Hot continuous rolling loop system control method based on dynamic matrix controller

A dynamic matrix and control method technology, applied in rolling mill control device, tension/pressure control, metal rolling, etc., can solve the problems of tension fluctuation stability, product quality, interference, etc., to achieve stable operation and improve dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below through specific embodiments.

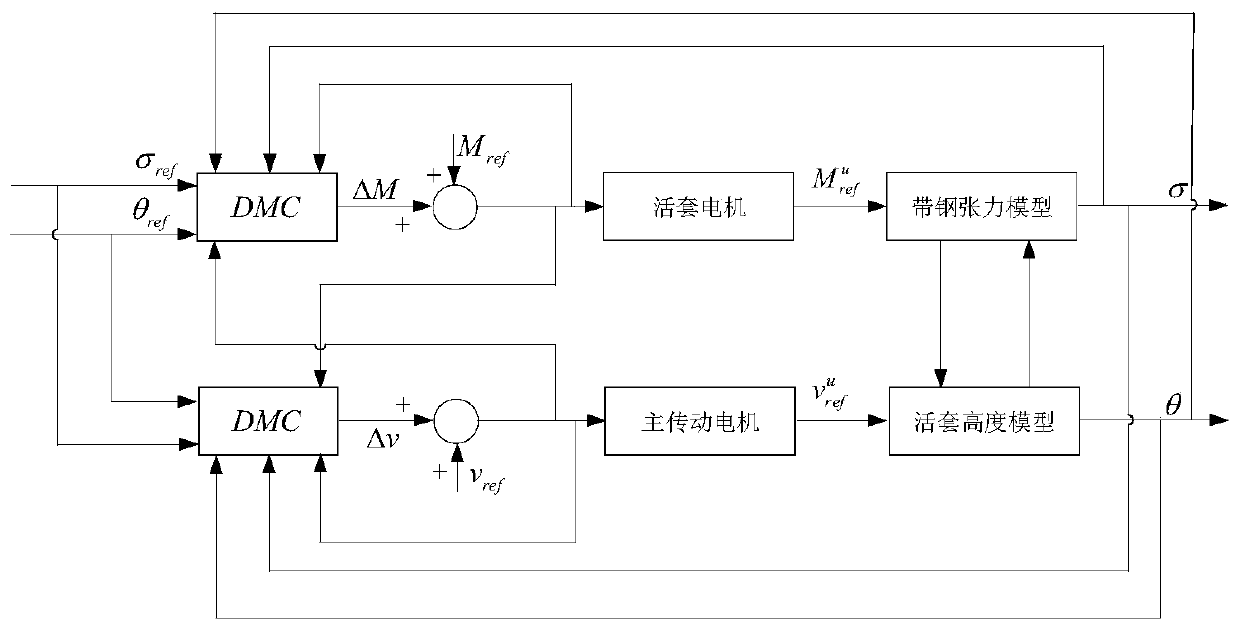

[0031] A control method for the hot rolling looper system based on a dynamic matrix controller. The optimal speed control amount and torque increment based on the dynamic matrix algorithm can be solved in a coordinated manner to control the looper angle and strip tension, which is highly stable. The strip hot rolling processing provides a guarantee. Include the following steps:

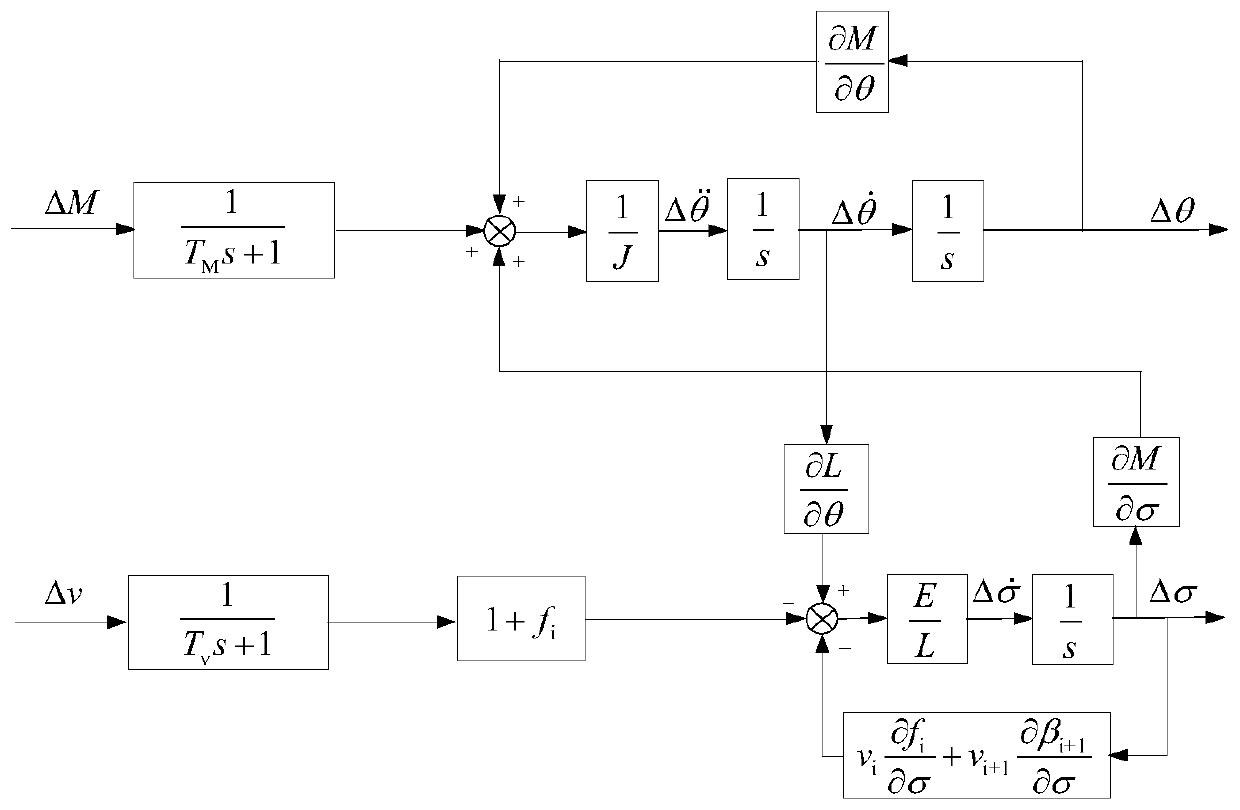

[0032] 1) The main motor and the looper motor are approximated as the first-order inertia link, and the dual-input and double-output linearization model of the looper system is established according to the dynamic model of the looper and the strip steel tension.

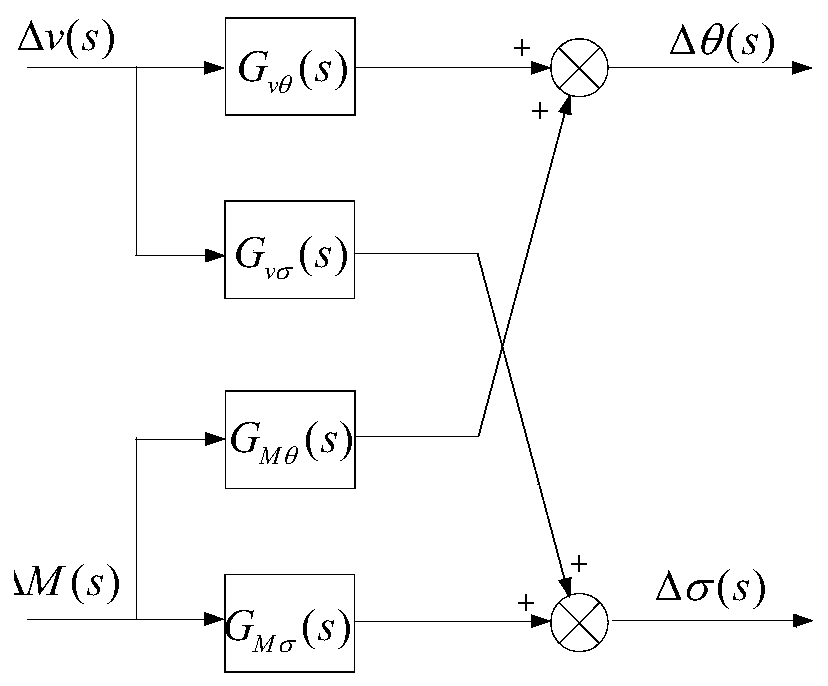

[0033] According to the structure of the looper system of hot continuous rolling, through the analysis of the dynamic coupling process of the looper system, taking ΔM, Δv as the system input, and Δθ, Δσ as the system output, draw the dynamic system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com