A cathode busbar configuration method for a super-large aluminum electrolytic cell

A cathode busbar and aluminum electrolytic cell technology, which is applied in the field of cathode busbar configuration, can solve the problems of electrolytic cell stability reduction, damage to current efficiency, and local magnetic field of electrolytic cell is too large, so as to achieve stable operation, improve current efficiency, and busbar The effect of flexible configuration methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

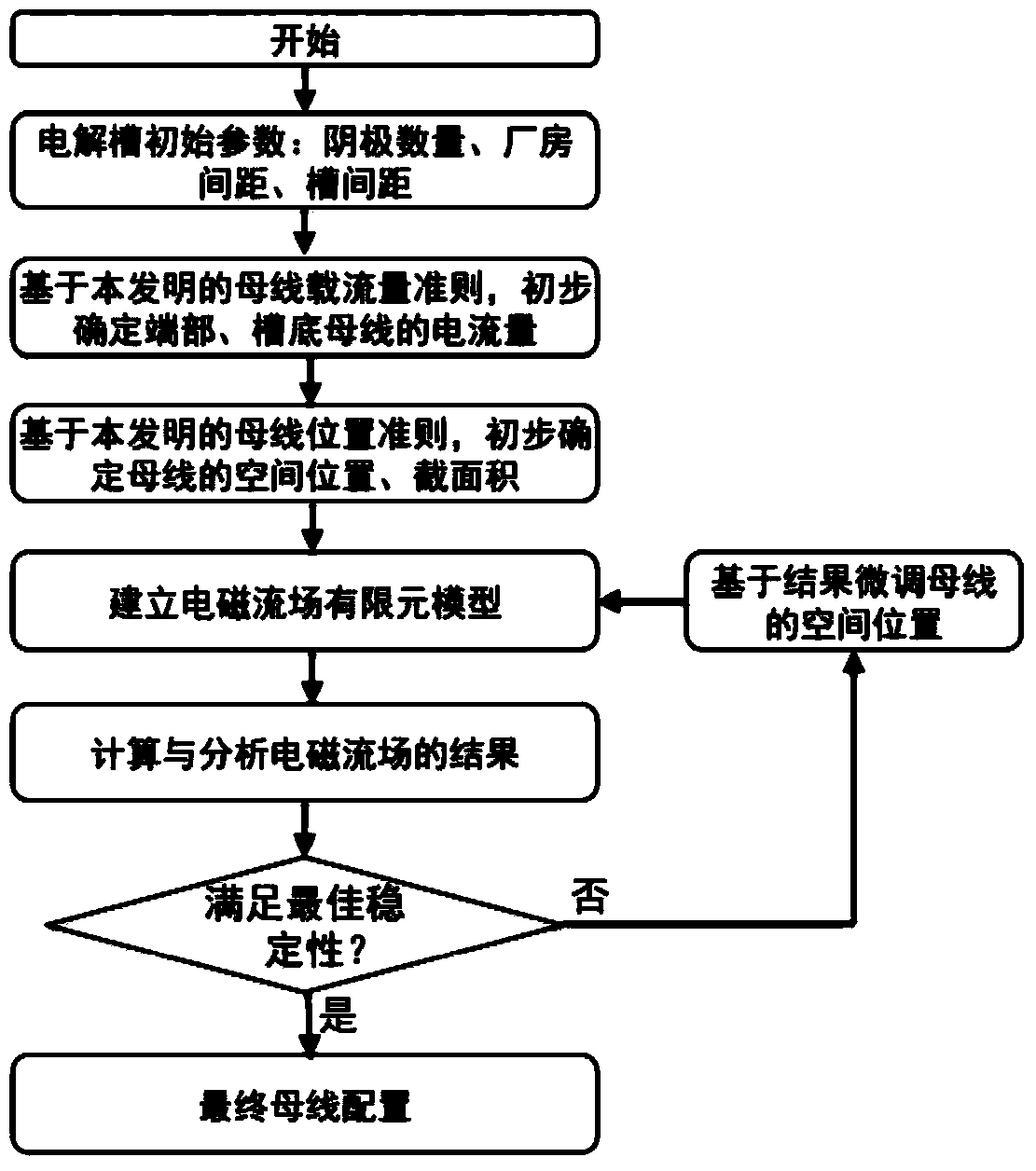

Method used

Image

Examples

Embodiment 1

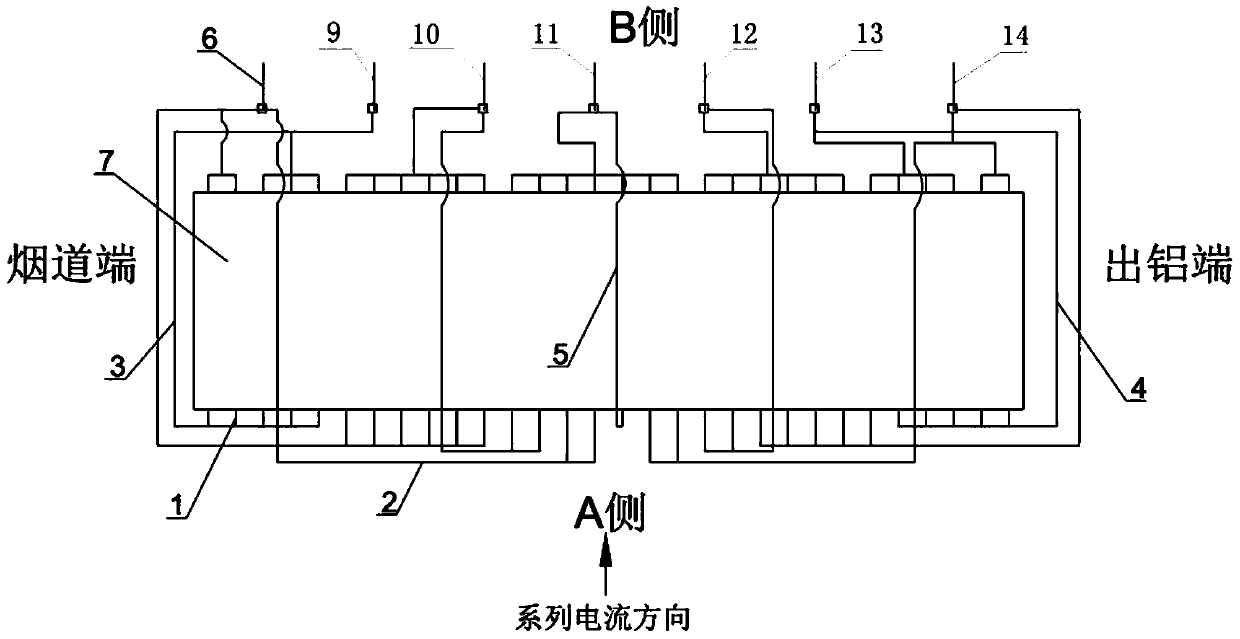

[0032] This example takes a 540kA pre-baked aluminum electrolytic cell as the object, and there are 30 cathode carbon blocks in total. This electrolytic series will not adopt the external compensation bus scheme, and mainly consists of the cathode soft bus 1, the large surface bus 2 on the power inlet side, and the smoke in this tank. Compensation busbar 3 at the road end, busbar 4 at the aluminum end of the tank, compensation busbar 5 at the bottom of the tank, column busbar and tank body 7. The distribution of the bus current is carried out based on the cathode bus configuration method of the ultra-large aluminum electrolytic cell of the present invention. For the current on the A side, according to the current rating criteria, the current distribution of the flue end is 99kA (11 groups of cathodes), the distribution of the aluminum outlet is 81kA (9 groups of cathodes), and the distribution of the bus at the bottom of the tank is 90kA (10 groups of cathodes), and The bus ba...

Embodiment 2

[0038] This embodiment also takes a 540kA prebaked aluminum electrolytic cell as an example, with a total of 30 cathode carbon blocks. The difference is that this embodiment uses an external compensation bus. It is mainly composed of cathode soft busbar 1, large surface busbar on the power inlet side 2, compensation busbar at the flue end of the tank 3, aluminum outlet busbar 4 of the tank, compensation busbar 5 at the bottom of the tank, column busbar, external compensation busbar 8 and tank body 7. And the external compensation busbar 8 is 1 / 3 of the current of the slot series, namely 180kA, of which 100kA flows through the aluminum outlet end and 80kA flows through the flue end. The distribution method of the cathode busbar of the ultra-large aluminum electrolytic cell of the present invention is used to distribute the busbar current. In this example, in addition to the current of the cell, the magnitude of the terminal current also needs to consider the magnitude of the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com