Quality control method suitable for remote quality control system of gas multi-parameter monitor

A quality control method and monitoring instrument technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve problems such as single configuration, intensified adsorption, and inability to guarantee the accuracy of gas concentration, etc., to achieve convenient use, operation and maintenance, and configuration Flexible approach, less impactful effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

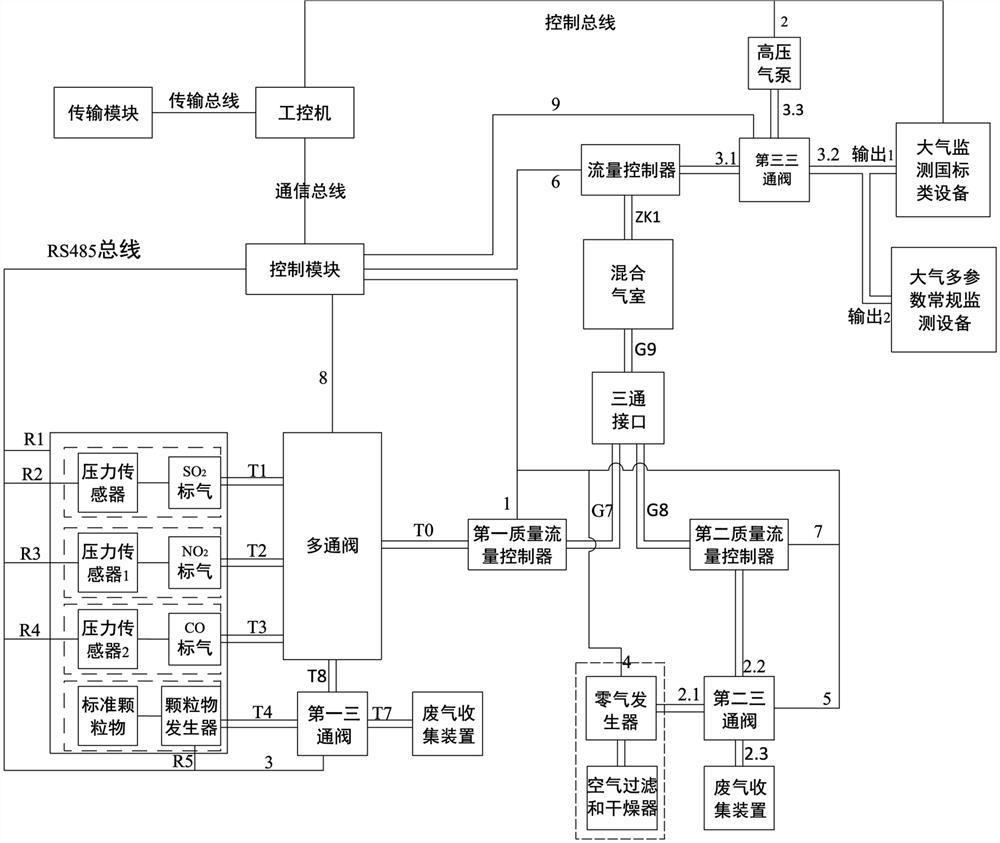

[0030] like figure 1 As shown, the remote quality control system includes a multi-way valve, a zero gas generator, a standard gas cabinet, a mixed gas chamber, a control module, an industrial computer, and national standard equipment for atmospheric monitoring;

[0031] The calibration gas cabinet has built-in calibration gas cylinders and standard particulate matter cylinders of various gas types, and the calibration gas cylinders are respectively equipped with pressure sensors, and each pressure sensor is connected to the control module for monitoring the gas pressure value in the calibration gas cylinders;

[0032] The standard gas cylinders are respectively connected to different input ports of the multi-way valve, and the standard particle bottle is connected to the input port of the multi-way valve through the particle generator and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com