Device and method for testing control logic of start-stop system of high-temperature gas cooled reactor

A high-temperature gas-cooled reactor shutdown system technology, applied in the field of high-temperature gas-cooled reactor startup and shutdown systems, can solve problems such as poor applicability, economic losses, and errors in reading test results, so as to achieve stable operation and improve reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

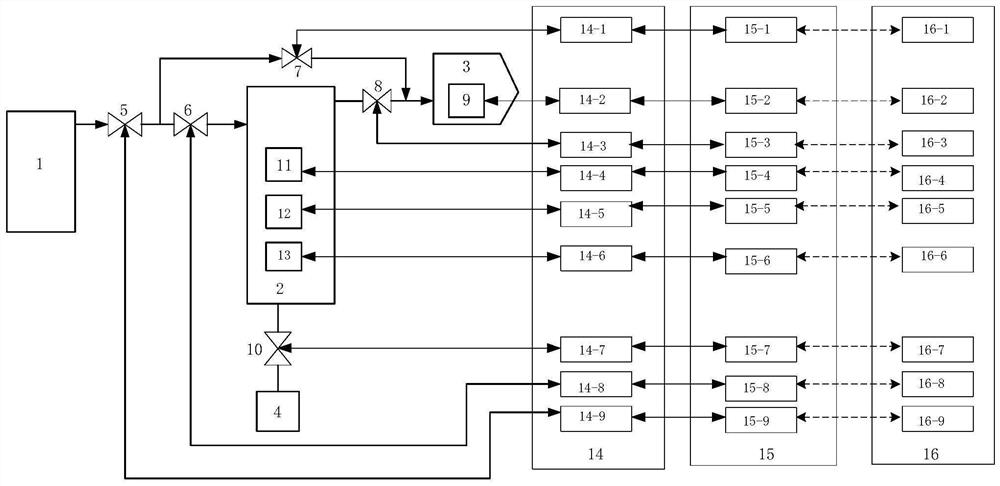

Image

Examples

Embodiment 1

[0043] Taking the 200MW high-temperature gas-cooled reactor unit as an example, two sets of nuclear steam supply systems are used to connect one steam turbine to form a nuclear power unit. The thermal power of each nuclear steam supply system is 250MW, the total thermal power is 500MW, and the electric power is 211MW. The primary loop of the reactor uses helium as the coolant, and the operating pressure is 7MPa. The pressure of the water supply system of the secondary loop of the reactor is the rated parameter during the whole process of operation, that is, the outlet medium pressure of the steam generator is 13.90MPa, and the design pressure of the steam-water separator is 6.4MPa. The rated operating pressure is 5MPa, and the design temperature is 370°C.

[0044] Concrete work process of the present invention is:

[0045] (1) Verification of the commissioning process of steam-water separator 2:

[0046] The simulation modeling server 16 simulates the reactor to start (the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com