Method for treating membrane concentrate by applying solar evaporation device

An evaporation device, solar energy technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage treatment equipment, etc., can solve the problems of serious corrosion and scaling of evaporation equipment, high equipment cost and operating cost, etc. Good thermal stability, avoid equipment corrosion and structural problems, and achieve the effect of secondary use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0013] Specific implementation mode one: the method for applying the solar evaporation device to process the film concentrate in this embodiment is implemented according to the following steps:

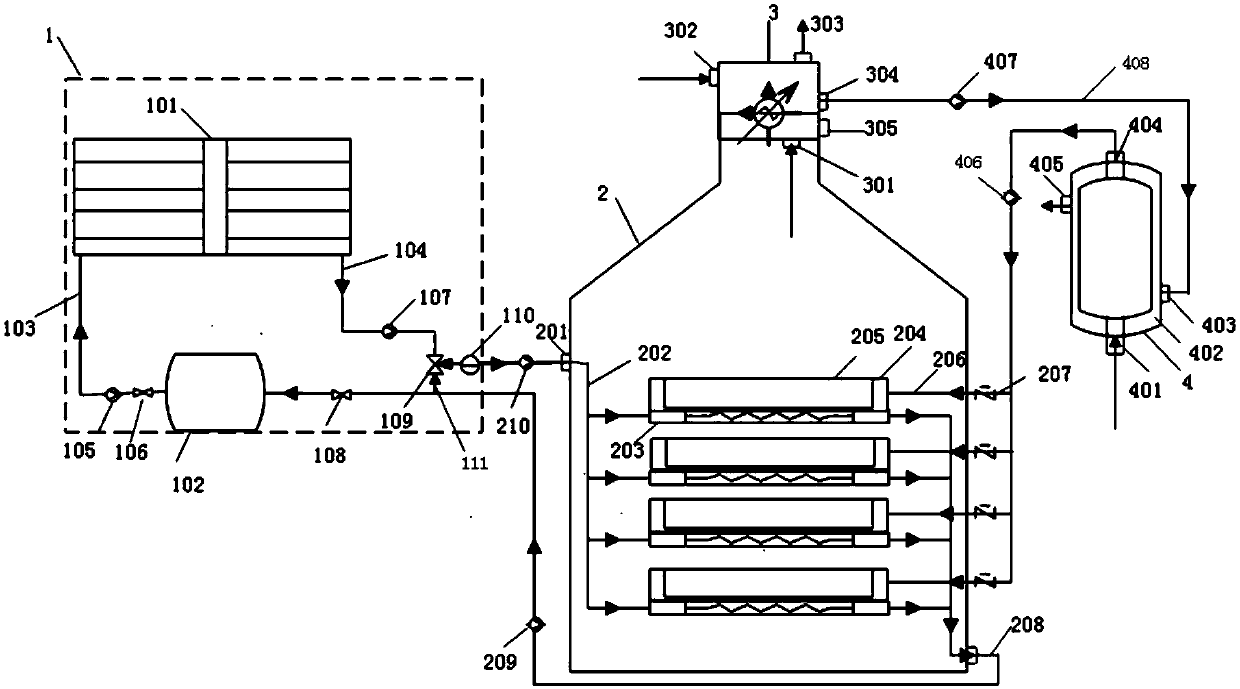

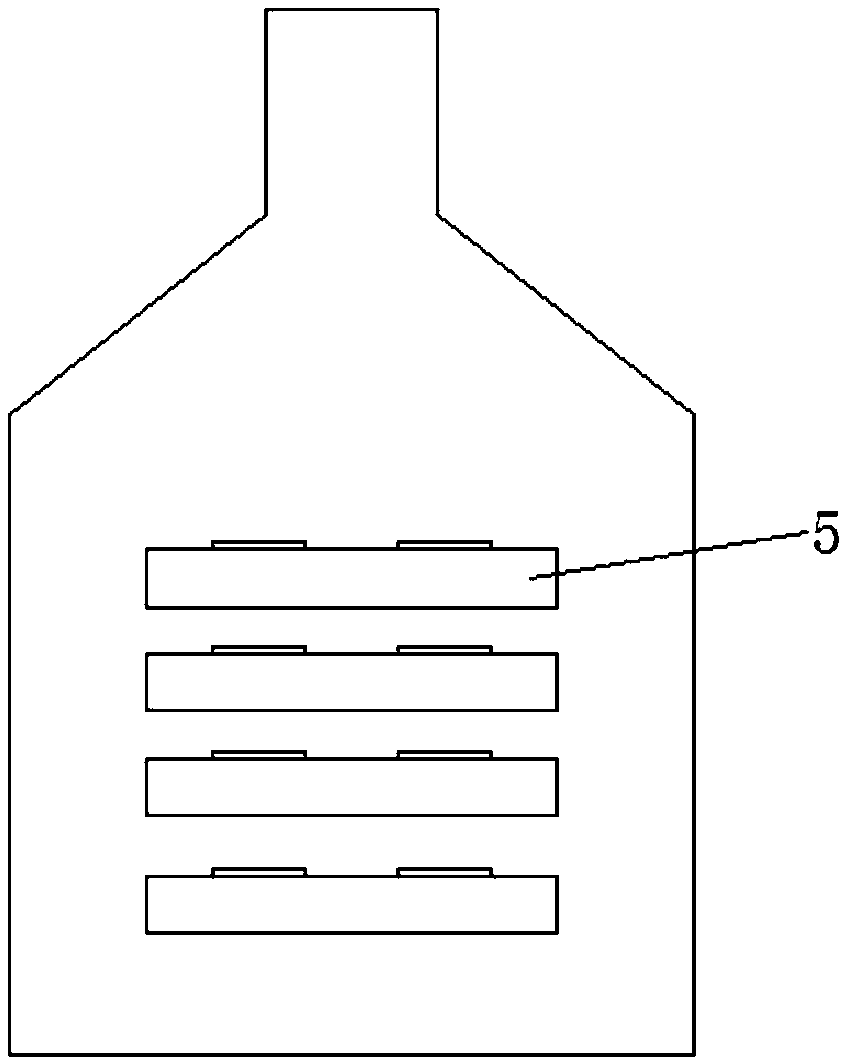

[0014] One, the solar evaporation device comprises a solar heat collecting unit 1, an evaporator 2, a condenser 3 and a preheating device 4, and the solar heat collecting unit 1 includes a solar heat collector 101 and a heat medium storage tank 102, and in the heat medium storage tank 102 The heat medium flows into the solar collector 101 through the heat medium input pipeline 103 for heating, and then flows into the three-way valve 109 through the heat medium output pipeline 104 to mix with the heat medium from the heat medium return pipeline 208, and passes through the heat medium The control button 110 stably outputs the heat medium with a temperature of 120-180°C, and then flows into each parallel heat medium coil heat exchanger 203 through the heat medium transportation pipeline 2...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the solar evaporation device includes a solar heat collection unit 1, an evaporator 2, a condenser 3 and a preheating device 4, and the solar heat collection unit 1 includes solar energy The heat collector 101 and the heat medium storage tank 102, the inlet of the solar heat collector 101 is communicated with the liquid outlet of the heat medium storage tank 102 through the heat medium input pipeline 103, and one end of the heat medium return pipeline 208 is connected with the heat medium storage tank 102. The liquid inlet is connected, the other end of the heat medium return pipe 208 is respectively connected with the liquid outlet of each heat medium coil heat exchanger 203, and the outlet of the solar collector 101 is connected to the three-way valve 109 through the heat medium output pipe 104 One end of the branch pipe 111 is connected with the heat medium return pipe ...

specific Embodiment approach 3

[0022] Embodiment 3: This embodiment is different from Embodiment 1 or Embodiment 2 in that a first liquid pump 105 is provided in the heat medium input pipe 103 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com