Automobile label wear-resistance testing stand

A technology of wear resistance and test bench, which is applied in the direction of testing wear resistance, etc., can solve the problems of inconvenient labeling wear resistance performance detection of auto parts, and achieve the effect of simple structure, easy use and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

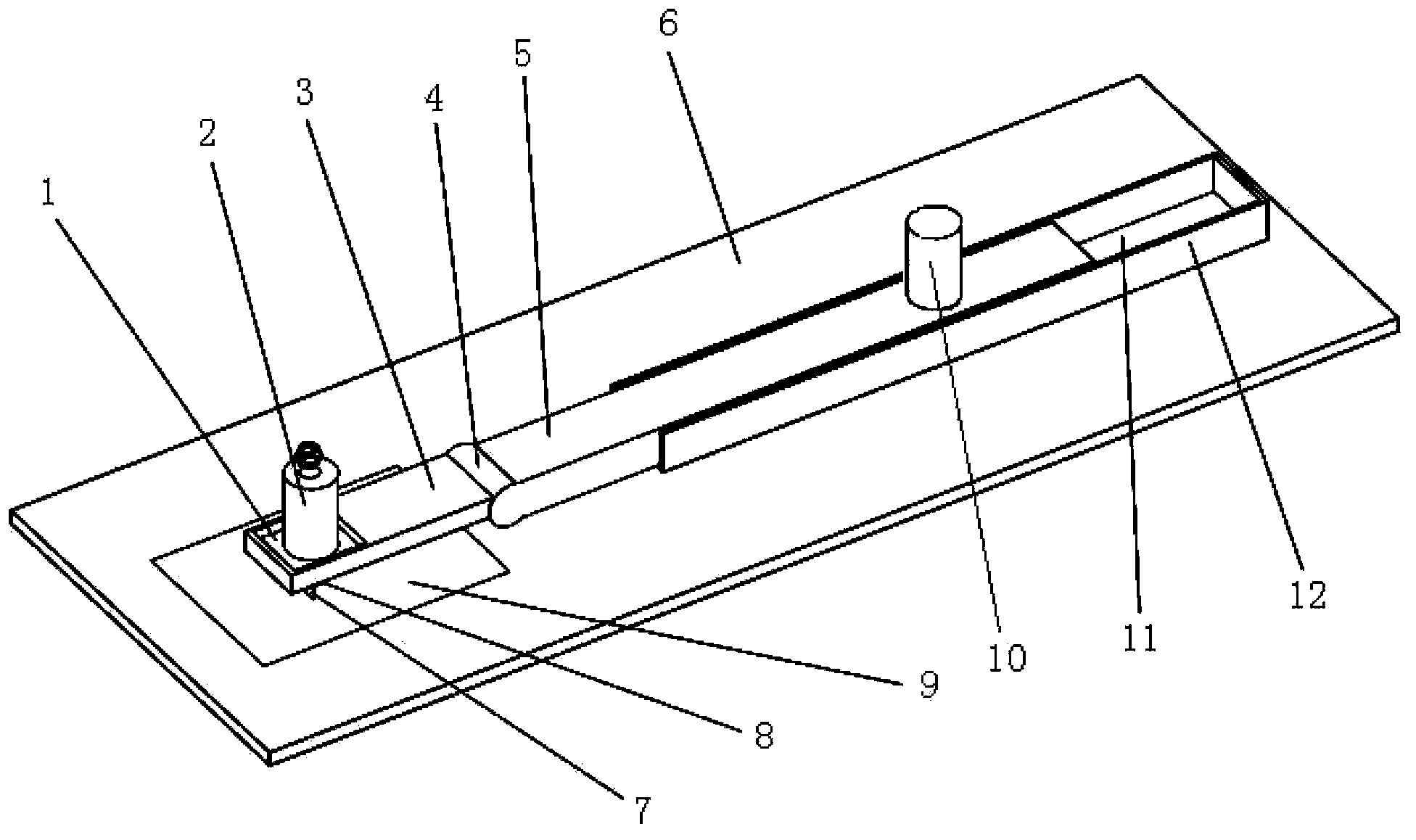

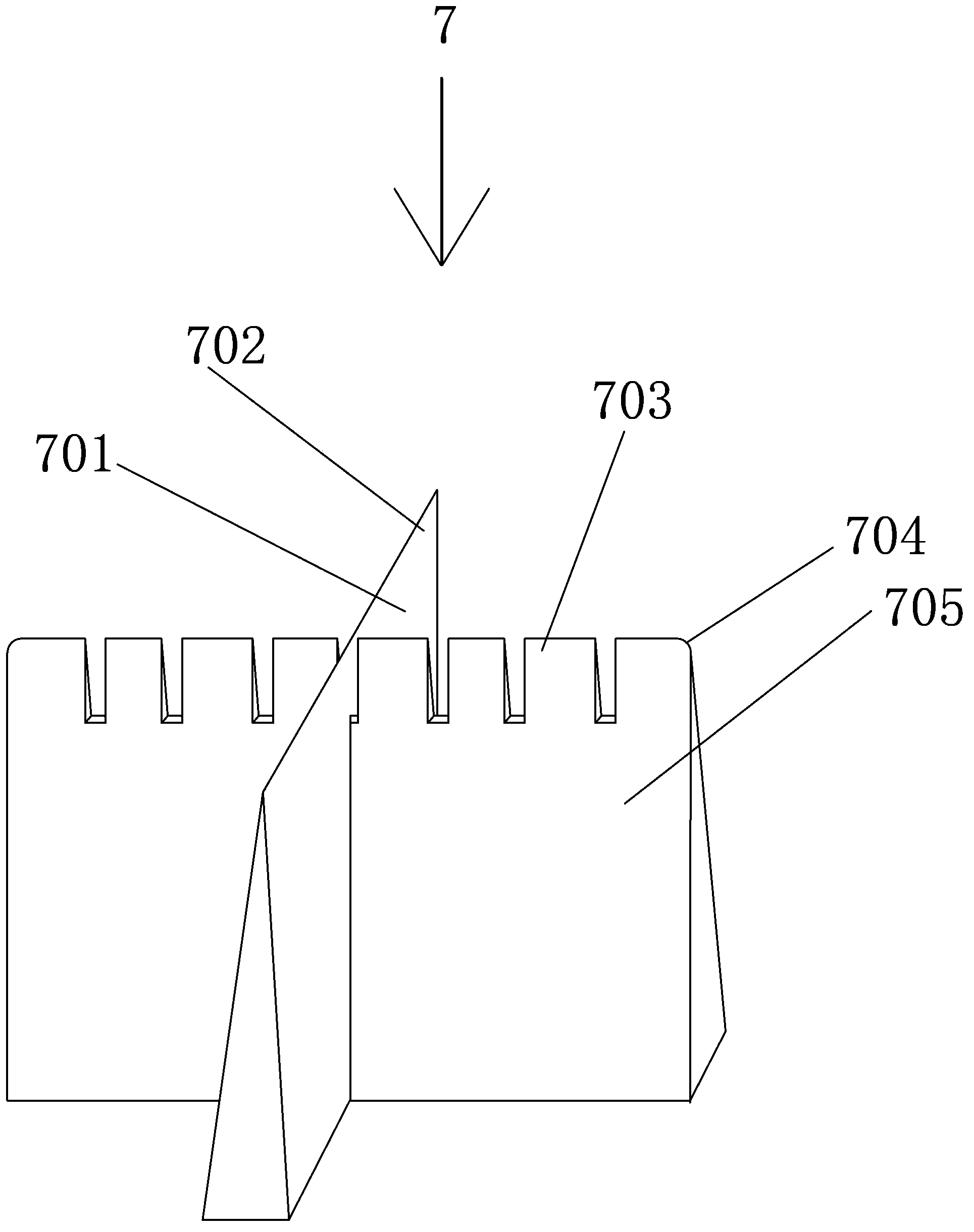

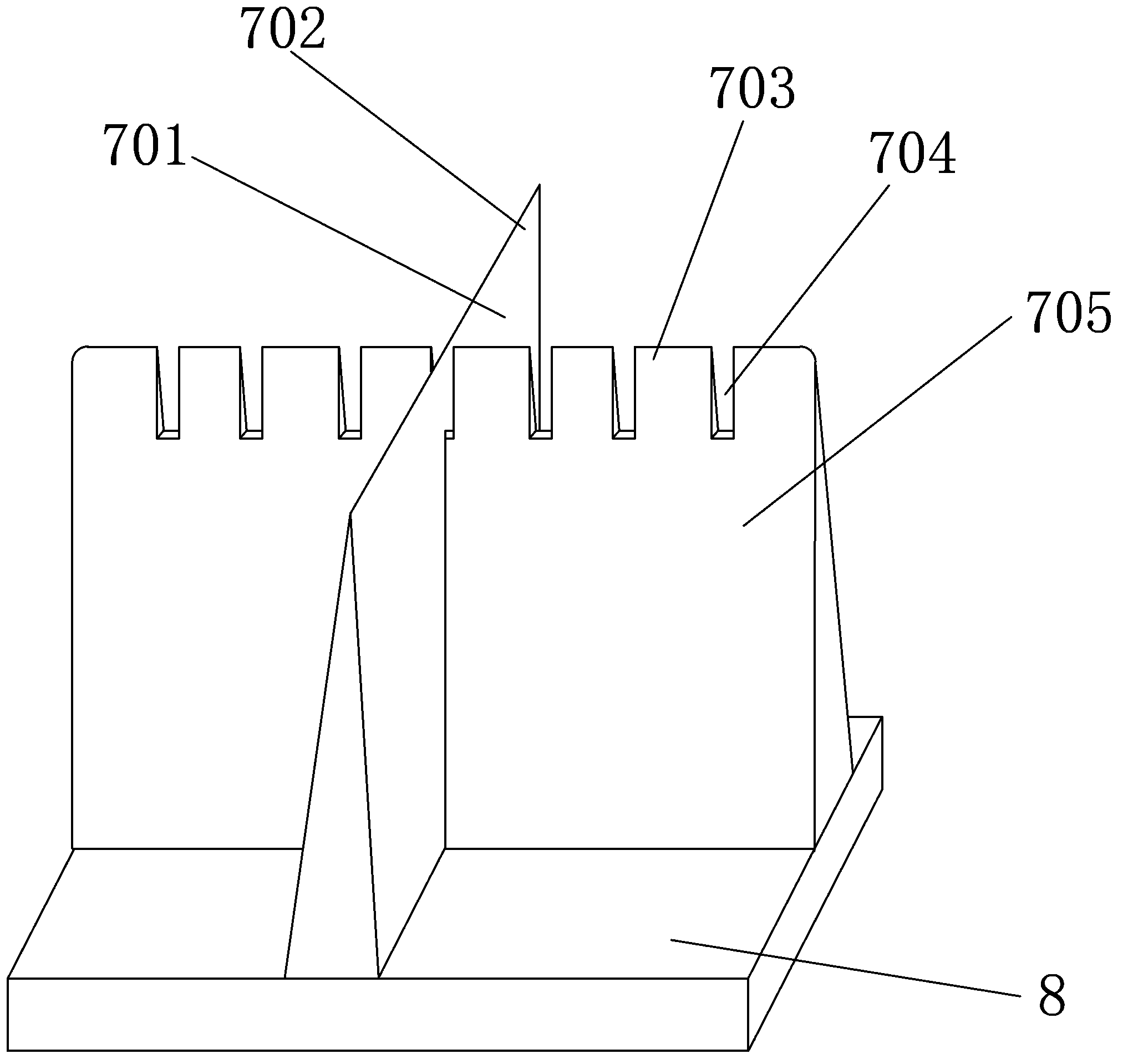

[0024] Embodiment: a kind of automobile label wear-resisting performance test bench, such as figure 1 , figure 2 , image 3 As shown, it includes cross scraper 7 in the shape of "ten", weight 2, pressure plate 3, slide rail 12, knife lock plate 8 and flat plate 6, the No. 1 blade 701 of the cross scraper is a horizontal straight edge 702, and the cross scraper No. 2 blade 705 has a horizontal sawtooth edge 703, and the corners at both ends of the No. 2 blade are arc corners 704; the lower surface of the lock plate is provided with a cross-shaped lock groove, directly above the cross scraper The upper surface of the pressing plate is provided with a pit 1, and the inner wall of the pit is provided with a sponge pressing edge. The compression side of the sponge is convenient to compress the weight placed in the pit, so that the pit will not throw the weight out when the pit moves, which is safe, and the vibration of the weight will not occur in the inspection.

[0025] Such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com