Modified animal litter

a technology for animal litter and sachets, applied in the field of animal litters, can solve the problems of reluctance to use litter boxes, material with very little, if any, deodorizing properties, etc., and achieve the effect of steady and consistent suppression of malodors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Acid-Activated Bentonite

[0042]West Colony sodium bentonite (325 g) was added equally to two sets of flasks. Each set contained three 5-liter round bottom flasks, and each flask contained respectively 4 liters of 1 N, 2 N, or 18 N of sulfuric acid with a stir bar. Each flask was attached to a condenser in a reflux set-up and one set was heated to 60° C., while the second set was heated to 100° C. for 2 hrs with stirring. The heating was accomplished with a temperature-controlled heating mantle and a stir plate. After cooling, the mixture was decanted to remove the acidic aqueous layer. The remaining mixture from each flask was separately washed with deionized water and filtered by suction filtration. The final filtrate after 3 washings showed a pH of 2 using a pH meter. The solids were dried in an oven at 110° C. for 2 hrs or until dry.

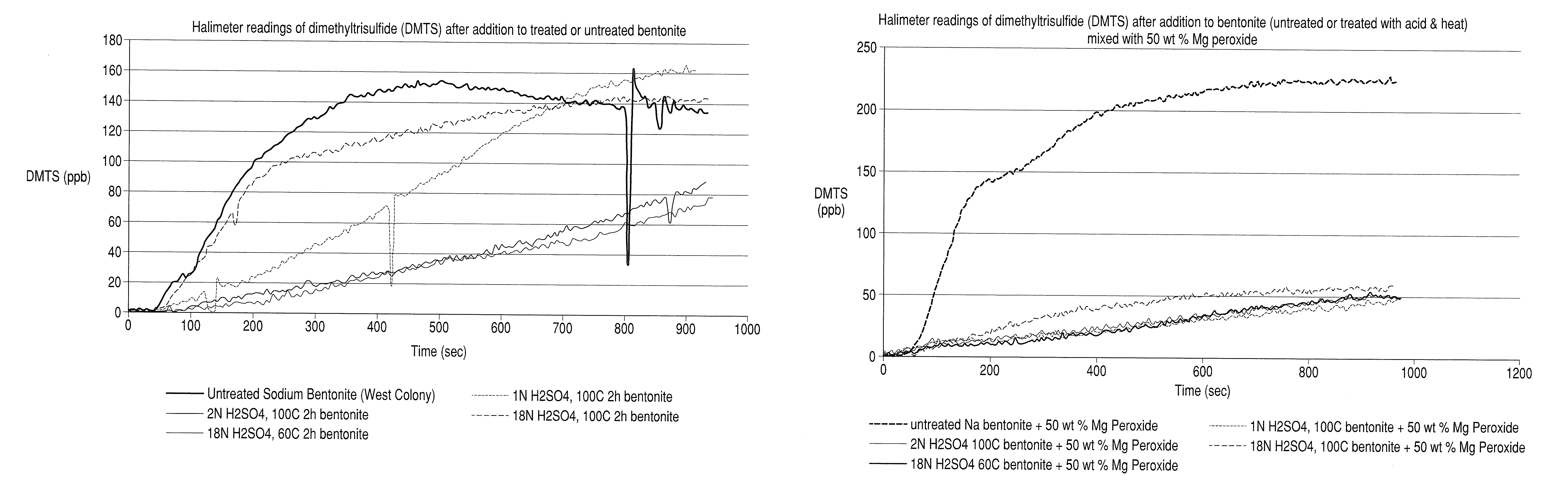

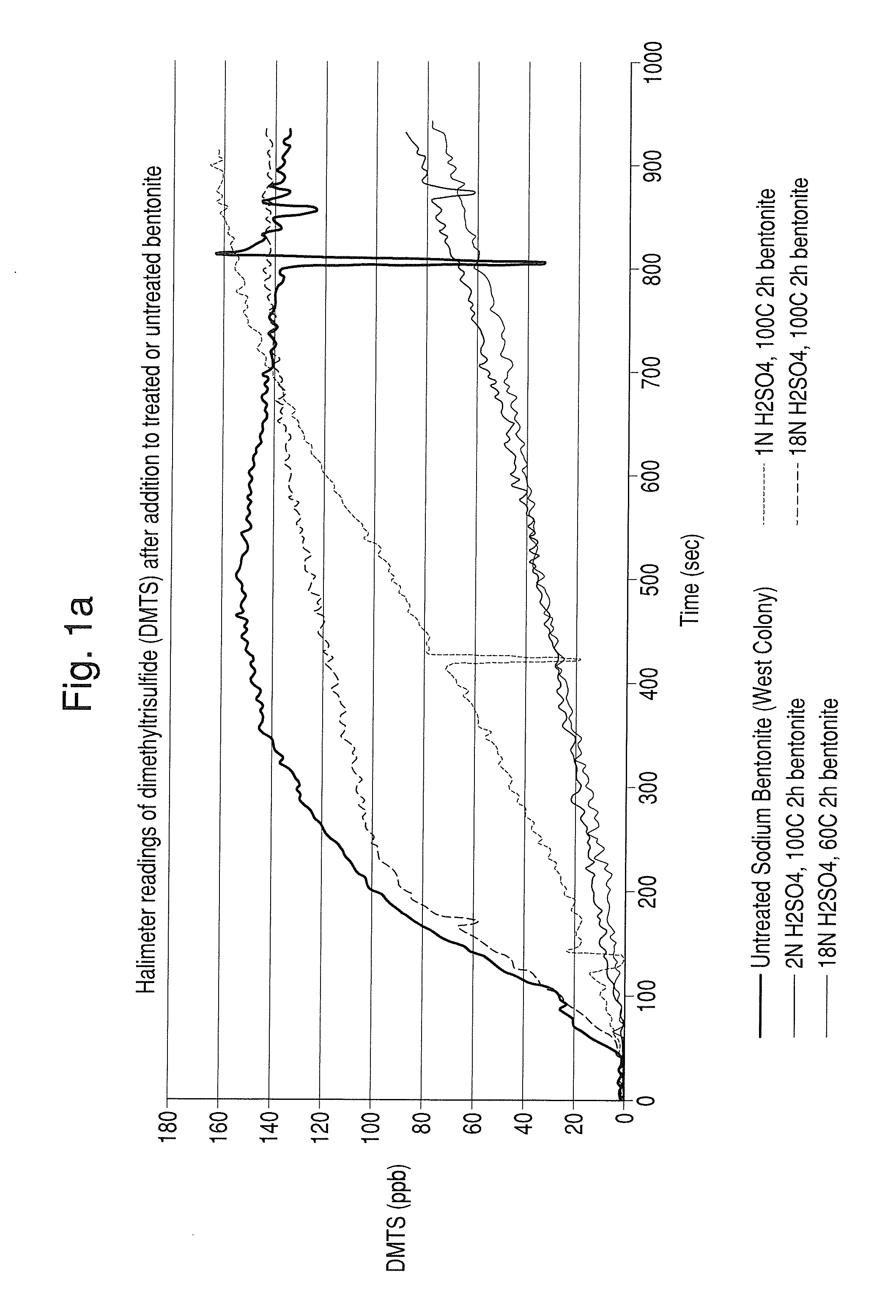

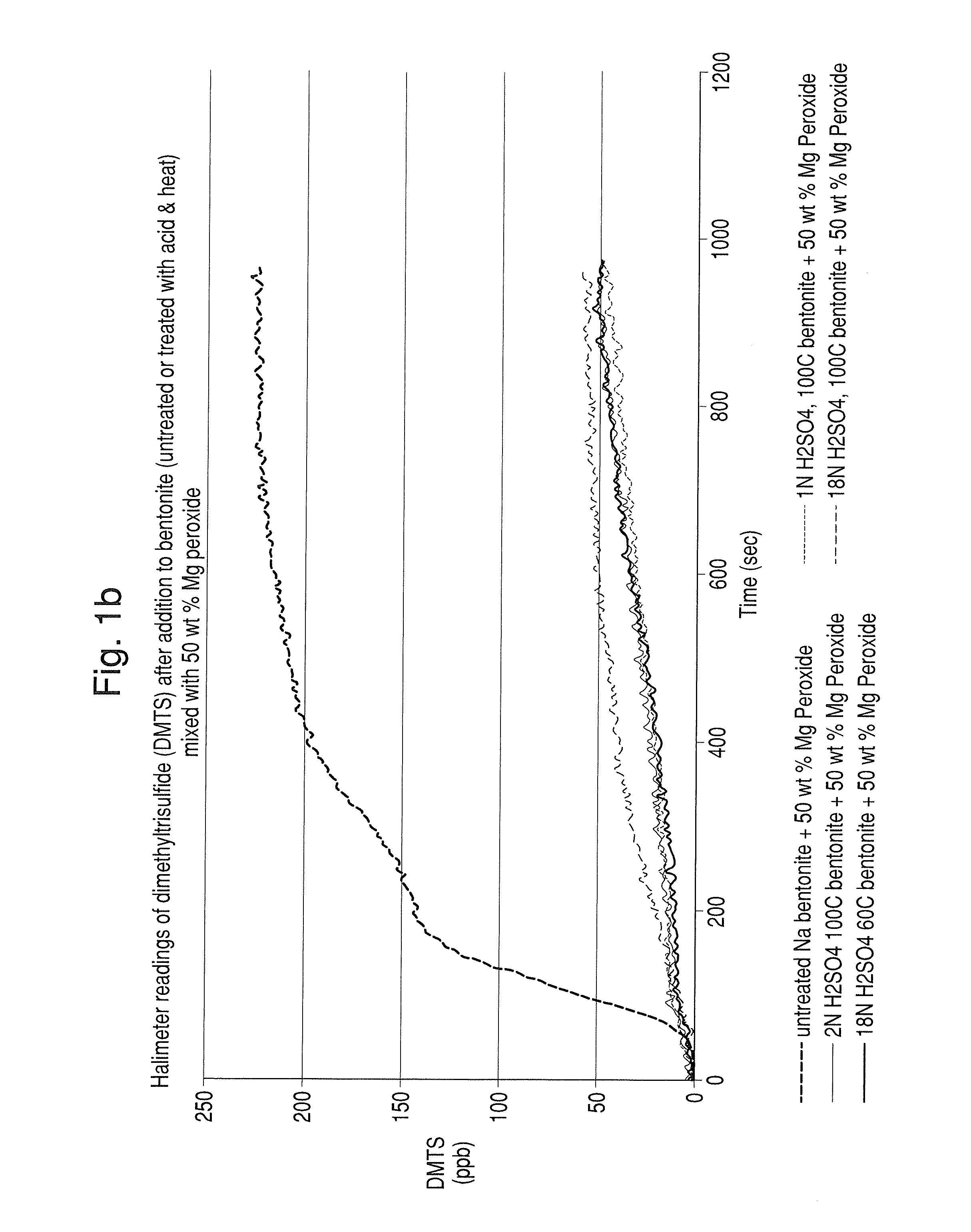

Halimeter Testing of Acid-Activated Bentonite±Mg Peroxide Against Sulfur Malodor

[0043]The acid-activated bentonite; with or without mag...

example 2

Sniff Testing of Acid-Activated Bentonite Added With Cat Urine and Synthetic Cat Fecal Malodor

[0047]Acid-activated bentonite (60 ml) samples that were prepared from Example 1 were each placed in a 8 oz. glass jar with and without 10 v / v %, magnesium peroxide, and the jar was covered with aluminum foil and with holed caps.

[0048]Controls in this example included untreated sodium bentonite with and without 10 v / v %, magnesium peroxide. Cat urine from Sharp Veterinary Research (Texas) was utilized and synthetic cat fecal malodor was prepared. For the cat urine malodor test, the processed cat urine was heated to 35° C. then added to the litter jars each day for three days (5 ml / jar / day) using a 60 ml syringe. Seven panelists rated the malodor at Day 5 (Day 1=first addition of urine) relative to the controls. For the cat fecal malodor test, 1 drop (˜0.03 g) of synthetic fecal malodor was combined with 5 grams of synthetic feces substrate and added to the litter jars (the litter samples co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com