Fluidized bed reactor

A technology for fluidized bed reactors and reaction tubes, which is applied in the fields of chemical instruments and methods, inorganic chemistry, silicon compounds, etc., and can solve the difficulties in assembly, installation and maintenance of fluidized bed reactors, heavy weight of fluidized bed reactors, Large volume and other problems, to achieve the effect of easy installation and maintenance, simple installation and maintenance, and pollution prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

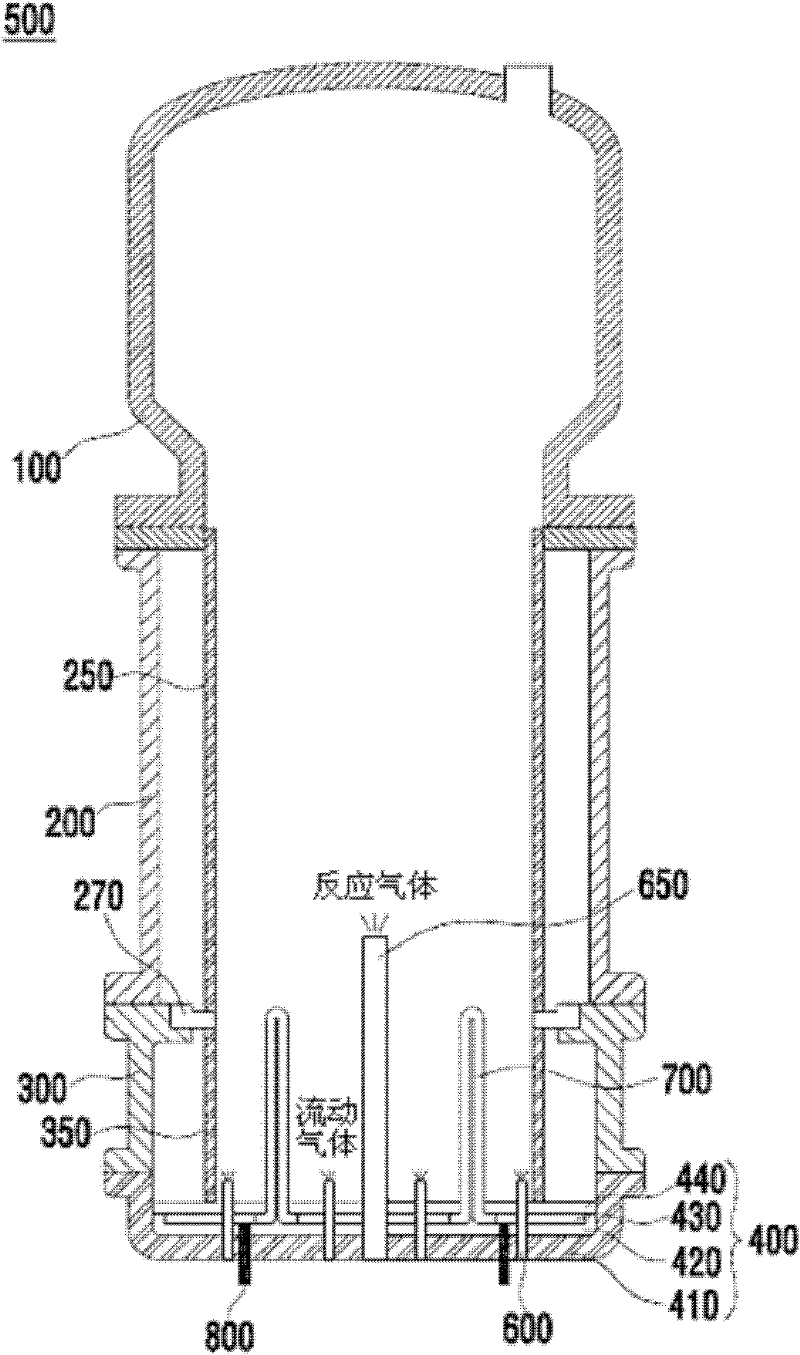

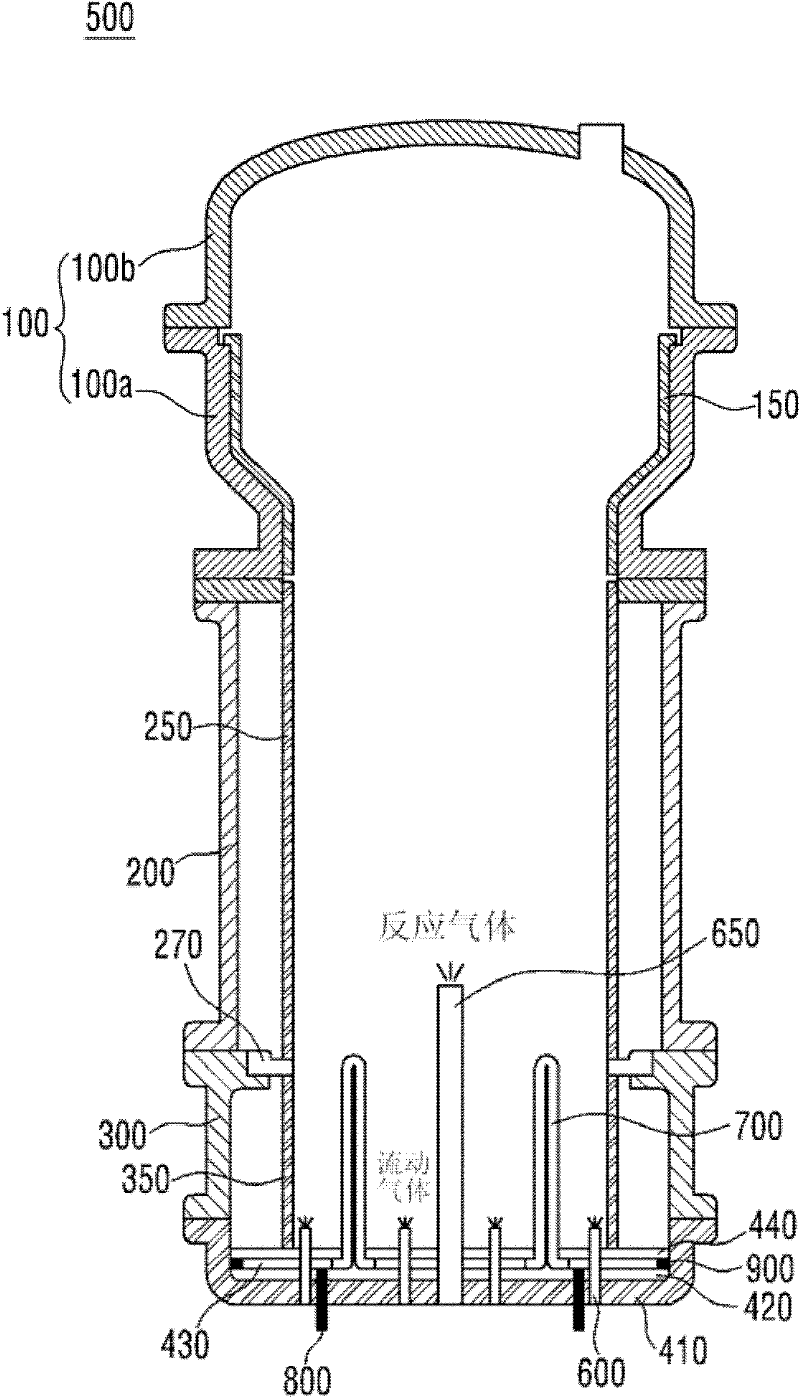

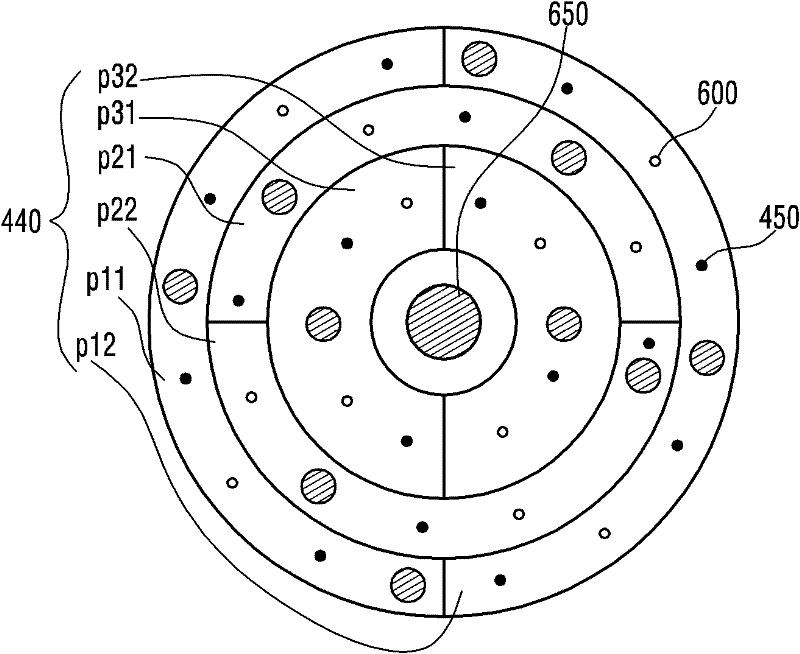

[0032] Figure 1a and Figure 1b A fluidized bed reactor of an embodiment of the invention is shown. Such as Figure 1a and Figure 1b As shown, the fluidized bed reactor 500 of the embodiment of the present invention includes a top cover 100 , a first main body part 200 , a second main body part 300 and a bottom part 400 .

[0033] The top cover 100 is connected to the first body part 200 and has a diameter larger than that of the first reaction tube 250 of the first body part 200 . When the gas and fine particles in the fluidized bed reactor 500 pass through the top cover 100 from the first reaction tube 250, the flow velocity of the gas and fine particles decreases due to the increase in diameter.

[0034] Therefore, the post-processing burden of exhausted gas or fine particles is reduced. The inner wall of the top cover 100 may be composed of an inorganic material that is not easily deformed at high temperature. For example, the inner wall of the top cover 100 may be m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com