Two-speed wind distributing method for blast furnace blower

A blower and blast furnace technology, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as blast furnace blower load not keeping up, performance loss of blower blast furnace, blast furnace blower equipment damage, etc., to eliminate faulty blast furnace slag filling accidents, ensure non-slag filling operation, and reduce the effect of accident economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

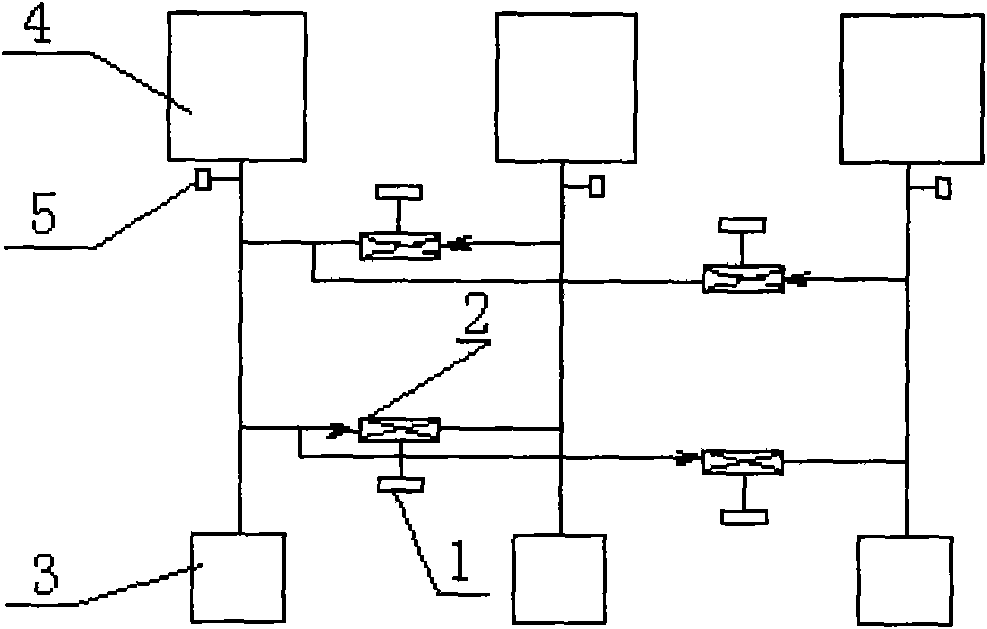

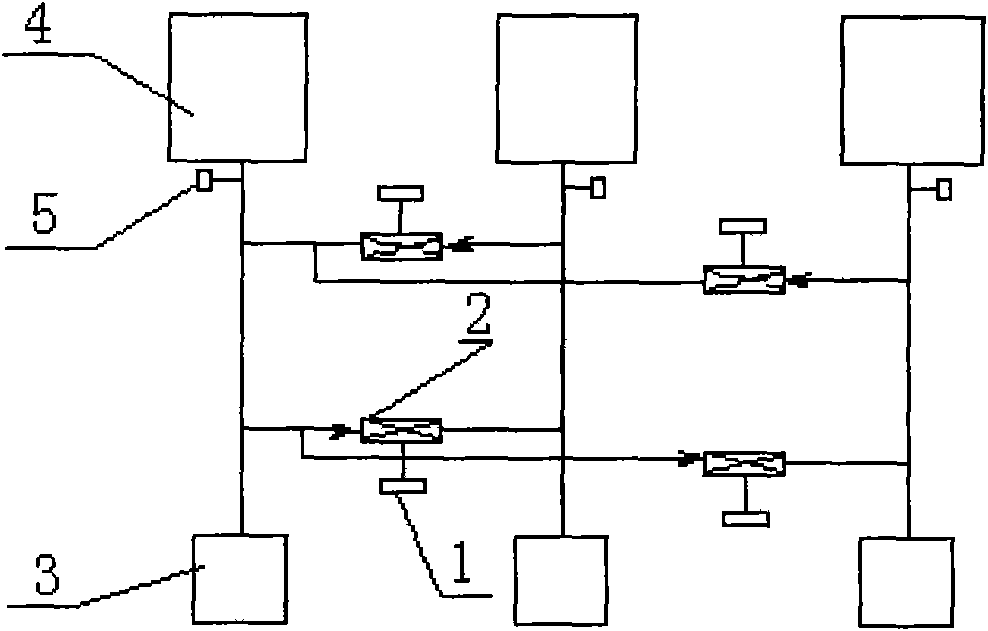

[0014] Such as figure 1 As shown, DCS and PLC control system 5 are installed on multiple air blowers 5 of each blast furnace 4 of the present invention (generally, a blast furnace is equipped with 4 to 6 air blowers) to realize constant monitoring and interlock control, and two-speed air blowers are configured between each other. The blower device 1 adopts multi-machine interconnection, automatic judgment after failure, and automatic blower, and uses a double-speed blower to perform double-speed blower blower to ensure the safe and normal operation of the blast furnace and blast furnace blower.

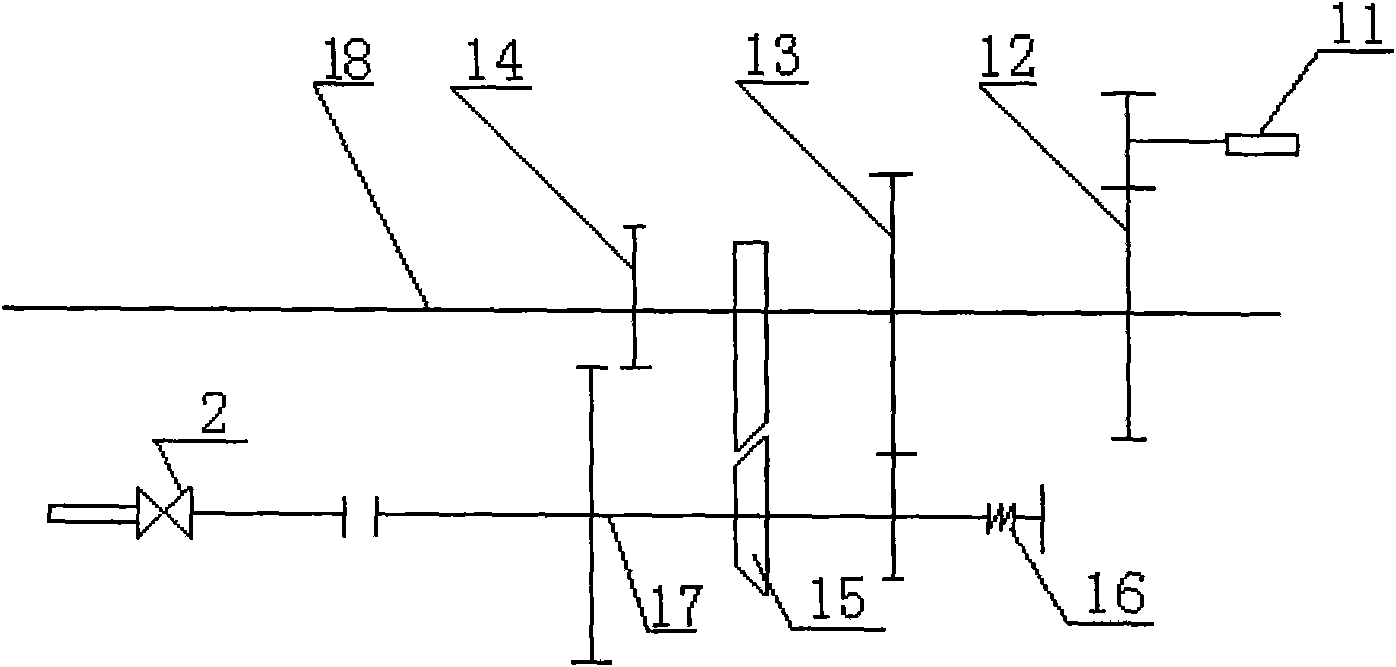

[0015] According to the present invention, the double-speed fan adopts a double-speed motor or a mechanical double-speed control device to control the opening of the angle of the valve 2 in sections. 30%-40% of the flow rate of the valve, the air vol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com