Abrasive pad assembly

a technology of abrasive pads and parts, which is applied in the direction of flexible wheels, grinding machines, manufacturing tools, etc., can solve the problems of previously known abrasive pads that wear out too frequently, and achieve the effect of increasing wear resistance and proper surfacing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

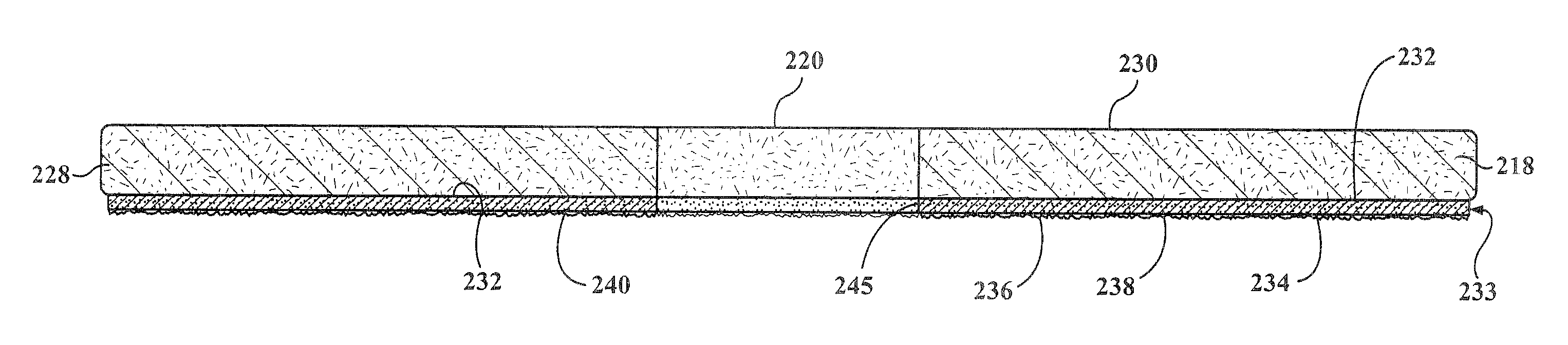

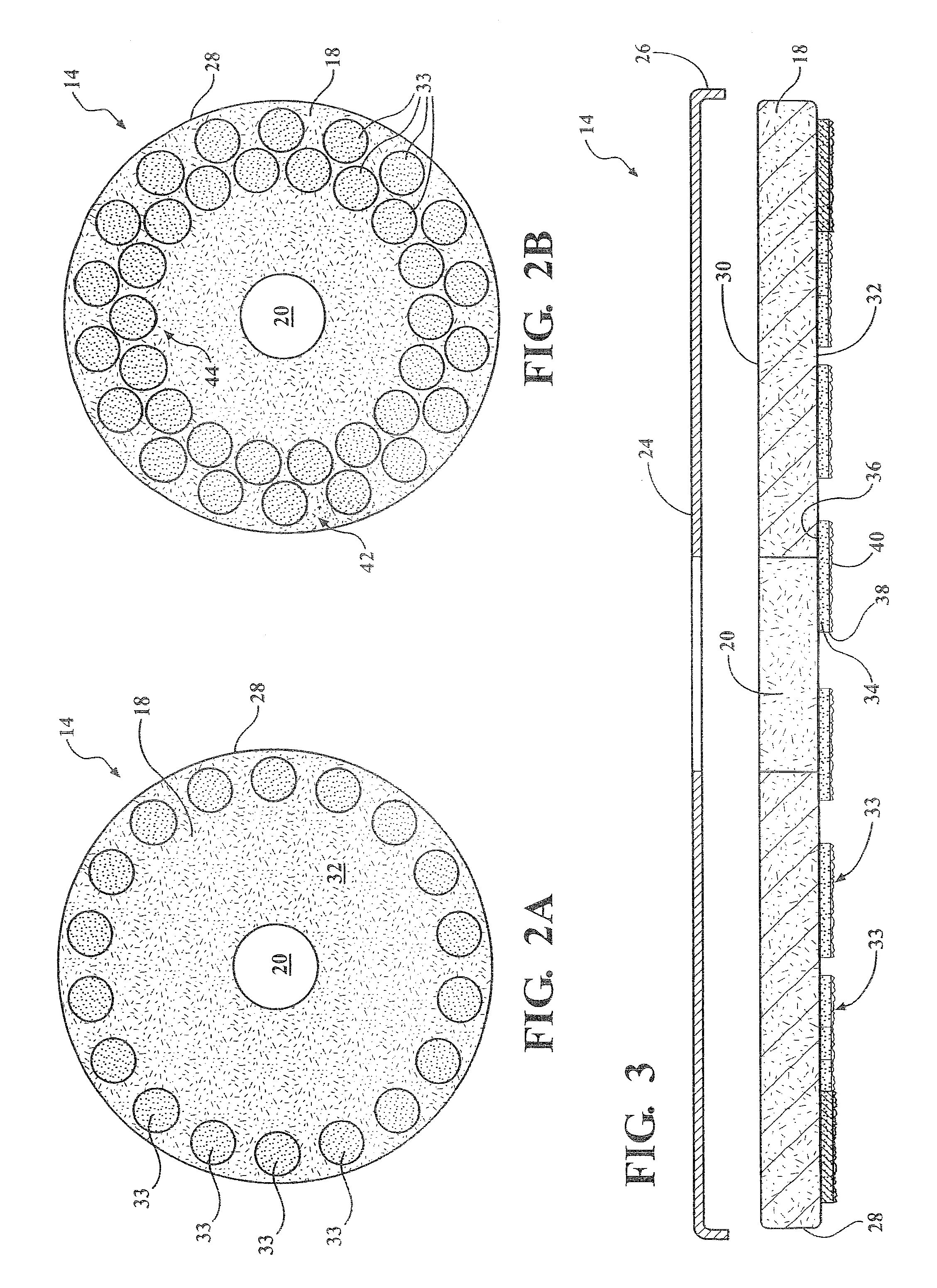

[0022]The present invention has utility as an abrasive pad assembly for a surfacing machine that provides an abrasive pad that provides increased wear resistance and the ability to properly surface a floor having an uneven surface. Providing an abrasive pad having a diamond abrasive member affixed to an exterior surface of a circular pad member spaced apart from the circular pad member provides focused wear on the resilient diamond abrasive member which prevents wear on the circular pad member.

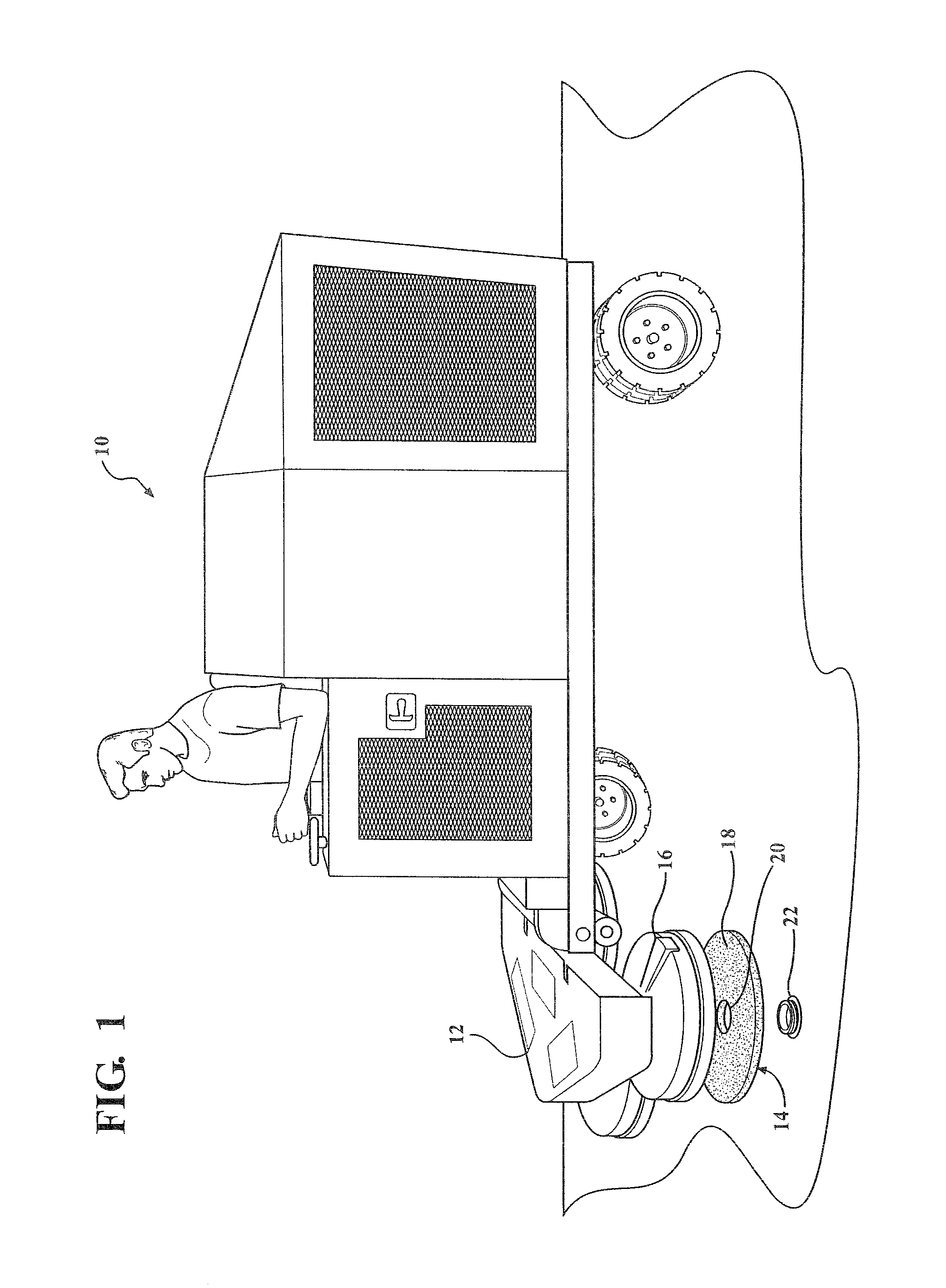

[0023]With reference to FIG. 1, a surfacing machine for providing a surfacing on a surface floor is generally illustrated at 10. The surfacing machine includes a motor 12 that actuates the abrasive pad assembly 14 contained within shield 16. The pad assembly 14 includes a pad member 18 which is secured to the shield 16. The pad assembly 14 is operatively attached to the motor 12 which actuates the pad member 18 to perform the floor surfacing operation. Specifically, the motor 12 actuates the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| abrasive | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com