Cycling footwear structure with a composite sole and a method to realise such structure

a composite sole and footwear technology, applied in the direction of uppers, bootlegs, stiffners, etc., can solve the problems of abandoning certain innovative technical solutions for producing high-level products, and achieve the effects of reducing production equipment costs, increasing power generated by athletes, and high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

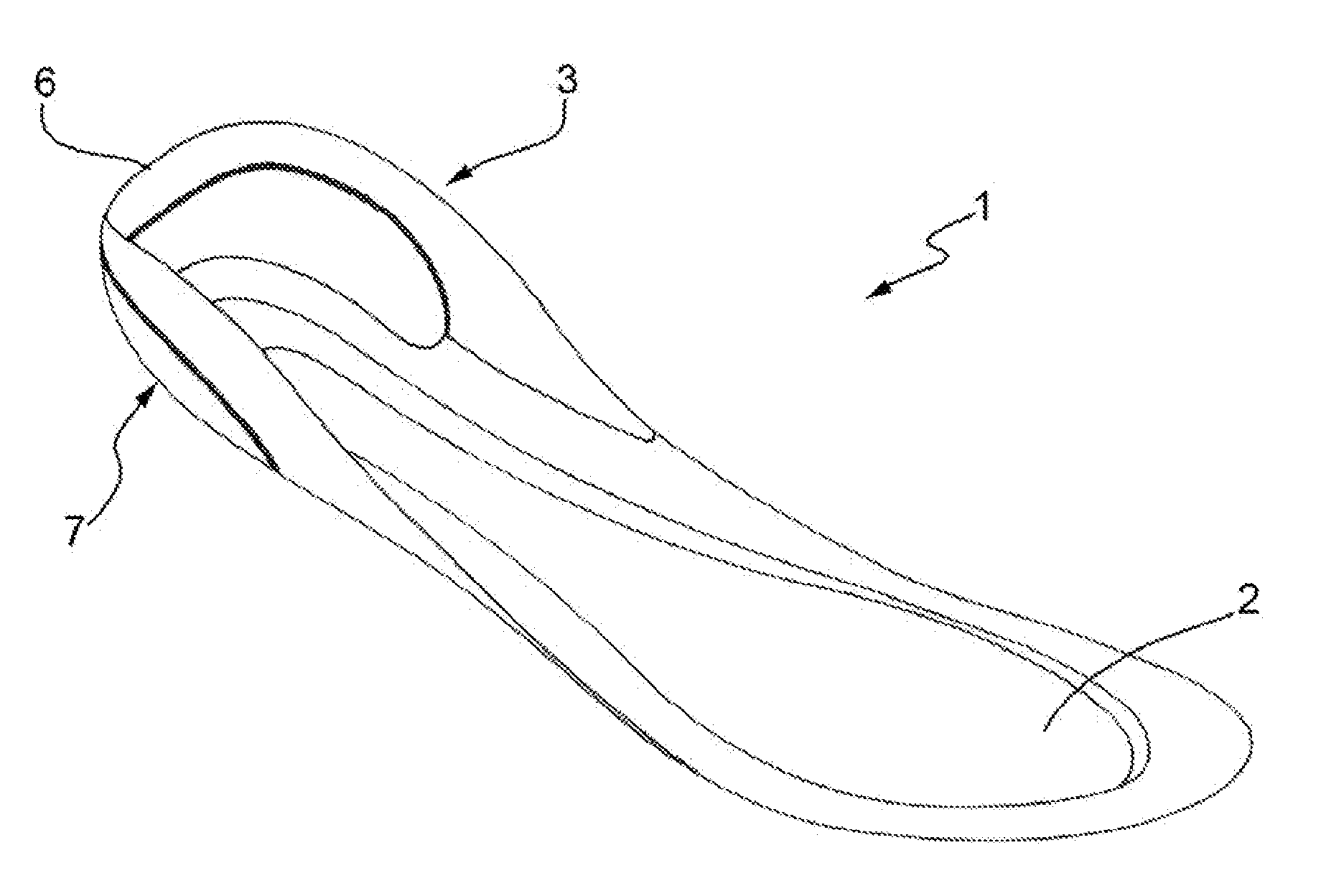

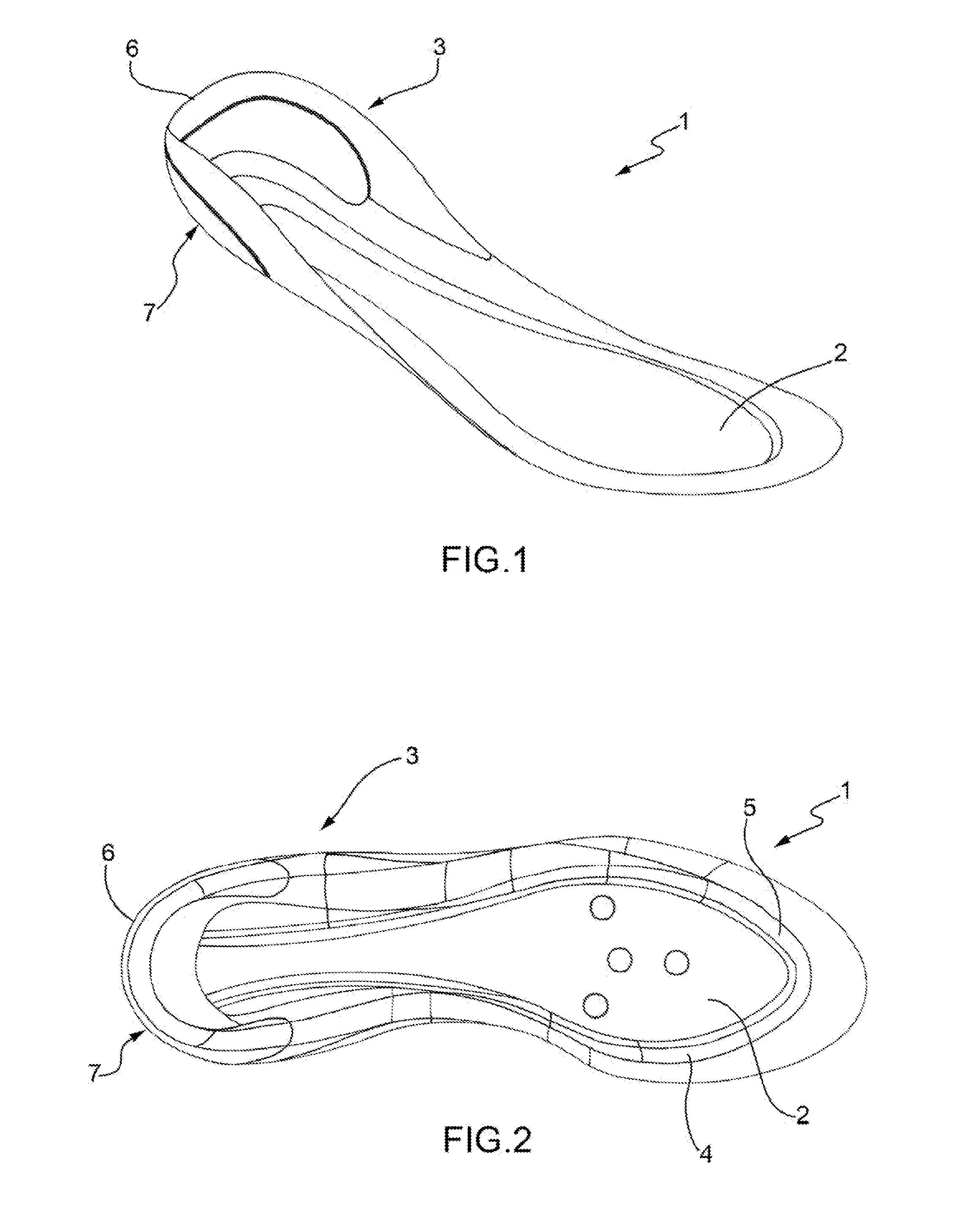

[0020]With reference to the figures, 1 indicates a composite sole of a cycling footwear structure (not illustrated) according to the present invention.

[0021]Said composite sole 1 is made up of at least two parts: the first part that comprises a base sole 2 and the second part made up of at least one stiffening element 3.

[0022]The stiffening element 3 is substantially annular-shaped with a variable section passing from its front part 5 to its back part 6.

[0023]The base sole 2, as visible in FIG. 2, has, substantially along at least part of its perimeter, a recess 4, in which the front part 5 of the stiffening element 3 is positioned.

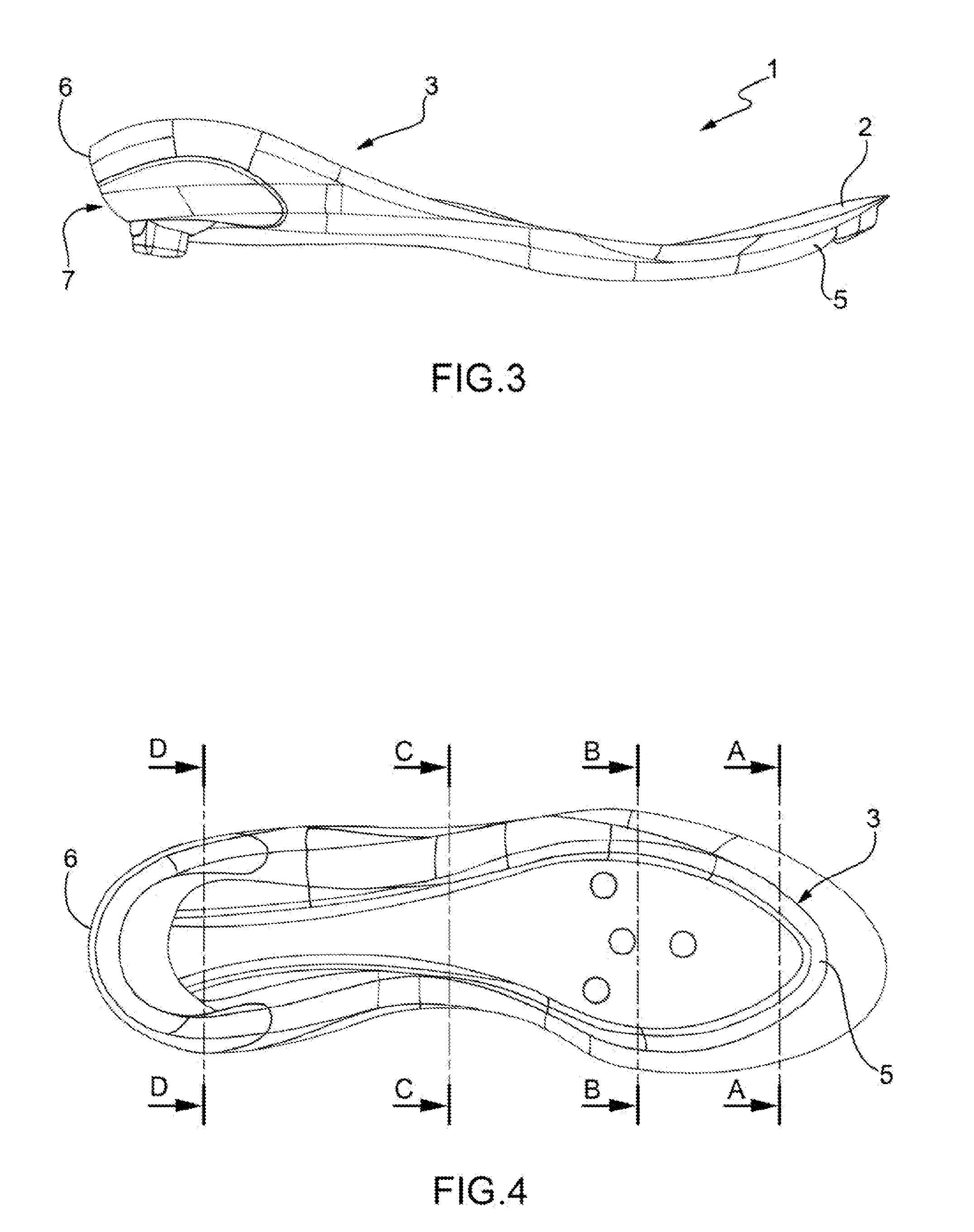

[0024]As visible in FIGS. 4-8, the stiffening element 3 has, in its front part 5, a section A′, taken along the axis A-A of FIG. 4. Such a section A′ is substantially two-dimensional, with the two dimensions being substantially equal to one another.

[0025]Section A′ can also have other configurations and / or geometries that are different from the two-dimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com