LPCVD initial-deposition furnace temperature accurate control method

A precise control and initial deposition technology, applied in the field of LPCVD deposition, can solve the problems that the adjustment effect cannot be reflected in time, the disturbance cannot be detected in time, large overshoot or oscillation, etc., to achieve stable operation, avoid fluctuations in furnace temperature, and ensure consistency sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

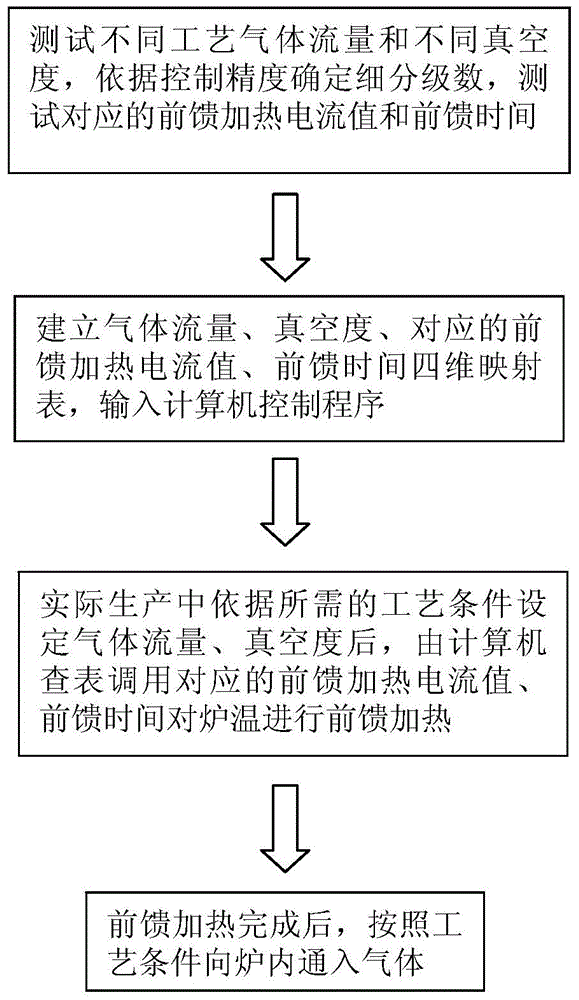

[0013] Such as figure 1 Shown, the precise control method of the furnace temperature of LPCVD initial deposition of the present invention, comprises the steps:

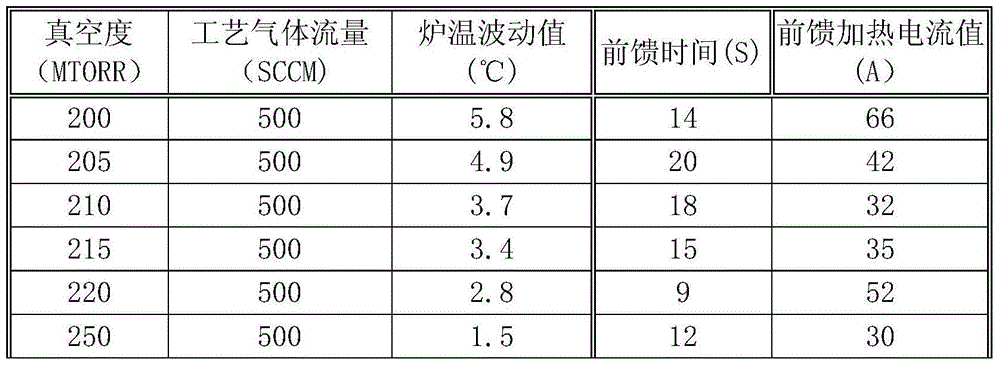

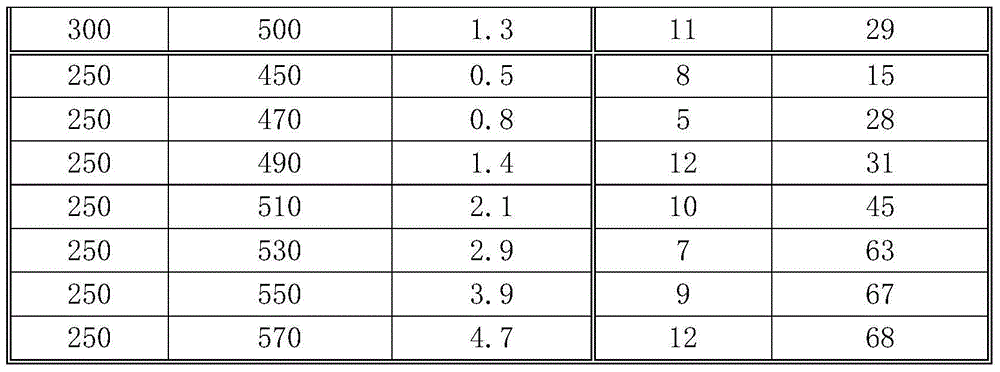

[0014] S1. Measure the value and time of the furnace temperature fluctuation according to different butterfly valve opening angles, pumping speeds, and flow rates of different process gases, determine the subdivision series according to the control accuracy, and calculate different process gas flow rates and different The feedforward heating current value and feedforward time corresponding to the vacuum degree are shown in the table below:

[0015]

[0016]

[0017] S2. Input the four-dimensional mapping table composed of gas flow, vacuum degree, corresponding feedforward heating current value, and feedforward time into the computer;

[0018] S3. After setting the gas flow rate and vacuum degree according to the required process conditions during production, the computer controls the LPCVD furnace to perform fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com