Power transmission system of corn harvester

A technology for power transmission systems and harvesters, applied in harvesters, agricultural machinery and tools, applications, etc., can solve problems such as difficult maintenance, unreasonable design mechanisms, and lack of reliability, so as to reduce occupied space and overcome high costs , The effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

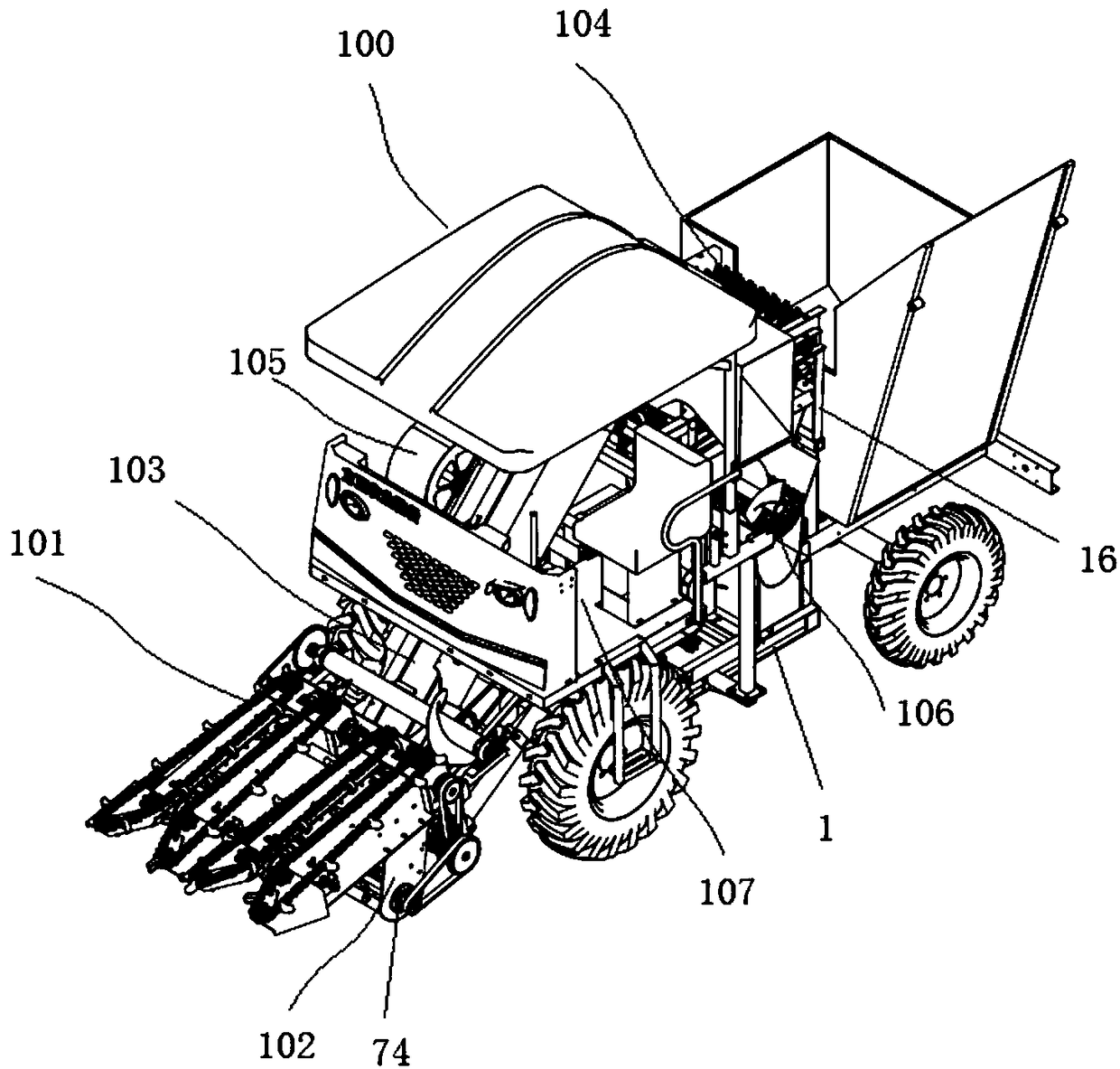

[0031] Such as figure 1 As shown, the present invention provides a power transmission system of a corn harvester 100, which includes a walking power transmission unit and a working power transmission unit arranged on the chassis frame 1;

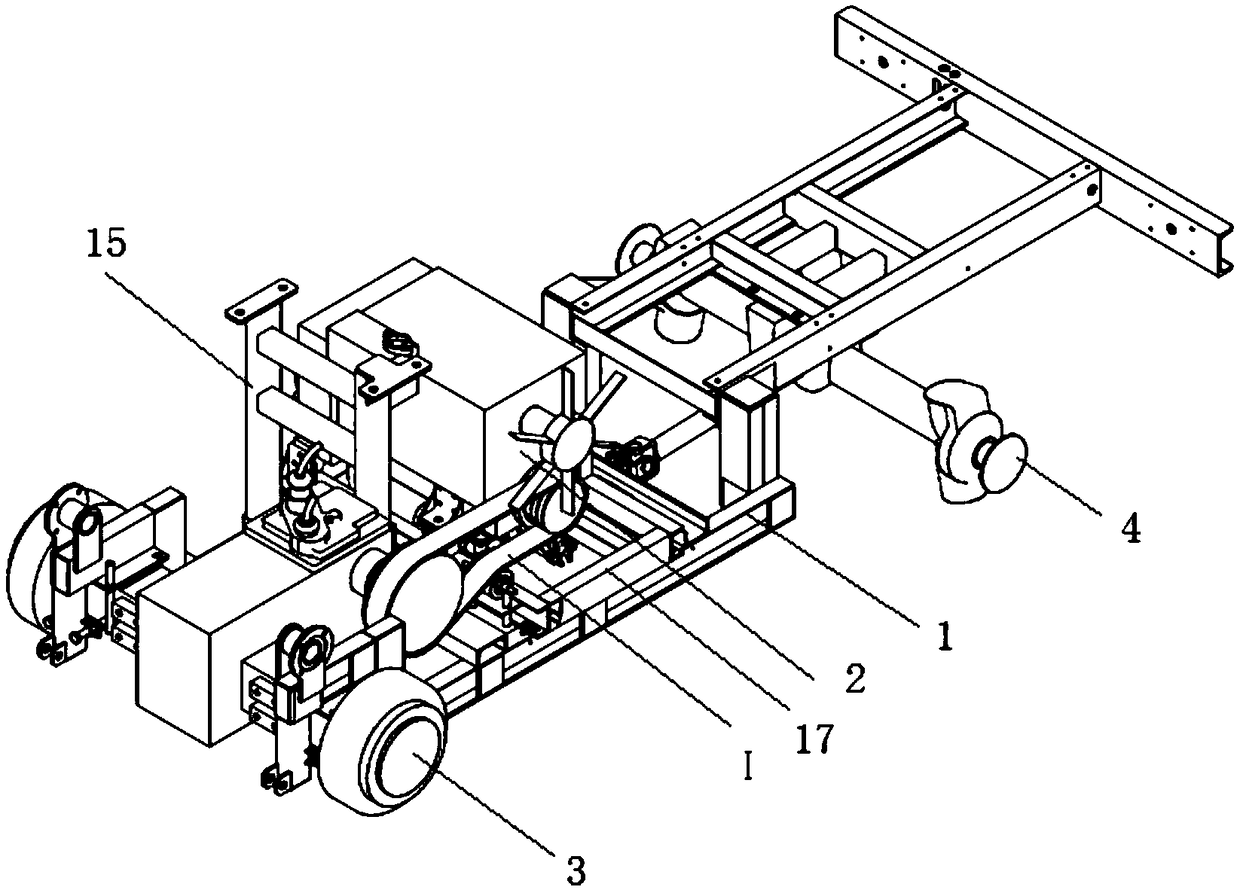

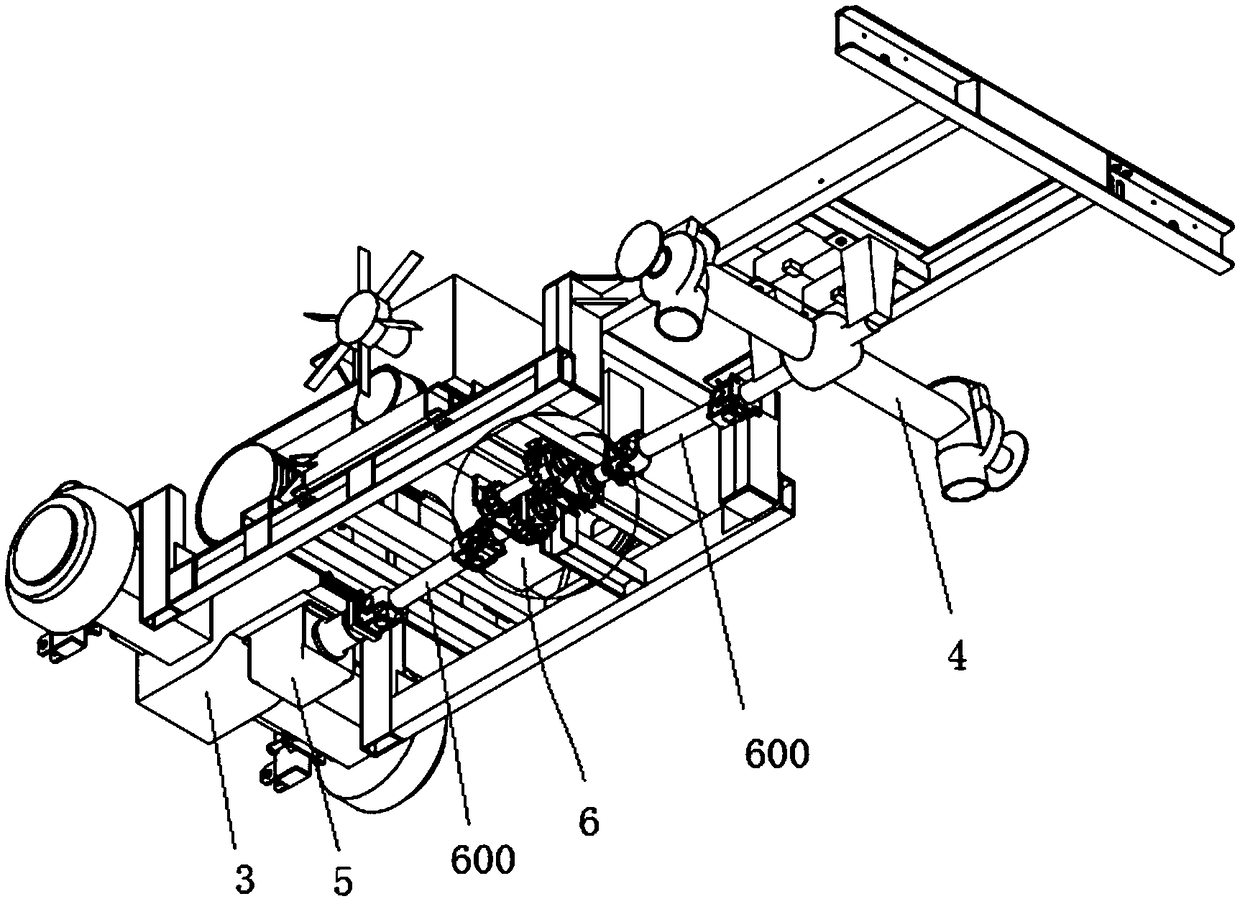

[0032] Such as figure 2 , image 3 As shown, the walking power transmission unit includes an engine 2, a drive axle 3, a steering axle 4, a four-wheel drive gearbox 5 and a transmission mechanism 6; Above the middle part of the chassis frame 1, the first output shaft of the engine 2 is connected to the drive axle 3 through the first transmission assembly I, and the four-wheel drive gearbox 5 is installed at the bottom of the drive axle 3, and the built-in gears of the four-wheel drive gearbox 5 and the drive axle 3. The built-in gear meshes, and the output end of the four-wheel drive gearbox 5 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com