System and Method for Forming Artificial Turf Products with a Woven Appearance

a technology of synthetic turf and appearance, applied in the field of system and method for forming artificial/synthetic sports grass or turf fabric materials or products, can solve the problems of less natural appearance, less yarn weight, and the tendency of turf fibers to flatten in the direction of weave, so as to improve the support of tufts, improve the effect of tufting, and/or more precise distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

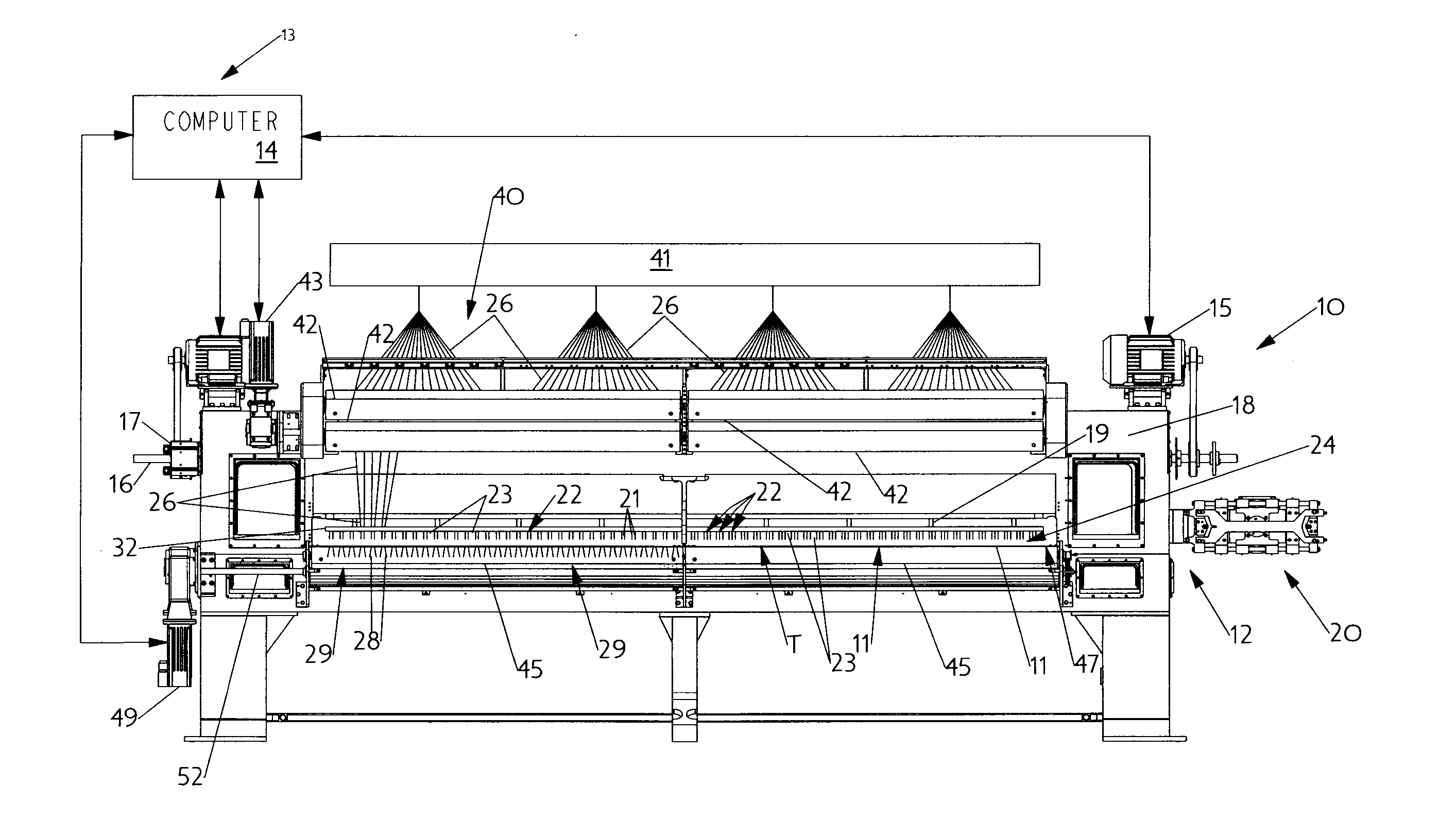

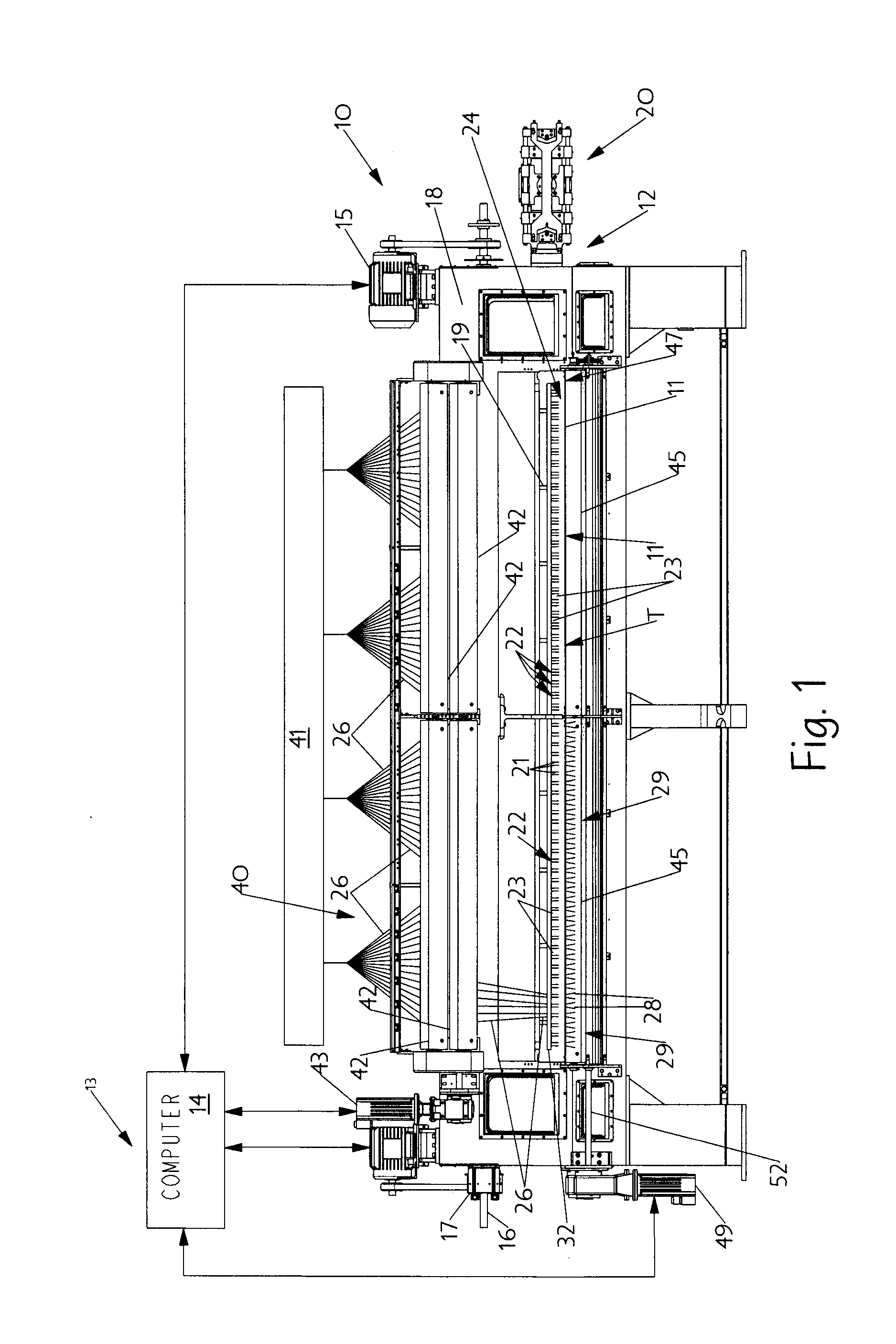

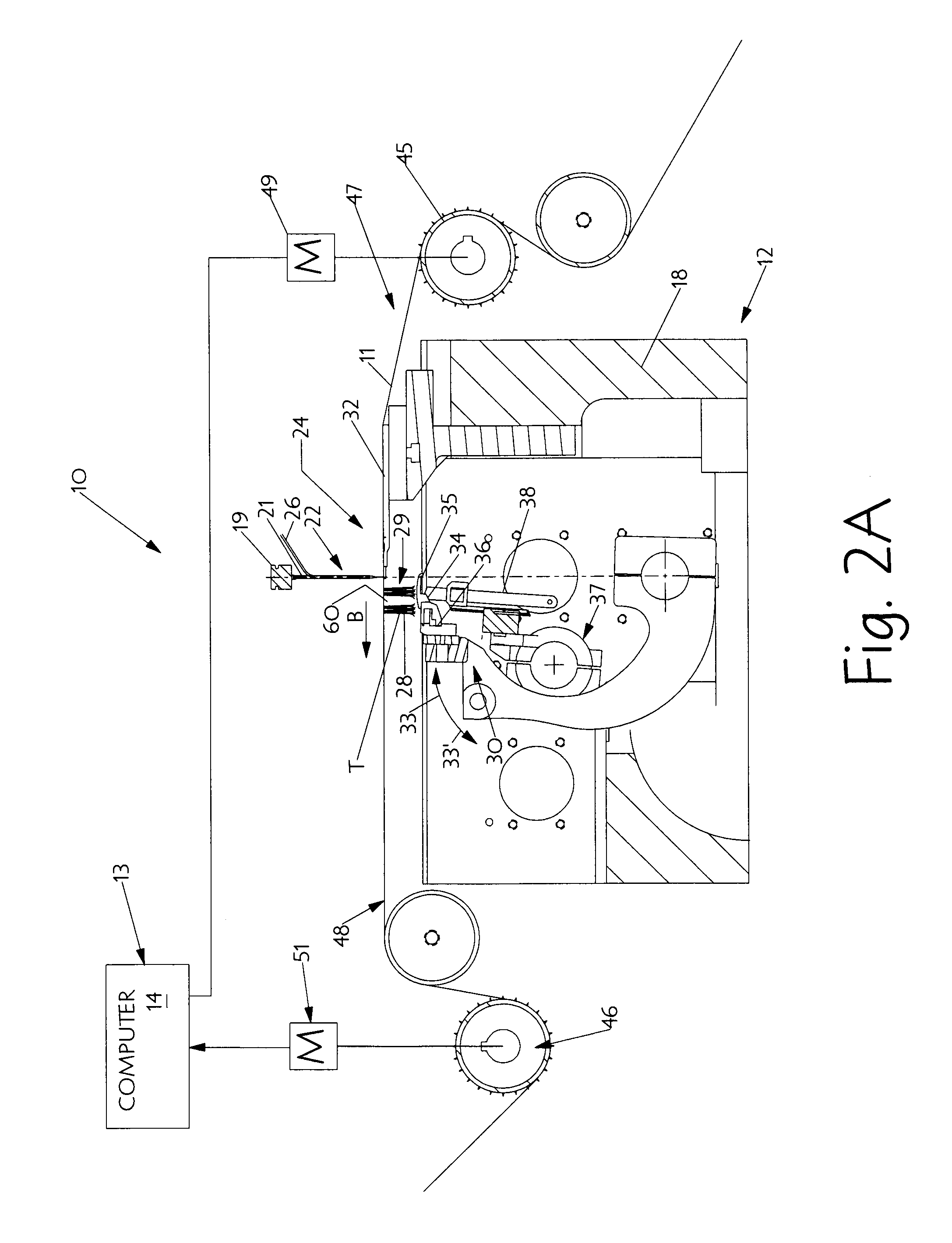

[0019]Referring now in greater detail to the drawings in which like numerals indicate like parts throughout the several views, as illustrated in FIGS. 1-2B, according to an example embodiment, the present invention is directed to a system 10 and method for controlling the movement of a backing material 11 through a tufting machine 12. The system and method of the present invention is designed to produce tufted artificial / synthetic grass or turf fabric products or materials that have an enhanced natural grass / turf, such as providing the artificial / synthetic grass or turf tufted fabric products or materials with a woven look or appearance, as opposed to a traditional tufted appearance, without requiring highly specialized machinery for producing artificial / synthetic grass or turf tufted fabric products or materials. The resultant artificial / synthetic grass or turf tufted fabric materials T accordingly are formed with a series of dense groupings of stitch formations or tuft groups 29 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com