Electromagnet inspection apparatus and method

a technology of electromagnetic and magnetic inspection apparatus and method, applied in the direction of instruments, magnetic variables, magnetic properties, etc., can solve the problems of limited penetration depth into the material, time-consuming and expensive, and inherent limitations of electromagnetic inspection apparatus and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

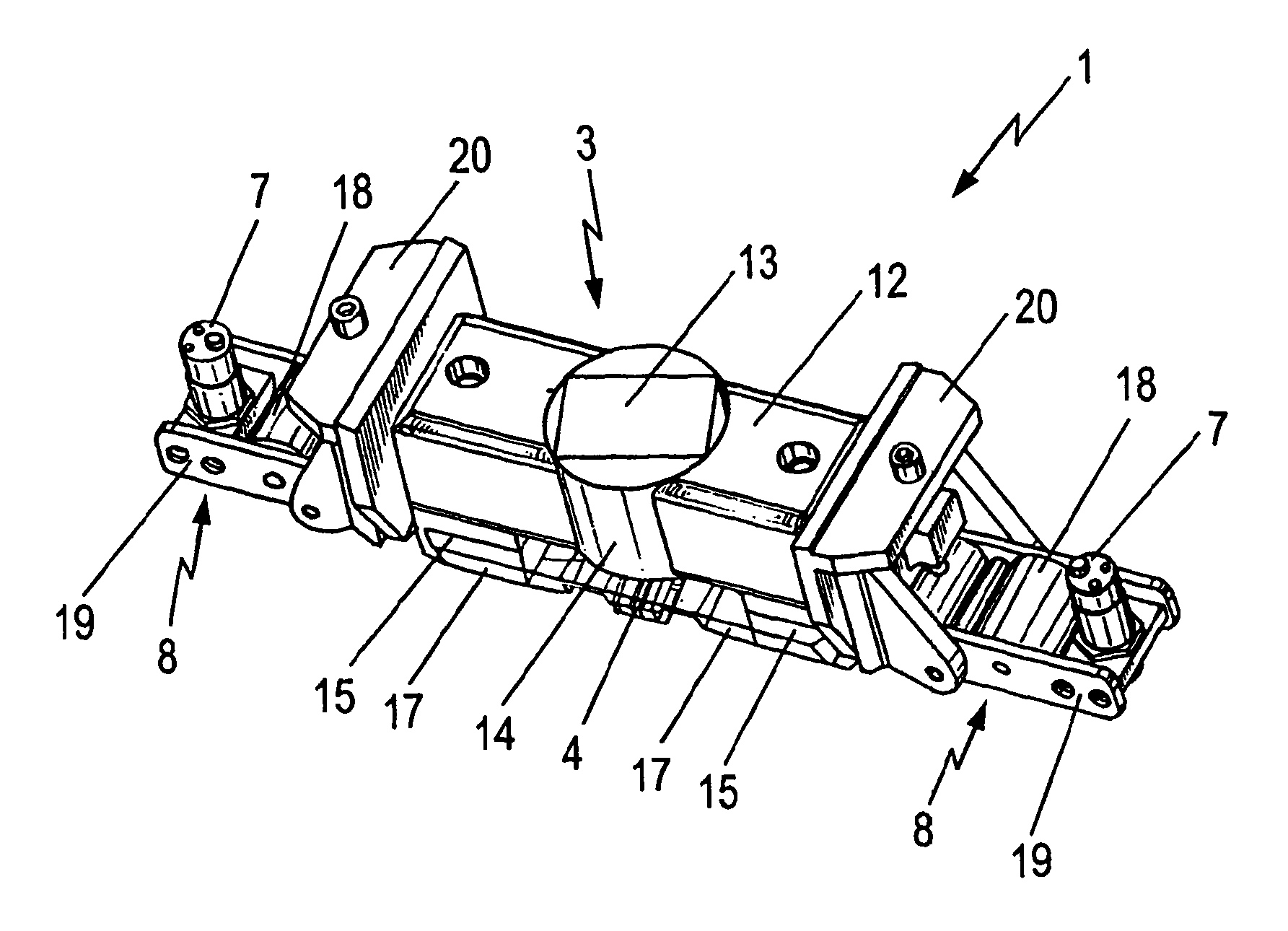

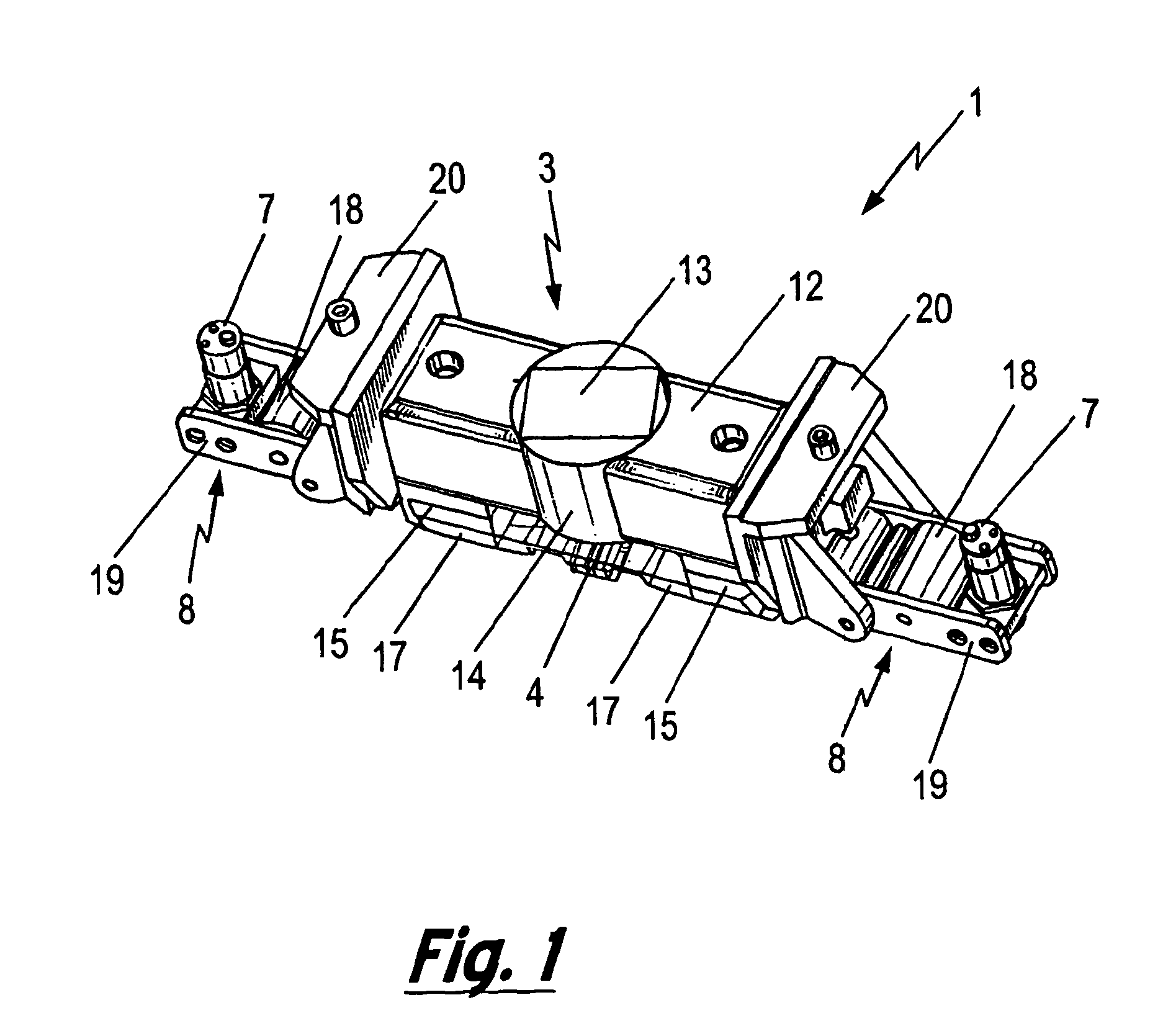

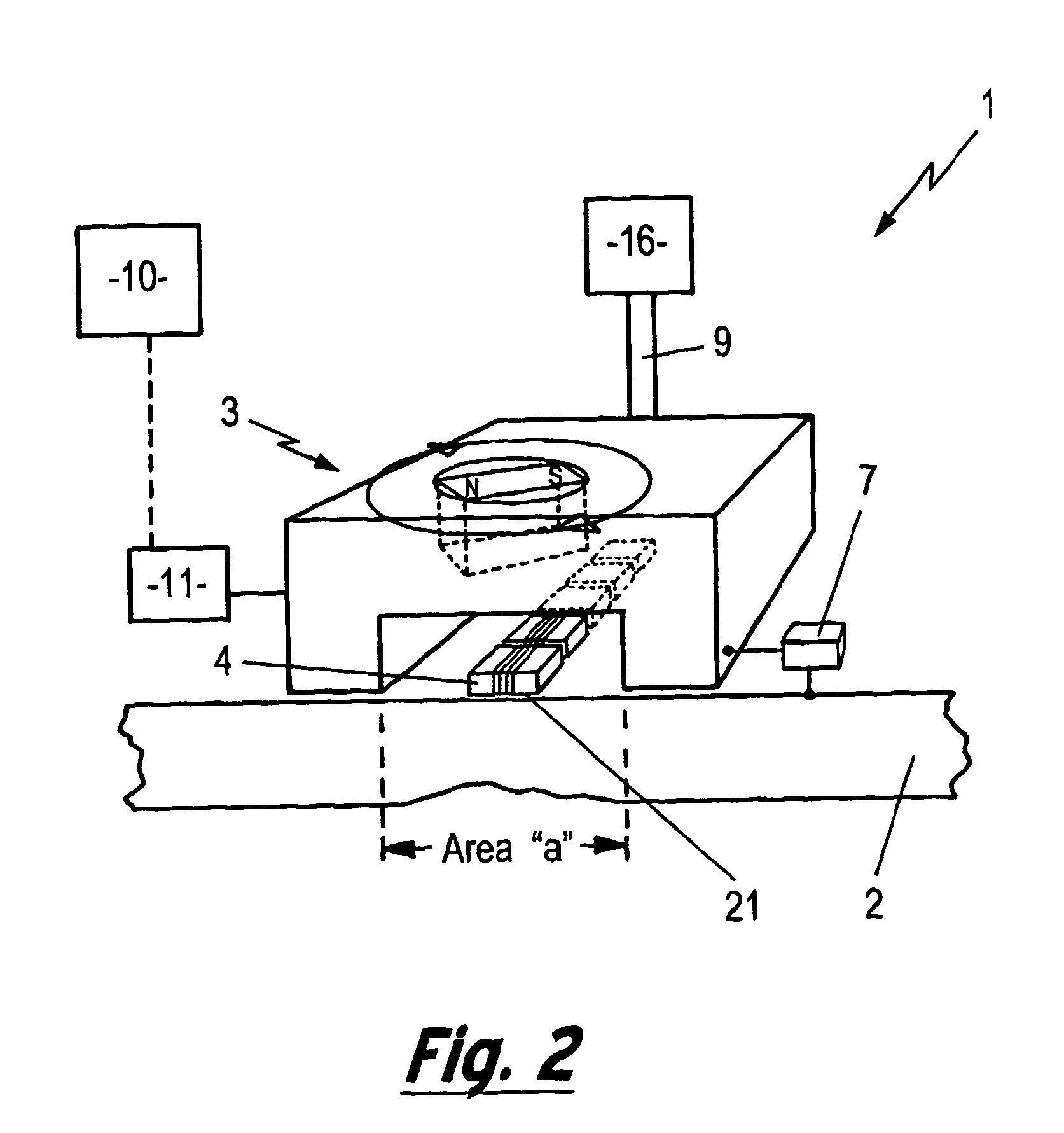

[0068]FIG. 1 presents a perspective view of a sensor module 1 in accordance with an embodiment of the invention while FIG. 2 presents a schematic representation of the sensor module 1 located with a component to be tested 2. The sensor module 1 can be seen to comprise a DC magnetiser unit 3, an array of eddy current probes 4, each eddy current probe 4 comprising an eddy current coil 5 with an integrated magnetic field sensor 6 e.g. a Hall sensor, one distance sensor 7 and two suspension wheel mechanisms 8. Electronic connectors 9 are employed to provide power to the sensor module 1 e.g. for the DC magnetiser unit 3, the eddy current coils 5, the Hall sensors 6 etc.

[0069]Signals detected by the sensor module 1 are transmitted to a data acquisition computer 10 that is employed to record all of the eddy current and Hall sensor data. The computer 10 may form an integrated part of the sensor module 1 or be located remotely. Transmission of the data may be via hardwiring e.g. via a fibre ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com