Configuration method for cathode buses of electrolytic baths with controllably adjustable vertical magnetic fields and structure adopting method

A vertical magnetic field and cathode busbar technology, which is applied in the field of cathode busbar configuration of aluminum electrolytic cells, can solve the problems of excessive magnetic field compensation in electrolytic cells, abnormal fluctuations in electrolytic cells, and different magnetic field compensation requirements. The method is simple and the overall stability is improved. The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing.

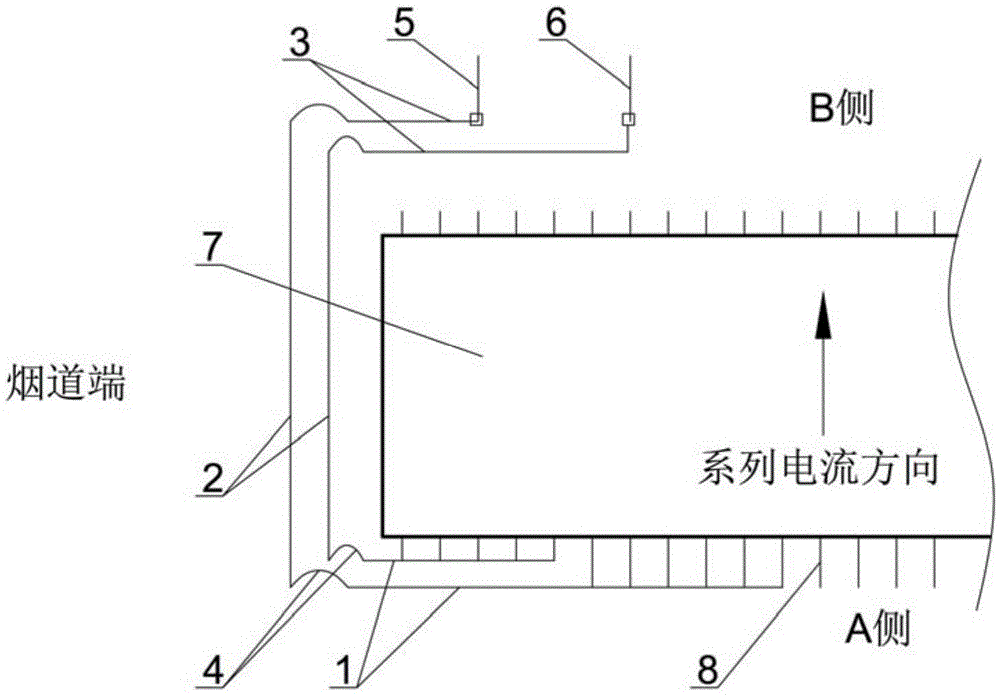

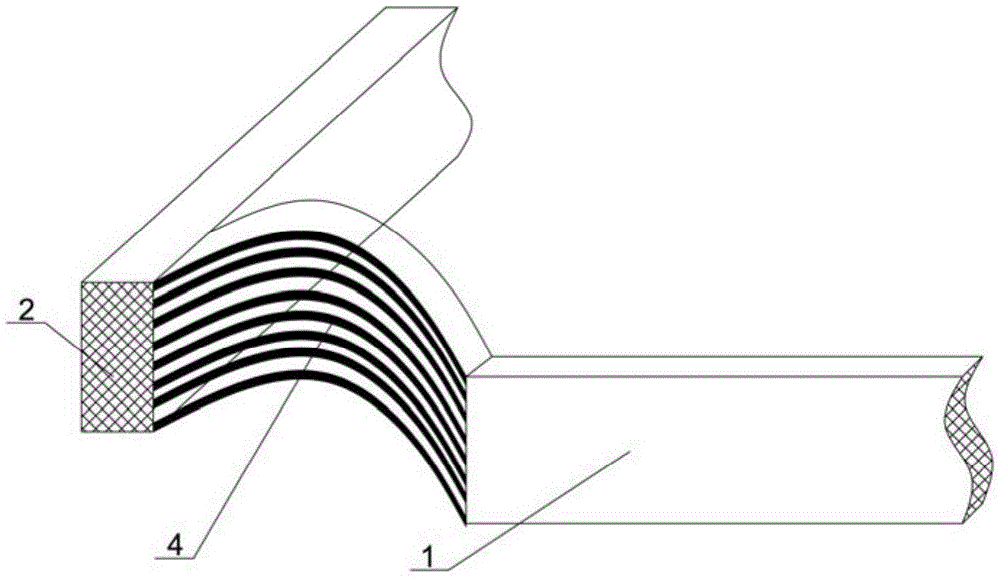

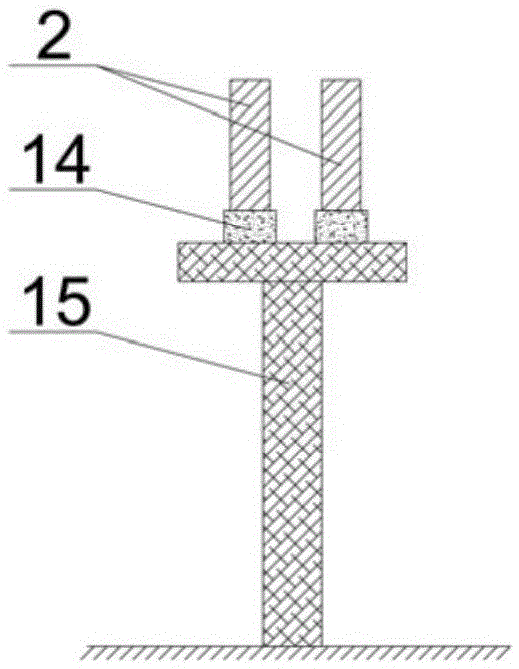

[0031] see figure 1 and figure 2 , a configuration method and structure of the cathode bus bar of an electrolytic cell with a controllable and adjustable vertical magnetic field. There are three parts on the outlet side part 3 of the end busbar, the inlet side part 1 of the end busbar and the end part 2 of the end busbar, and the vertical magnetic field adjustment is adopted between the end part 2 of the end busbar and the outlet side part 3 of the end busbar The soft busbar 4 is connected so that the end part 2 of the end busbar can move as needed along the vertical direction and the horizontal direction, so as to realize the dynamic adjustment of the most important end compensation busbar of the aluminum electrolytic cell. The number of busbars flowing through the end is consistent with the existing design. The number of busbars flowing through the end is two or four, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com