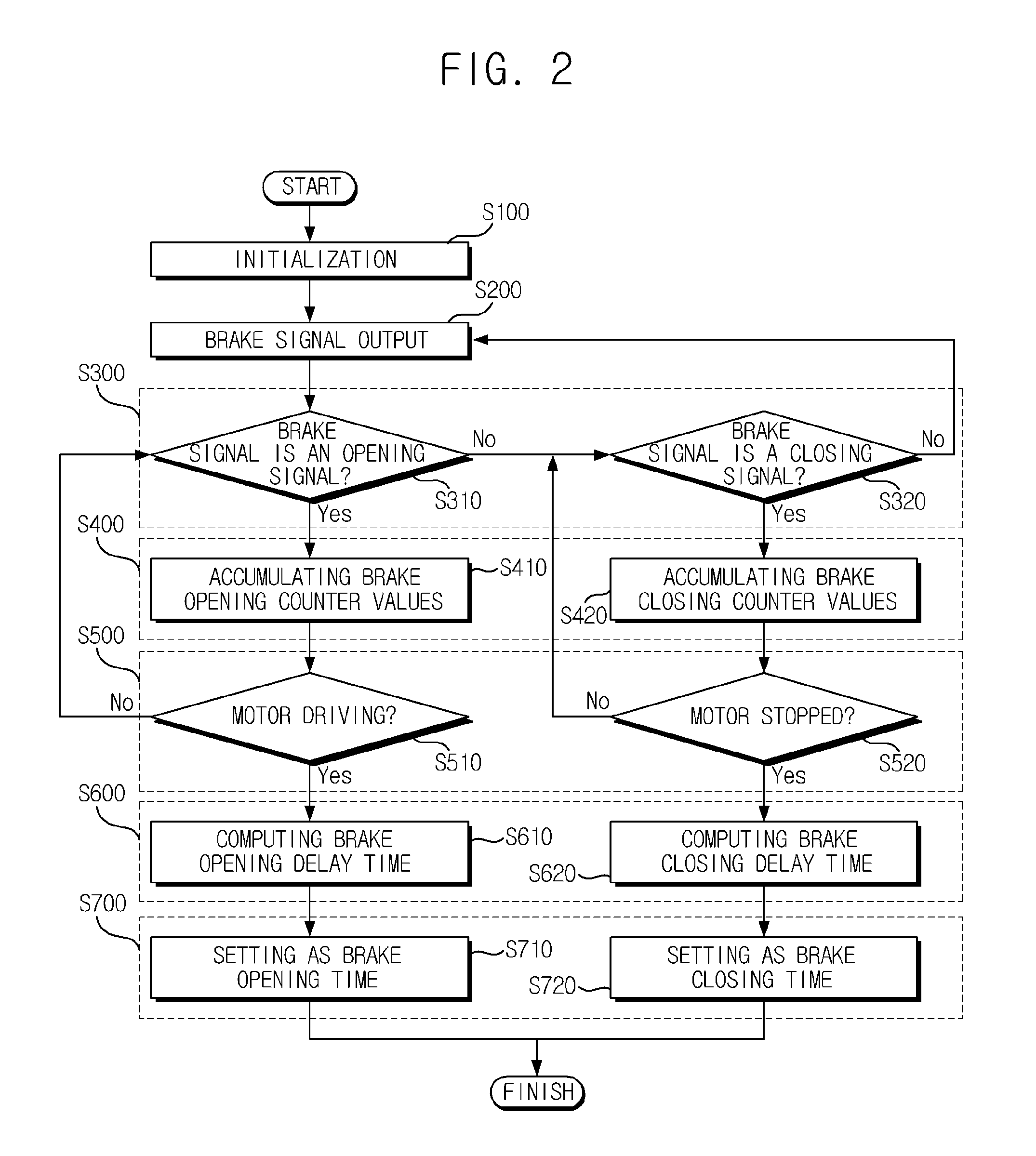

Method for measuring opening and closing delay time of elevator brake

Disclosed is a method for measuring opening and closing delay time of elevator brake, the method including outputting, by a brake signal output unit, a brake signal, receiving, by a brake signal checking unit, the brake signal and determining whether the brake signal is an opening signal or a closing signal to output an opening / closing determination signal, receiving, by a brake counter unit, the opening / closing determination signal, and starting a count for measuring a brake opening time or a brake closing time to accumulate and output counted value, determining, by a motor drive checking unit, whether a motor configured to drive an elevator is driven upon receipt of the counted values and outputting a drive determination signal, and receiving, by a brake opening / closing delay computation unit, the drive determination signal and the counted value to compute a brake opening / closing delay time.

Owner:LSIS CO LTD

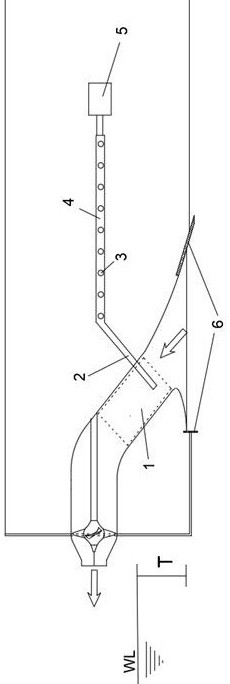

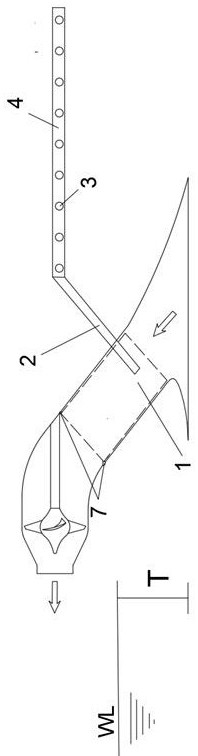

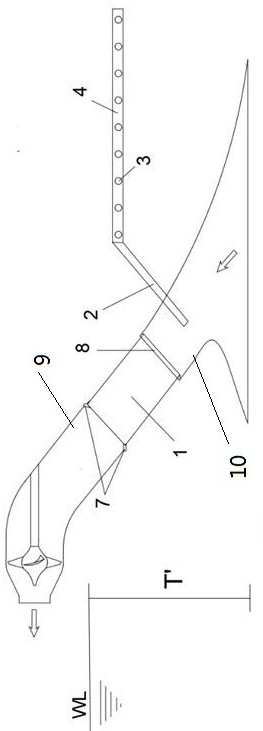

Water-jet propulsion pump device with telescopic water inlet flow channel and implementation method thereof

ActiveCN111846178AAchieve stable operationBroad market and application prospectsPropulsive elementsEnvironmental geologyMarine engineering

The invention discloses a water-jet propulsion pump device with a telescopic water inlet flow channel and an implementation method thereof, and belongs to the field of ship engineering. The device comprises a water-jet propulsion pump and a water inlet flow channel. The water inlet flow channel comprises a near-nozzle water inlet flow channel and a near-water inlet flow channel, the near-nozzle water inlet flow channel is located at a water inlet end of the water-jet propulsion pump, and the near-water inlet flow channel is movably connected with a ship plate; the device is provided with a telescopic water passing part, one end of the telescopic water passing part is fixedly connected with a near-nozzle water inlet flow channel, and the other end of the telescopic water passing part is connected with the near-water inlet flow channel; and the telescopic water passing part moves upwards or downwards in the near-water inlet flow channel so that the water inlet flow channel is telescopic,a draft T' reaches a proper range, the stable operation of the water-jet propulsion device is realized, and the water-jet propulsion pump device and the method have wide market and application prospects in the design and operation of propulsion ships and high-speed boats.

Owner:YANGZHOU UNIV

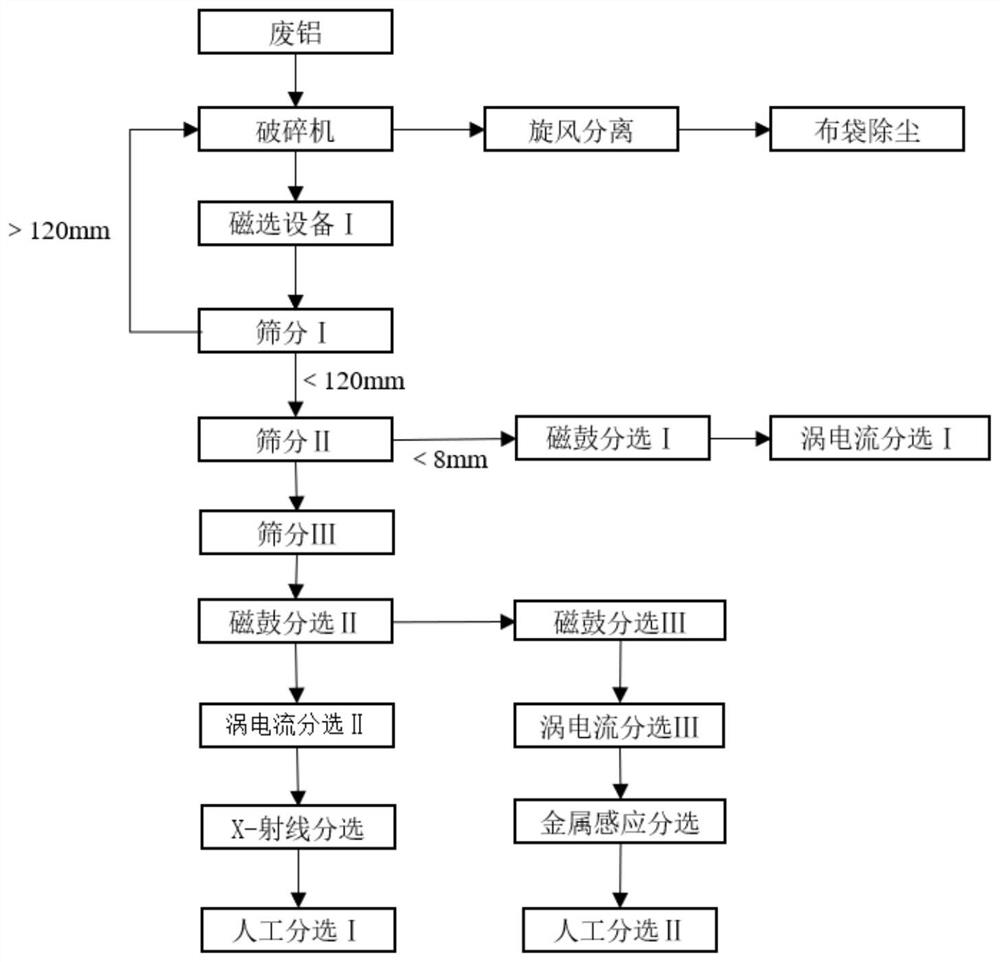

Efficient waste aluminum crushing and sorting system and method

ActiveCN113893939AChange the situation that sorting mainly relies on manual workReasonable configurationVortex flow apparatusMagnetic separationDust controlProcess engineering

The invention relates to an efficient waste aluminum crushing and sorting system and method. The efficient waste aluminum crushing and sorting system comprises a crushing system, a sorting system and a dust removal system. The crushing system comprises a crusher, magnetic separation equipment I and a screening device I; the dust removal system comprises a cyclone separator, a cloth bag dust removal device and a chimney; and the sorting system comprises a screening device II, a screening device III, magnetic drum sorting equipment I, eddy current sorting equipment I, magnetic drum sorting equipment II, magnetic drum sorting equipment III, eddy current sorting equipment II, eddy current sorting equipment III, X-ray sorting equipment and metal induction sorting equipment. According to the efficient waste aluminum crushing and sorting system and method, the problems mainly solved by the efficient waste aluminum crushing and sorting system and method are as follows: (1) the problems of backward technical route and poor device continuity are solved; (2) the problem that secondary pollution is easily generated in the crushing process is solved; (3) the problem of rough manufacturing of a crushing technology is solved; (4) the problem that the recycling rate of waste aluminum is low is solved; and (5) the problems that the automation degree is low and a large amount of labor is needed are solved.

Owner:顺尔茨环保(北京)有限公司

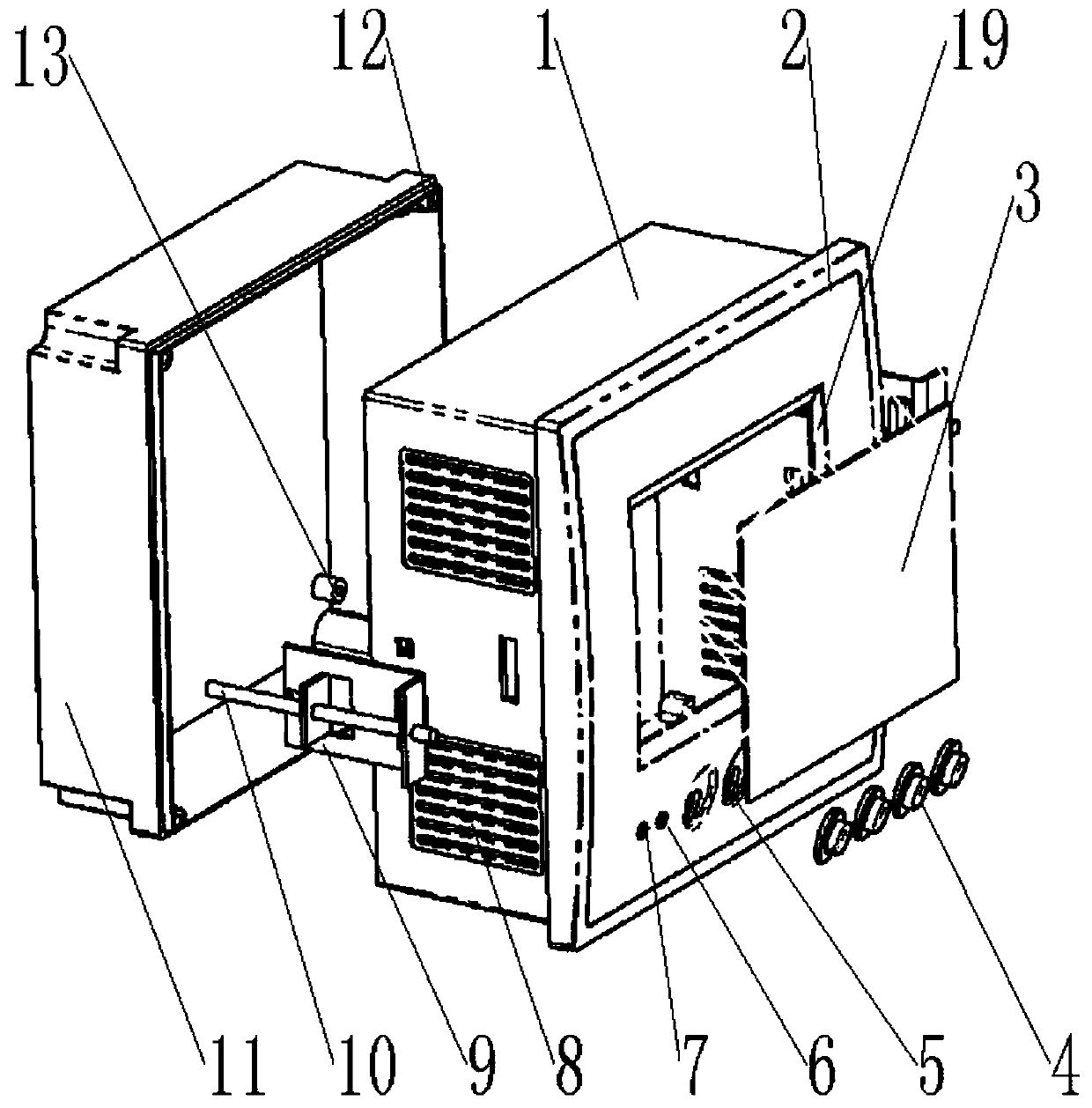

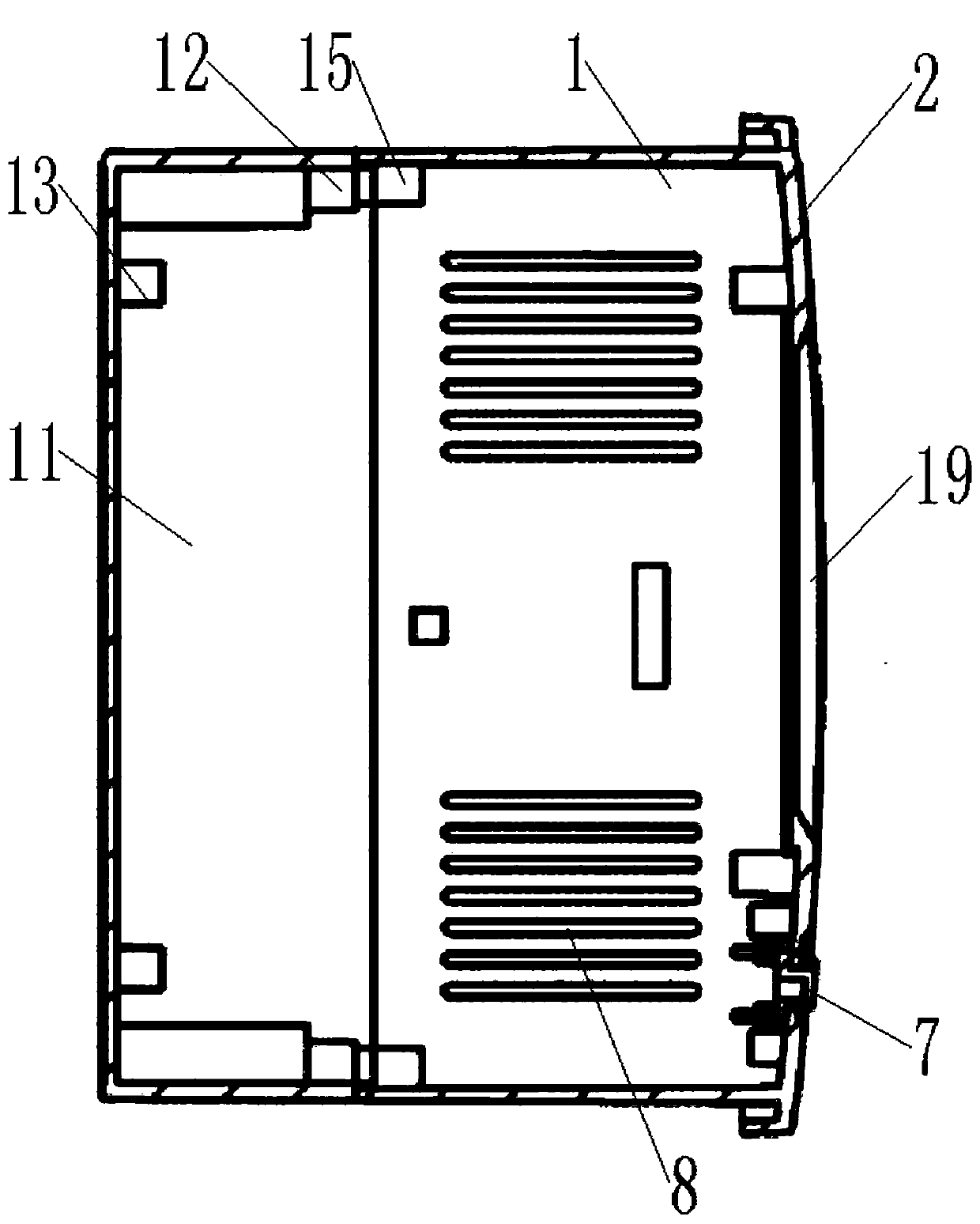

Intelligent electric isolation switch operation box

InactiveCN110768133AReal-time displayAchieve real-time displaySupervisory desks/panelsCircuit arrangementsStructural engineeringReal time display

The invention relates to the technical field of an operation box, and specifically relates to an intelligent electric isolation switch operation box. The intelligent electric isolation switch operation box comprises a box body and a rear cover. A protection board is arranged on the outer wall of one side of the box body; a square groove is formed in the outer wall of one side of the protection board; corner connectors are arranged at the four corners of the outer wall of one side of the square groove respectively; a display screen is inserted into the square groove and located among the four corner connectors; a plurality of button holes and round holes are formed in the inner wall of one side of the protection board; buttons are inserted into the button holes; indicator lamps are insertedinto the round holes; four third nut pipes are arranged on the inner wall of the protection board; and the display screen is fixed to the third nut pipes through bolts. The beneficial effects are that through the display screen, real-time display of all parameters of the device and real-time display of conditions of all workpieces are realized, thereby avoiding manpower waste caused by opening the box and checking the workpieces one by one, reducing wear of the operation box caused by repeated opening of the box, and achieving visualization of real-time parameters of the operation box.

Owner:珠海施诺电力科技有限公司

Automatic paper cutting equipment

PendingCN113696245AExtended service lifeGuarantee the position of the highest pointMetal working apparatusMaterial transportIndustrial engineering

The invention discloses automatic paper cutting equipment, and relates to the technical field of paper cutting equipment. The automatic paper cutting equipment comprises a base, and is characterized in that a stabilizing frame is fixed on the base, the stabilizing frame is of an inverted L-shaped structure, and a slitting device for realizing material slitting is arranged on one side of the stabilizing frame in a lifting manner; a bearing device used for bearing materials and conveying the materials to a slitting position is arranged on one side of the base, a circulating support is fixed to the other side of the base, and two clamping plates are arranged on one side of the circulating support. According to the automatic paper cutting equipment, the production efficiency of the equipment is improved, the manpower consumption of the equipment is reduced, the labor intensity of operators is reduced, the safety of the equipment is improved, and it is guaranteed that potential safety hazards cannot occur when the operators operate the equipment.

Owner:王金涛

Method for treating membrane concentrate by applying solar evaporation device

InactiveCN109592730AAvoid equipment corrosion and structural problemsAchieve stable operationGeneral water supply conservationWater/sewage treatment apparatusEvaporatorSolar thermal collector

The invention discloses a method for treating membrane concentrate by applying a solar evaporation device and belongs to the technical field of treatment of membrane concentrate. By adoption of the method, the problems of serious corrosion and scaling and high equipment cost and operation cost in the existing evaporation equipment are solved. The treatment method comprises the following steps that(1) a heat medium in a heat-medium storage tank flows into a solar heat collector for heating through a heat-medium input pipeline, and flows into a three-way valve through a heat-medium output pipeline to be mixed with the heat medium from a heat-medium return pipeline so as to regulate the temperature of the heat medium; (2) a heat-medium coil heat exchanger is arranged below each evaporation groove, the heat medium returns into the heat-medium storage tank through the pipeline; (3) steam after the membrane concentrate in an evaporation pool flows into a condenser, and the membrane concentrate in the evaporation pool realizes solid-liquid separation under heating of the coil heat exchanger. The method disclosed by the invention has the beneficial effects that solar energy is adopted asa heat source of the evaporation device, so that the operation cost is reduced; a sequencing-batch type evaporation structure is adopted in an evaporator, so that the heat-supply stability is good.

Owner:HEILONGJIANG HEIKE TECH CO LTD +1

Method for measuring opening and closing delay time of elevator brake

ActiveUS20150059460A1Improve performanceAchieve stable operationApparatus for force/torque/work measurementElevatorsAutomotive engineering

Disclosed is a method for measuring opening and closing delay time of elevator brake, the method including outputting, by a brake signal output unit, a brake signal, receiving, by a brake signal checking unit, the brake signal and determining whether the brake signal is an opening signal or a closing signal to output an opening / closing determination signal, receiving, by a brake counter unit, the opening / closing determination signal, and starting a count for measuring a brake opening time or a brake closing time to accumulate and output counted value, determining, by a motor drive checking unit, whether a motor configured to drive an elevator is driven upon receipt of the counted values and outputting a drive determination signal, and receiving, by a brake opening / closing delay computation unit, the drive determination signal and the counted value to compute a brake opening / closing delay time.

Owner:LSIS CO LTD

Mobile bearing device for family passenger car

PendingCN109291892AImprove stabilityMobile and flexibleSpraying apparatusVehicle servicing/repairingEngineeringMobile bearing

The invention discloses a mobile bearing device for a family passenger car and belongs to the technical field of passenger cars. The mobile bearing device for the family passenger car comprises a locating bearing part, a bearing driving part, a scraping output part and a limiting material scraping part; the limiting material scraping part comprises a limiting bearing frame, a sliding locating component and a transmission material scraping component; and the transmission material scraping component is arranged in a vertical state. According to the mobile bearing device for the family passengercar, first, when a passenger car to be maintained needs to be moved, the whole device is driven by the bearing driving part mounted at the bottom of the locating bearing part to move on the external surface of the passenger so as to finish the moving operation of the whole-body position of the car; when the passenger car moves to one position needing to be maintained, the whole locating bearing part is fixedly adsorbed to the external side wall of the passenger car so as to achieve a precondition of stable operation; and by using the scraping output part, the limiting material scraping part isdriven to rotate; and therefore, coating maintenance operation of the position to be maintained can be finished.

Owner:董淑翠

Grading recycling system and grading recycling method for waste aluminum ring-pull cans

PendingCN113913613ATo achieve non-downgrade useReasonable configurationIngot casting plantsIncreasing energy efficiencyDust controlProcess engineering

The invention relates to a grading recycling system and a grading recycling method for waste aluminum ring-pull cans. The system comprises a sorting system, a crushing system, a paint removing system, a melting system, a refining system, a casting system, a dust removal system and a waste gas treatment system. The sorting system is connected with the crushing system, and the dust removal system is connected with the crushing system and the sorting system. The paint removing system is connected with the crushing system, the melting system and the waste gas treatment system. The refining system is connected with the melting system and the casting system is connected with the refining system. The coating removal rate of the waste aluminum ring-pull can is greater than 99%; the non-degradation use of the waste aluminum ring-pull can is realized; the recovery rate of the waste aluminum ring-pull cans is greater than 96%; the purity of the sorted waste aluminum ring-pull cans is greater than 98%; and the grading recycling system is safe, environment-friendly, reasonable in configuration and capable of realizing continuous and stable operation. And through the advanced crushing technology, continuous operation of the device can be achieved, and meanwhile the service life of the device is prolonged.

Owner:顺尔茨环保(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com