Arched Bra wire

a bra wire and bra technology, applied in the field of female underwear and swimsuits, can solve the problems of mainly discomfort caused by wearing the bra, no significant improvement, and unsatisfactory wearing comfort, and achieve the effect of keeping the comfort degree in wearing, significant progress, and comfortable wearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

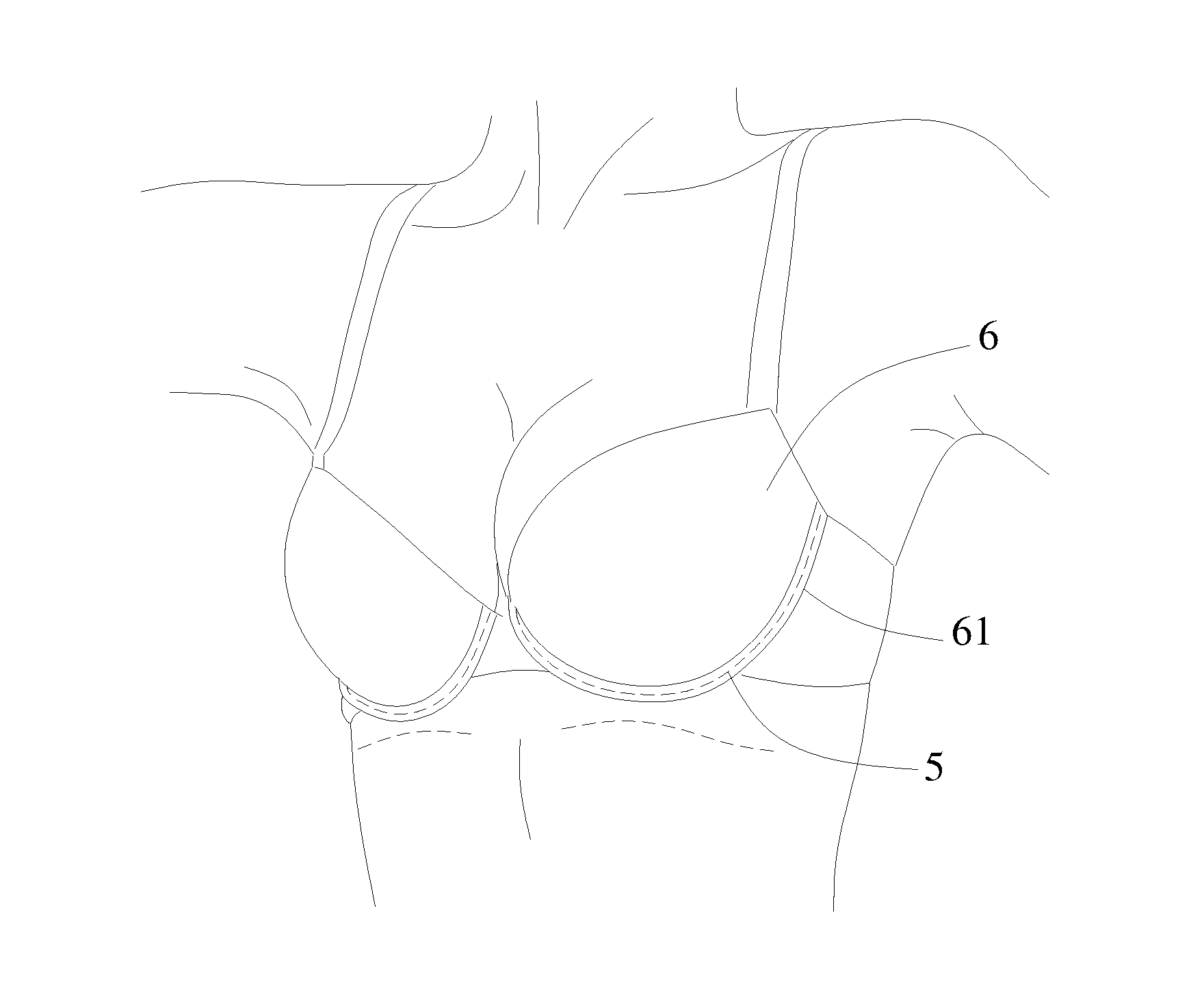

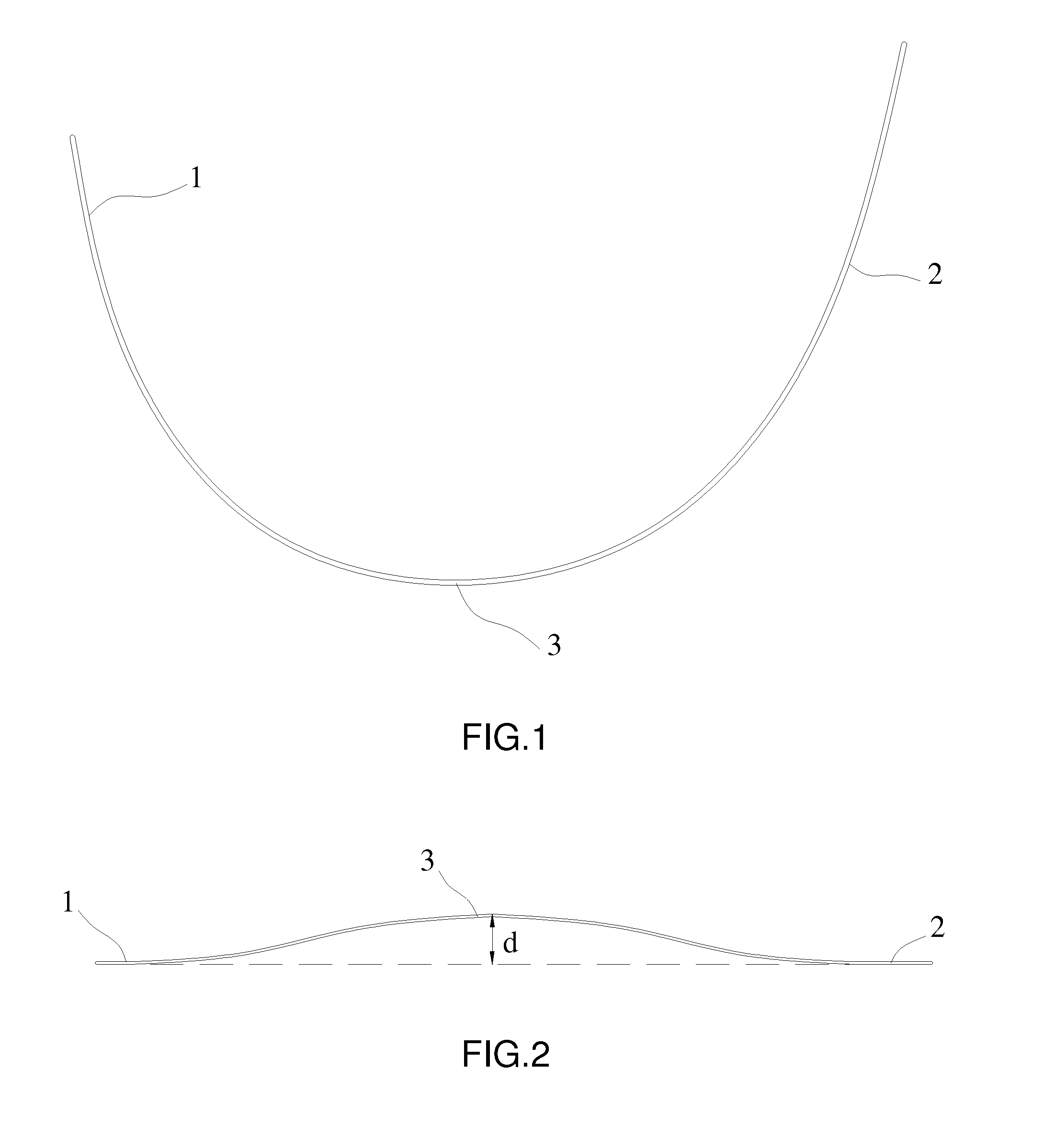

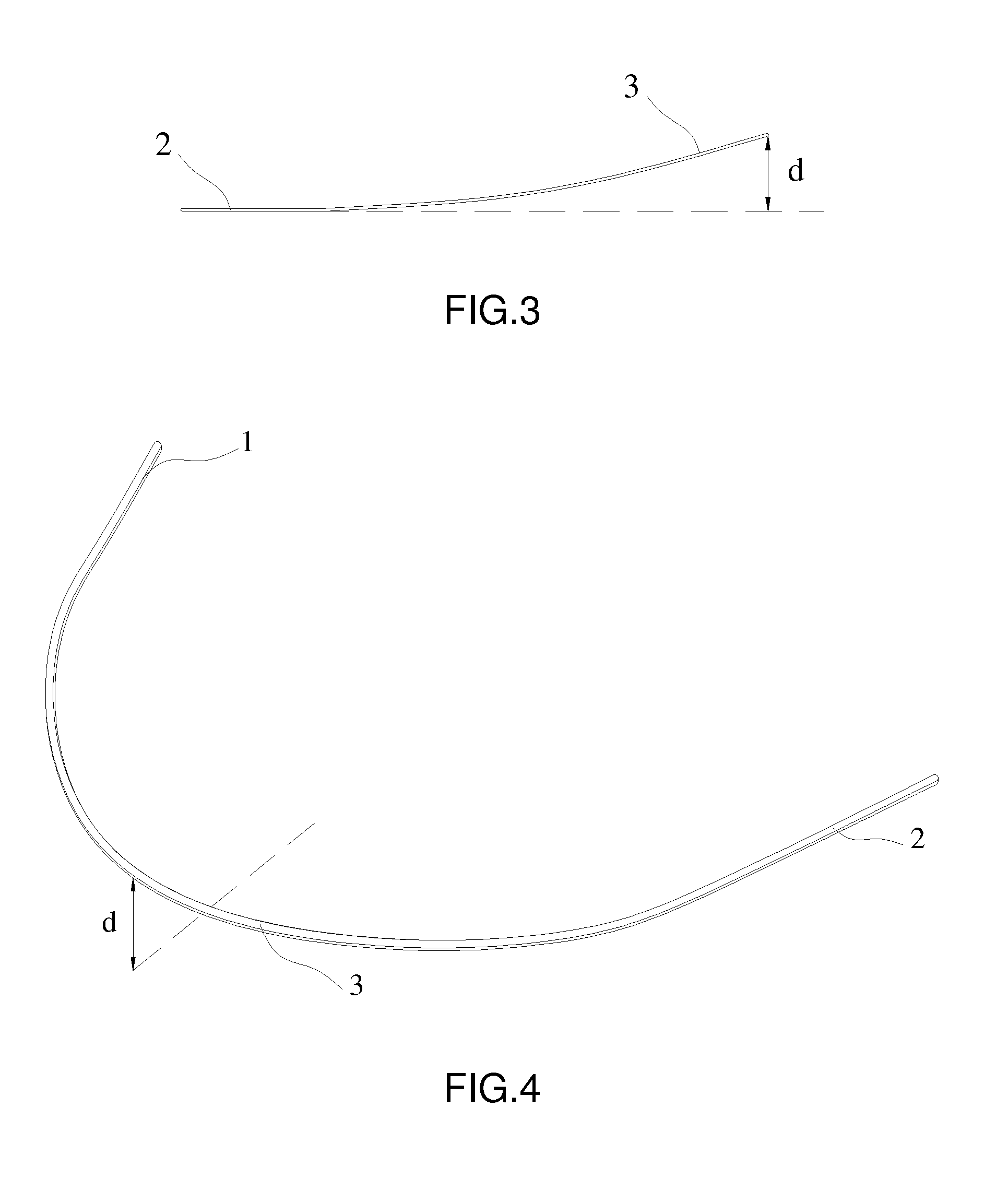

[0035]As shown in FIGS. 1 and 4, an arched bra wire is used for being embedded on the lower edge of a bra cup for playing a supporting role (only one is shown in the figures) and is formed by bending a steel wire, the whole bra wire is in the shape of an arc, the bra wire comprises a first part 1 facing towards the middle part of the bra and a second part 2 deviating from the middle part of the bra, the first part 1 and the second part 2 are inclined plane sections, an arc-shaped section 3 is arranged between the first part 1 and the second part 2, and at least part of the arc-shaped section 3 is arched to the outer side of the bra for being in the shape of the arc. As shown in FIGS. 2, 3 and 4, the highest height d of the arc-shaped arch at the middle of the arc-shaped section 3 is 5 mm.

[0036]From FIG. 1 to FIG. 4, we can see that the steel wire for constituting the bra wire is made to be flat, a plane is formed at the bottom part of the first part 1 and the second part 2, the midd...

embodiment 2

[0037]As shown in FIGS. 5-7, an arched bra wire is used for being embedded on the lower edge of a bra cup for playing a supporting role (only one is shown in the figures) and is formed by bending a steel wire, the whole bra wire is in the shape of an arc, the bra wire comprises a first part 11 facing towards the middle part of the bra and a second part 21 deviating from the middle part of the bra, the first part 11 and the second part 21 are inclined plane sections, an arc-shaped section 31 is arranged between the first part 1 and the second part 2, and at least part of the arc-shaped section 31 is arched to the outer side of the bra for being in the shape of the arc. As shown in FIGS. 6 and 7, the highest height dl of the arc-shaped arch at the middle of the arc-shaped section 31 is 8 mm.

[0038]From the sectional views of FIG. 8-FIG. 10, we can see that the steel wire constituting the bra wire is flat, the steel wire has an oblique angle a1, from the figures, we can see that the fir...

embodiment 3

[0039]As shown in FIGS. 11-13, a bra wire is used for being embedded on the lower edge of a bra cup for playing a supporting role (only one is shown in the figures) and is formed by bending a steel wire, the whole bra wire is in the shape of an arc, the bra wire comprises a first part 12 facing towards the middle part of the bra and a second part 22 deviating from the middle part of the bra, the first part 12 and the second part 22 are inclined plane sections, an arc-shaped section 32 is arranged between the first part 1 and the second part 2, and at least part of the arc-shaped section 32 is arched to the outer side of the bra for being in the shape of the arc. As shown in FIGS. 11 and 13, the highest height d2 of the arc-shaped arch at the middle of the arc-shaped section 32 is 10 mm.

[0040]From the sectional views of FIG. 14-FIG. 16, we can see that only the arc-shaped section part 32 has the oblique angle a2 which is in line with the bra shape, a2 is 54 degrees, and the first par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com