Patents

Literature

33results about How to "Flexible configuration method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

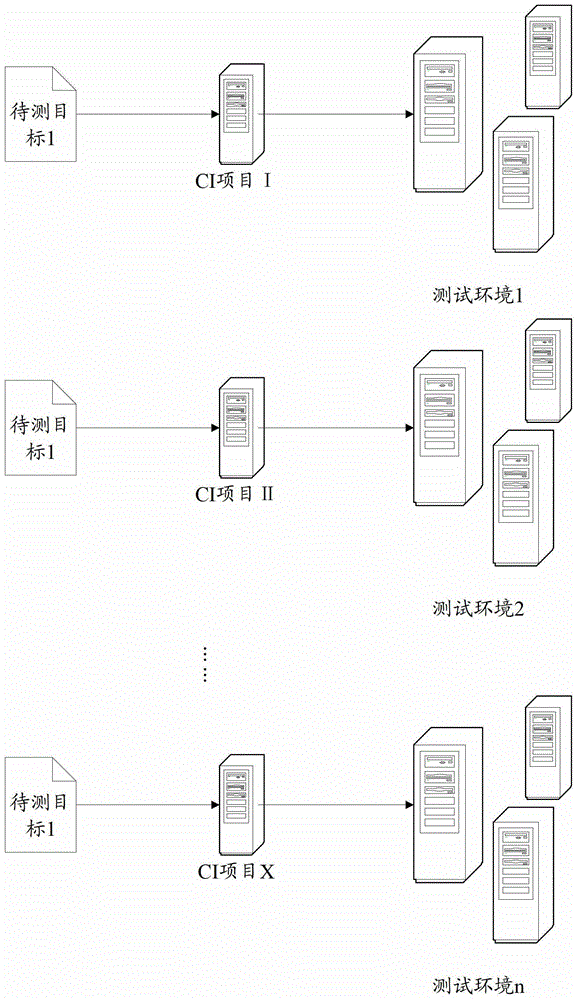

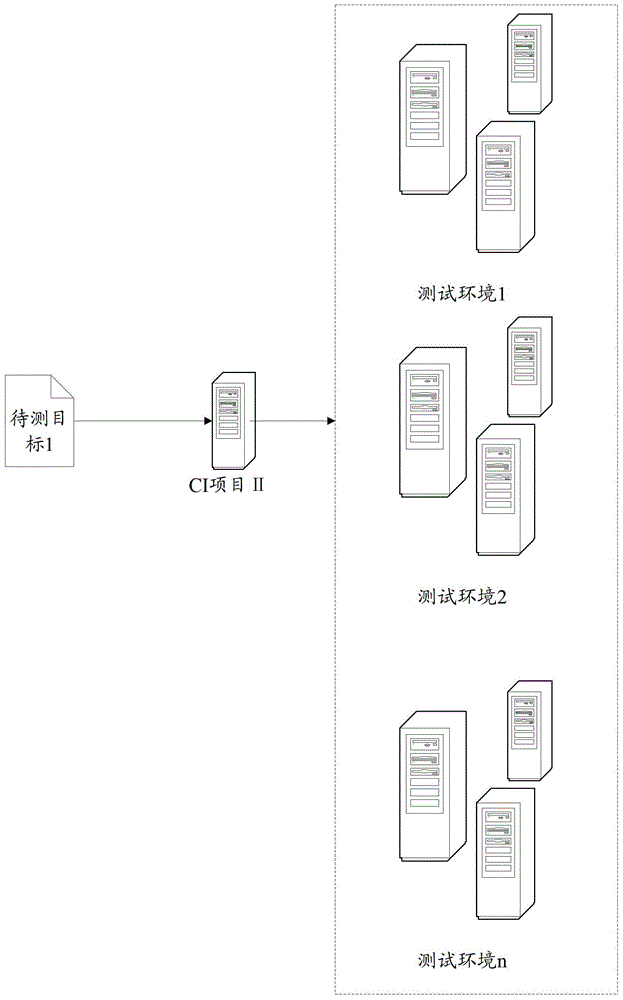

Continuous integration testing method and system

ActiveCN103577907AImprove reusabilityFlexible configuration methodResourcesContinuous integrationTest script

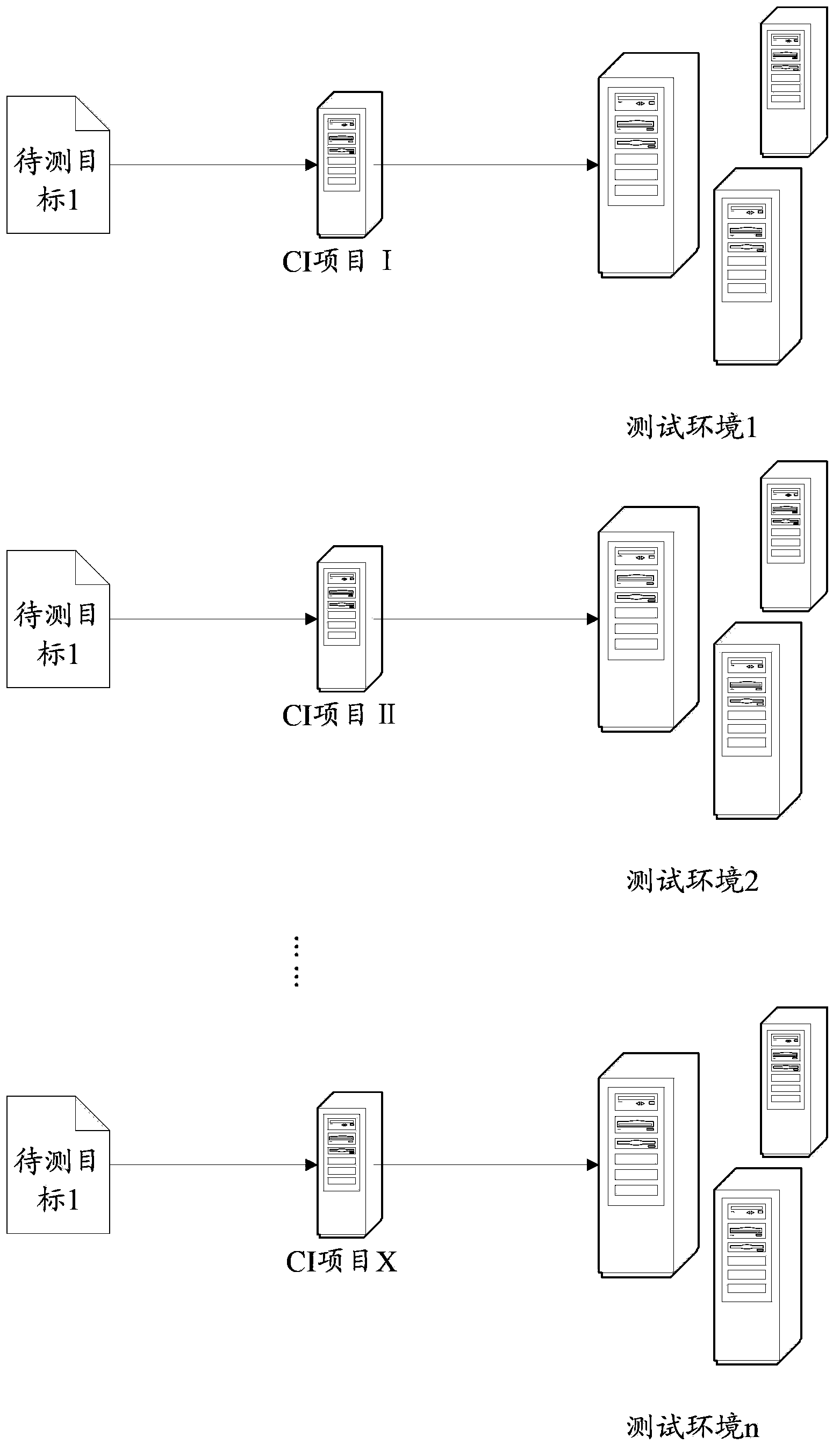

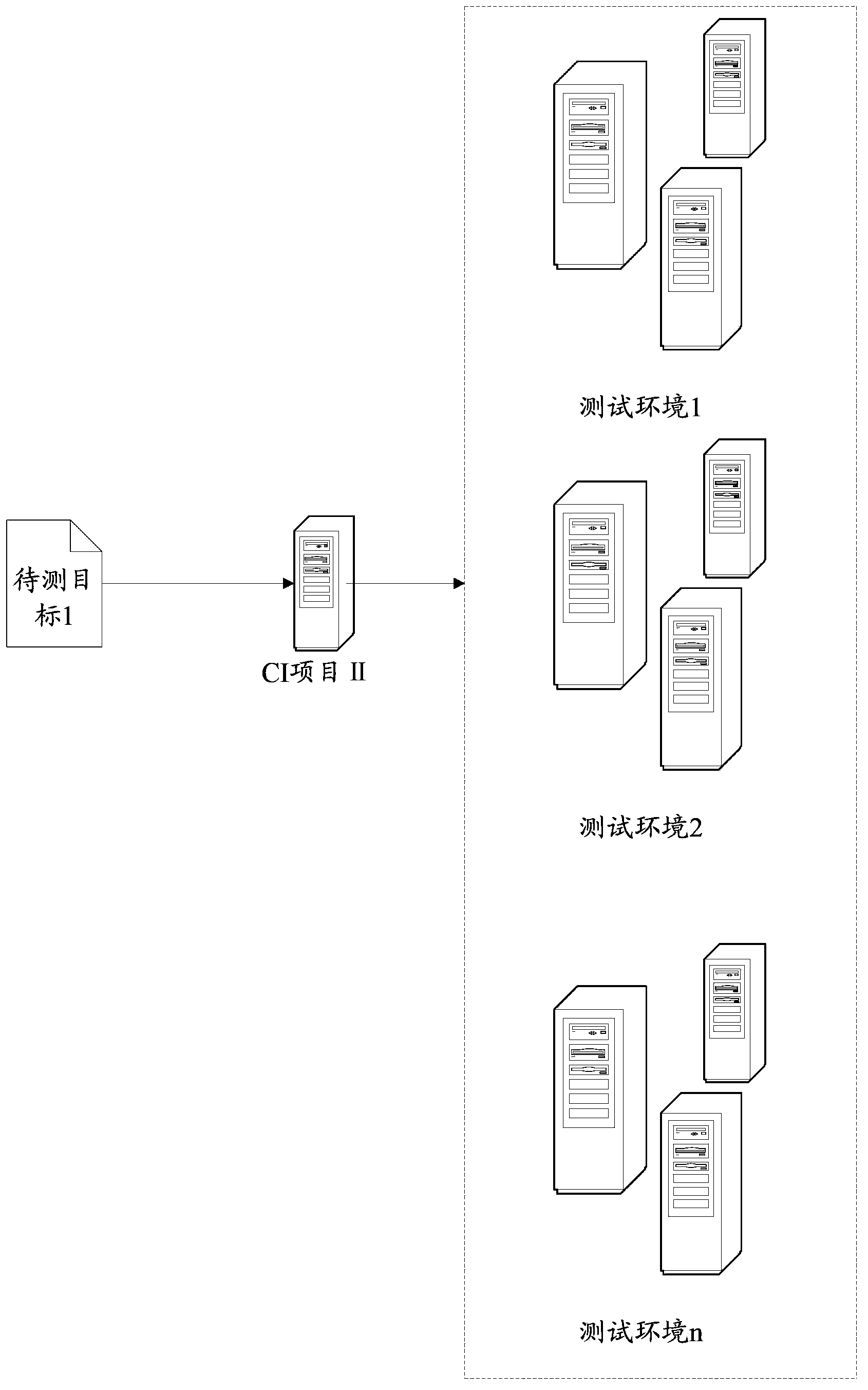

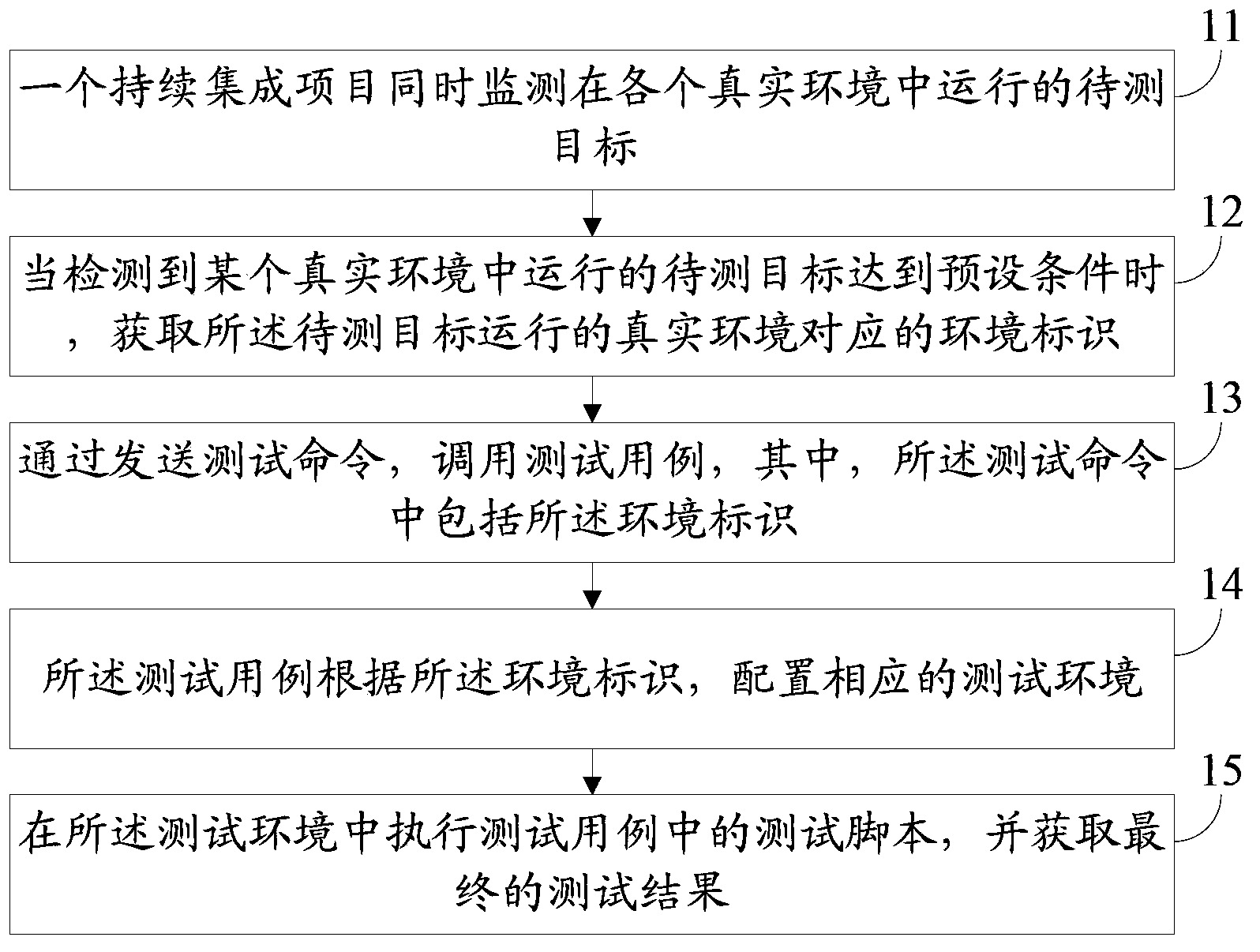

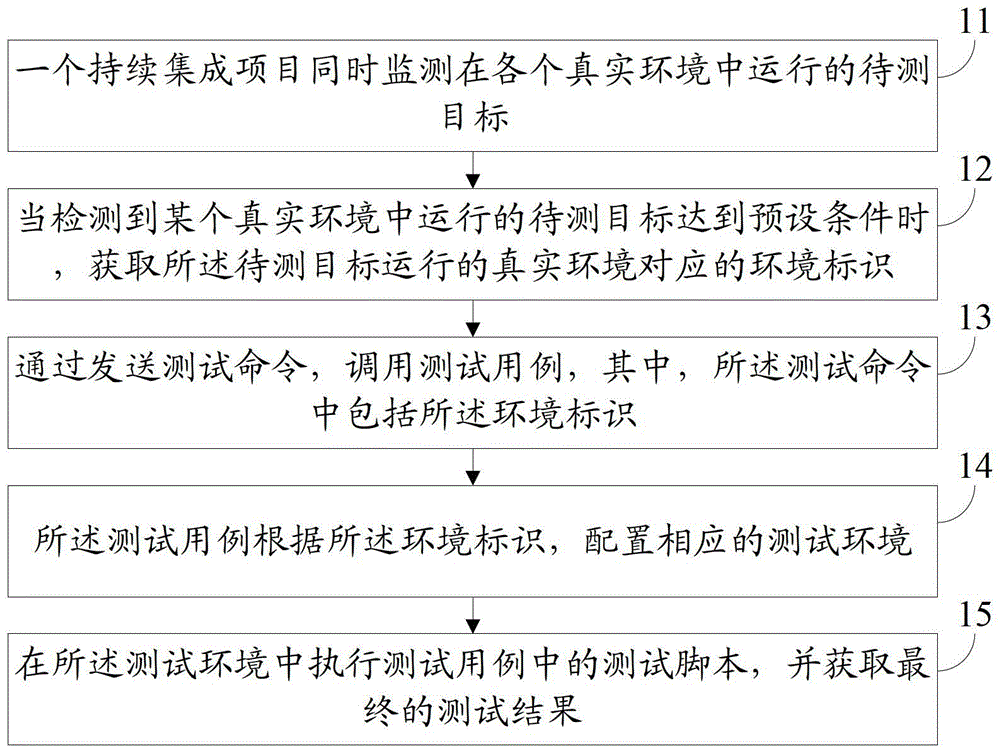

The invention provides a continuous integration testing method which is applicable to all testing environments and high in reusability and can reduce working loads and complexity in maintenance. The method includes the following steps that a continuous integration project monitors targets which are to be tested and operate in all real environments at the same time; when the target which is to be tested and operates in a certain real environment reaches the preset conditions and is detected, an environment identification corresponding to the real environment where the target to be tested operates is obtained; a test case is called by sending a test order, wherein the test order comprises the environment identification; the test case is allocated with the corresponding test environment according to the environment identification; a testing script in the test case is executed in the testing environment and a final testing result is obtained. According to the continuous integration testing method, the reusability is high; even if the target to be tested is changed, only one CI project and one test case are needed to be maintained and the work loads and the complexity of the continuous integration test are greatly improved.

Owner:ADVANCED NEW TECH CO LTD

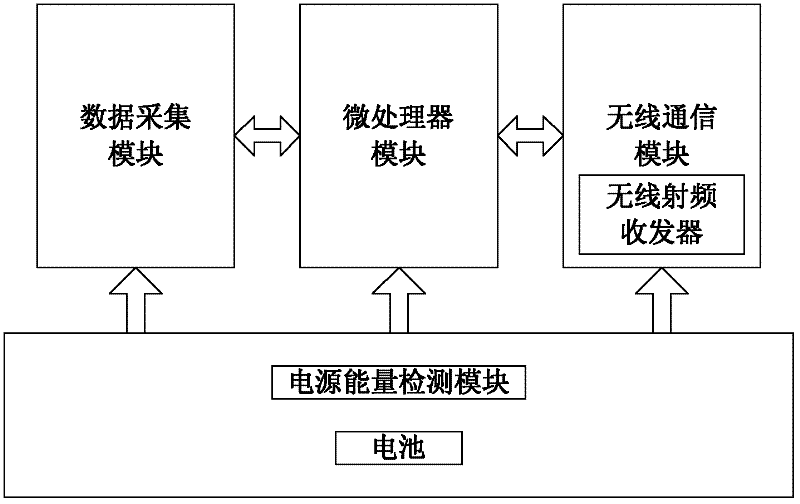

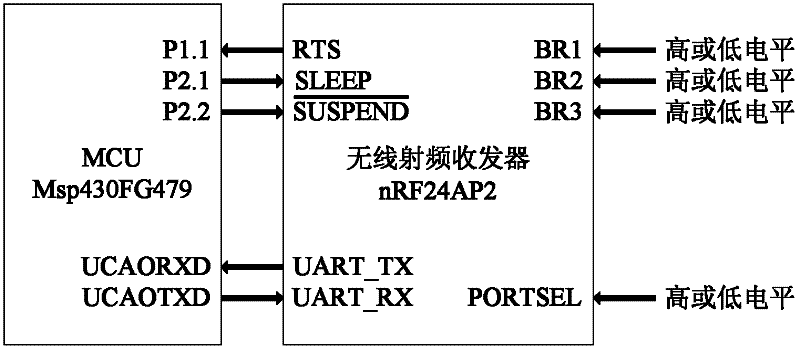

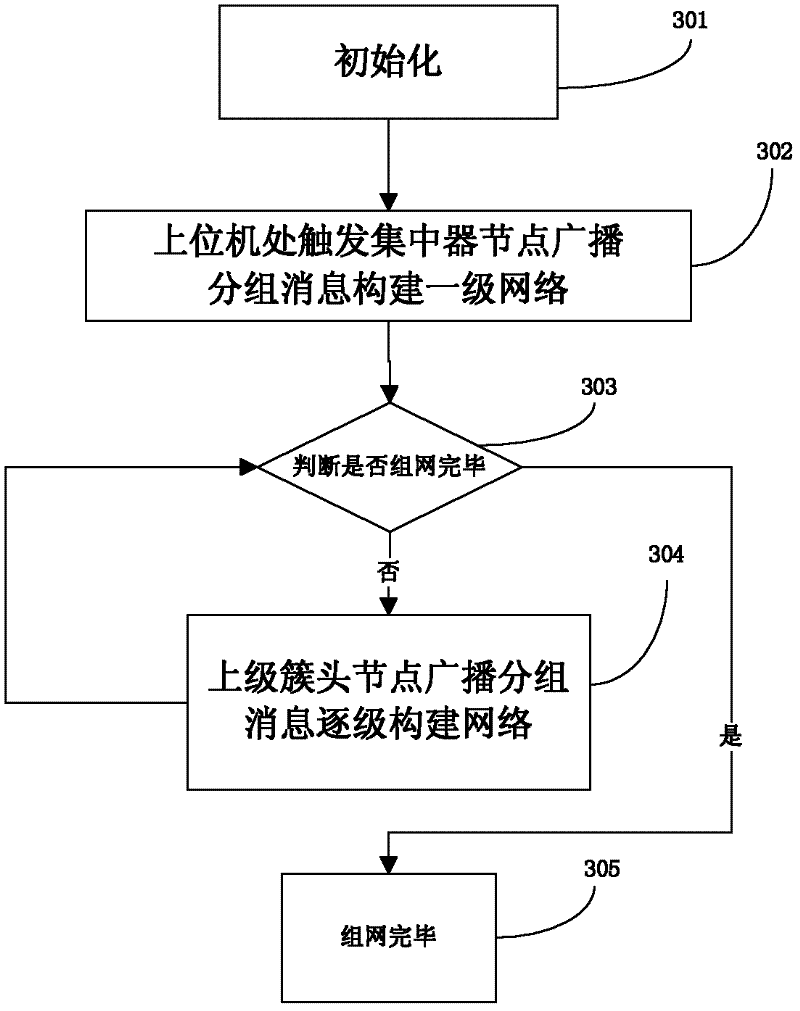

Networking method of wireless sensor network and wireless sensor network system

InactiveCN102647472AAvoid paralysisStable jobNetwork topologiesTransmissionRest energyWireless mesh network

The invention relates to a networking method of a wireless sensor network. According to the method, broadcast messages are sent through triggering a concentrator or a cluster head node by a host machine, and in addition, stage-by-stage networking is completed according to answering messages, wherein various factors such as the hop count, the position information, the rest energy and the external environment of the wireless sensor network node are integrally considered, a cluster head node and a blade node are voted through equivalent distances, in addition, a classical binary tree structure is adopted for networking, the cluster head node and the blade node are more scientifically distributed, and the energy utilization rate of the single node is effectively improved, so the node can be ensured to stably work in three years or even a long period, and the breakdown of the whole network caused by too early failure of partial nodes is avoided. The structure of the host machine of a wireless sensor network system is simple, the configuration method is flexible, developers do not need to deep understand the wireless protocol, the network building and application can be completed only through carrying out corresponding network configuration on the wireless sensor network node on the host machine, and the networking is convenient and flexible.

Owner:ZHEJIANG UNIV

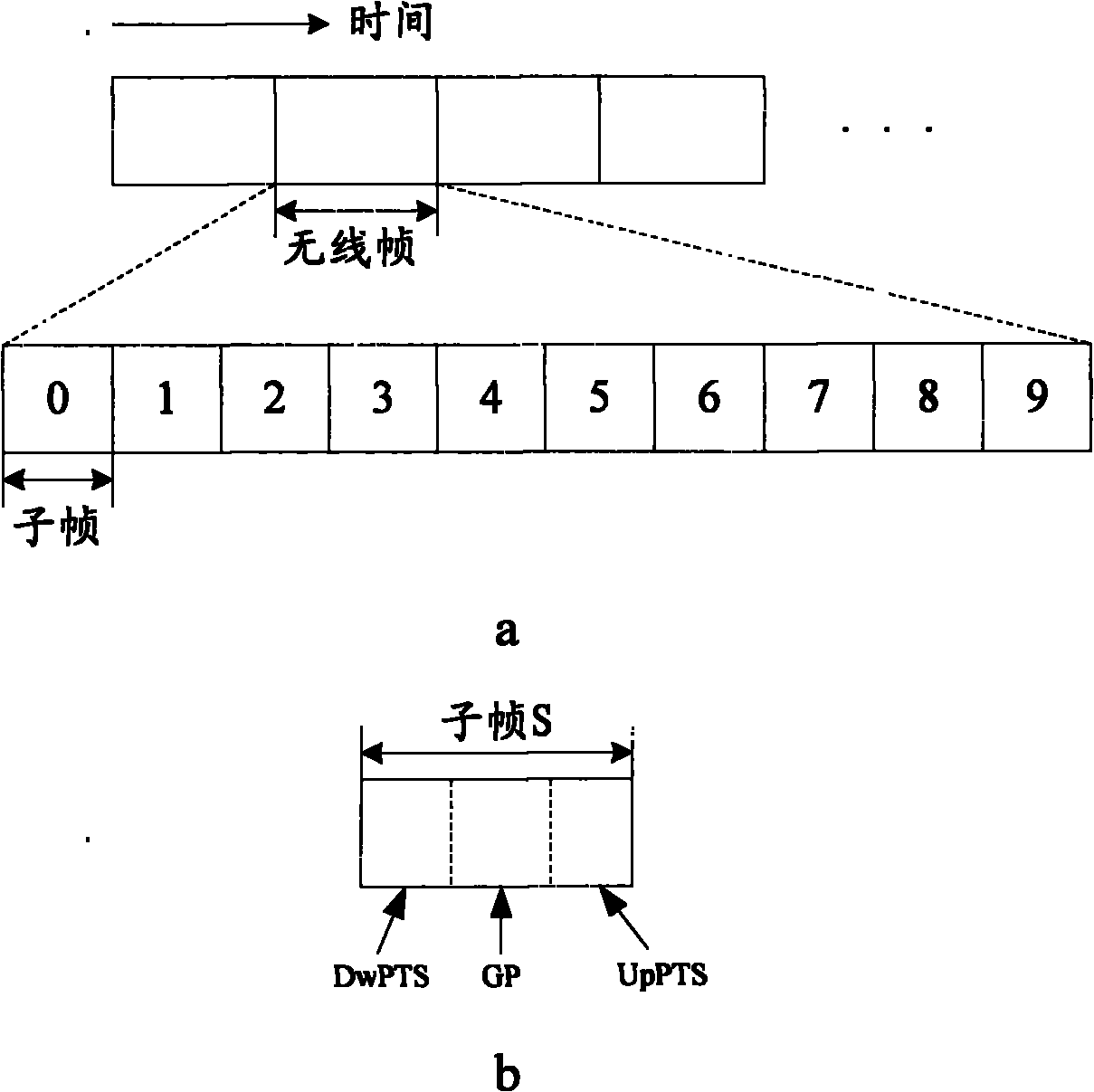

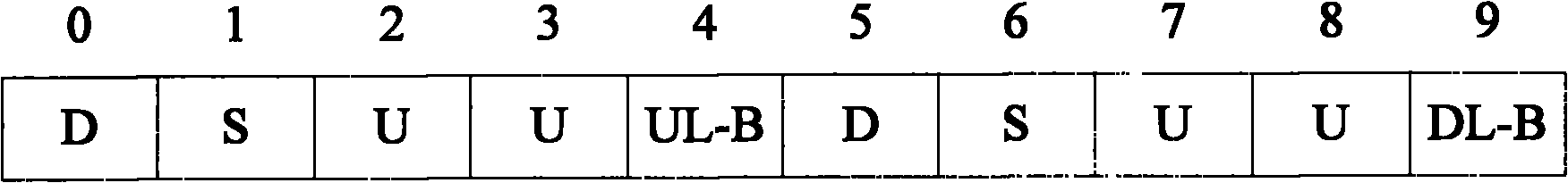

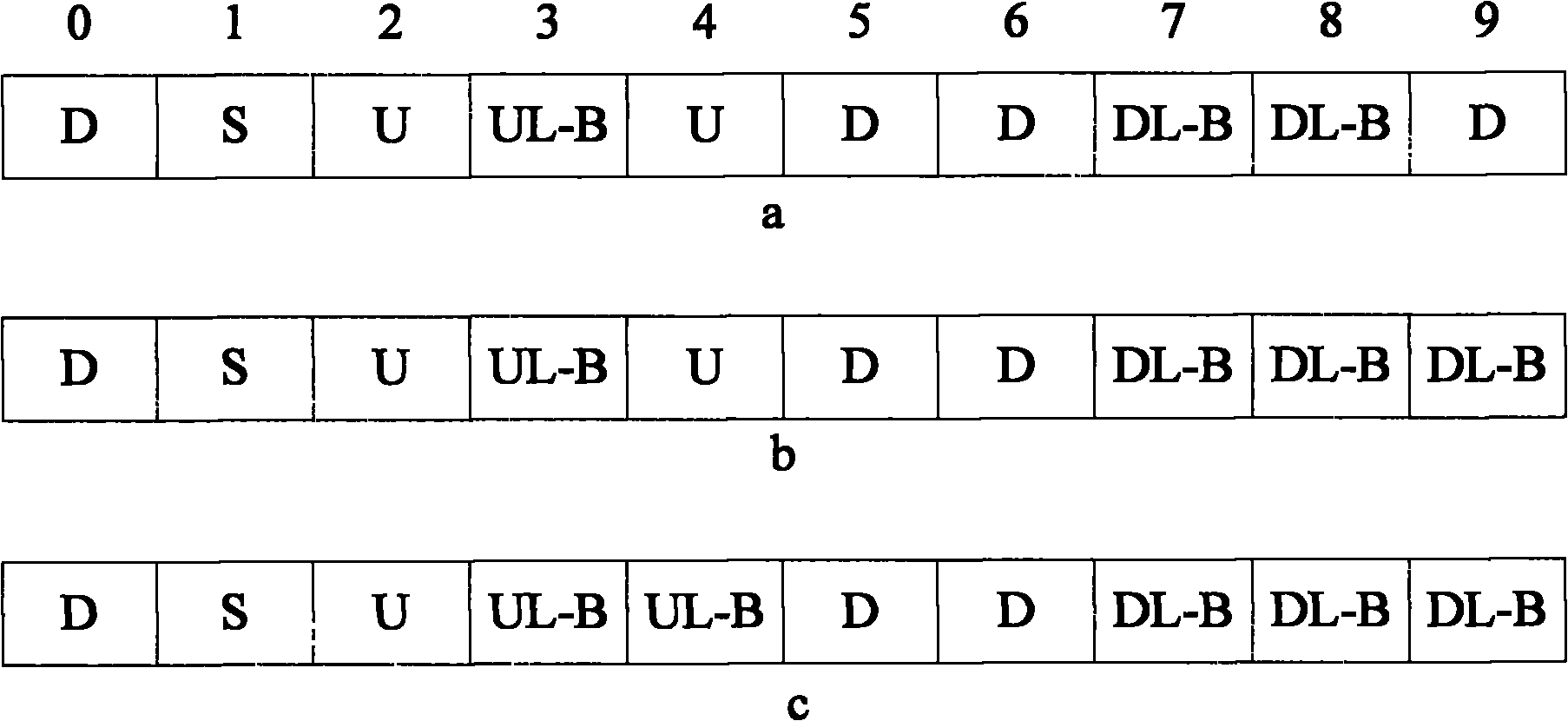

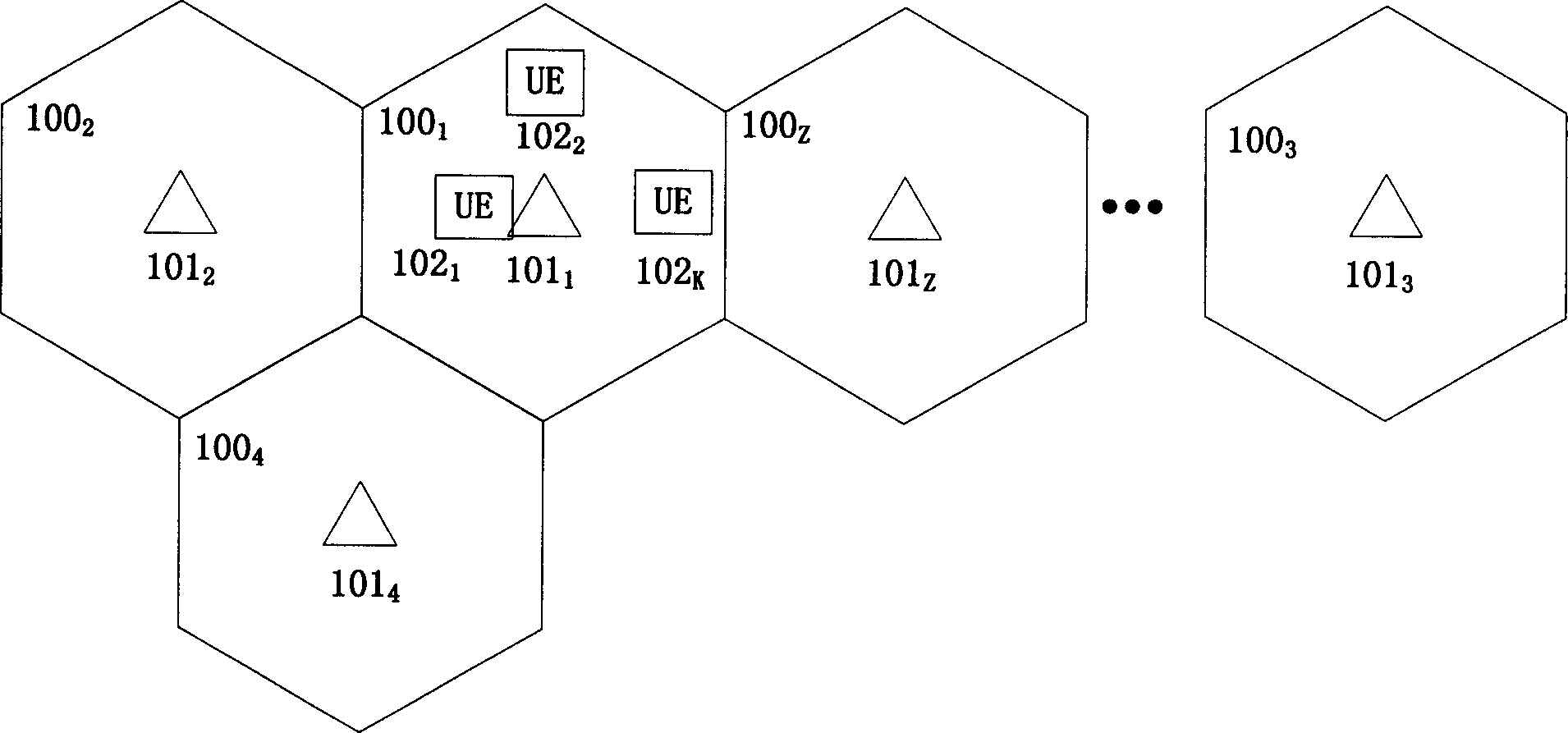

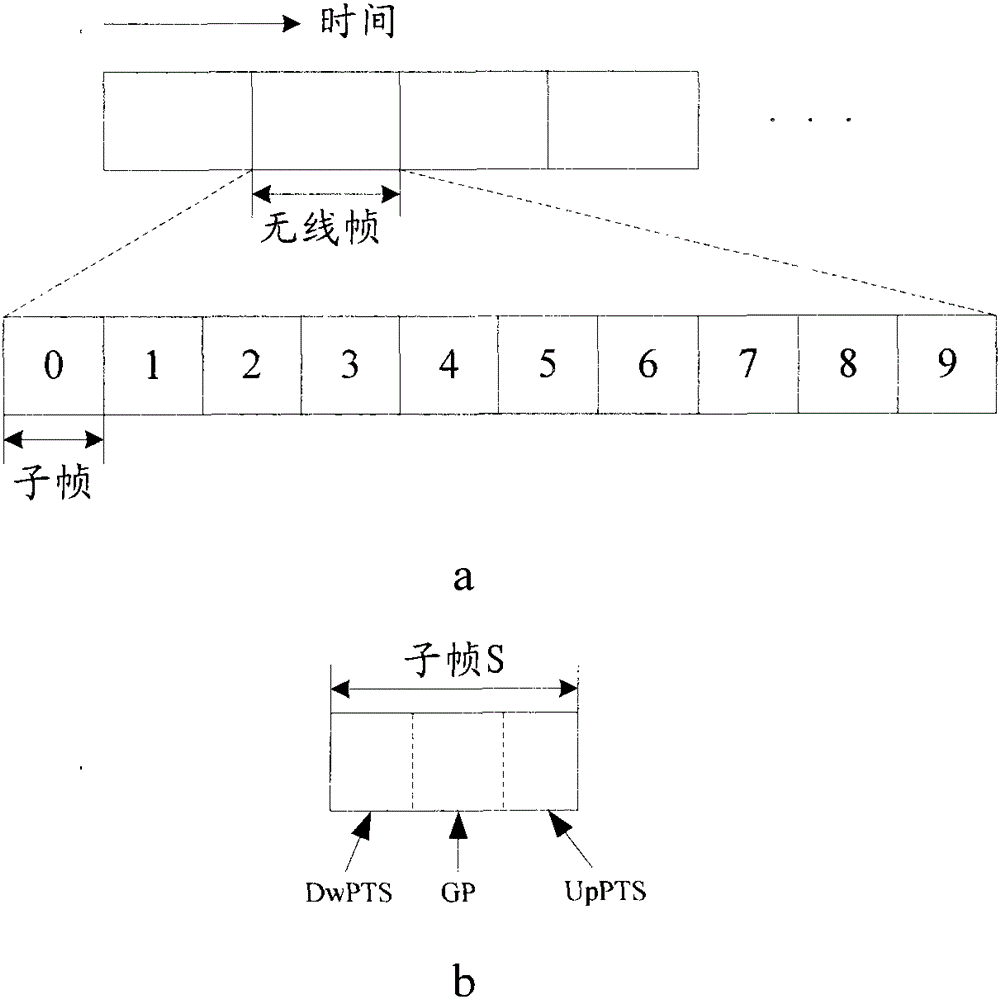

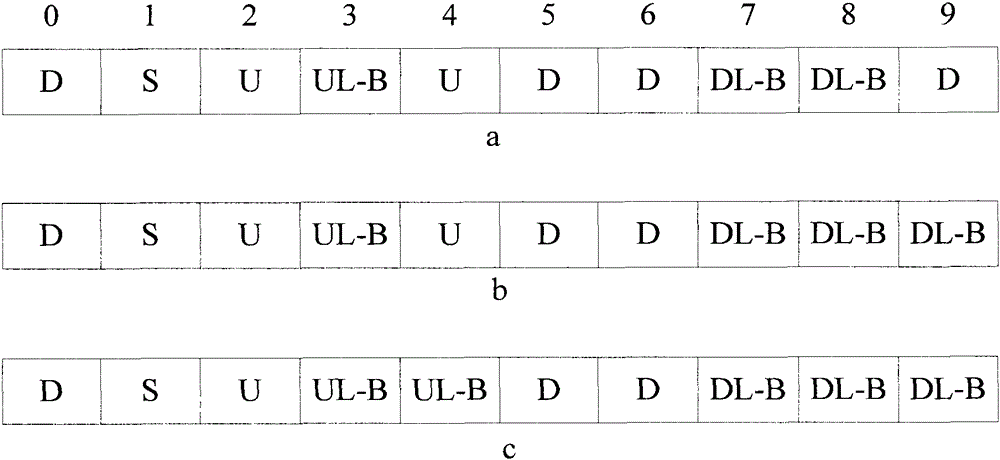

Method and device for transmitting downlink feedback information for trunk link

InactiveCN101925188AFlexible configuration methodAvoid lossError prevention/detection by using return channelWireless network protocolsEngineeringInformation transfer

The invention discloses a method for transmitting downlink feedback information of a trunk link, which comprises the steps of: when the configuration of a relay subframe of a radio frame ensures that the downlink feedback information of the trunk link can not loaded according to a mode specified in a time division duplex long-term evolution protocol, determining a new loading mode of the downlink feedback information by a base station according to the relay subframe of the radio frame, informing information of the relay subframe of the radio frame or the new loading mode to a relay station; and loading and transmitting the downlink feedback information according to the new loading form. At the same time, the invention discloses a device realizing the method. The invention has the advantages of simple realization and practicality.

Owner:ZTE CORP

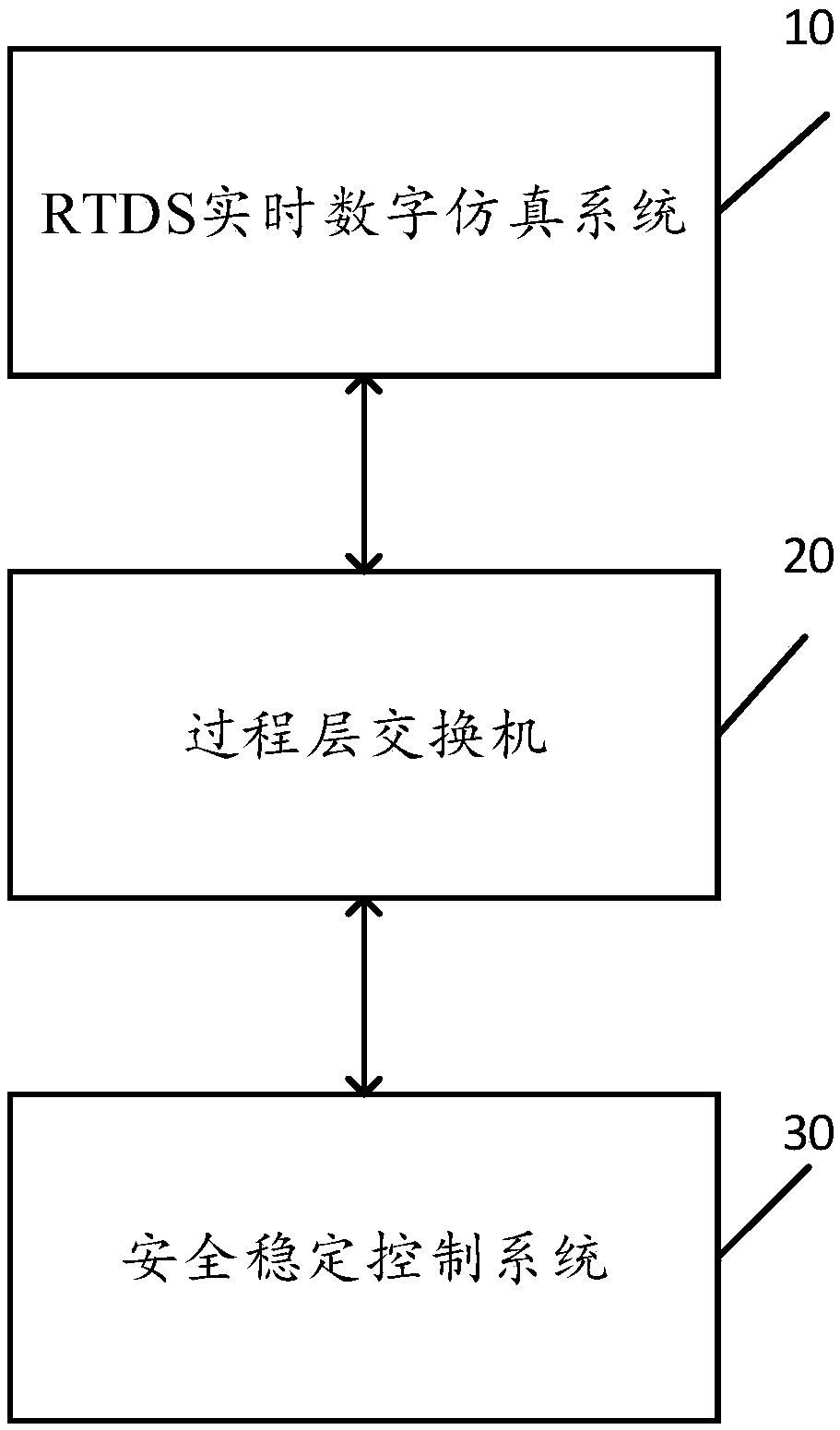

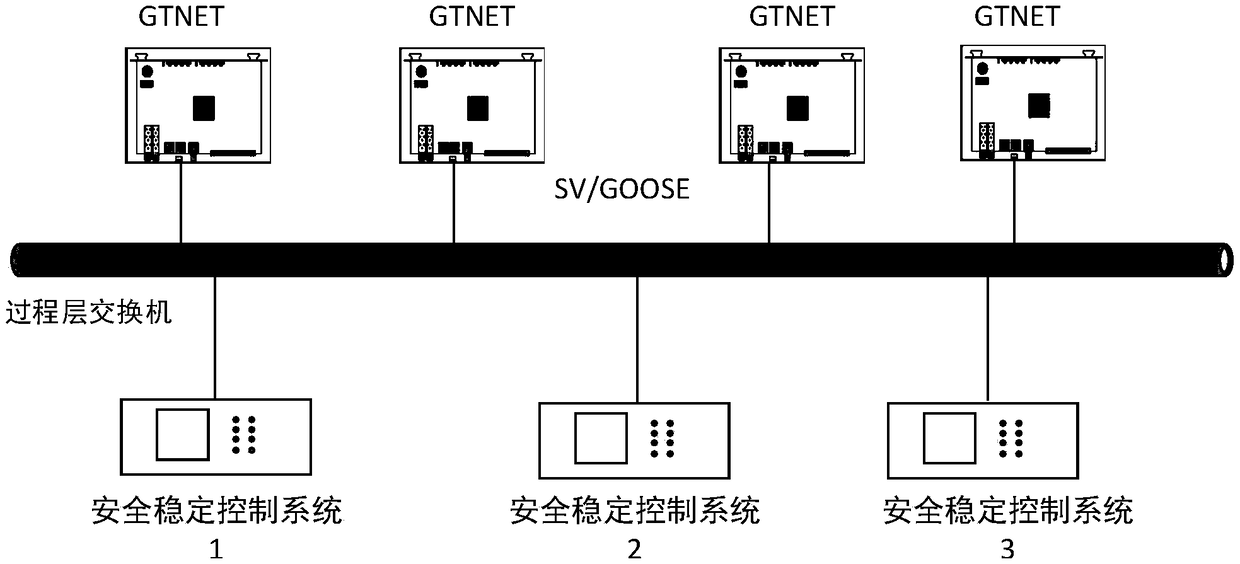

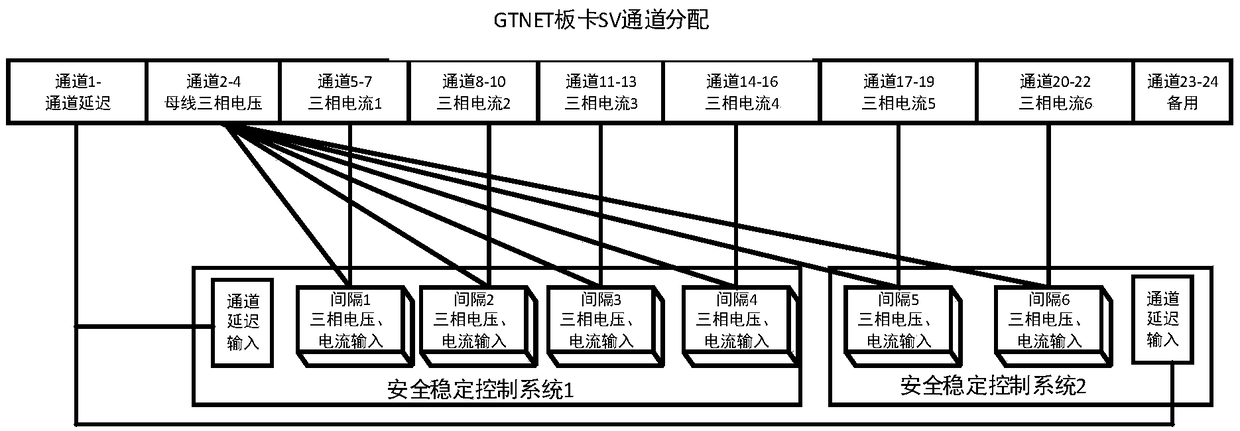

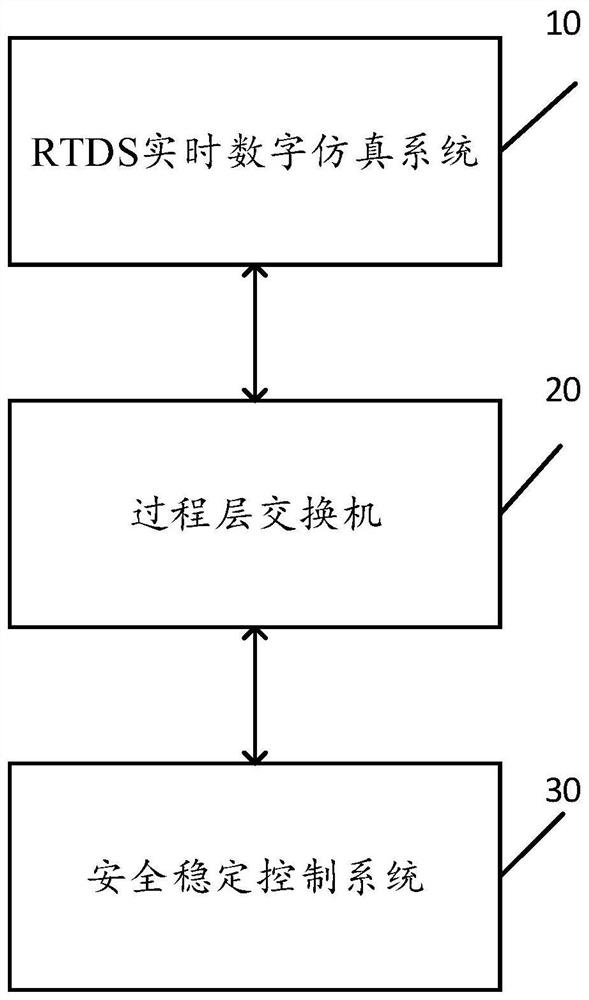

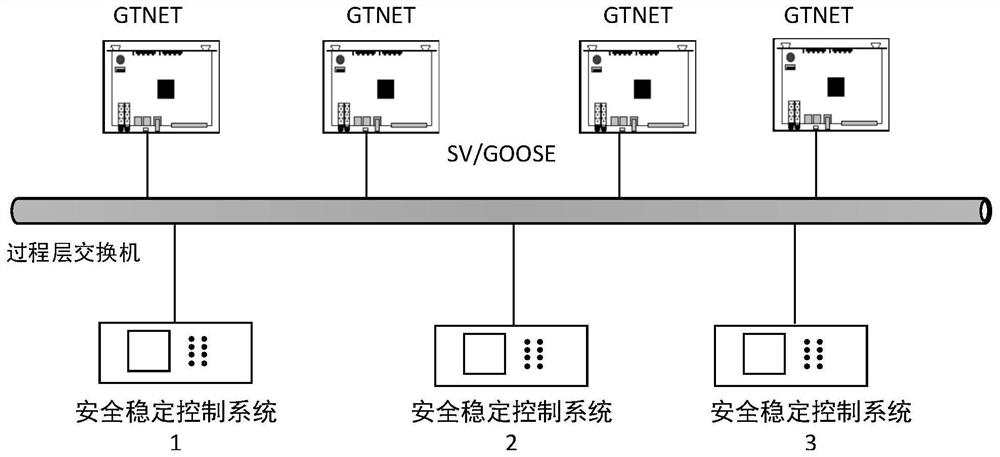

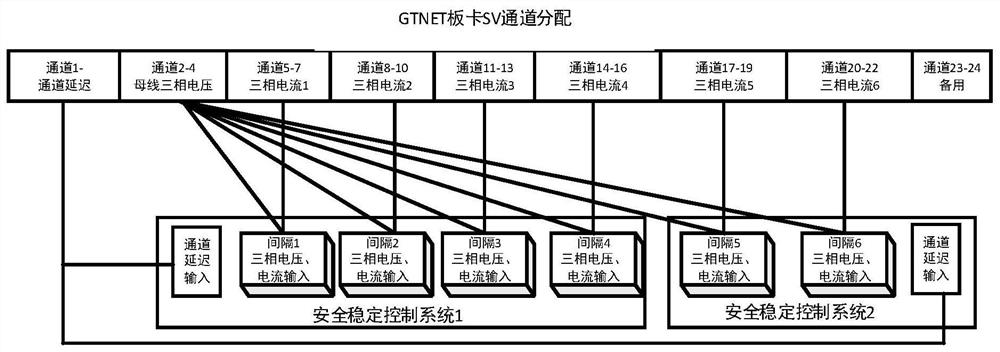

Digital closed-loop test system and method for stability control system

ActiveCN108919777ASimple designImprove Simulation EfficiencyProgramme controlElectric testing/monitoringDigital interfaceControl system

The invention discloses a digital closed-loop test system for a stability control system. A RTDS (Real Time Digital Simulation System) comprises N pieces of parallel GTNET boards; a process layer switch is respectively connected with a security and stability control system and the N pieces of parallel GTNET boards through a cable; the GTNET boards transmit SV analog quantity and GOOSE switch quantity signals output by the RTDS to the security and stability control system through the process layer switch, wherein N is greater than 1; and GOOSE trip outlet signals output by the security and stability control system are transmitted to the GTNET boards of the RTDS through the process layer switch. According to the digital closed-loop test system for the stability control system provided by theinvention, the analog quantity and switch quantity acquisition and trip signal outlets of the stability control system are achieved through VLAN setting and a digital interface communication configuration file of a router, so that a complete digital closed-loop test system of the stability control system is formed; and full digitalization of input and output of the stability control test system is realized, and the efficiency and reliability of stability control policy verification can be improved.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

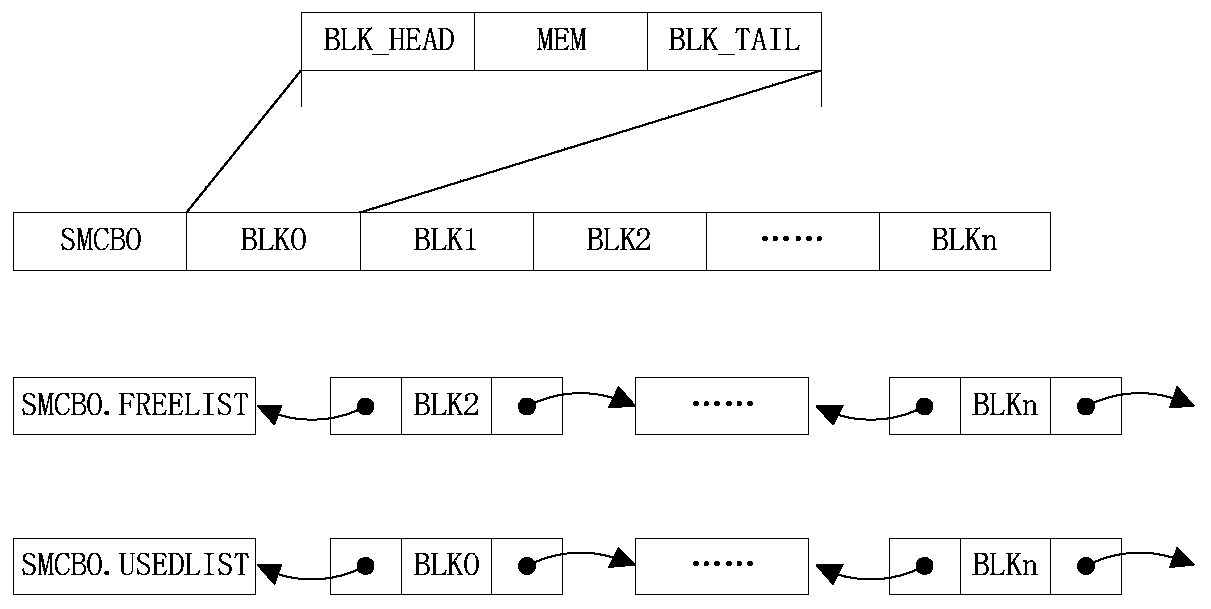

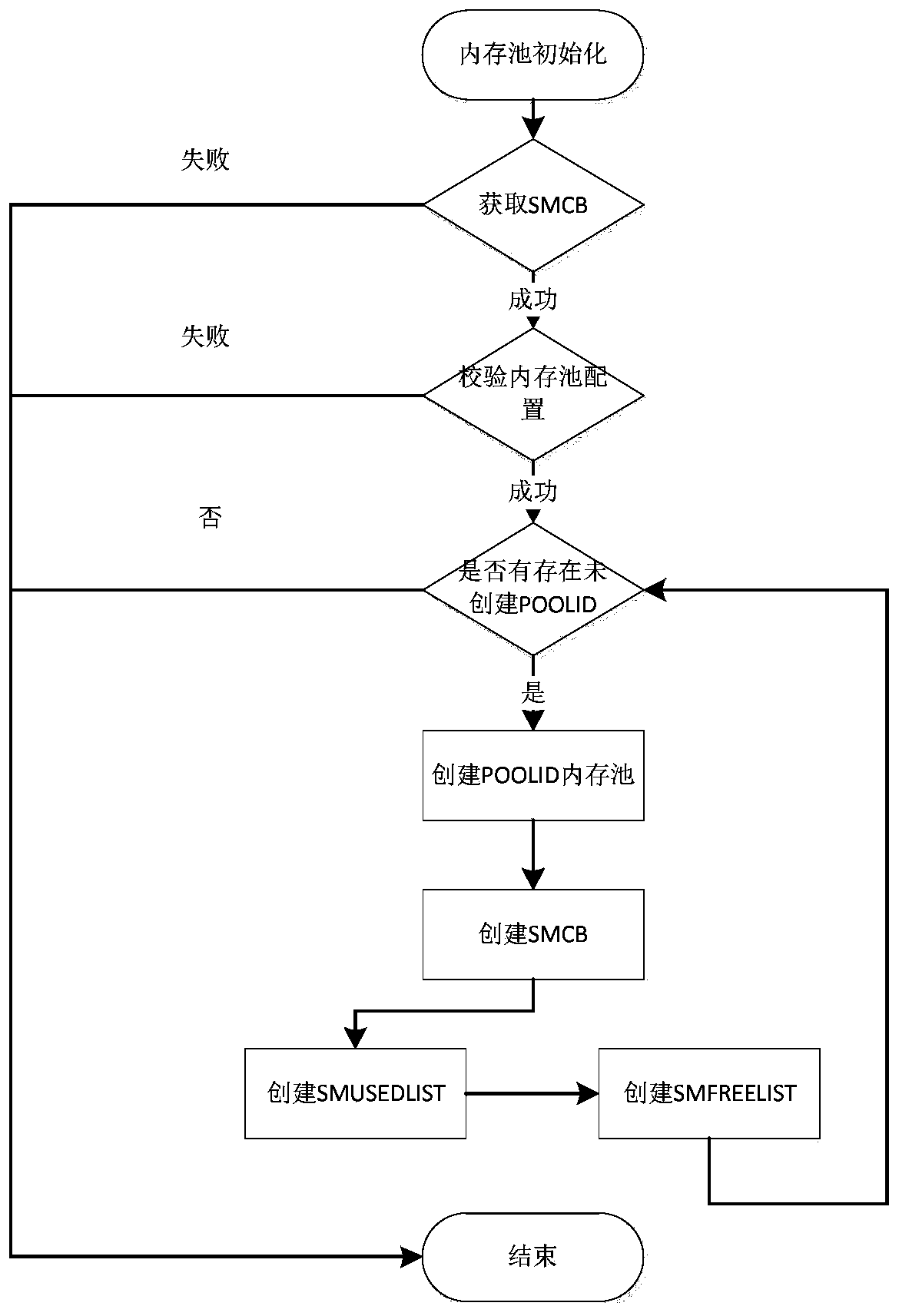

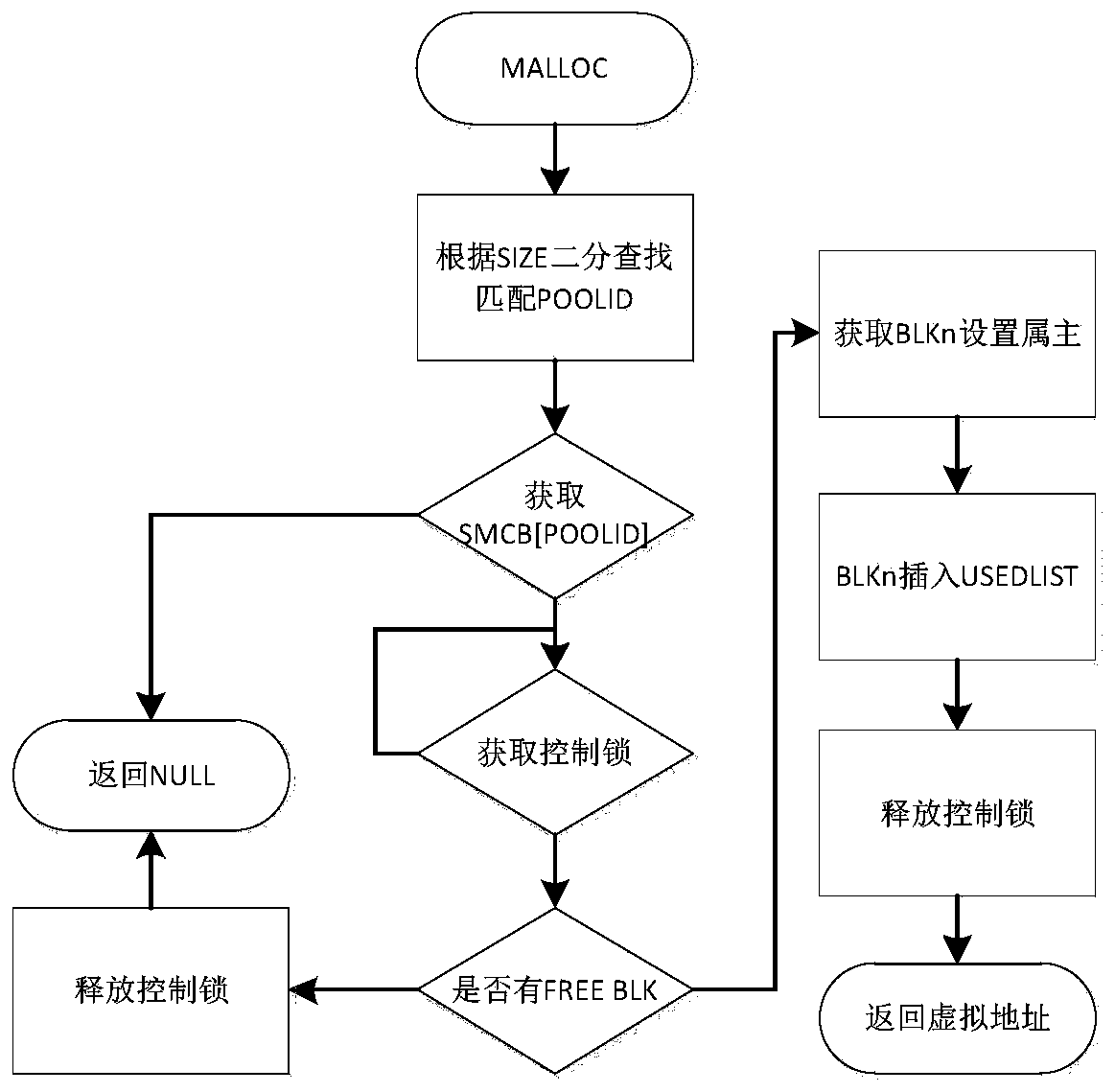

IPC communication method based on shared memory pool

PendingCN111427707AReduce the number of timesEnsure safetyInterprogram communicationMessage queueComputer architecture

The invention discloses an IPC communication method based on a shared memory pool. The method comprises the steps: carrying out the IPC communication, which comprises message receiving and message sending; wherein the message sending comprises the steps of applying for a shared memory, continuing if the application succeeds, otherwise ending; writing message data into the shared memory; convertingthe applied virtual address of the shared memory into a logic address; sending the logic address to a destination receiving queue; message receiving of the receiving queue comprises the steps that the receiving message queue receives the logic address; restoring the logic address into a memory pool ID and a shared memory minimum management unit logic address according to a conversion formula; obtaining a virtual address through the memory pool ID logic address, wherein the sum of the virtual address and the shared memory minimum management unit logic address is equal to the actual storage address of the message; processing the message; releasing the logic address; memory pool creation management. According to the method provided by the invention, the information copying times of the kernel during IPC communication are reduced. The system overhead is reduced.

Owner:BEIJING ZUOJIANG TECH

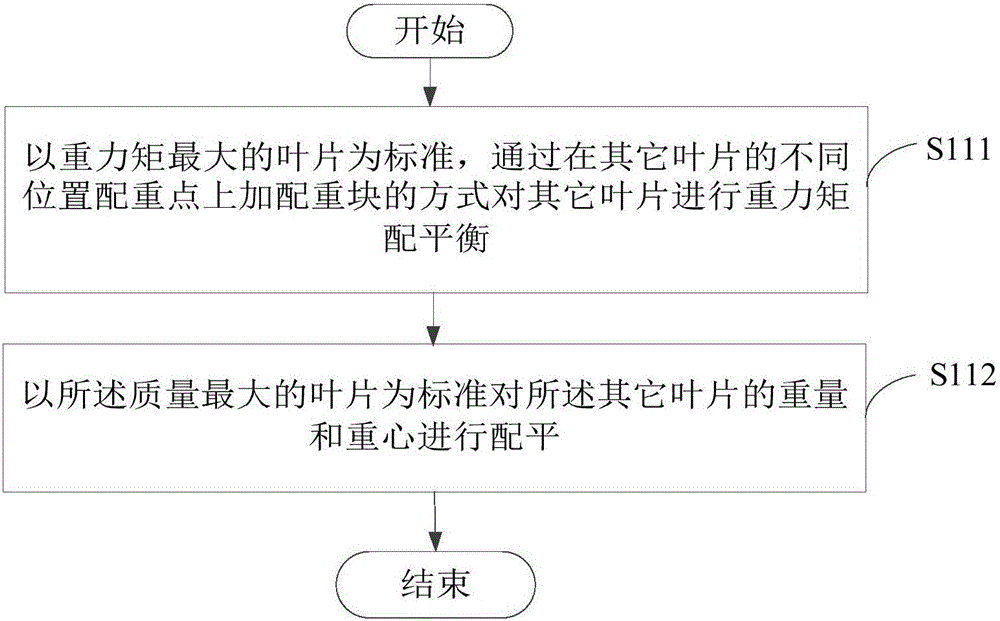

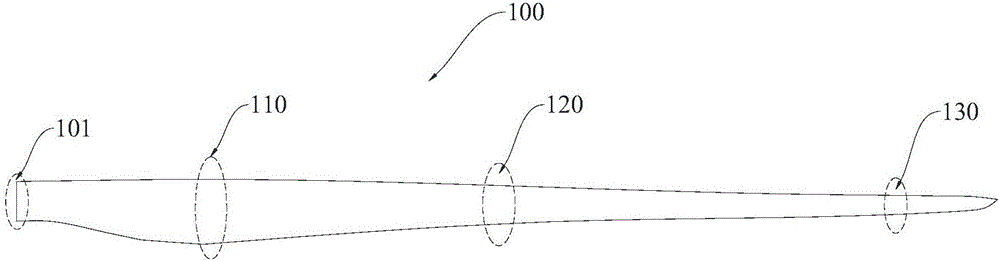

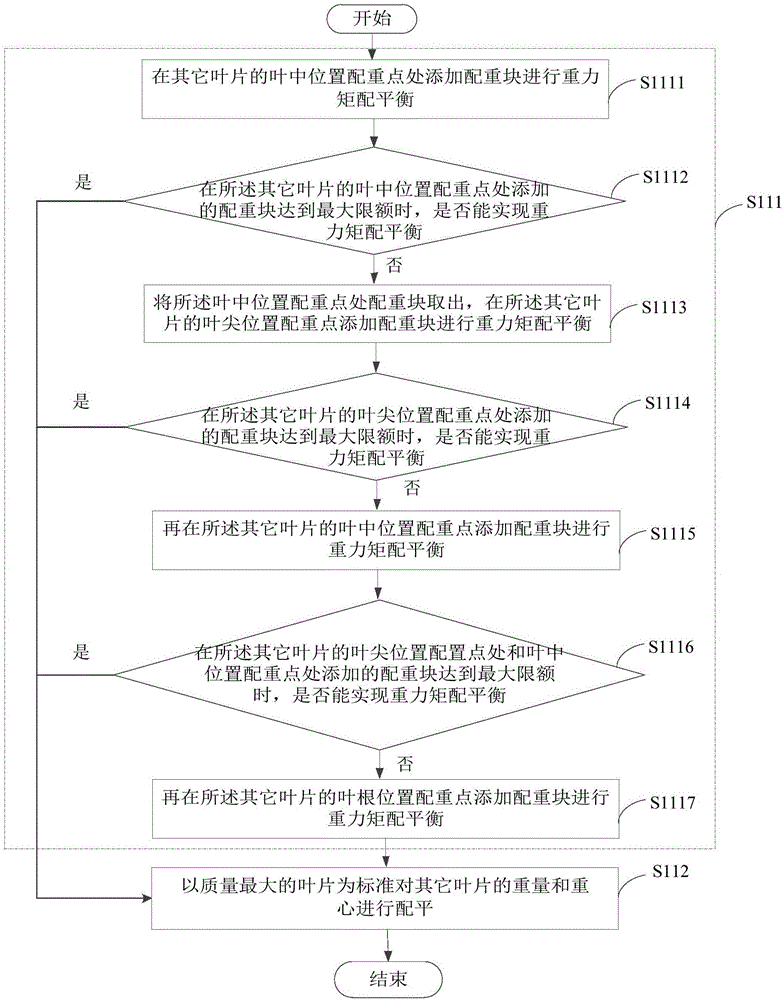

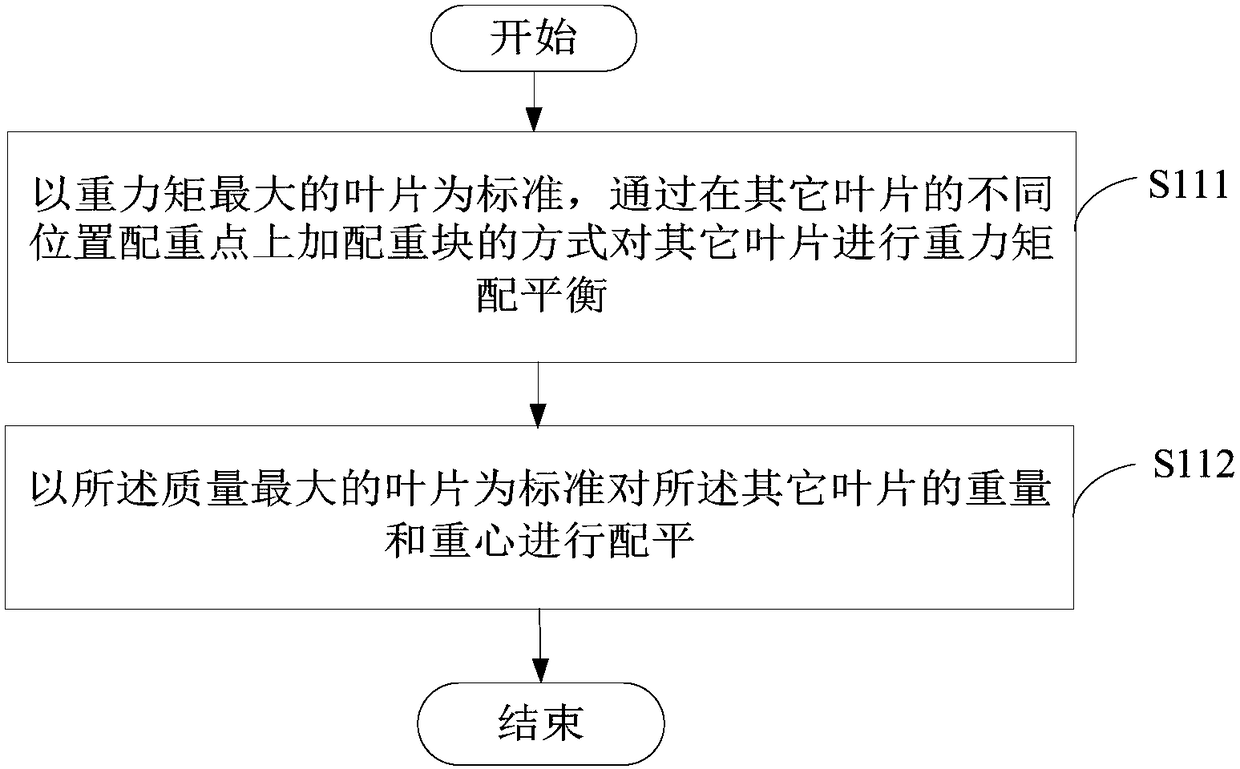

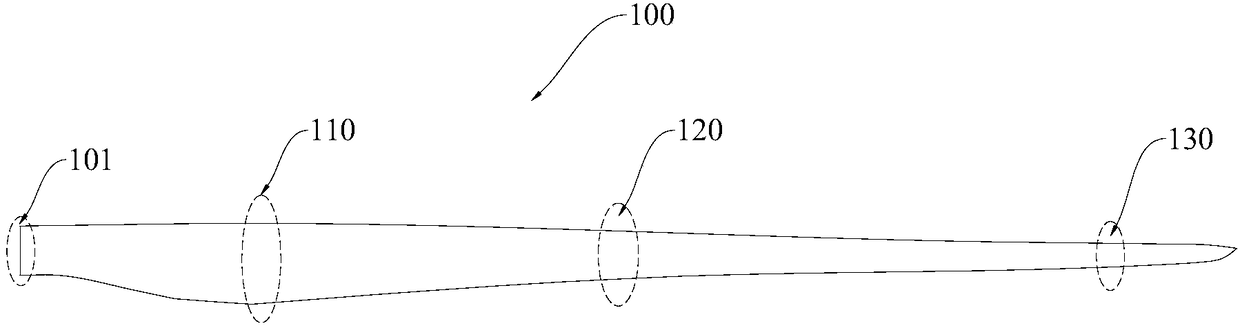

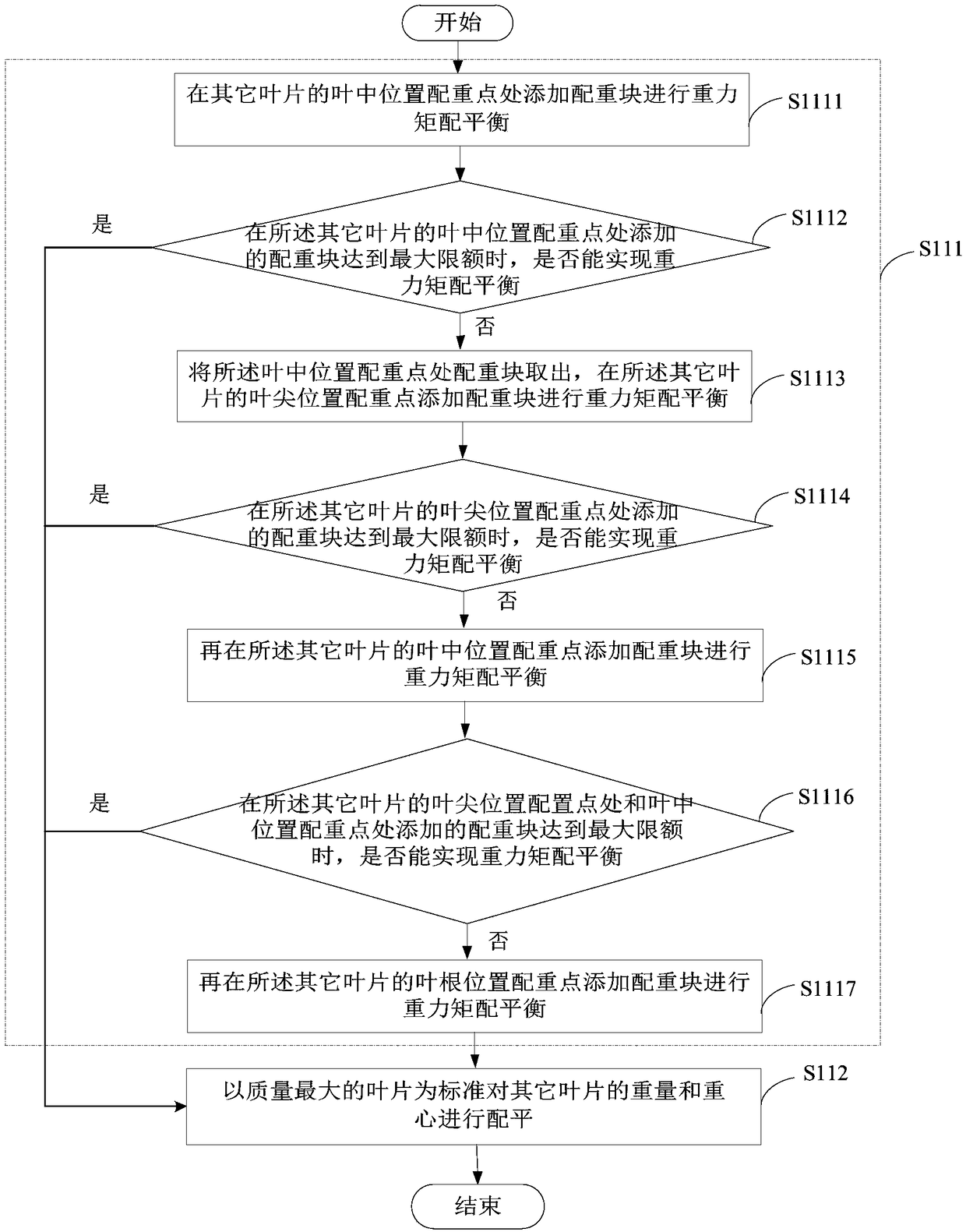

Blade mate-balance method, blades and wind driven generator

ActiveCN106121907ASolve the short service lifeSolve technical problems with short service lifeEngine fuctionsMachines/enginesWind drivenWind force

The invention provides a blade mate-balance method, blades and a wind driven generator. The method is applied to the wind driven generator. The wind driven generator comprises the blades of different gravity torques, weights and gravity centers. Each blade comprises a blade root position counterweight point, a blade middle position counterweight point and a blade tip position counterweight point. The method specifically comprises the steps that with the blade of the highest gravity torque as the standard, the other blades are subjected to gravity torque mate-balance by adding balancing weights on the different position counterweight points of the other blades; and after the other blades are subjected to gravity torque mate-balance, with the blade of the highest weight as the standard, mate-balance is carried out on the weights and gravity centers of the other blades. In this way, the blade mate-balance method is flexible and diverse, and the technical problem that as the gravity centers of blades shift too much, the service life of an existing wind driven generator is short can be solved.

Owner:三一(韶山)风电设备有限公司

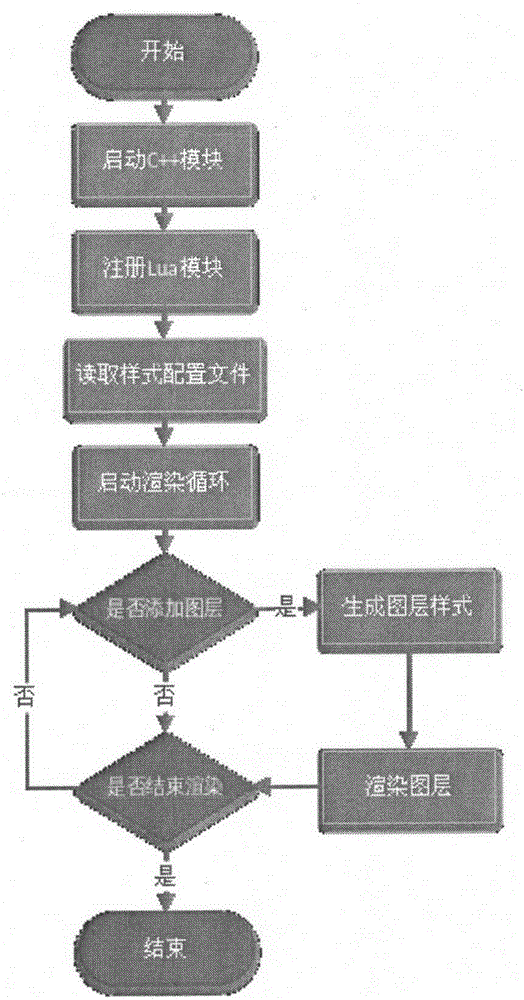

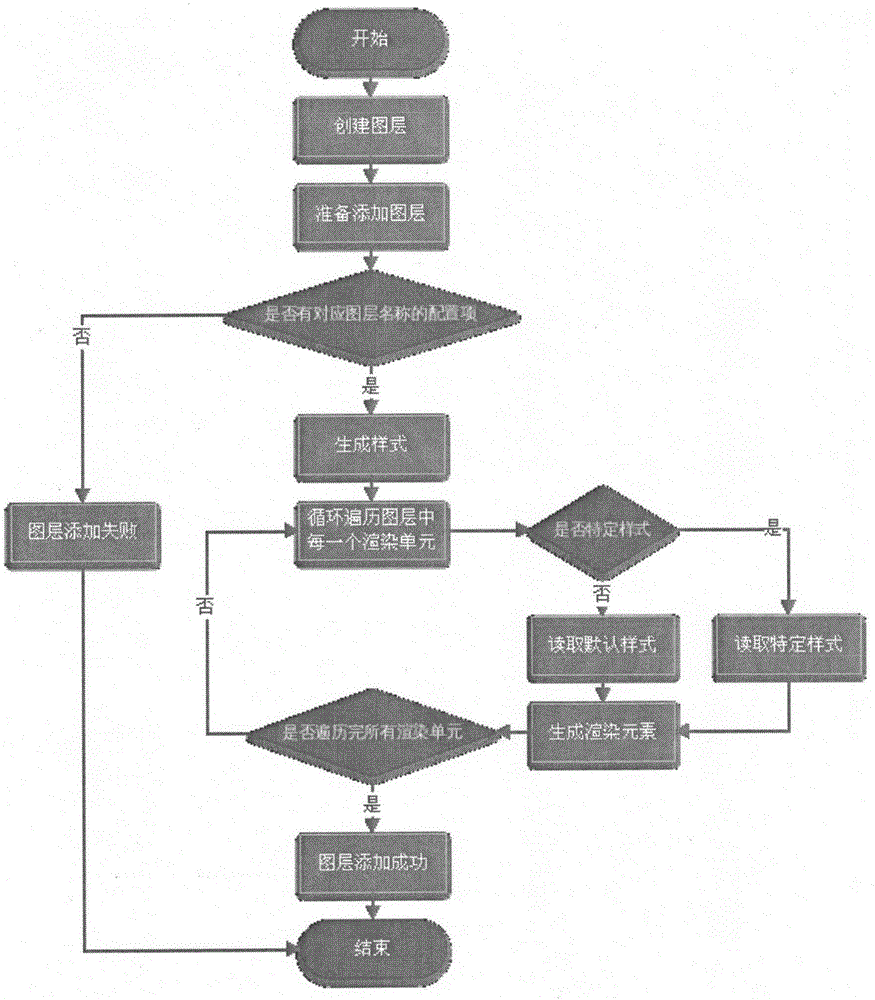

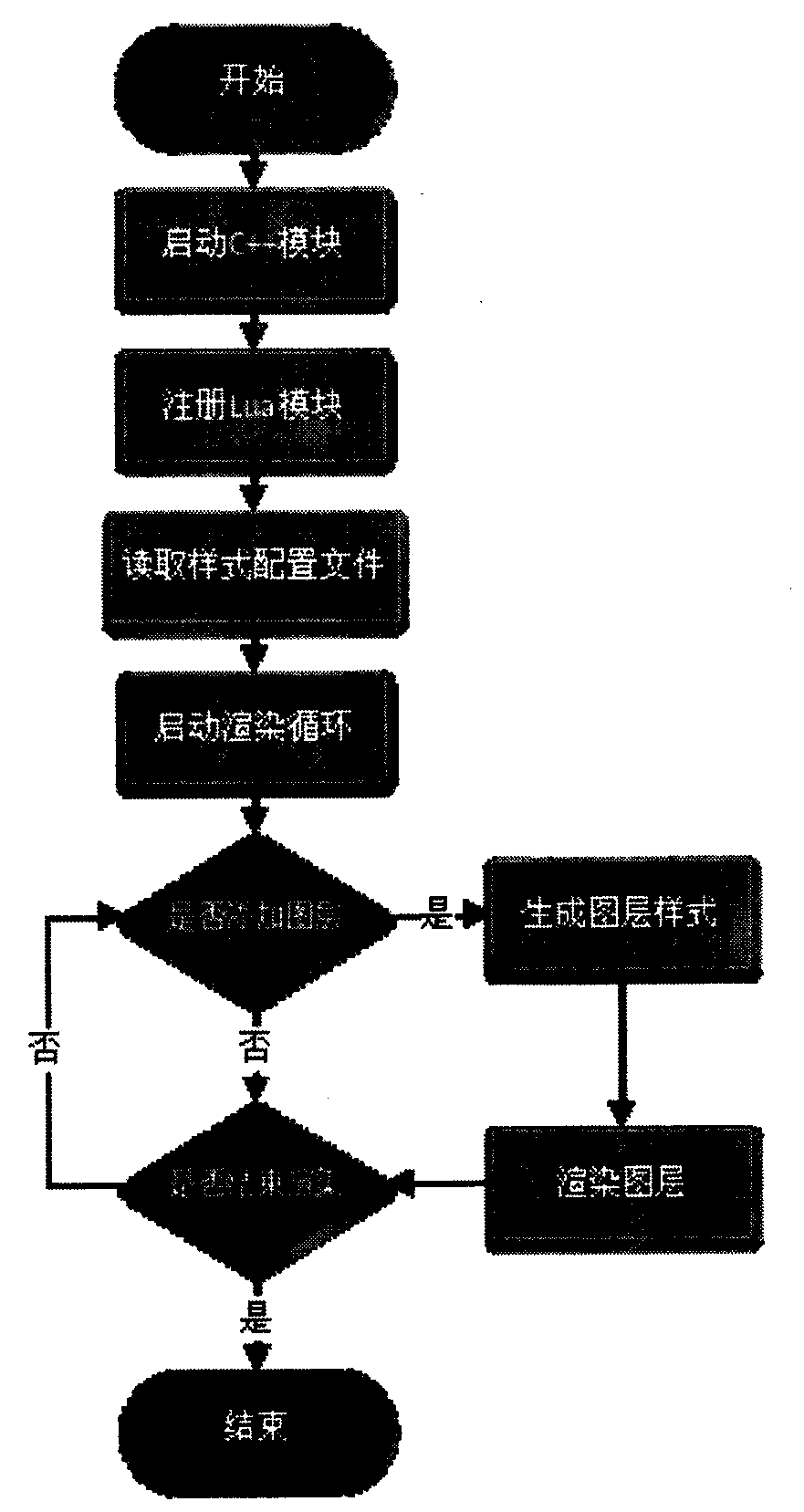

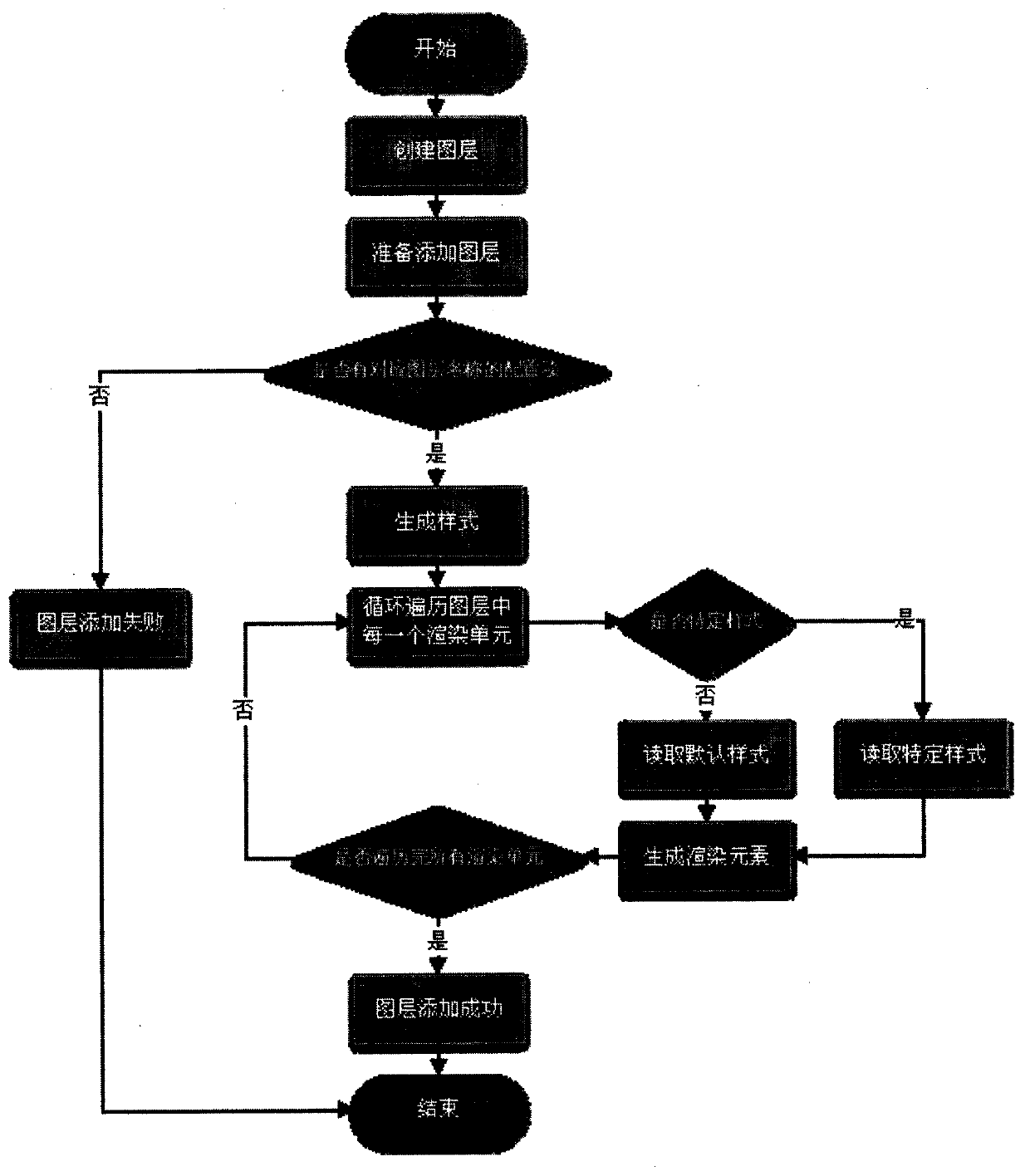

Method for configuring map style through Lua

ActiveCN106373176AFlexible rendering style configuration methodFlexible configuration methodTexturing/coloring3D-image renderingGeometric elementComputer science

The present invention provides a method of configuring a map style through the Lua. According to the method, a map is rendered in a hierarchical manner; each map layer is symbolization for geometric elements; and the same geometric element has different rendering styles in different layers. The method of the invention is a flexible and convenient indoor map rendering style configuration method. A user can set the style of an entire map layer, a single geometric element or a class of geometric elements through a Lua scripting configuration file and can quickly and intuitively view a display effect.

Owner:上海图聚智能科技股份有限公司

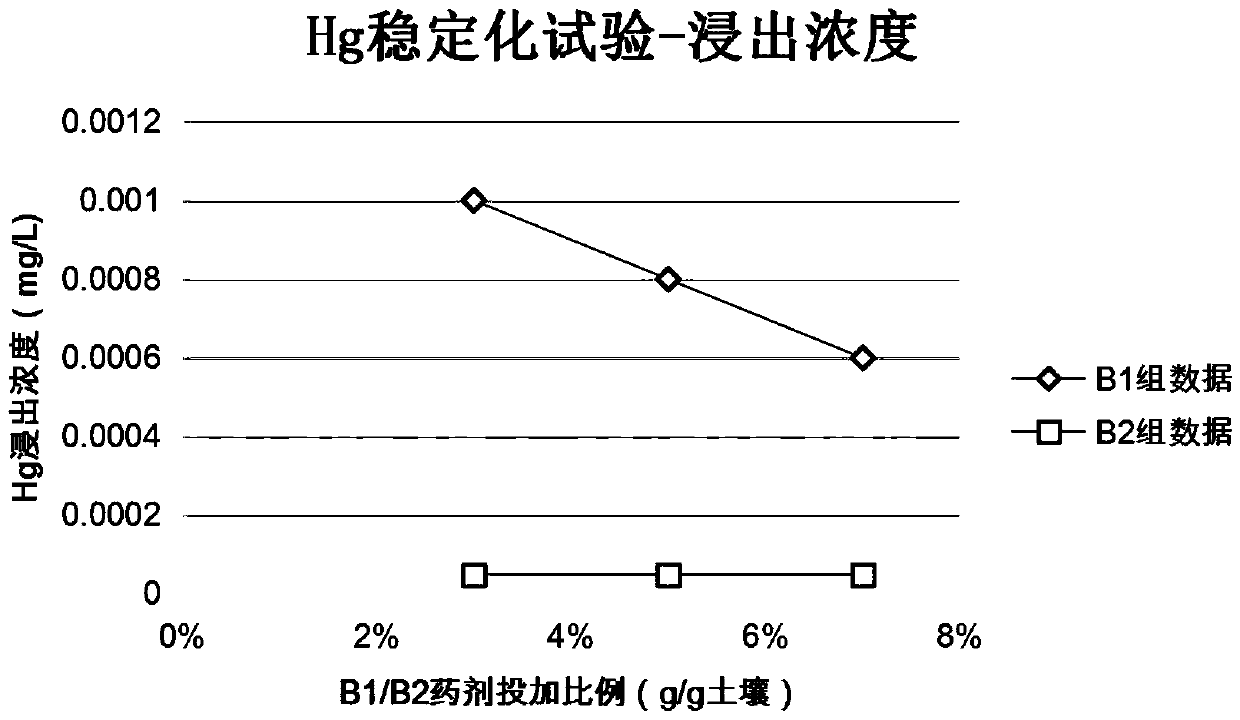

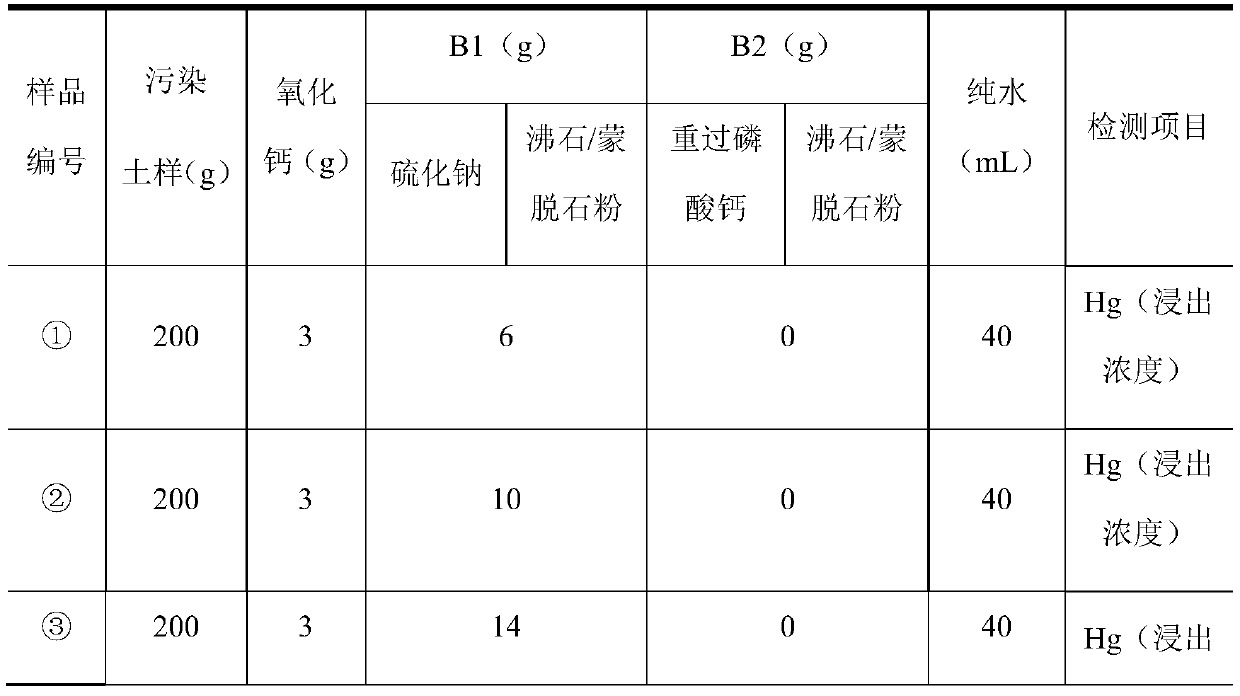

Preparation method and use method of agentia for stabilization repairing of mercury-contaminated soil

InactiveCN110369488ACo-precipitationWith adsorptionContaminated soil reclamationOrganic fertilisersZerovalent ironMercury contamination

The invention discloses a preparation method and a use method of agentia for stabilization repairing of mercury-contaminated soil. The preparation method includes the steps that 1, contaminated soil is excavated, screened and crushed; 2, the water content, pH value, redox potential value and initial concentration of mercury in the soil are measured by sampling analysis; and 3, the ratio of components in the agentia is determined, and materials in the components are crushed and mixed evenly. The agentia includes a component A and a component B, the component A includes calcium oxide and zero-valent iron powder, and the component B includes sodium sulfide, triple superphosphate, montmorillonite powder, zeolite powder and ferrous sulfate. The invention further provides the use method of the agentia for stabilization repairing of the mercury-contaminated soil. According to the preparation method and the use method, the mechanisms of 'coarse stabilization' and 'fine stabilization' are combined, he preparation method and the use method are suitable for a variety of soil environments, the agentia is flexibly used, the configuration method is simple, field service is convenient, and the cost can be further saved.

Owner:SHANGHAI GREENMENT ENVIRONMENTAL TECH CO L

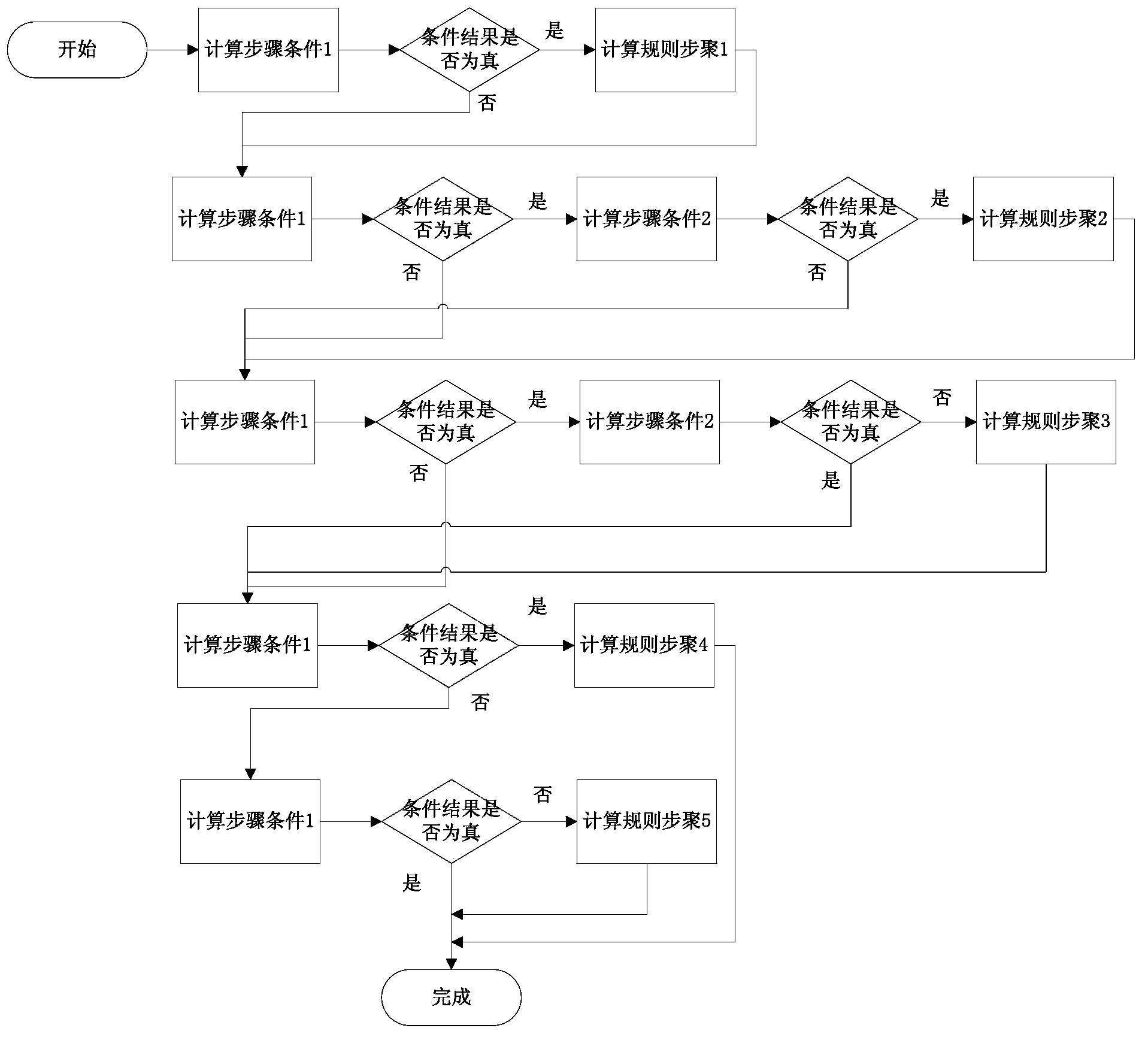

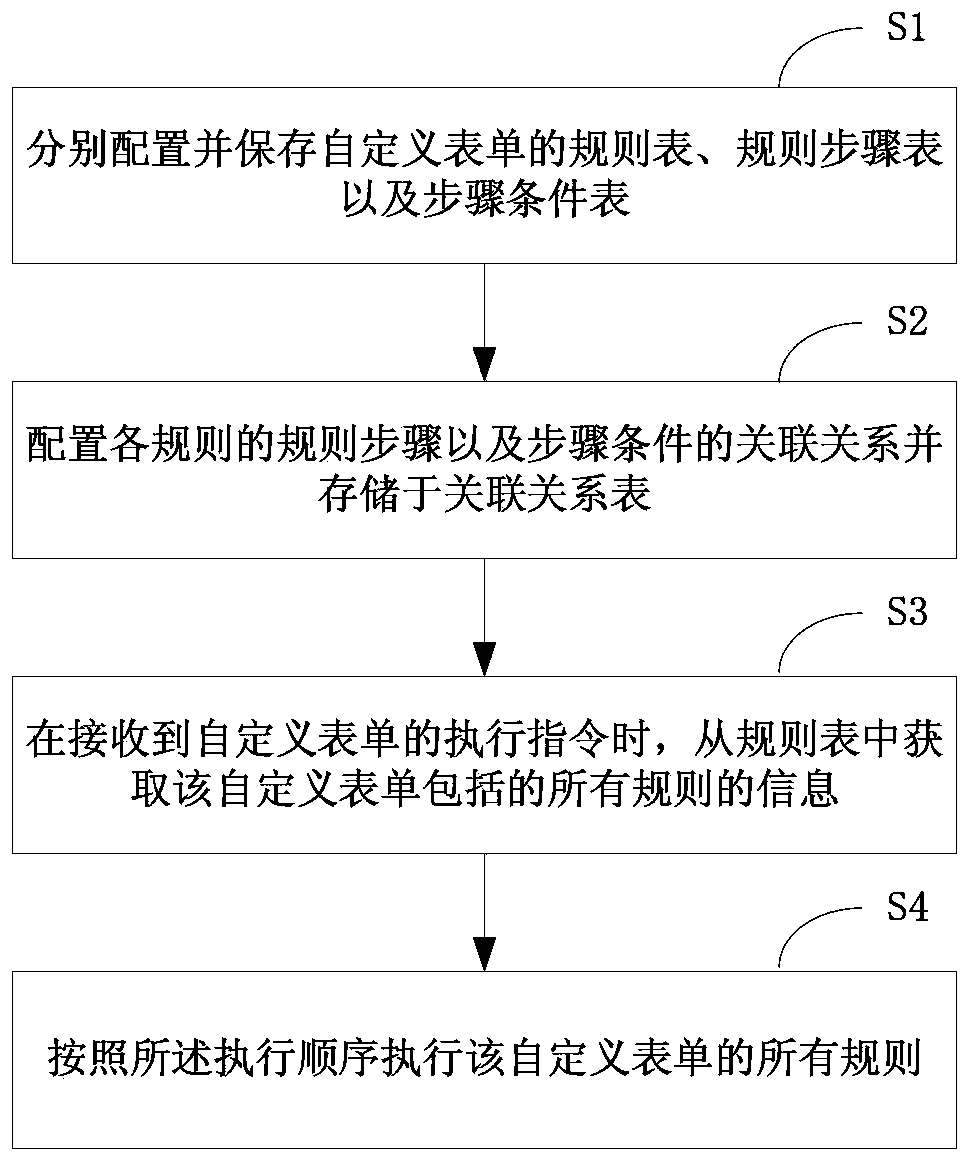

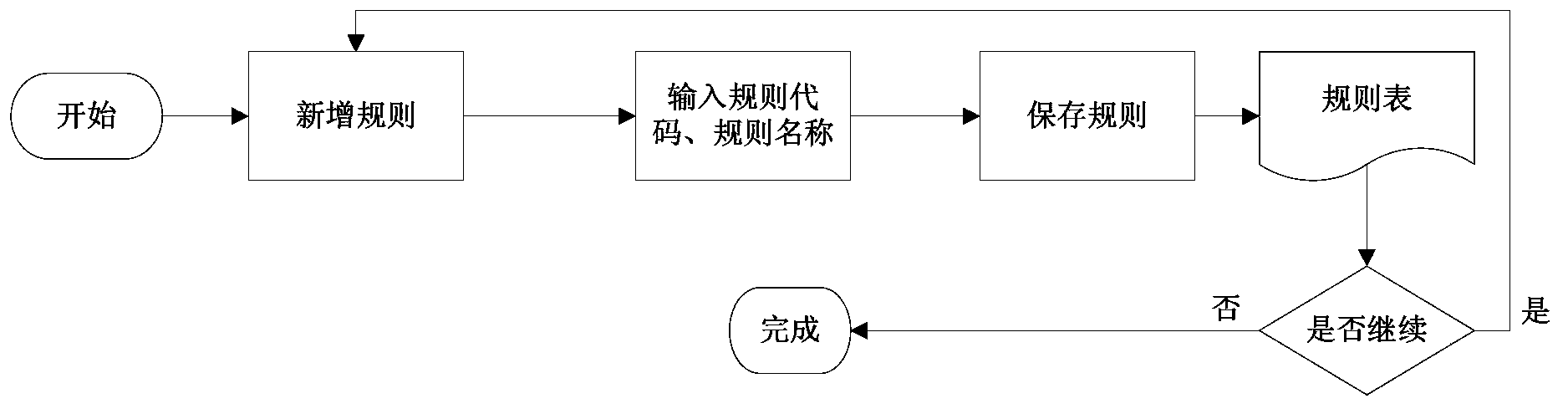

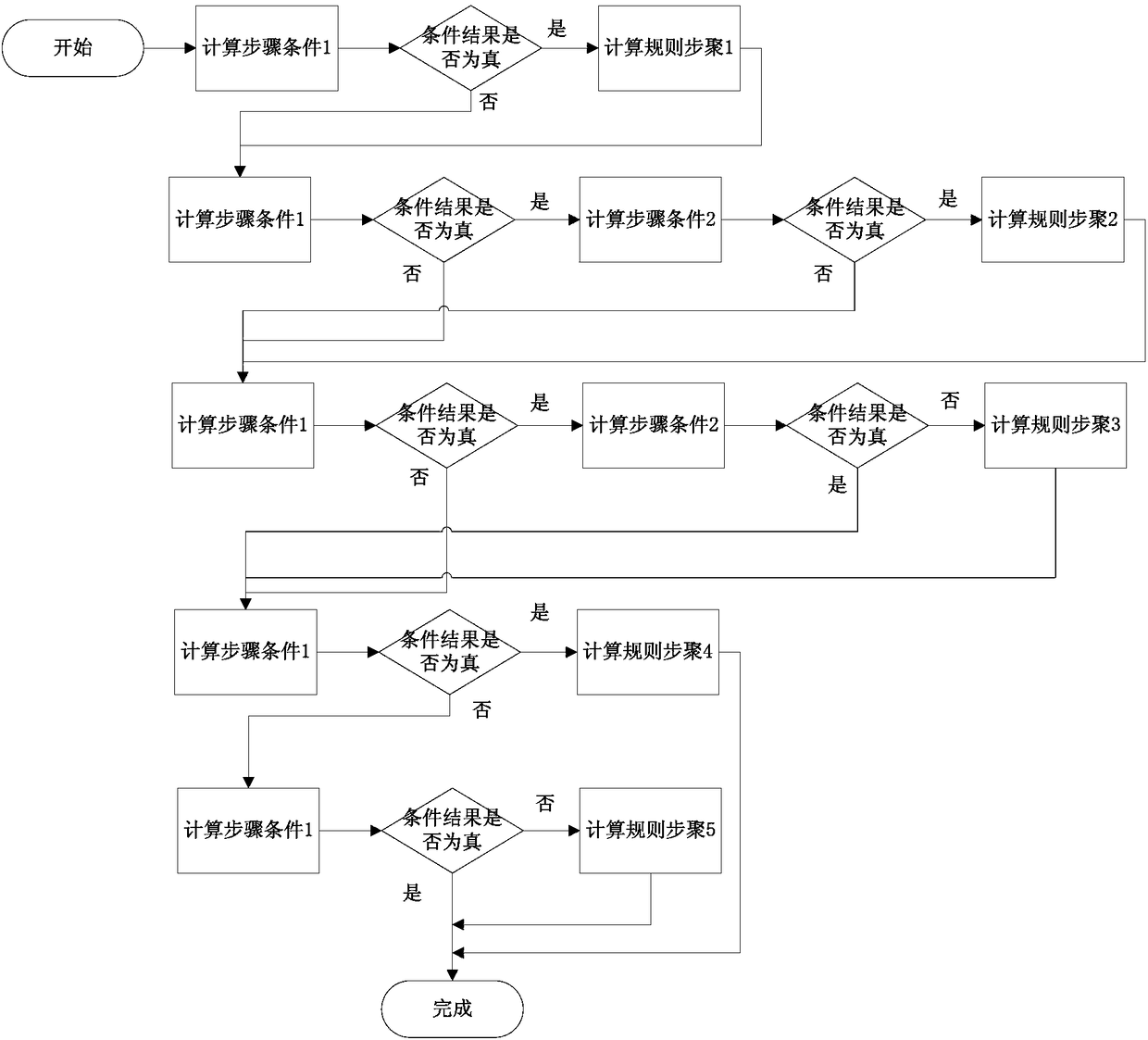

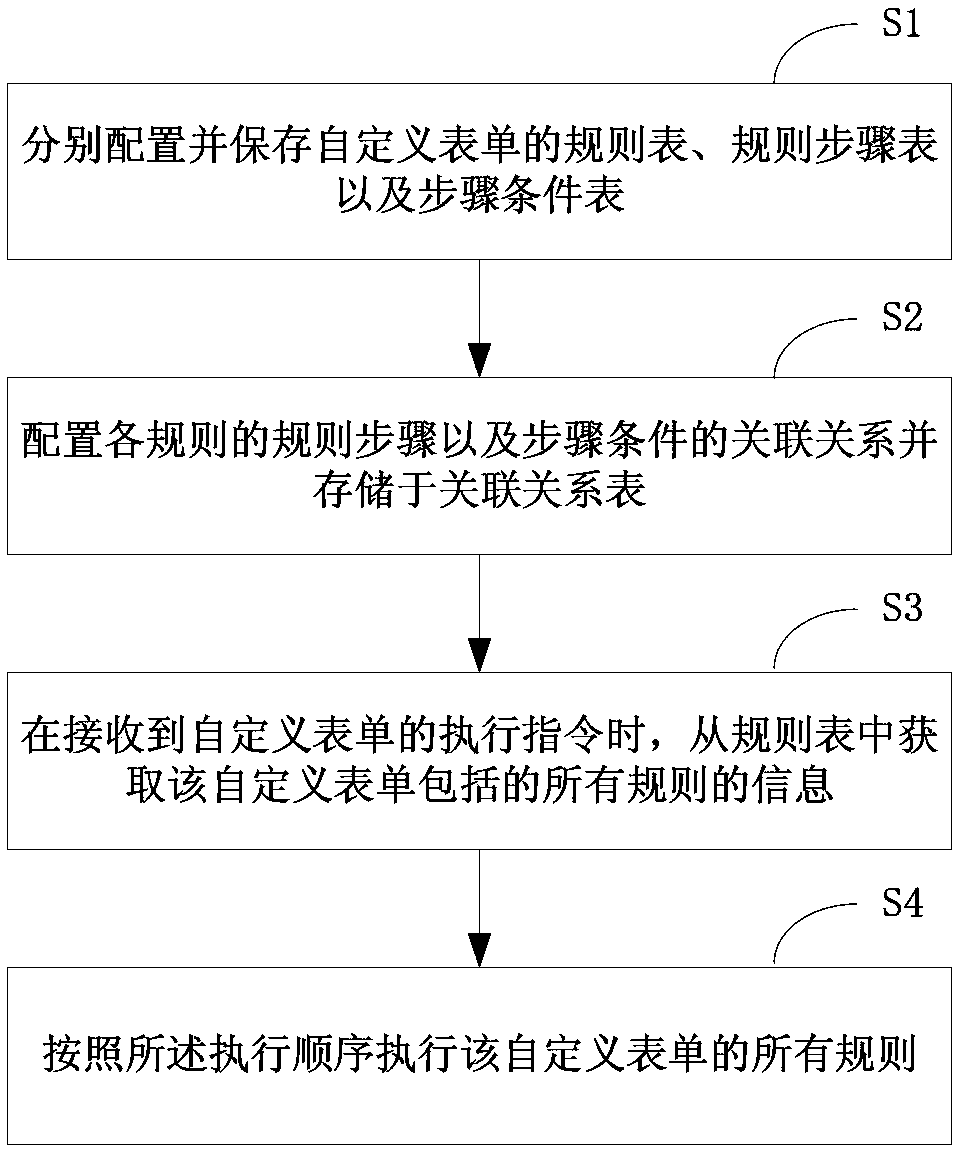

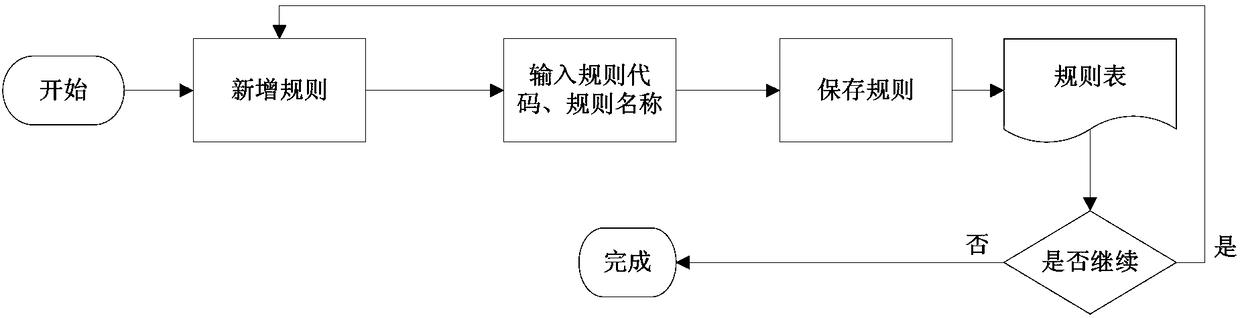

Method and system for configuring and calling rules of customized form

ActiveCN104239017ASimple configurationFlexible configuration methodSpecific program execution arrangementsProgramming languageExecution unit

The invention relates to a method and a system for configuring and calling the rules of a customized form. The system comprises a first configuring unit, a second configuring unit, an instruction response unit and an executing unit. The method includes the steps of S1, respectively saving the rule table, the rule step table and the rule condition table of the customized form; S2, configuring the correlation of the rule step and the step condition of each rule according to the executing logic of each rule and saving the correlation in a correlation table; S3, when the executing instruction of the customized form is received, acquiring the information of all the rules contained by customized form; S4, executing all the rules of the customized form according to an executing order. By the method and the system, the rules in the customized form can be fast simply and flexibly configured, the step for calling the configured rules in the customized form is simplified, and system operation efficiency is increased.

Owner:SHENZHEN LAN YOU TECH

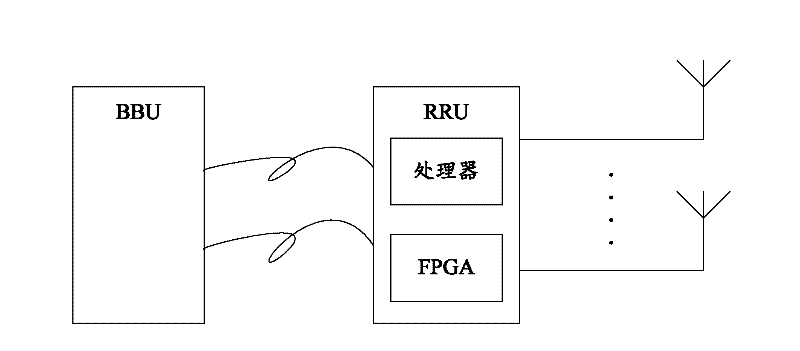

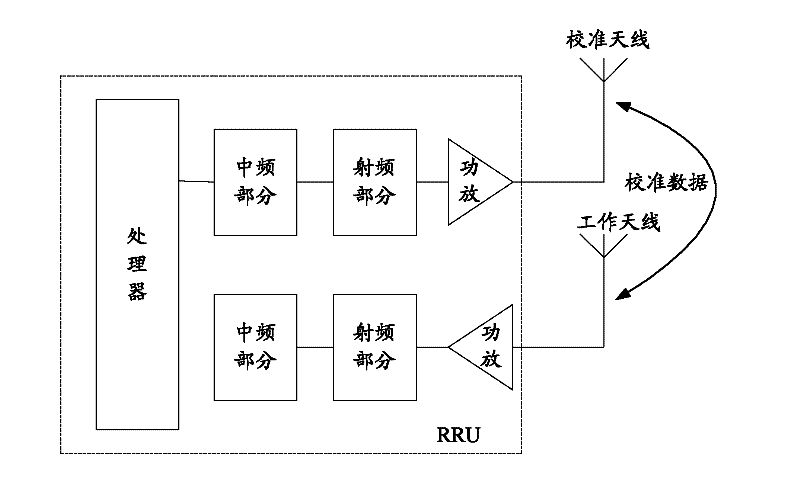

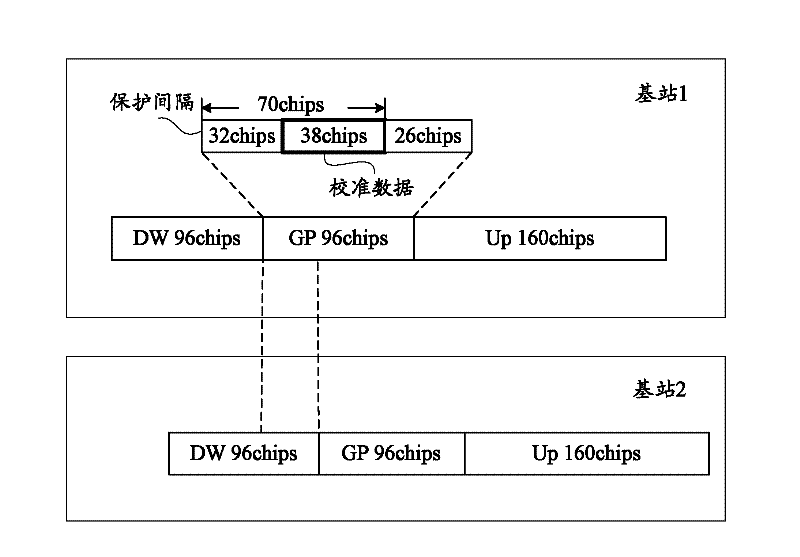

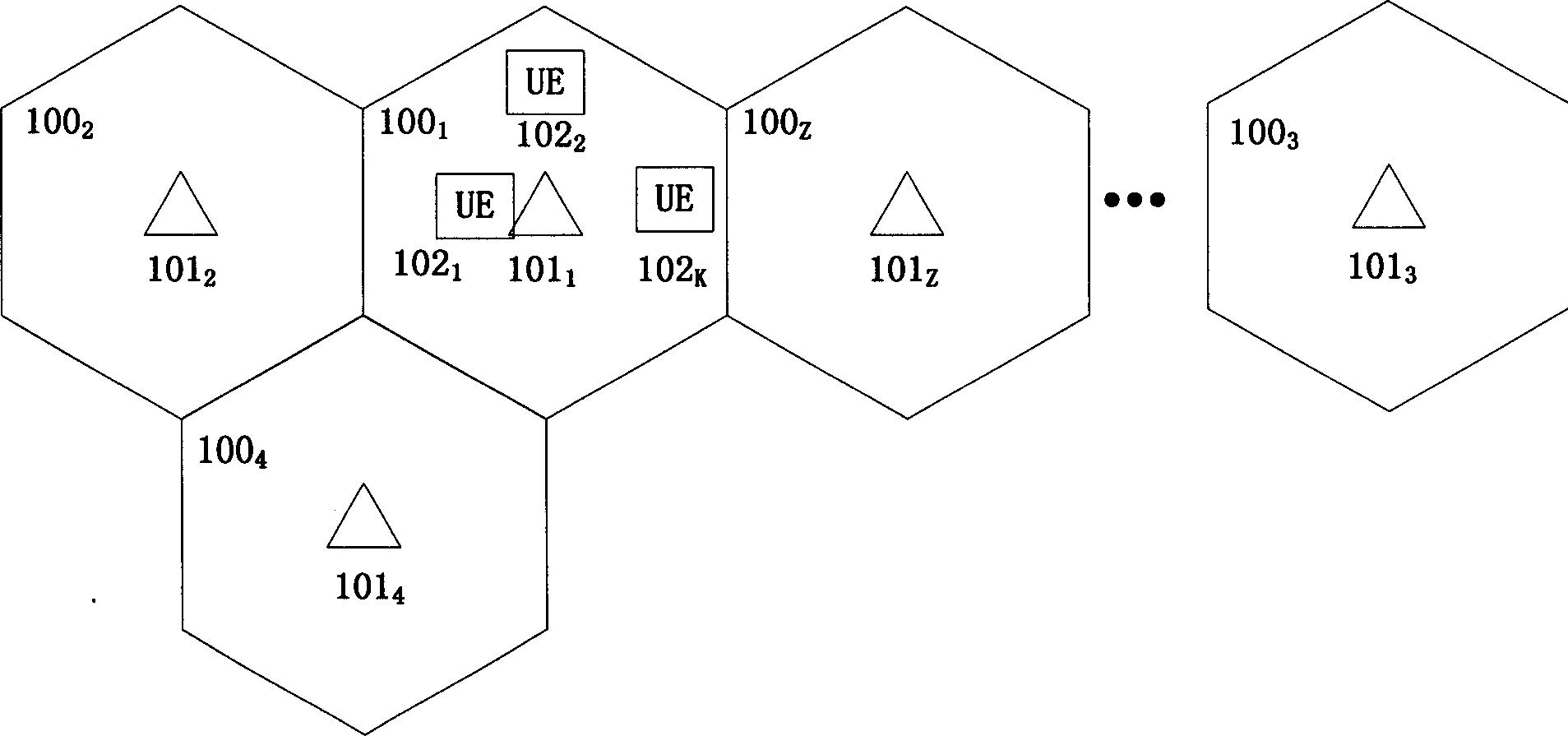

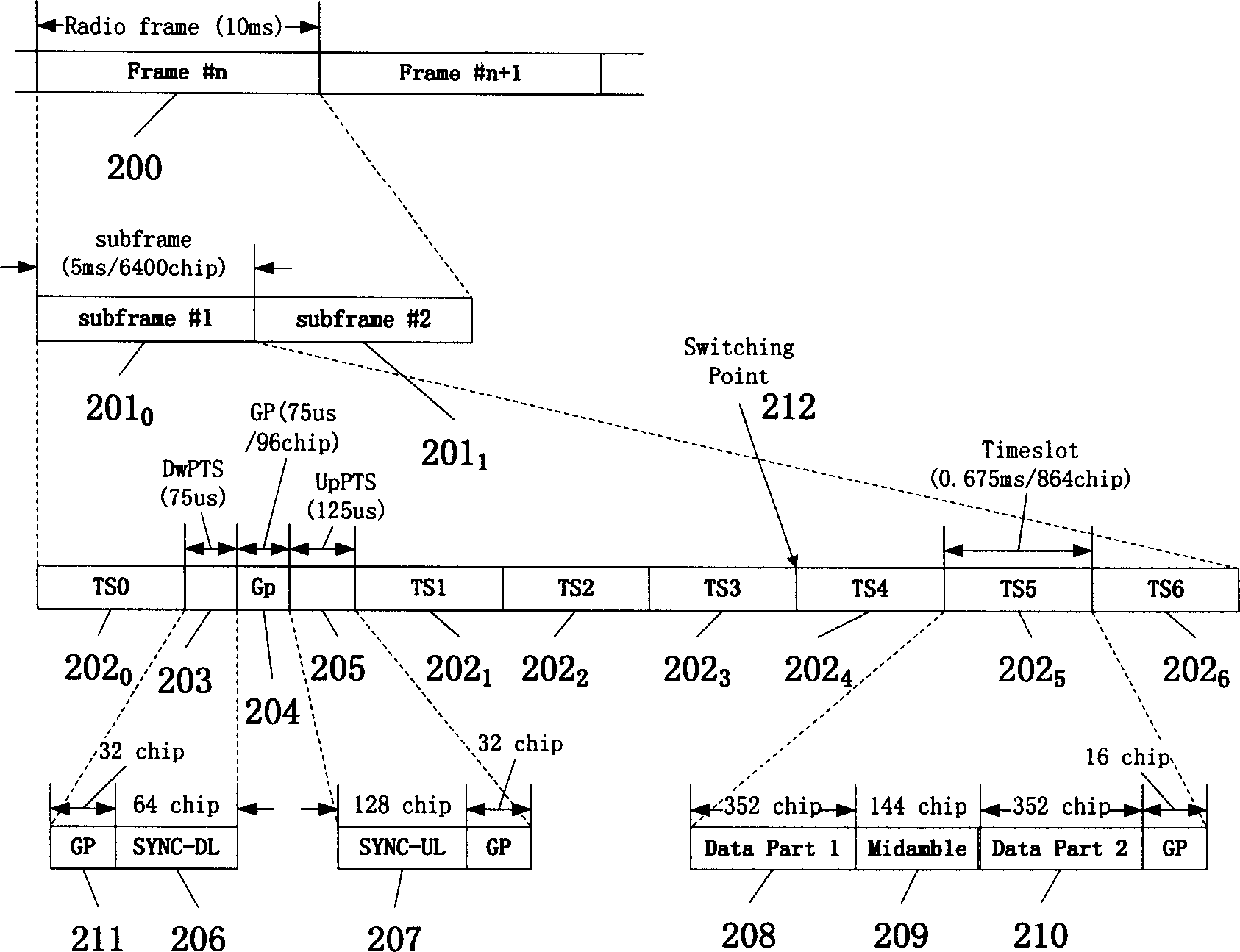

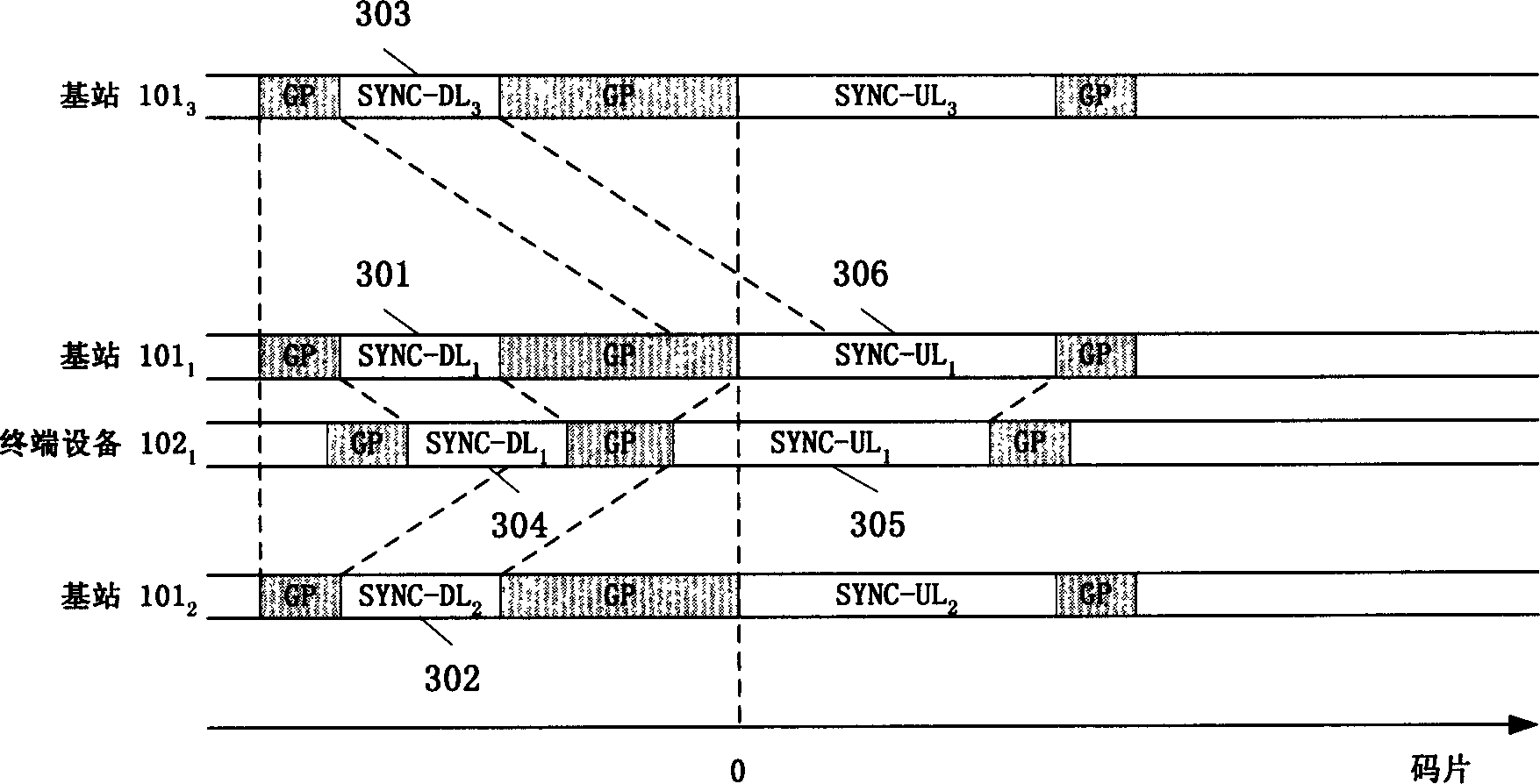

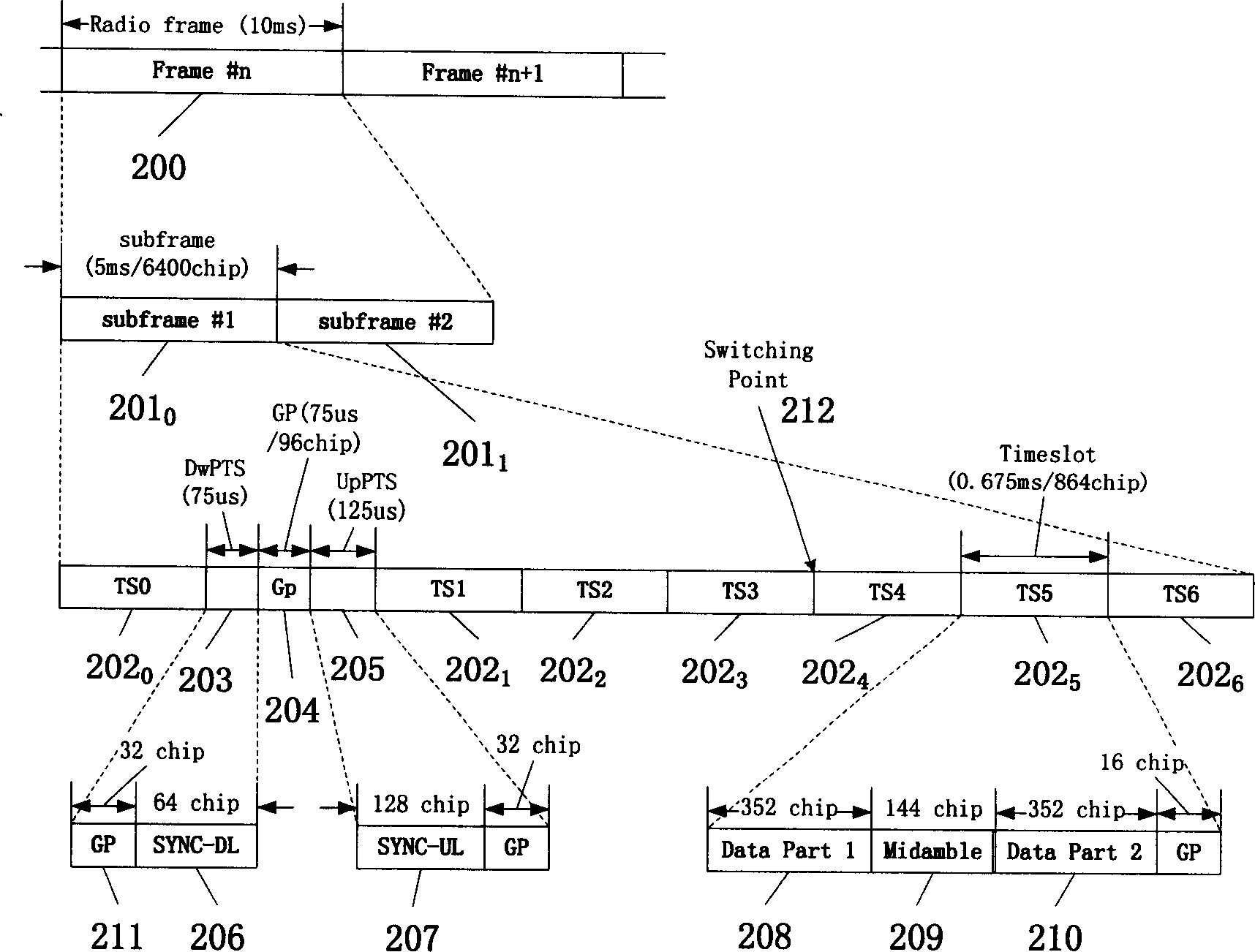

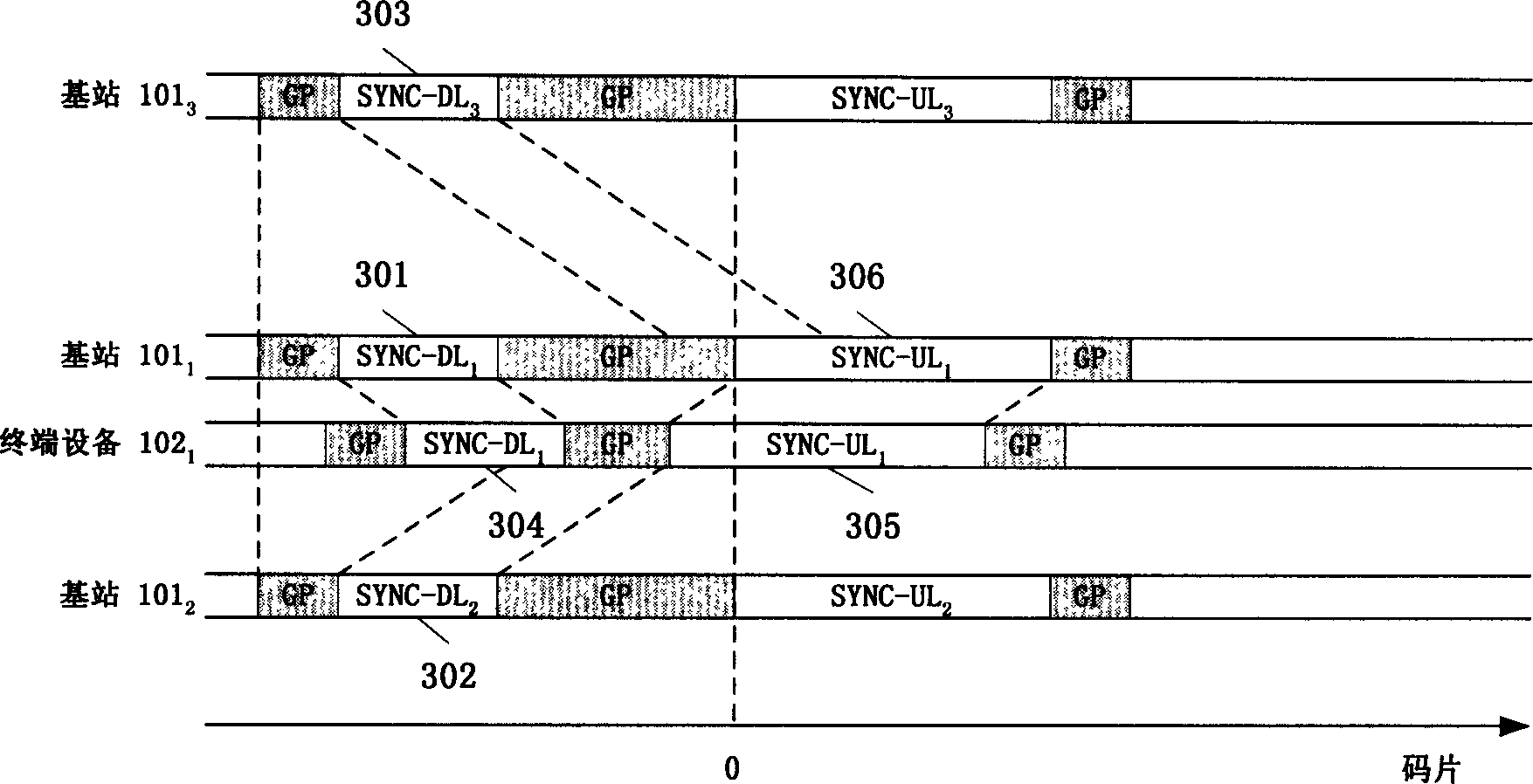

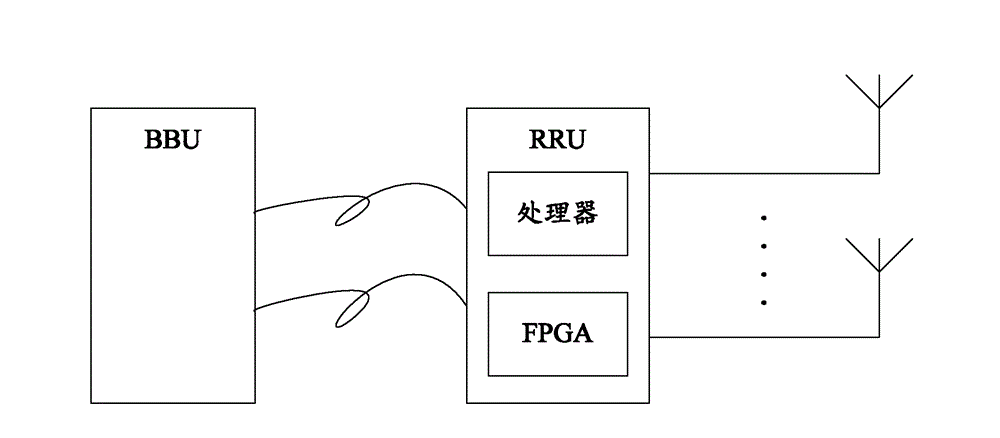

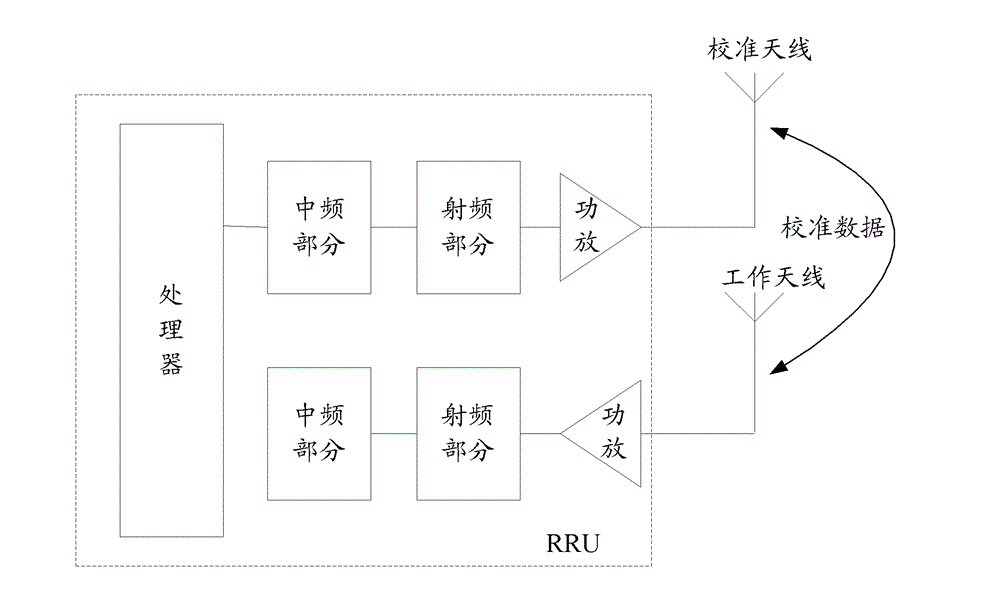

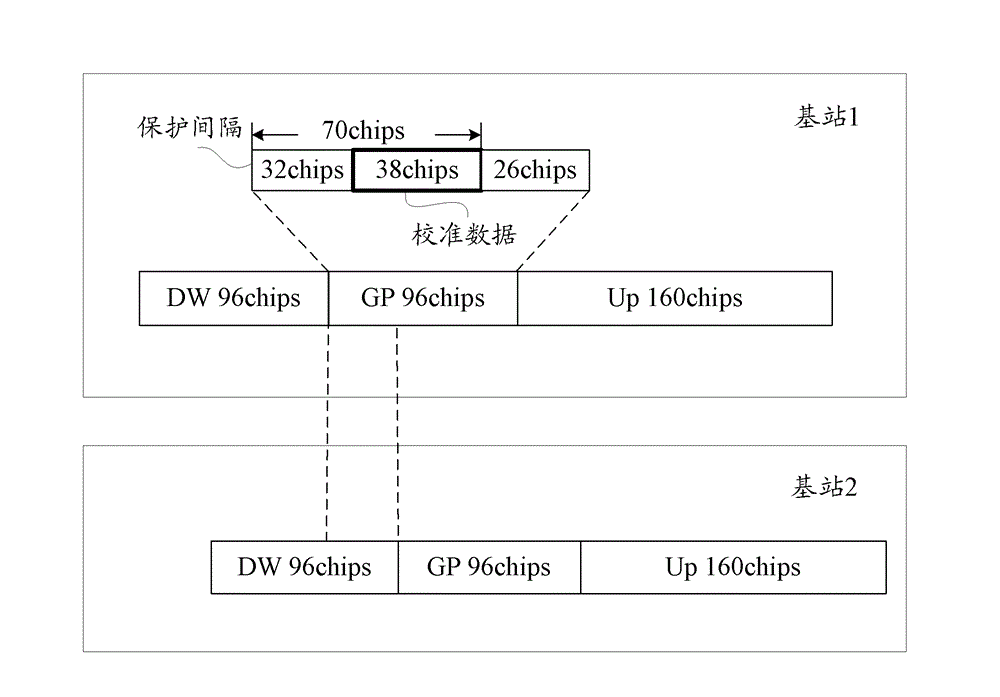

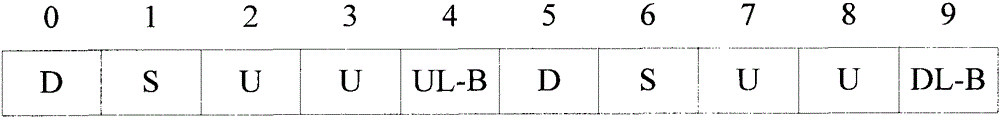

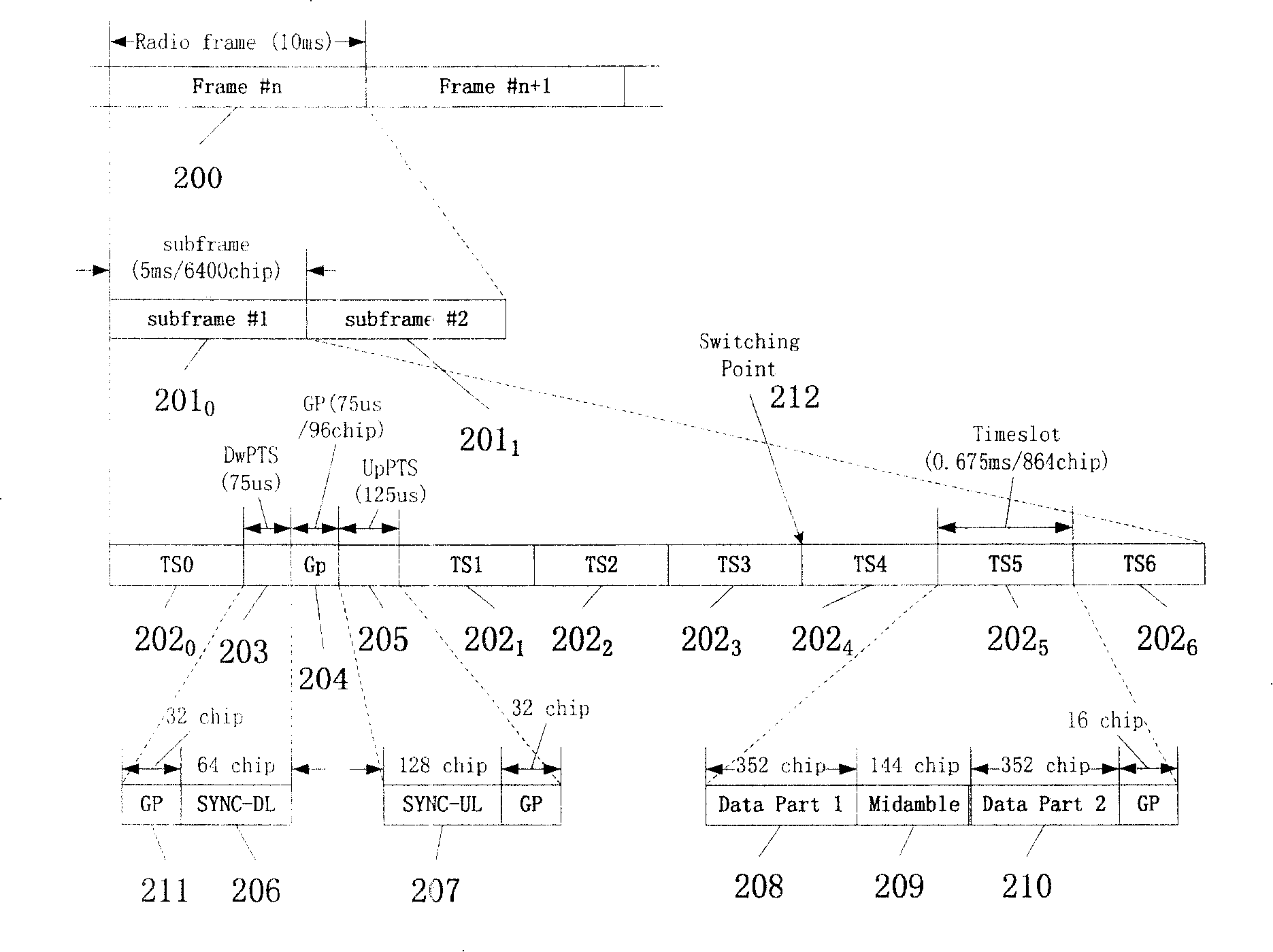

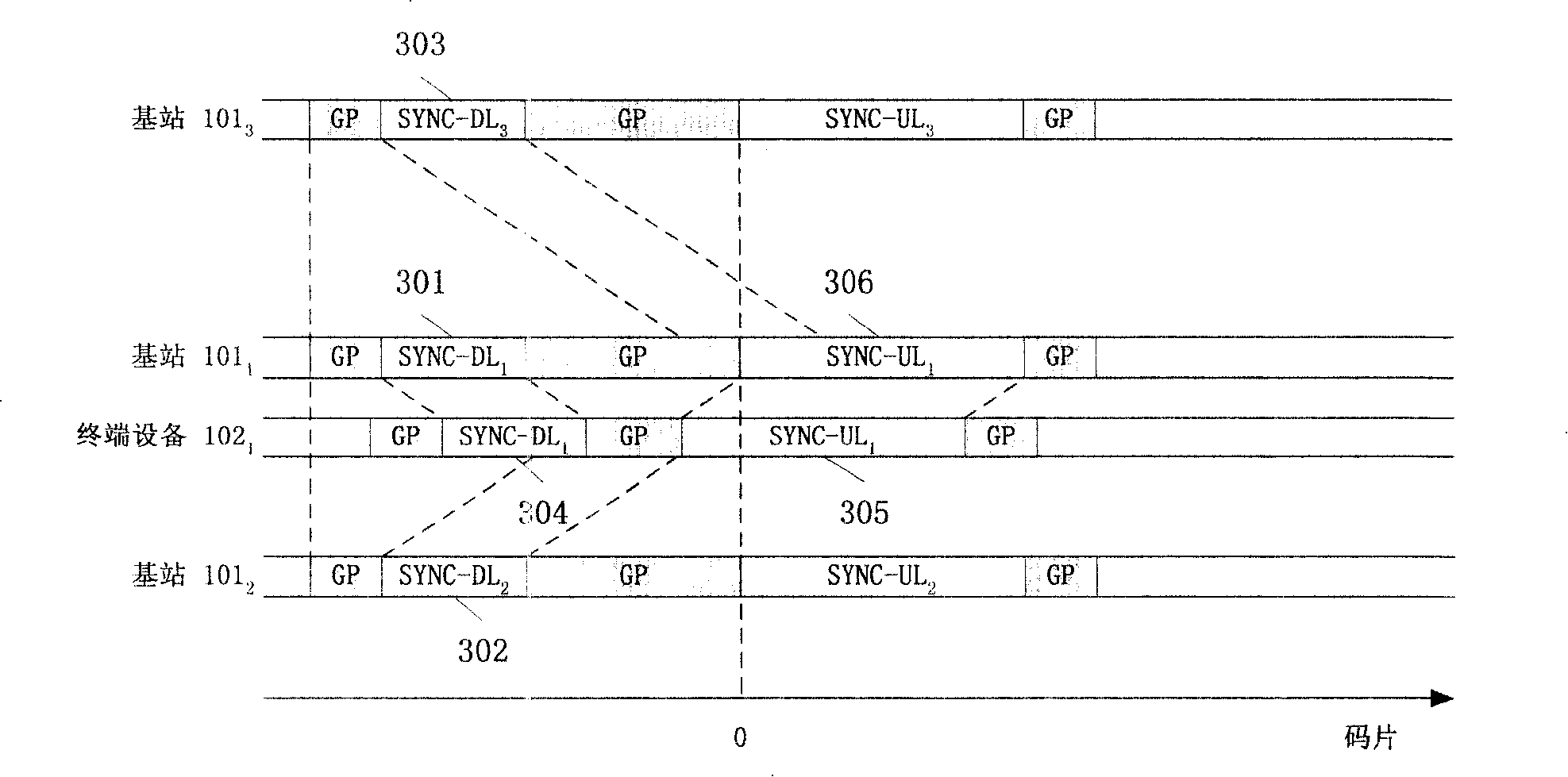

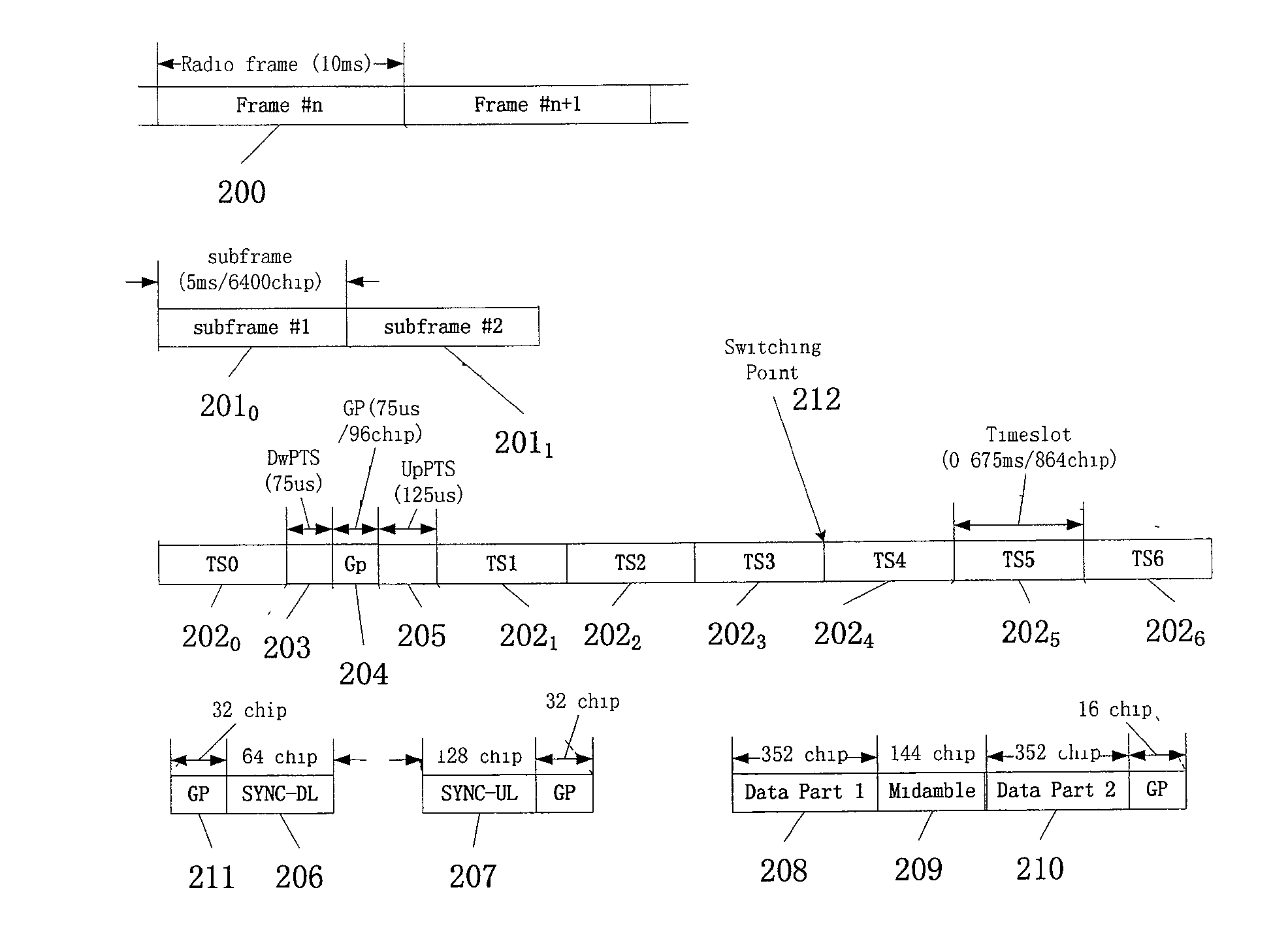

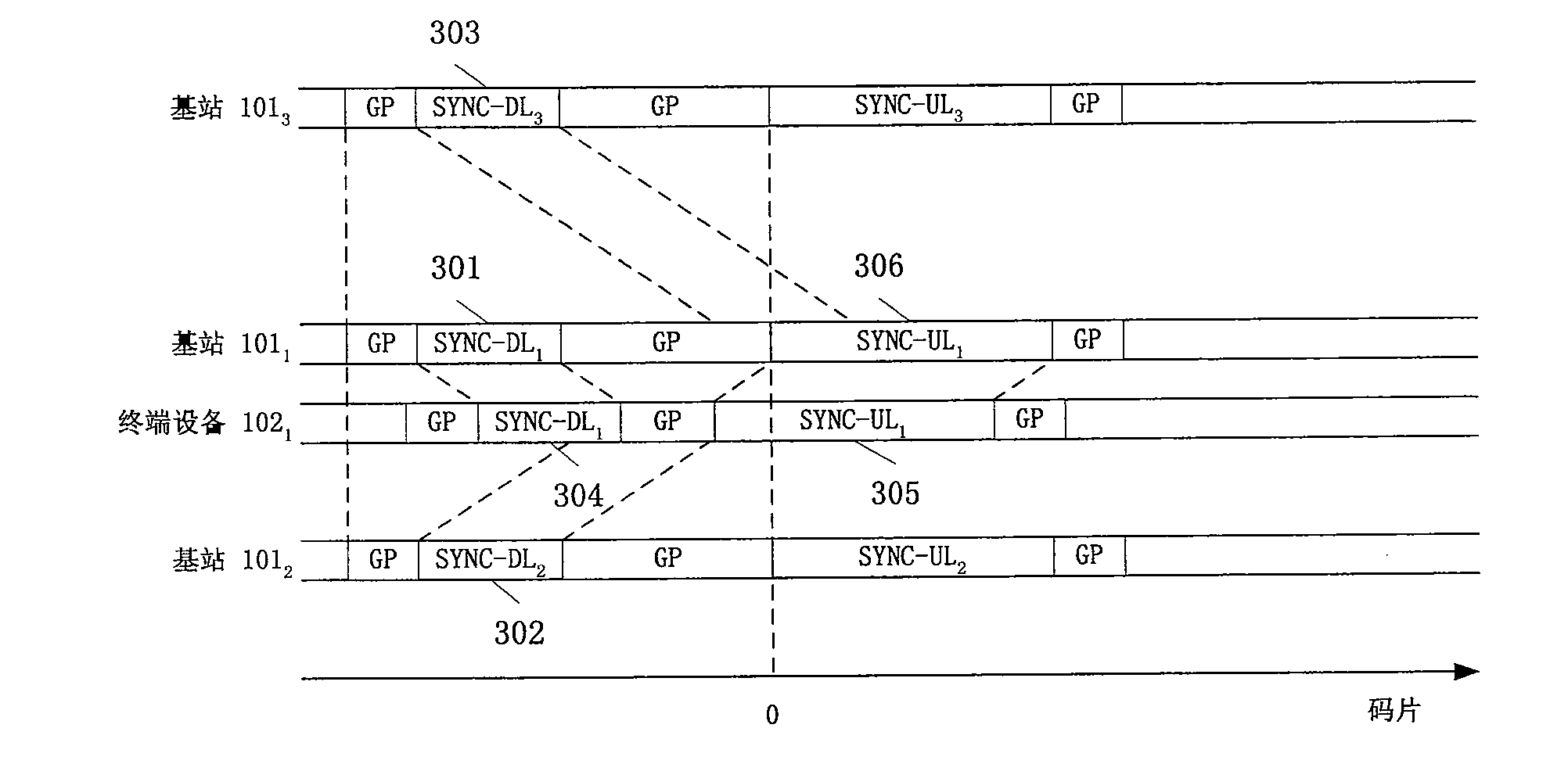

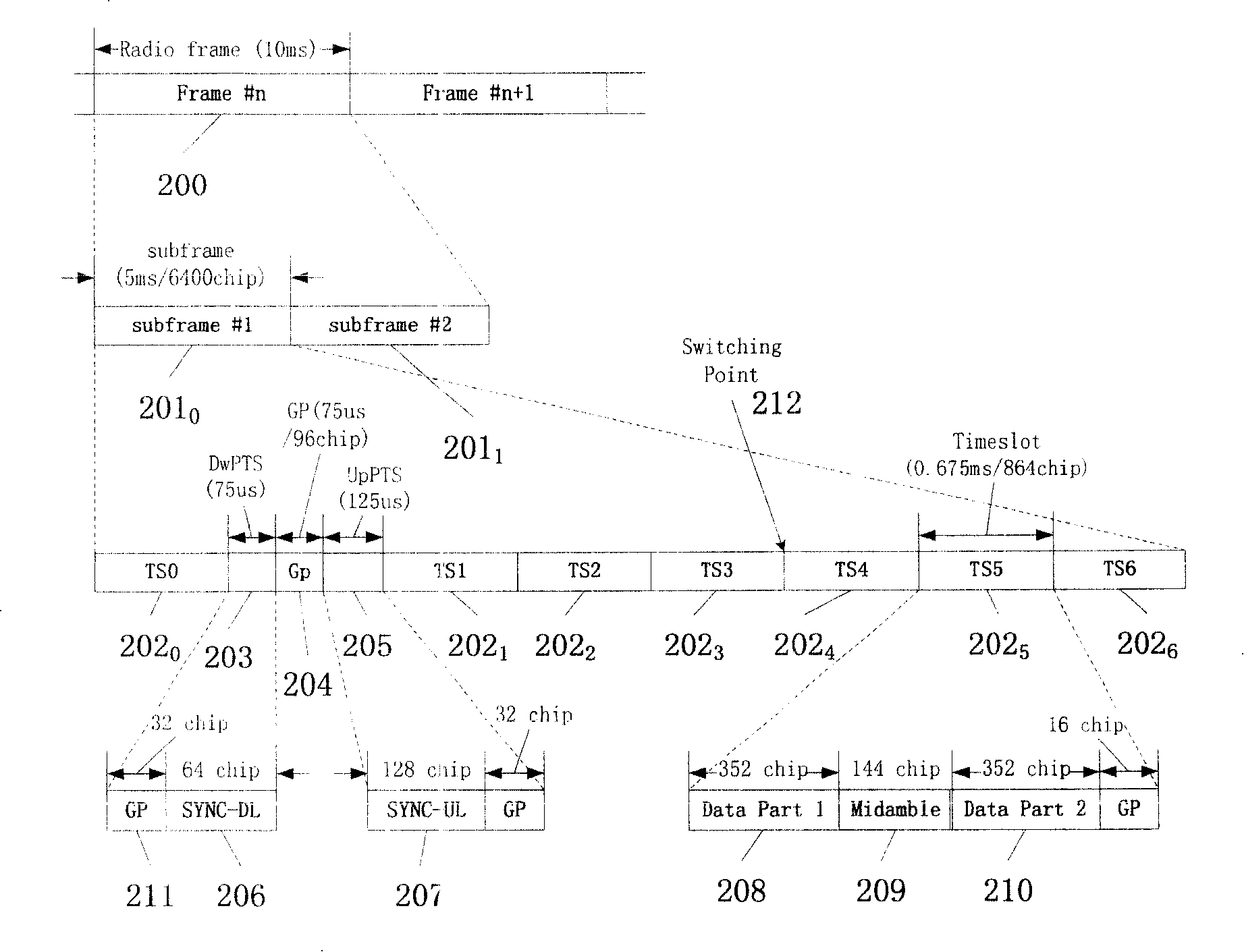

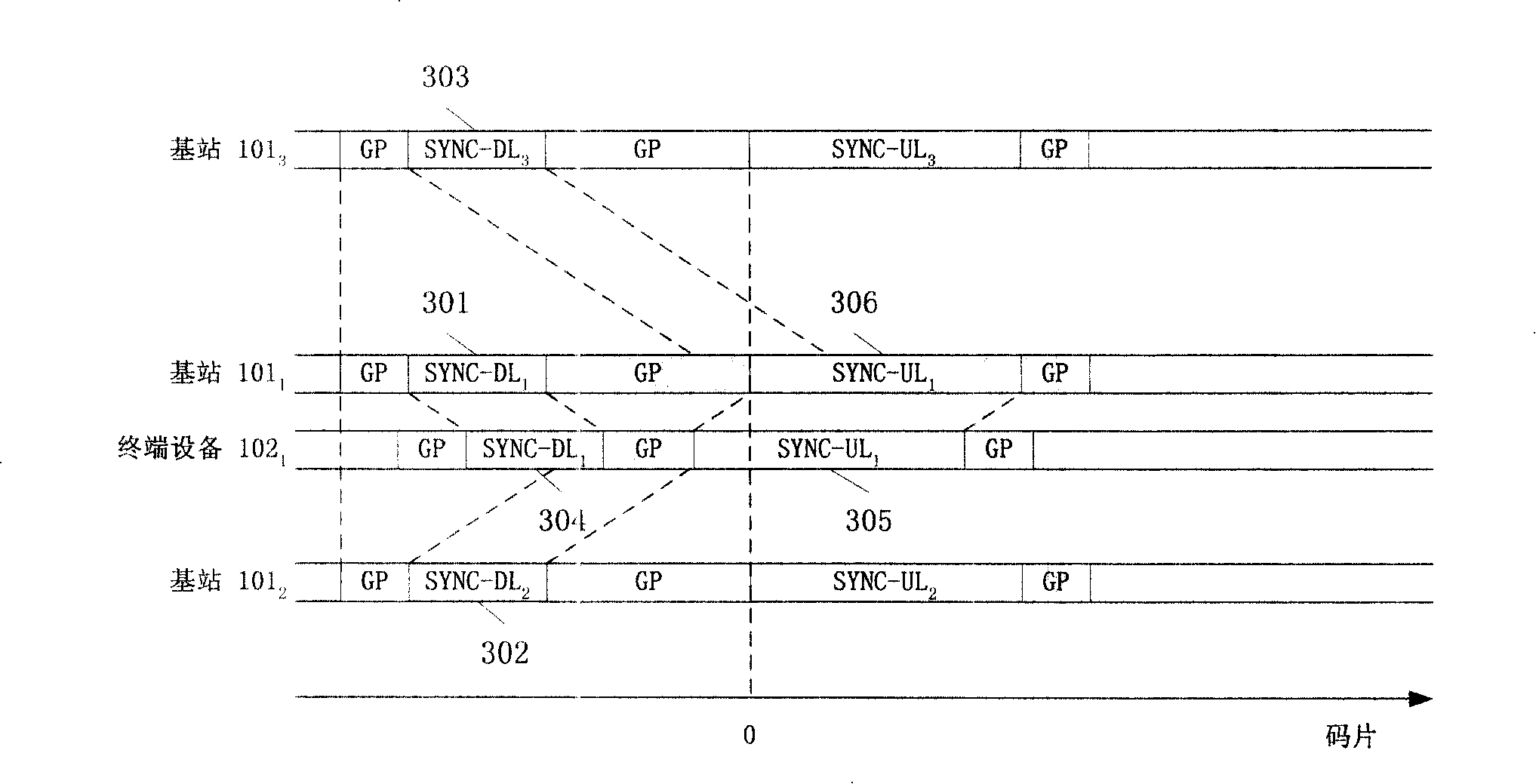

Method and device for transmitting and receiving calibration data of TD-SCDMA (time division-synchronization code division multiple access) base station

ActiveCN102647240AReduce far-end interferenceImprove anti-interference abilityReceivers monitoringWireless communicationAnti jammingData transmission

The application provides a method and device for transmitting and receiving calibration data of a TD-SCDMA (time division-synchronization code division multiple access) base station, and the method and the device are used for solving the problems that width phase consistency alarm is generated and a calibration effect is influenced during calibration in the prior art. The method for transmitting the calibration data of the TD-SCDMA base station comprises the following steps of: switching on a calibration switch when a downlink pilot frequency time slot is finished; controlling a transmission time slot through a register, and calibrating and transmitting calibration data of an antenna in the transmission timeslot reading register; and switching off the calibration switch when an uplink pilot frequency timeslot is finished. The method for receiving the calibration data of the TD-SCDMA base station comprises the following steps of: switching on the calibration switch when the downlink pilot frequency timeslot is finished; controlling a receiving timeslot through a register according to a transmission timeslot during data transmission, and storing calibration data received by a work antenna in the receiving timeslot into a memory; and closing the calibration switch when the uplink pilot frequency timeslot is closed. According to the application, the transmission timeslot and receiving timeslot of the calibration data can be regulated, remote interface is reduced, the anti-jamming capability during calibration can be enhanced, and the calibration effect is better.

Owner:DATANG MOBILE COMM EQUIP CO LTD

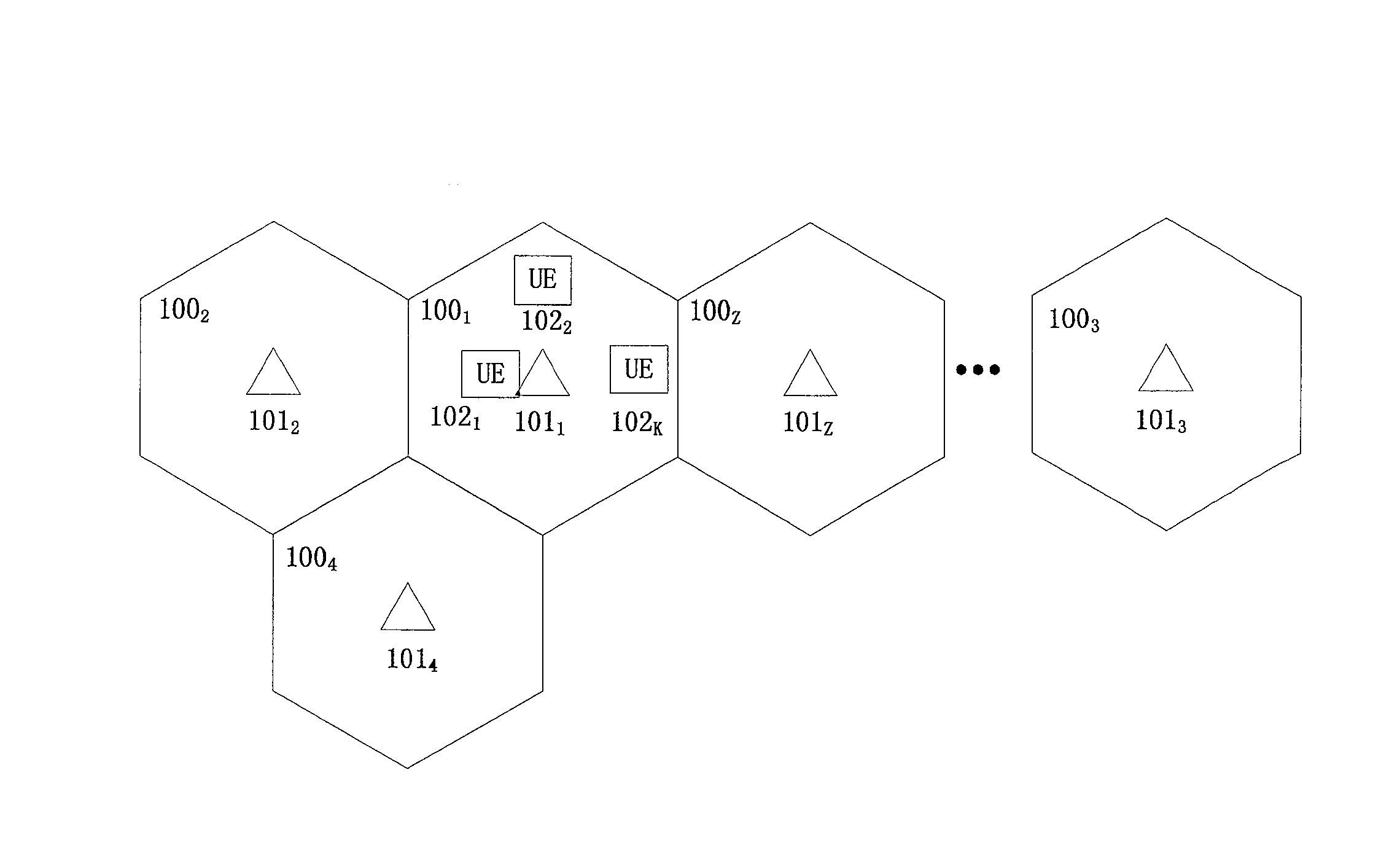

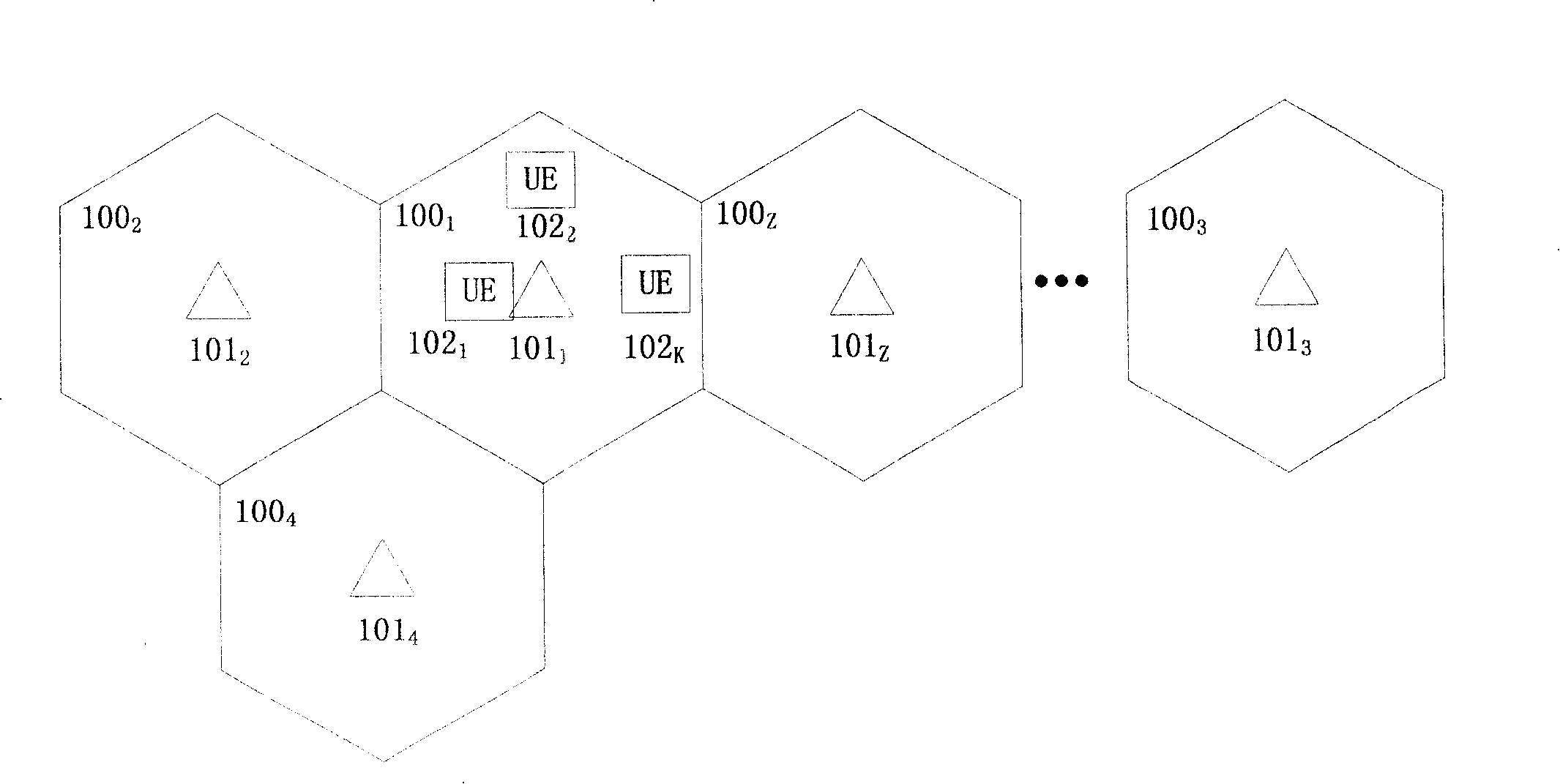

Method for reducing interference in CDMA system

InactiveCN1777053AFlexible configuration methodReduce distractionsTransmissionCode division multiple accessTerminal equipment

The method includes following steps: carrying out weighted spread spectrum for data to be transmitted from base station or subscriber terminal equipment; the method carried out weighting process for local code sequence when carrying out de-spread process for weighted spread signal received by base station or subscriber terminal equipment. Features are: flexible configuration of weighted sequence, high adaptability and reducing interference reliably.

Owner:KAIMING INFORMATION SCIENCE & TECHNOLOGY CO LTD

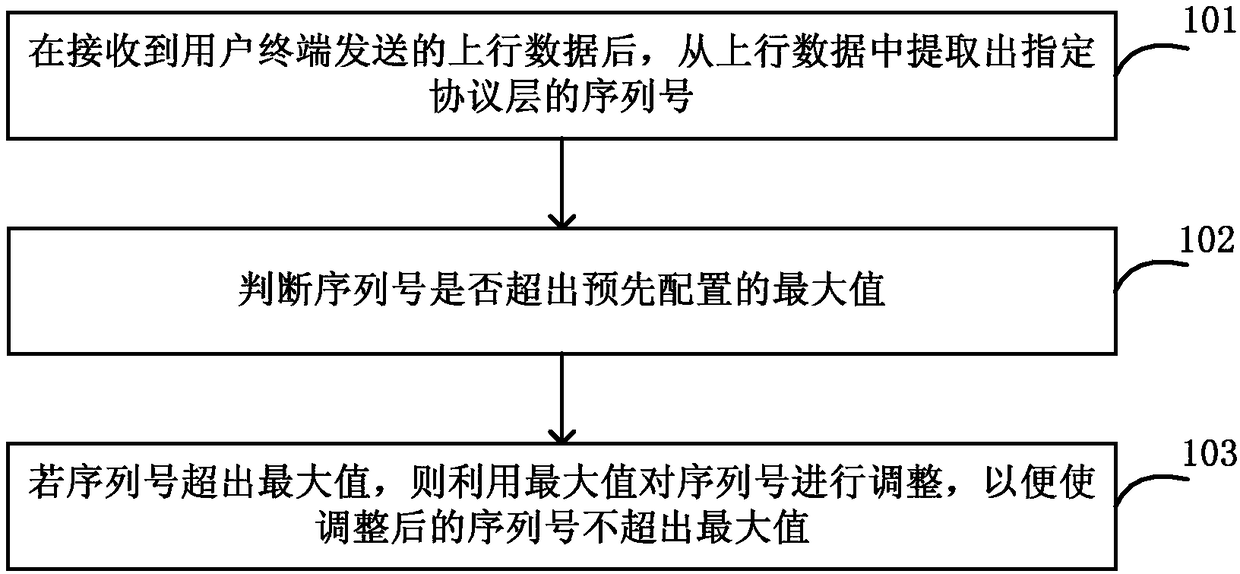

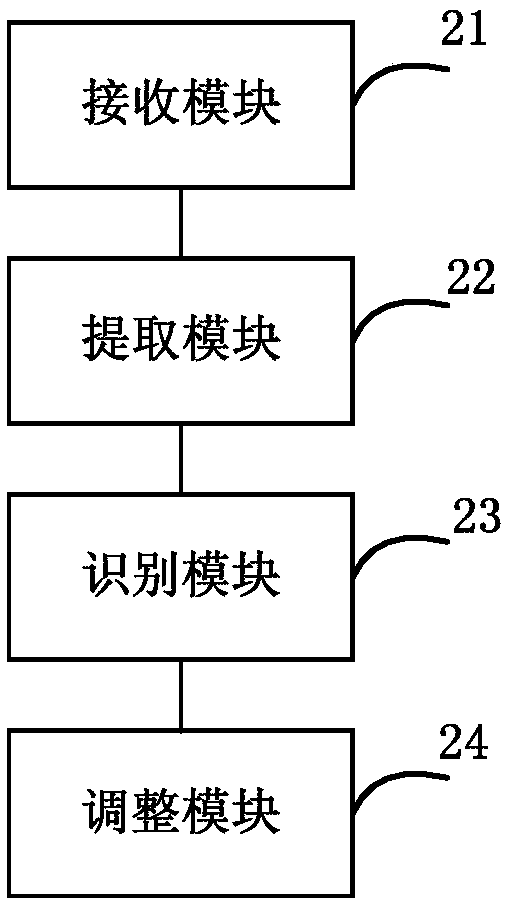

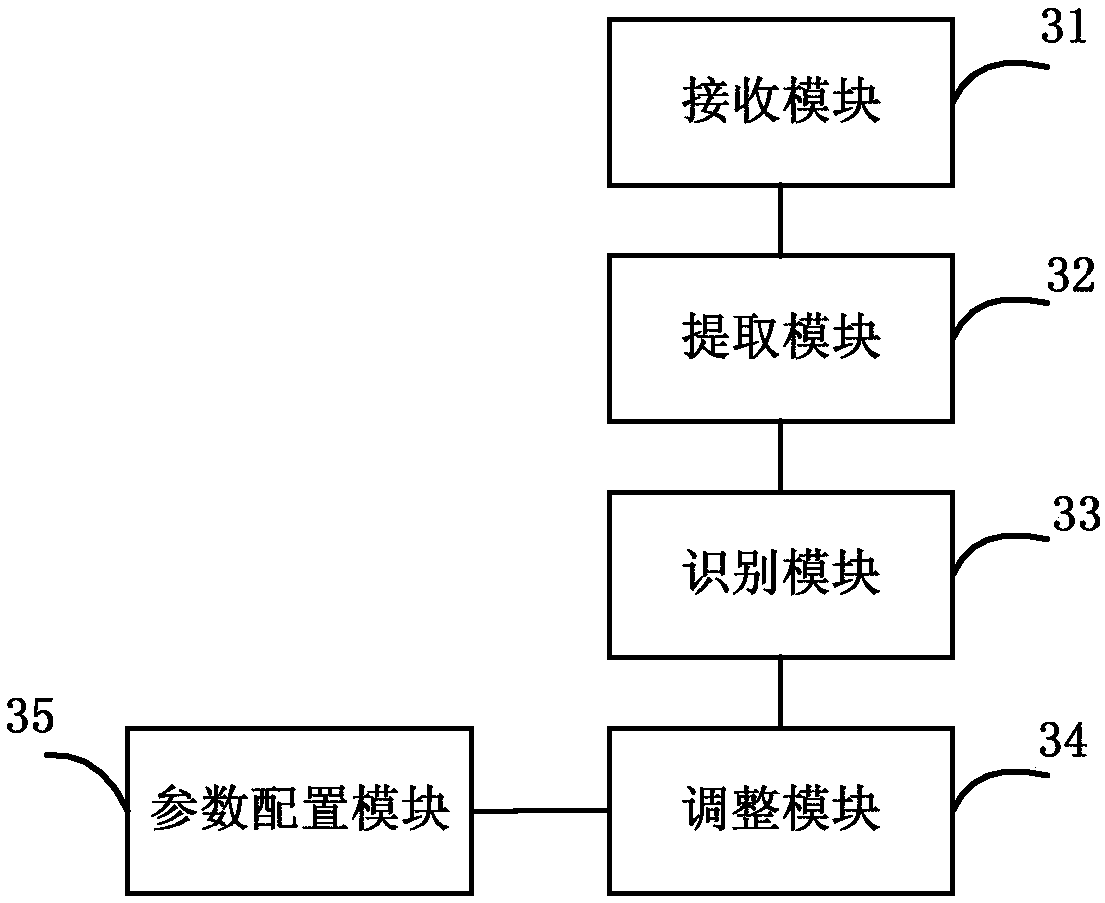

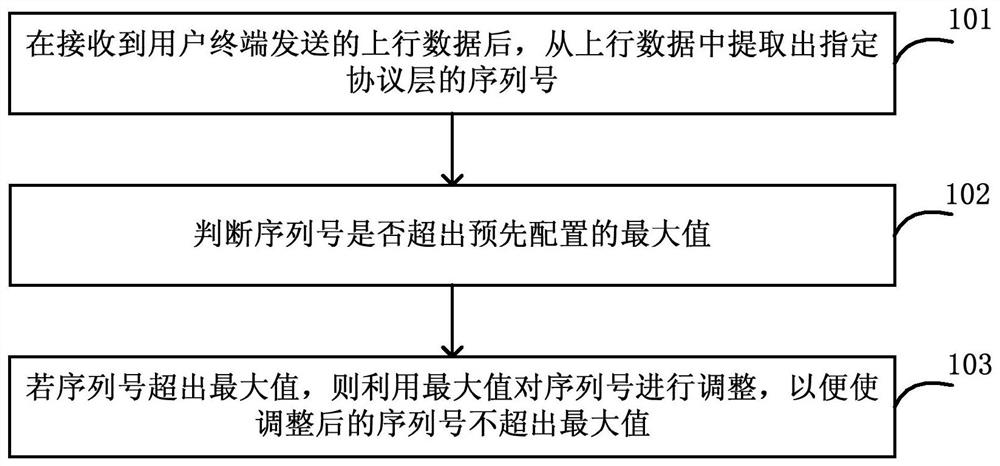

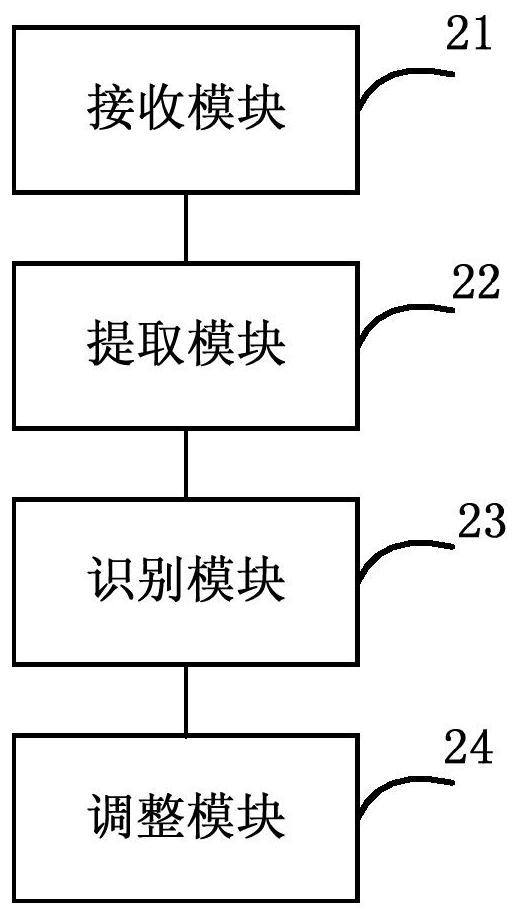

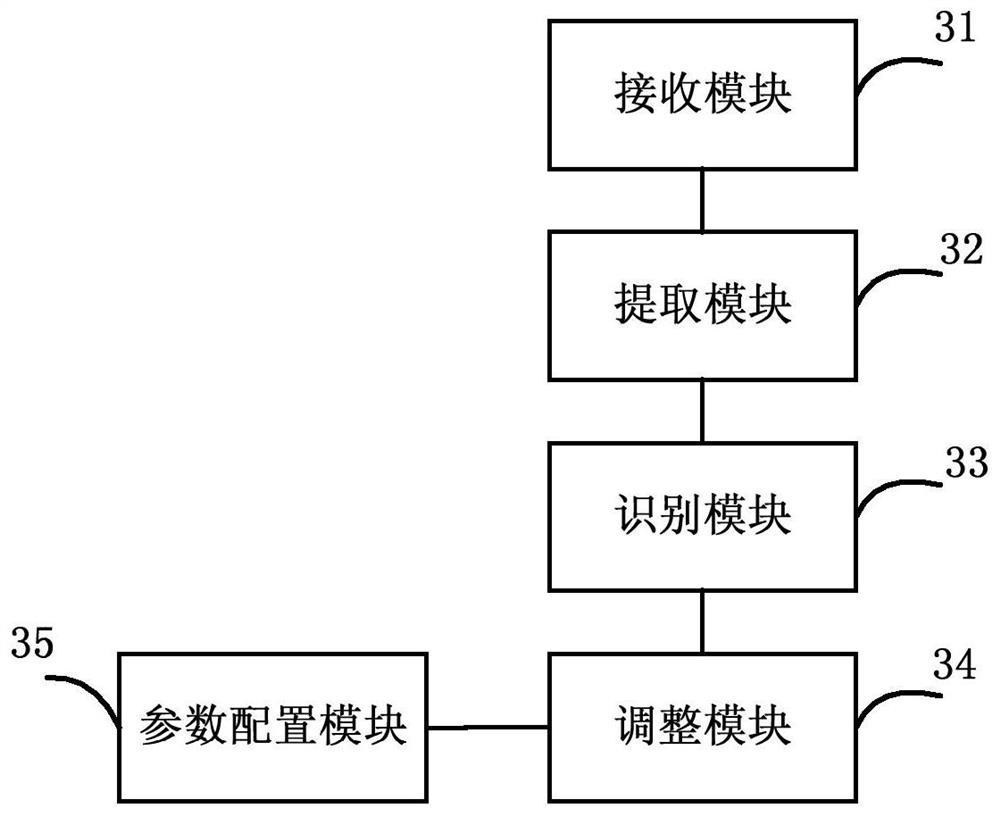

Serial number dynamic adjustment method and device, and base station

ActiveCN109429269AFlexible configuration methodReduce overheadNetwork traffic/resource managementWireless network protocolsNetwork overheadSerial code

The invention discloses a serial number dynamic adjustment method and device, and a base station, and relates to the field of communication. The serial number dynamic adjustment device receives uplinkdata sent by a user terminal, extracts a serial number of a specified protocol layer from the uplink data, judges whether the serial number exceeds a preconfigured maximum value or not, and adjusts the serial number by utilizing the maximum value and if the serial number exceeds the maximum value, so that the adjusted serial number does not exceed the maximum value. According to the serial numberdynamic adjustment method and device, the serial number is adjusted by utilizing the preconfigured maximum value, so that the adjusted serial number does not exceed the maximum value; and therefore,the problem of offline caused by inconsistent serial number configuration can be rapidly solved on the premise that the standard is not modified, so that a network configuration method is flexible, and the network overhead is reduced.

Owner:CHINA TELECOM CORP LTD

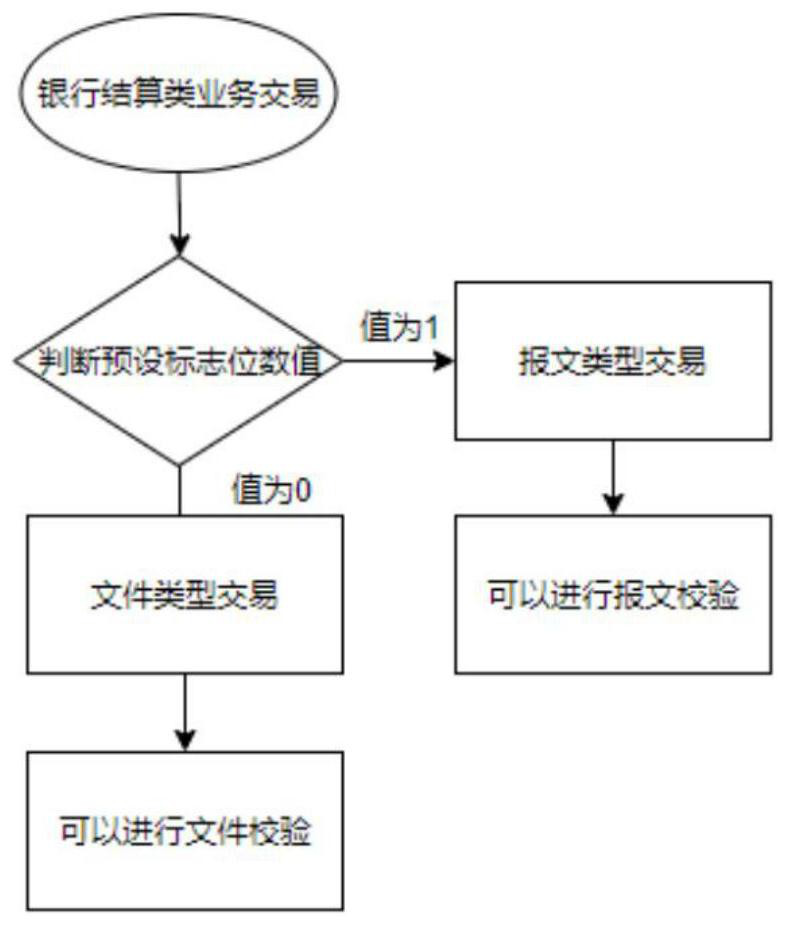

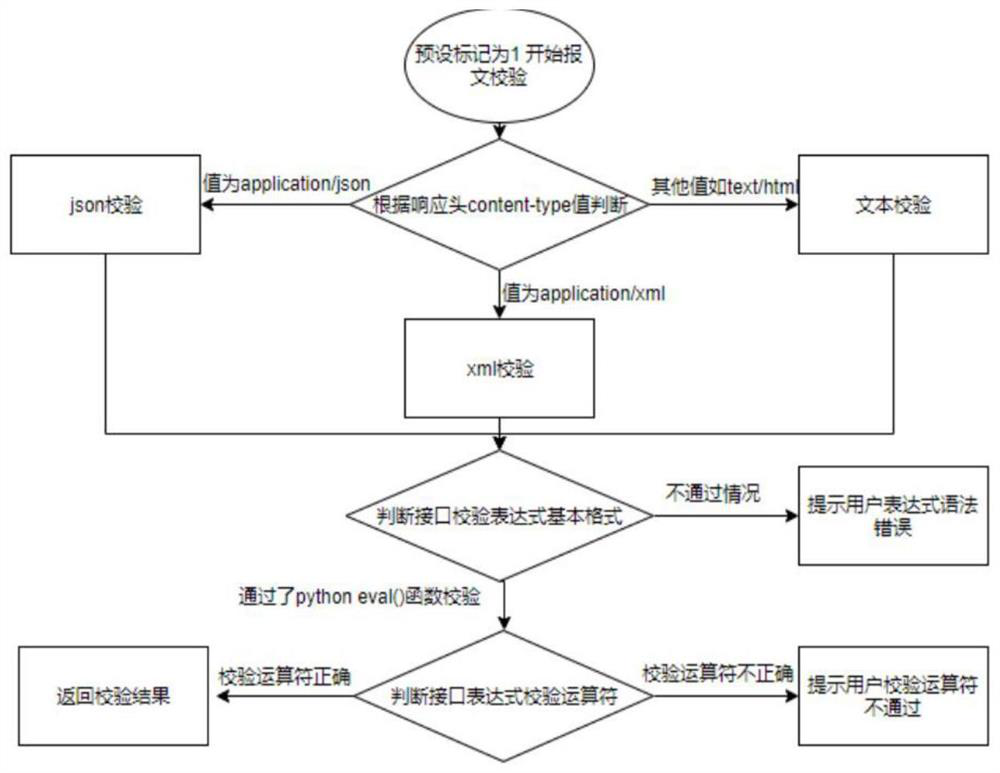

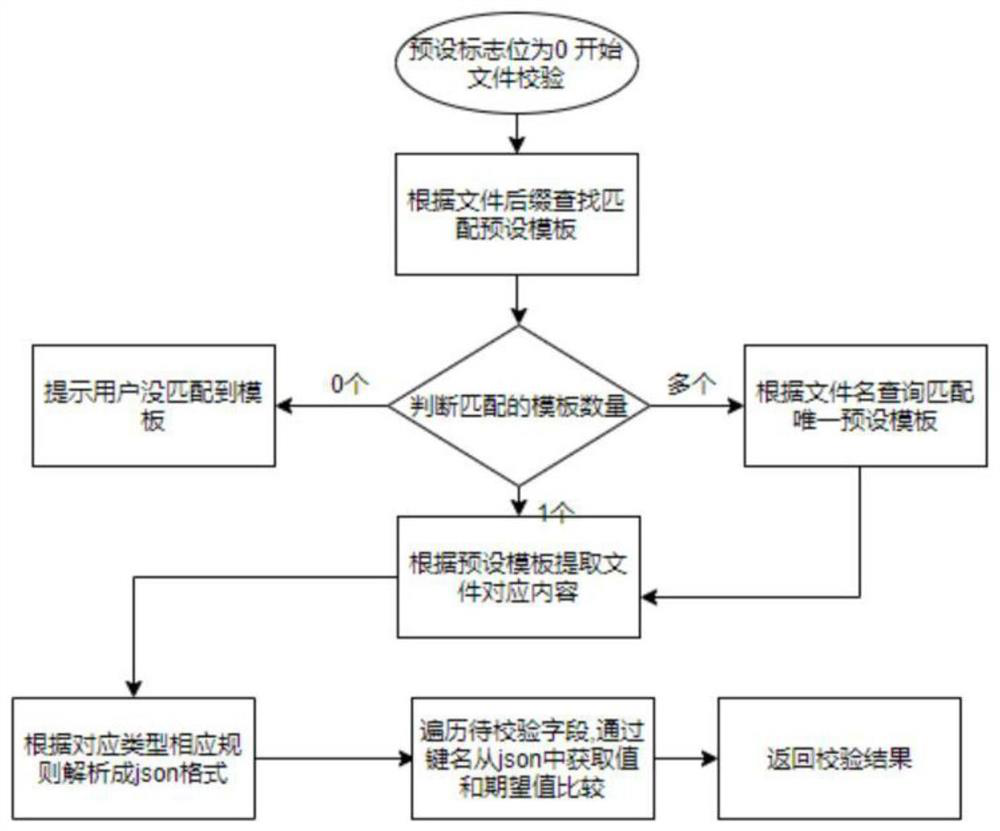

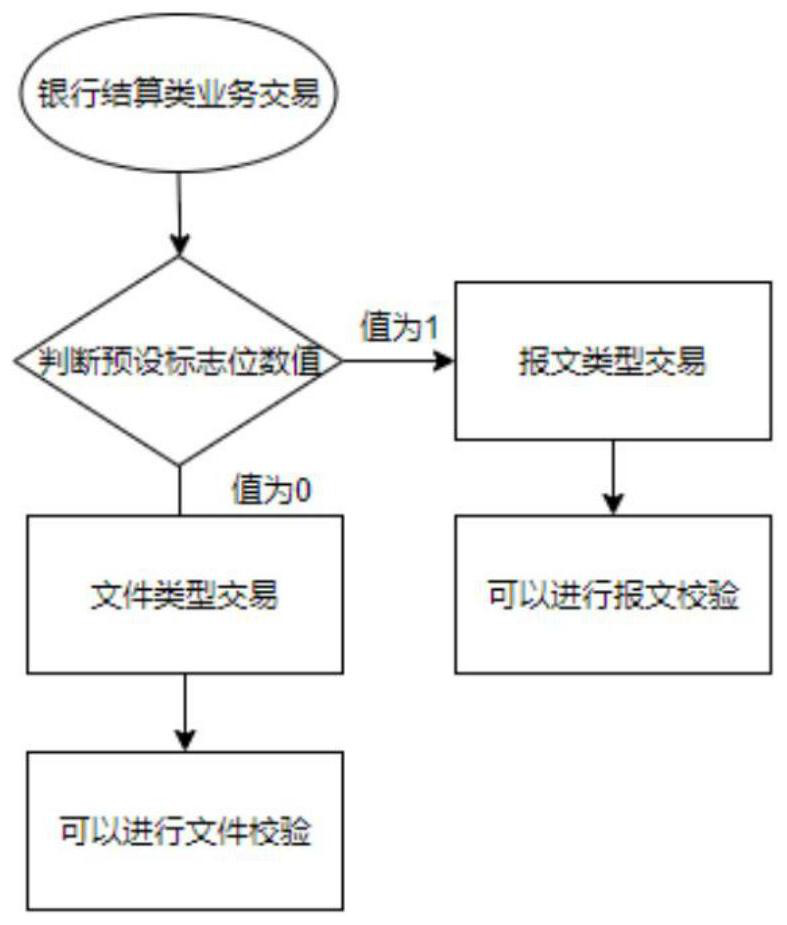

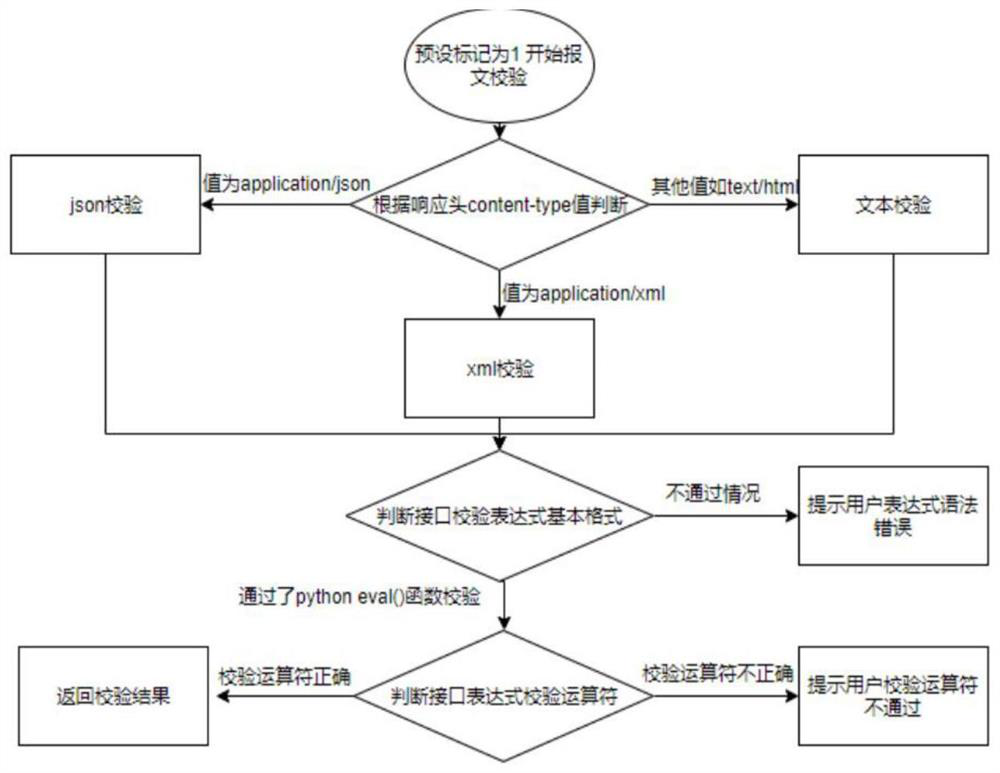

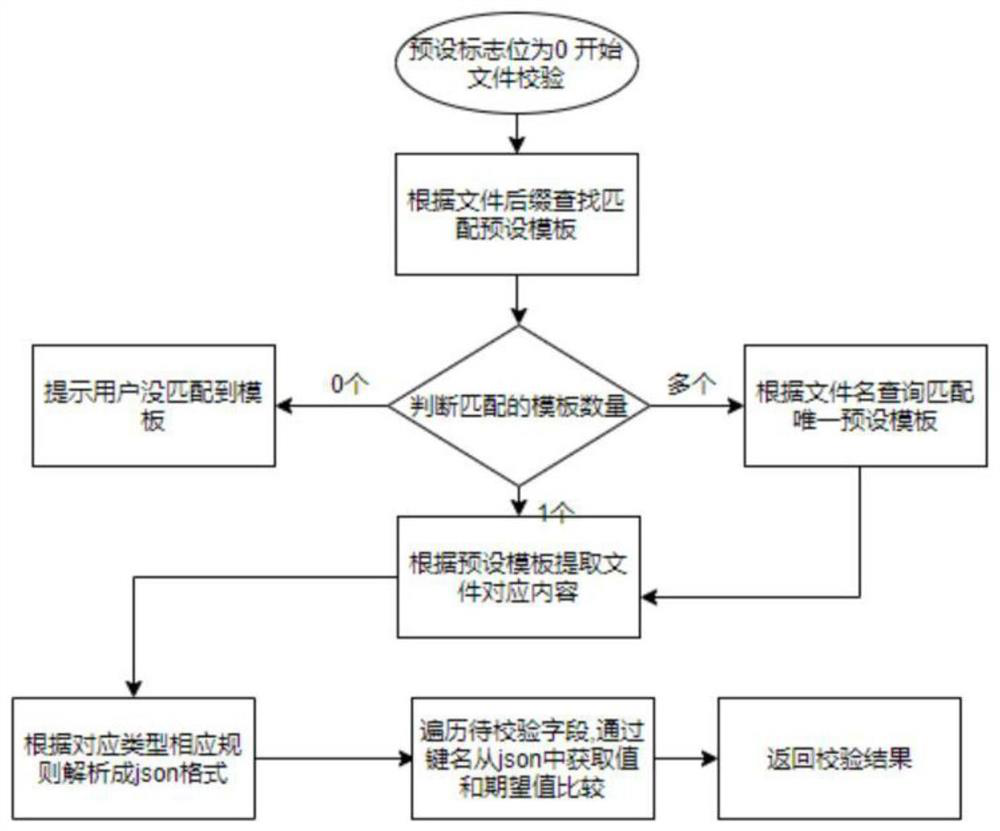

Automatic file verification method

ActiveCN111782517AFlexible configuration methodIncrease production capacitySoftware testing/debuggingTransmissionPersonalizationTheoretical computer science

The invention discloses an automatic file verification method. The method comprises the steps of firstly appointing an interface document protocol and determining a file format; secondly, making judgment according to a preset flag bit numerical value, and if the bank settlement transaction business belongs to a message type, entering message type verification; and if the bank settlement transaction business belongs to a file type, performing file type verification. According to the method, the file content can be automatically analyzed according to the file template field and converted into ageneral json format; whether a result meets expectation or not can be judged through comparison according to a preset check expression; and the file template can be configured in flexible and diversemethods, and personalized configuration can be carried out according to a file structure, a parameter sequence, a parameter length, a parameter number and specific values of parameters.

Owner:浙江保融科技股份有限公司

Method for reducing receiving interference in CDMA system

InactiveCN1777052AFlexible configuration methodReduce reception interferenceTransmissionCode division multiple accessEngineering

Based on distribution information of interference signal in signal sequence, the invention sets up sequence of weight value. Weighting process is carried out for signal sequence or sequence of local code to calculate relevant result. The normalization process is carried out for the said relevant result. The method takes full advantage of information of interference signal in signal sequence and sets up weighting value smartly so as to reach purpose of lowering received interference. Features of the method are simple and easy of implementation.

Owner:XUANPU INDUSTRY CO LTD

A continuous integration testing method and system

ActiveCN103577907BImprove reusabilityFlexible configuration methodSoftware testing/debuggingContinuous integrationTest script

This application provides a continuous integration testing method, which can be applied to various testing environments, has high reusability, and can reduce the workload and complexity of maintenance. The method includes: a continuous integration project simultaneously monitors the targets to be tested running in various real environments; The environment identification corresponding to the real environment; calling the test case by sending a test command, wherein the test command includes the environment identification; the test case configures a corresponding test environment according to the environment identification; in the test environment Execute the test script in the test case and get the final test result. The method described in this application has high reusability, and even if the target to be tested changes, only one CI project and one test case need to be maintained, which greatly increases the workload and complexity of continuous integration testing.

Owner:ADVANCED NEW TECH CO LTD

Method and device for sending and receiving calibration data of td-scdma base station

ActiveCN102647240BReduce far-end interferenceImprove anti-interference abilityTransmitters monitoringReceivers monitoringAnti jammingProcessor register

The application provides a method and device for transmitting and receiving calibration data of a TD-SCDMA (time division-synchronization code division multiple access) base station, and the method and the device are used for solving the problems that width phase consistency alarm is generated and a calibration effect is influenced during calibration in the prior art. The method for transmitting the calibration data of the TD-SCDMA base station comprises the following steps of: switching on a calibration switch when a downlink pilot frequency time slot is finished; controlling a transmission time slot through a register, and calibrating and transmitting calibration data of an antenna in the transmission timeslot reading register; and switching off the calibration switch when an uplink pilot frequency timeslot is finished. The method for receiving the calibration data of the TD-SCDMA base station comprises the following steps of: switching on the calibration switch when the downlink pilot frequency timeslot is finished; controlling a receiving timeslot through a register according to a transmission timeslot during data transmission, and storing calibration data received by a work antenna in the receiving timeslot into a memory; and closing the calibration switch when the uplink pilot frequency timeslot is closed. According to the application, the transmission timeslot and receiving timeslot of the calibration data can be regulated, remote interface is reduced, the anti-jamming capability during calibration can be enhanced, and the calibration effect is better.

Owner:DATANG MOBILE COMM EQUIP CO LTD

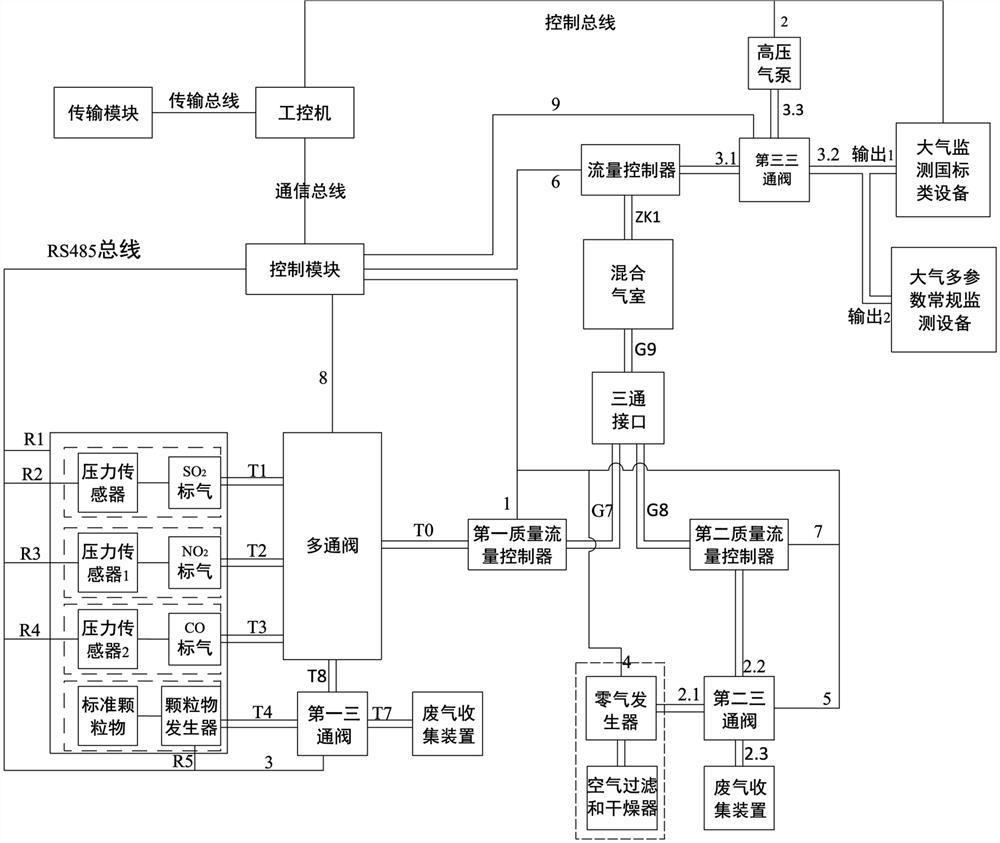

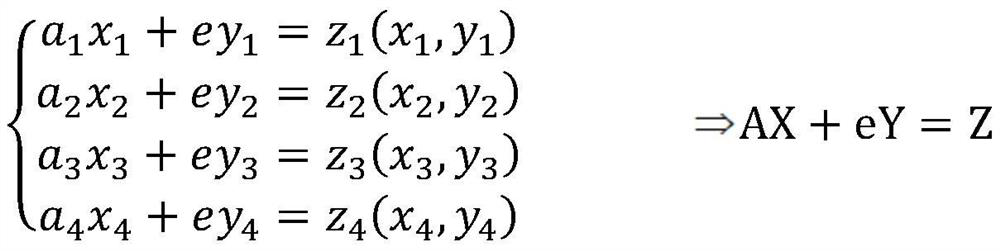

Quality control method suitable for remote quality control system of gas multi-parameter monitor

PendingCN112684108AReduce the effects of adsorptionFlexible configuration methodMaterial analysisControl engineeringQuality control system

The invention provides a quality control method suitable for a remote quality control system of gas multi-parameter monitor. The remote quality control system comprises a multi-way valve, a zero gas generator, a standard gas cabinet, a mixed gas chamber, a control module and an industrial personal computer; according to the quality control method, the control module adopts a PID algorithm, parameters in ax and ey are finely adjusted in the quality control process respectively, and when the parameters of a first mass flow controller are adjusted, ax'+ey=z is obtained, and when the parameters of a second mass flow controller are adjusted, ax+ey'=z is obtained until the output standard gas detected by atmospheric monitoring national standard equipment is z, the configuration parameter x' of the first mass flow controller and the configuration parameter y' of the second mass flow controller are obtained.

Owner:HENAN HANWEI ELECTRONICS

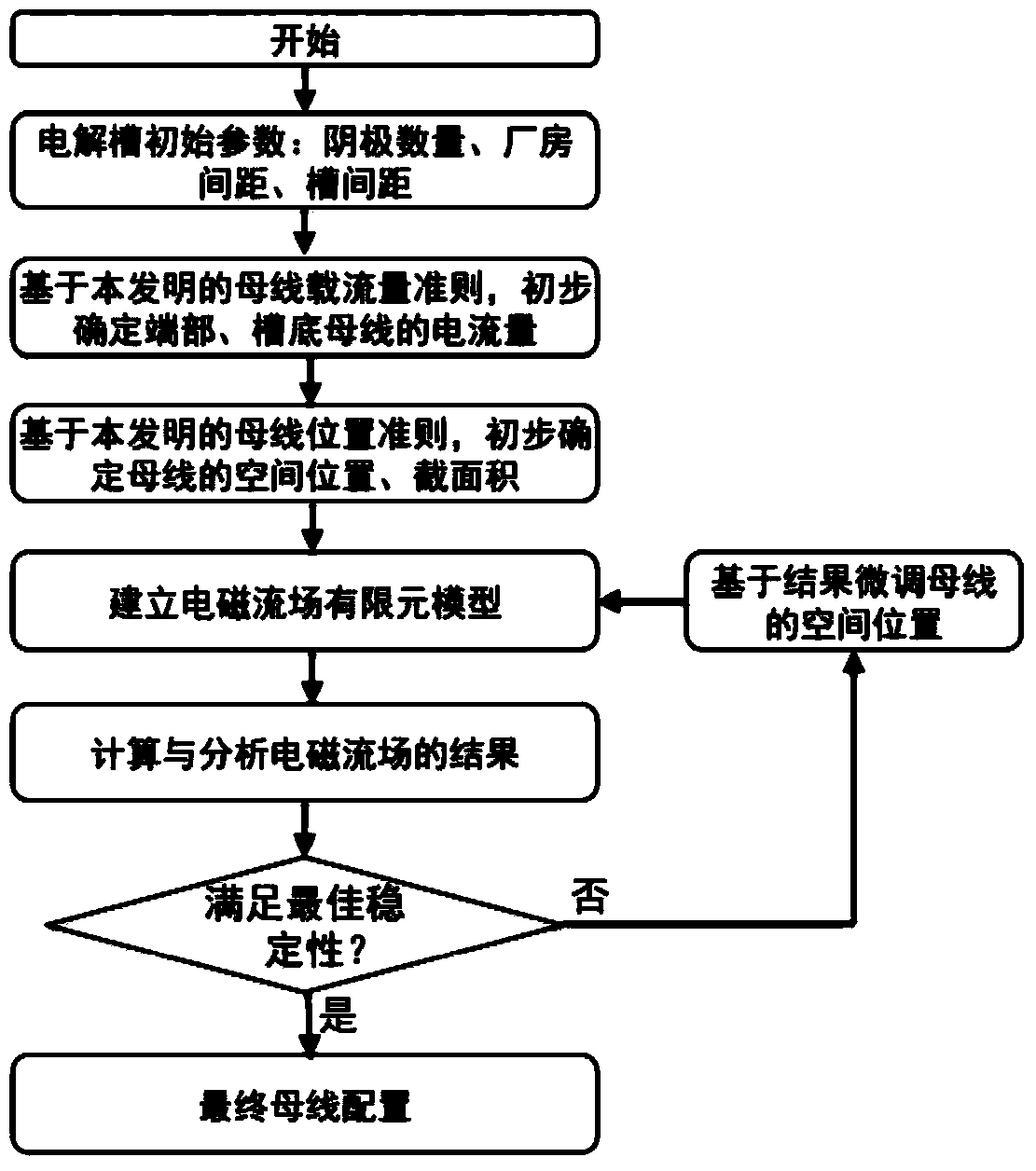

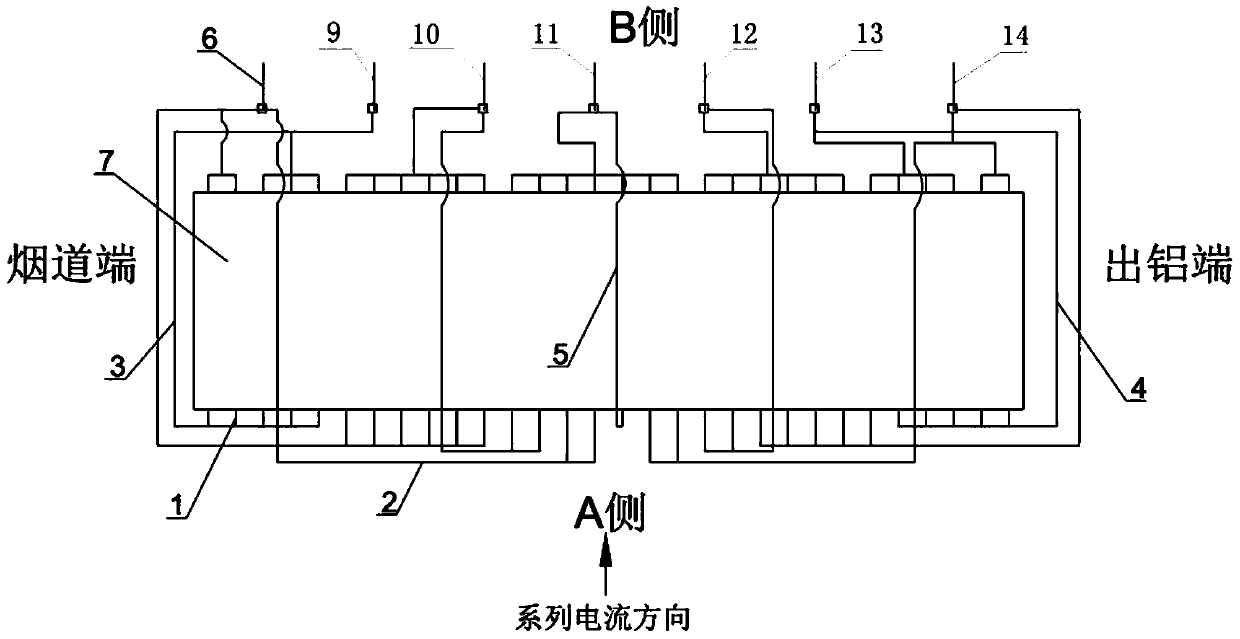

A cathode busbar configuration method for a super-large aluminum electrolytic cell

The invention discloses a cathode bus-bar configuration method of an ultra-large aluminum electrolytic cell. The total quantity of end compensating current is rated and cell bottom bus-bars adopt alternate compensation for offset, that is, the total current quantity flowing through a flue end is controlled within 100-150 kA, the current quantity of an aluminum discharge end is controlled within 80-120 kA, and the rest current on the A side bypasses the multiple cell bottom bus-bars. The routing manner of cathode bus-bars is designed accordingly, and specific parameters of cathode bus-bars of the electrolytic cell, independent compensation bus-bars, cell spacing and plant spacing are determined according to the calculated result of a magnetic fluid model. With the adoption of the cathode bus-bar configuration method of the ultra-large aluminum electrolytic cell, basic configuration of the bus-bars of the ultra-large aluminum electrolytic cell can be determined quickly, the vertical magnetic field and the horizontal magnetic field of melt can be effectively reduced, uniform distribution of the magnetic fields in the long axis direction of the cell is realized, stable operation of the aluminum electrolytic cell is realized, and the current efficiency of the electrolytic cell is improved.

Owner:CENT SOUTH UNIV

A method and device for transmitting relay link downlink feedback information

InactiveCN101925188BFlexible configuration methodAvoid lossError prevention/detection by using return channelWireless network protocolsInformation transmissionBase station

The invention discloses a method for transmitting downlink feedback information of a trunk link, which comprises the steps of: when the configuration of a relay subframe of a radio frame ensures that the downlink feedback information of the trunk link can not loaded according to a mode specified in a time division duplex long-term evolution protocol, determining a new loading mode of the downlink feedback information by a base station according to the relay subframe of the radio frame, informing information of the relay subframe of the radio frame or the new loading mode to a relay station; and loading and transmitting the downlink feedback information according to the new loading form. At the same time, the invention discloses a device realizing the method. The invention has the advantages of simple realization and practicality.

Owner:ZTE CORP

Blade matching and balancing method, blade and wind power generator

ActiveCN106121907BSolve technical problems with short service lifeFlexible configuration methodEngine fuctionsMachines/enginesWind drivenTip position

Owner:三一(韶山)风电设备有限公司

A digital closed-loop test system and method for stability control system

ActiveCN108919777BSimple designVerify validityProgramme controlElectric testing/monitoringDigital interfaceControl system

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

Device for reducing reception interference in CDMA system

ActiveCN100388648CFlexible configuration methodAdaptableCode division multiplexRadio transmission for post communicationCode division multiple accessEngineering

The invention provides a device to reduce receive interference in CDMA system. Wherein, according to distribution information of interfering signal in sequence, setting weight value sequence to weighting treat signal sequence or local code sequence and normalize the opposite calculation result. This invention is simple to realize, and makes full use of interference distribution information and flexible set to weight to achieve final purpose.

Owner:XUANPU INDUSTRY CO LTD

A method and system for configuring and invoking rules of custom forms

ActiveCN104239017BSimple configurationFlexible configuration methodCreation/generation of source codeProgramming languageExecution unit

The invention relates to a method and a system for configuring and calling the rules of a customized form. The system comprises a first configuring unit, a second configuring unit, an instruction response unit and an executing unit. The method includes the steps of S1, respectively saving the rule table, the rule step table and the rule condition table of the customized form; S2, configuring the correlation of the rule step and the step condition of each rule according to the executing logic of each rule and saving the correlation in a correlation table; S3, when the executing instruction of the customized form is received, acquiring the information of all the rules contained by customized form; S4, executing all the rules of the customized form according to an executing order. By the method and the system, the rules in the customized form can be fast simply and flexibly configured, the step for calling the configured rules in the customized form is simplified, and system operation efficiency is increased.

Owner:SHENZHEN LAN YOU TECH

Serial number dynamic adjustment method, device and base station

ActiveCN109429269BFlexible configuration methodReduce overheadNetwork traffic/resource managementWireless network protocolsAlgorithmNetwork overhead

The invention discloses a serial number dynamic adjustment method, device and base station, and relates to the communication field. Among them, after receiving the uplink data sent by the user terminal, the serial number dynamic adjustment device extracts the serial number of the specified protocol layer from the uplink data, and judges whether the serial number exceeds the pre-configured maximum value. If the serial number exceeds the maximum value, then use The maximum value adjusts the sequence number so that the adjusted sequence number does not exceed the maximum value. The present invention adjusts the serial number by using the pre-configured maximum value so that the adjusted serial number does not exceed the maximum value, thereby quickly solving the disconnection problem caused by inconsistent serial number configuration without modifying the standard , making the network configuration method flexible and reducing network overhead.

Owner:CHINA TELECOM CORP LTD

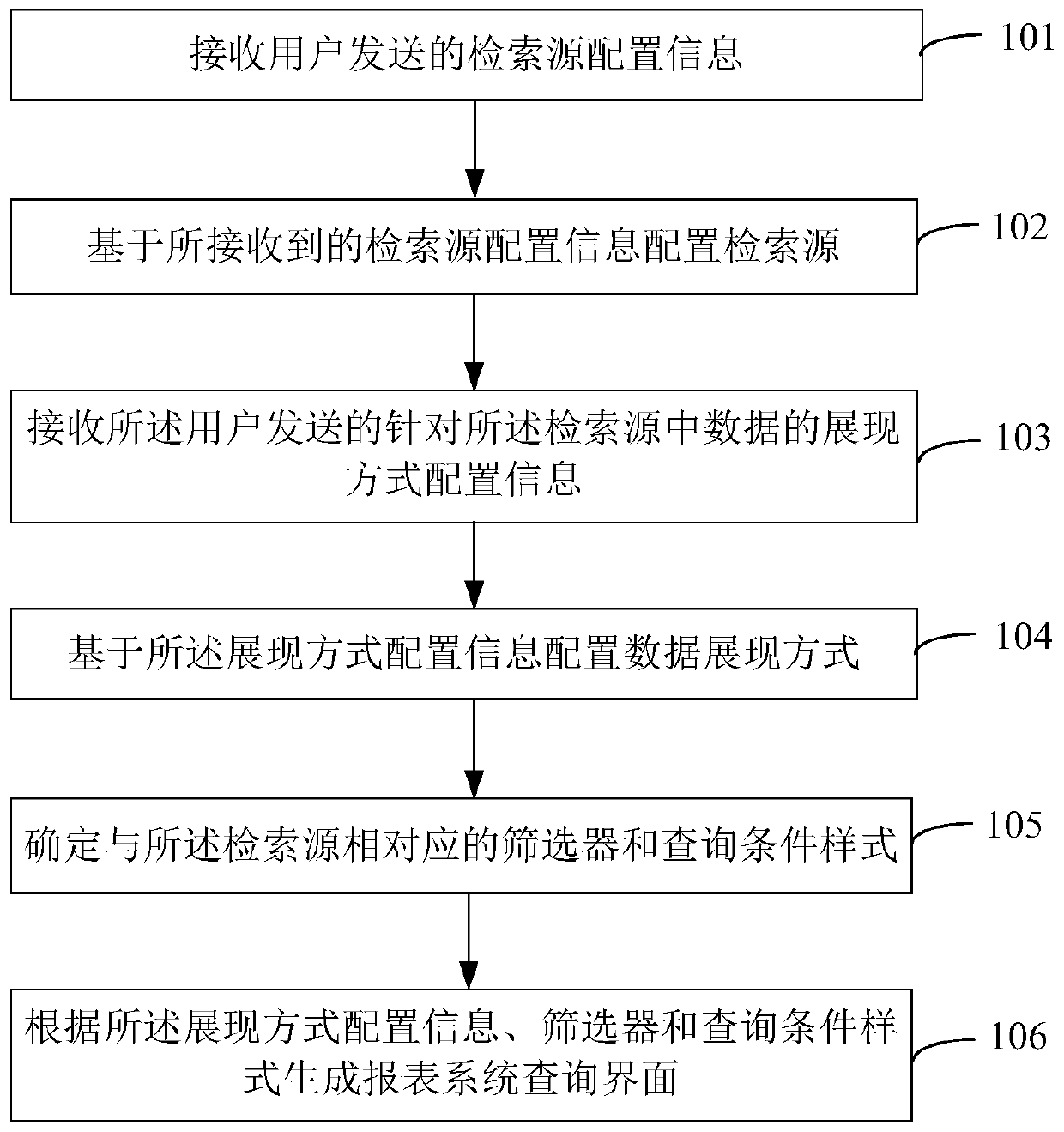

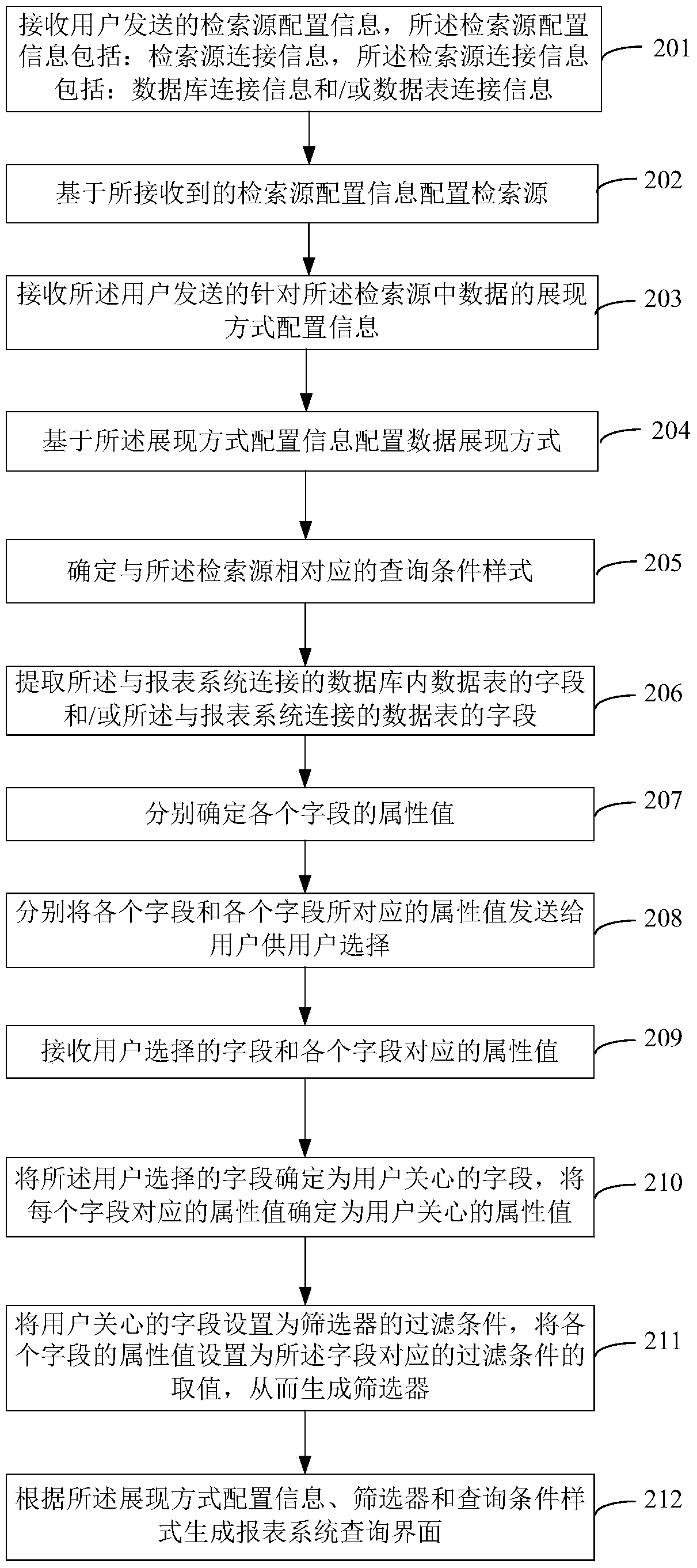

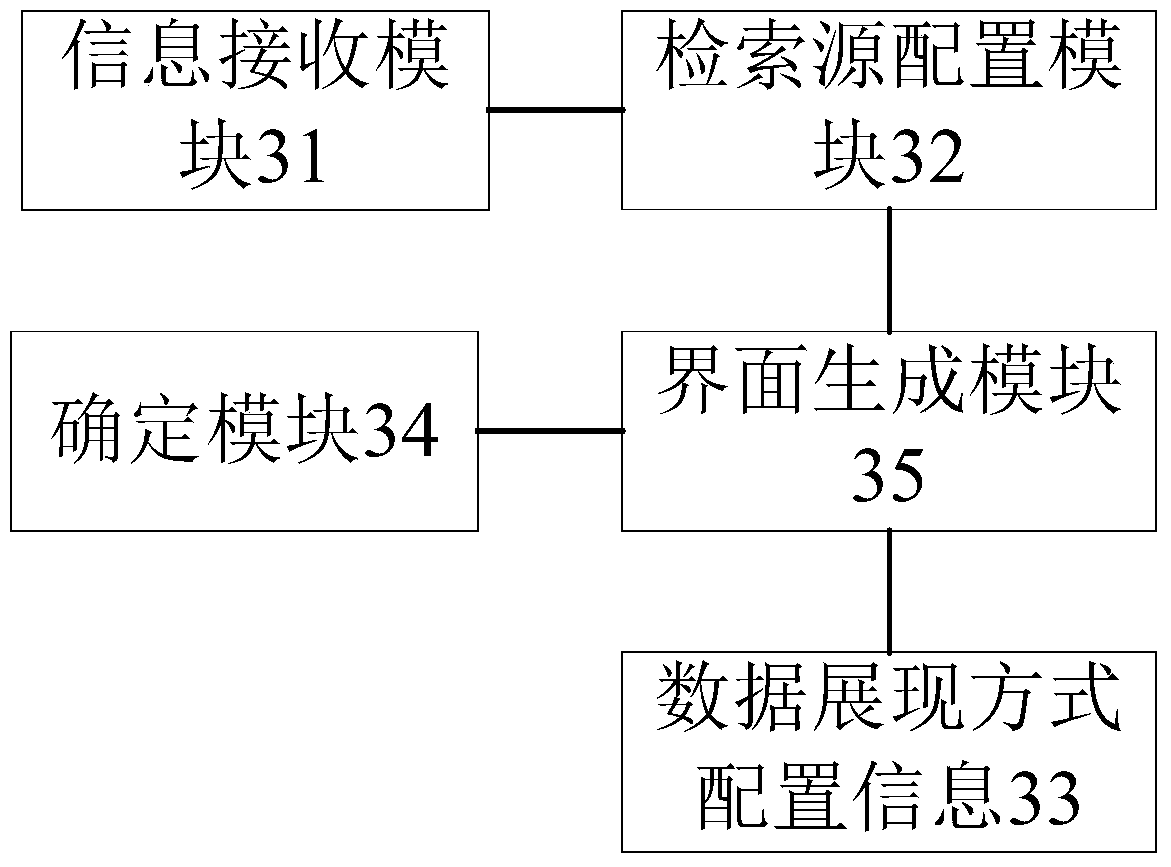

A report system configuration method and device

ActiveCN106776644BGood continuityMeet usage habitsDatabase management systemsSpecial data processing applicationsSystem configurationData mining

The embodiment of the invention provides a report system configuration method and device. The method comprises the steps that the report system receives retrieval source configuration information sent by a user; a retrieval source is configured based on the received retrieval source configuration information; presentation mode configuration information concerning data in the retrieval source sent by the user is received; a data presentation mode is configured based on the presentation mode configuration information; a filter and a query condition pattern corresponding to the retrieval source are determined; according to the presentation mode configuration information, the filter and the query condition pattern, a report system query interface is generated. The report system configuration method is flexible, and simple and convenient to operate, and the report system generated based on the method can meet the requirements of users in any field and has strong continuity.

Owner:DATANG SOFTWARE TECH

An automatic file verification method

ActiveCN111782517BFlexible configuration methodIncrease production capacitySoftware testing/debuggingTransmissionPersonalizationSoftware engineering

The invention discloses an automatic file verification method. The present invention first stipulates the interface document protocol, and determines the file format; secondly, judges according to the preset flag value, if the bank settlement transaction belongs to the message type, enter the message type verification; if the bank settlement transaction belongs to the file type , enter to check the file type. The present invention can automatically parse the file content according to the file template field, and convert it into a common json format. Quickly check whether the comparison result meets expectations according to the preset verification expression. The configuration method of the file template can be set flexibly and diversely, and can be personalized according to the file structure, parameter sequence, parameter length, parameter number, and parameter specific value.

Owner:浙江保融科技股份有限公司

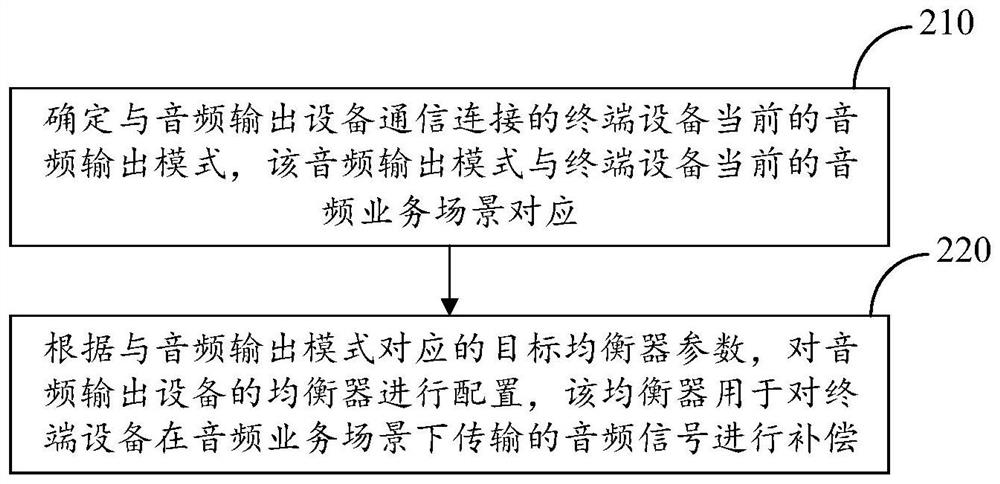

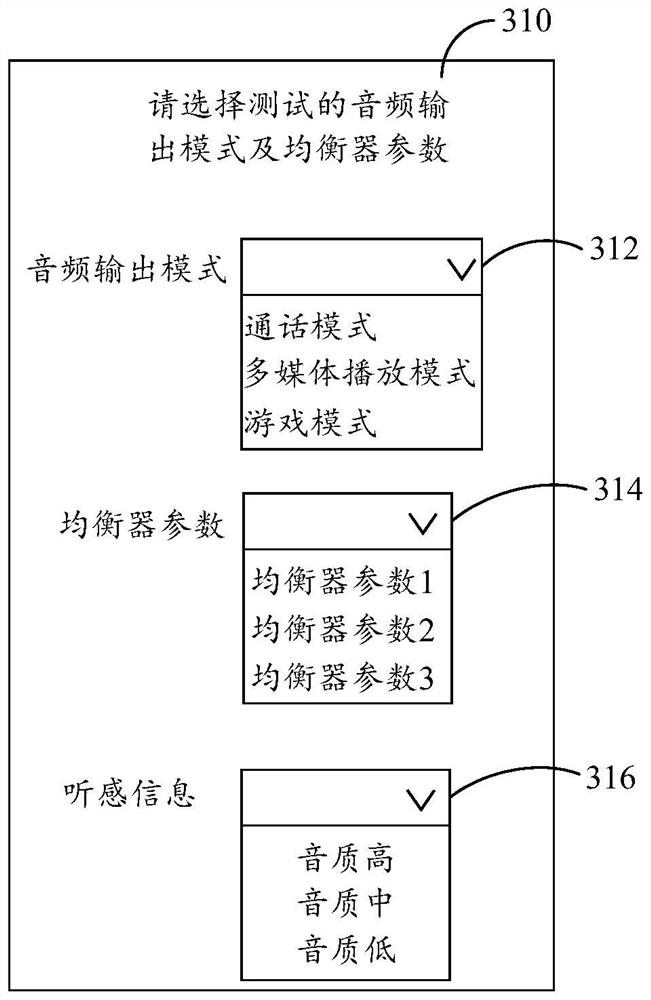

Parameter configuration method and device, electronic equipment and storage medium

PendingCN114302295AFlexible configurationFlexible configuration methodLoudspeaker signals distributionTerminal equipmentOutput device

The embodiment of the invention discloses a parameter configuration method and device, electronic equipment and a storage medium. The method can be applied to audio output equipment, and comprises the steps that a current audio output mode of terminal equipment in communication connection with the audio output equipment is determined, and the audio output mode corresponds to a current audio service scene of the terminal equipment; and according to a target equalizer parameter corresponding to the audio output mode, an equalizer of the audio output device is configured, and the equalizer is used for compensating an audio signal transmitted by the terminal device in the audio service scene. According to the parameter configuration method and device, the electronic equipment, the storage medium and the audio output equipment, the equalizer parameters can be adaptively configured based on the current audio output mode of the terminal equipment, the output effect of audio signals is improved, and the mode of configuring the equalizer parameters is more flexible.

Owner:REALME MOBILE TELECOMM SHENZHEN CO LTD

Method for reducing reception interference in CDMA system

ActiveCN100586035CFlexible configuration methodAdaptableCode division multiplexTransmissionCode division multiple accessElectrical and Electronics engineering

The invention provides a device to reduce receive interference in CDMA system. Wherein, according to distribution information of interfering signal in sequence, setting weight value sequence to weighting treat signal sequence or local code sequence and normalize the opposite calculation result. This invention is simple to realize, and makes full use of interference distribution information and flexible set to weight to achieve final purpose.

Owner:XUANPU INDUSTRY CO LTD

Device for carrying out weighted treatment on signal sequence using weight sequence

ActiveCN100388649CFlexible configuration methodAdaptableCode division multiplexRadio transmission for post communicationWeight valueInterference distribution

The invention provides a device to weighting treat signal sequence by weight value sequence. Wherein, according to distribution information of interfering signal in sequence, setting weight value sequence to weighting treat signal sequence or local code sequence and normalize the opposite calculation result. This invention is simple to realize, and makes full use of interference distribution information and flexible set to weight to achieve final purpose.

Owner:XUANPU INDUSTRY CO LTD

The method of configuring the map style through lua

ActiveCN106373176BFlexible rendering style configuration methodFlexible configuration methodTexturing/coloring3D-image renderingGeometric elementComputer science

The present invention provides a method of configuring a map style through the Lua. According to the method, a map is rendered in a hierarchical manner; each map layer is symbolization for geometric elements; and the same geometric element has different rendering styles in different layers. The method of the invention is a flexible and convenient indoor map rendering style configuration method. A user can set the style of an entire map layer, a single geometric element or a class of geometric elements through a Lua scripting configuration file and can quickly and intuitively view a display effect.

Owner:上海图聚智能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com