HIGH EFFICIENCY LOW NOx EMISSION BURNER APPARATUS

a burner and low nox emission technology, applied in lighting and heating apparatus, combustion types, combustion using lumps and pulverizing fuel, etc., to achieve the effect of low nox emission and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

embodiment 70

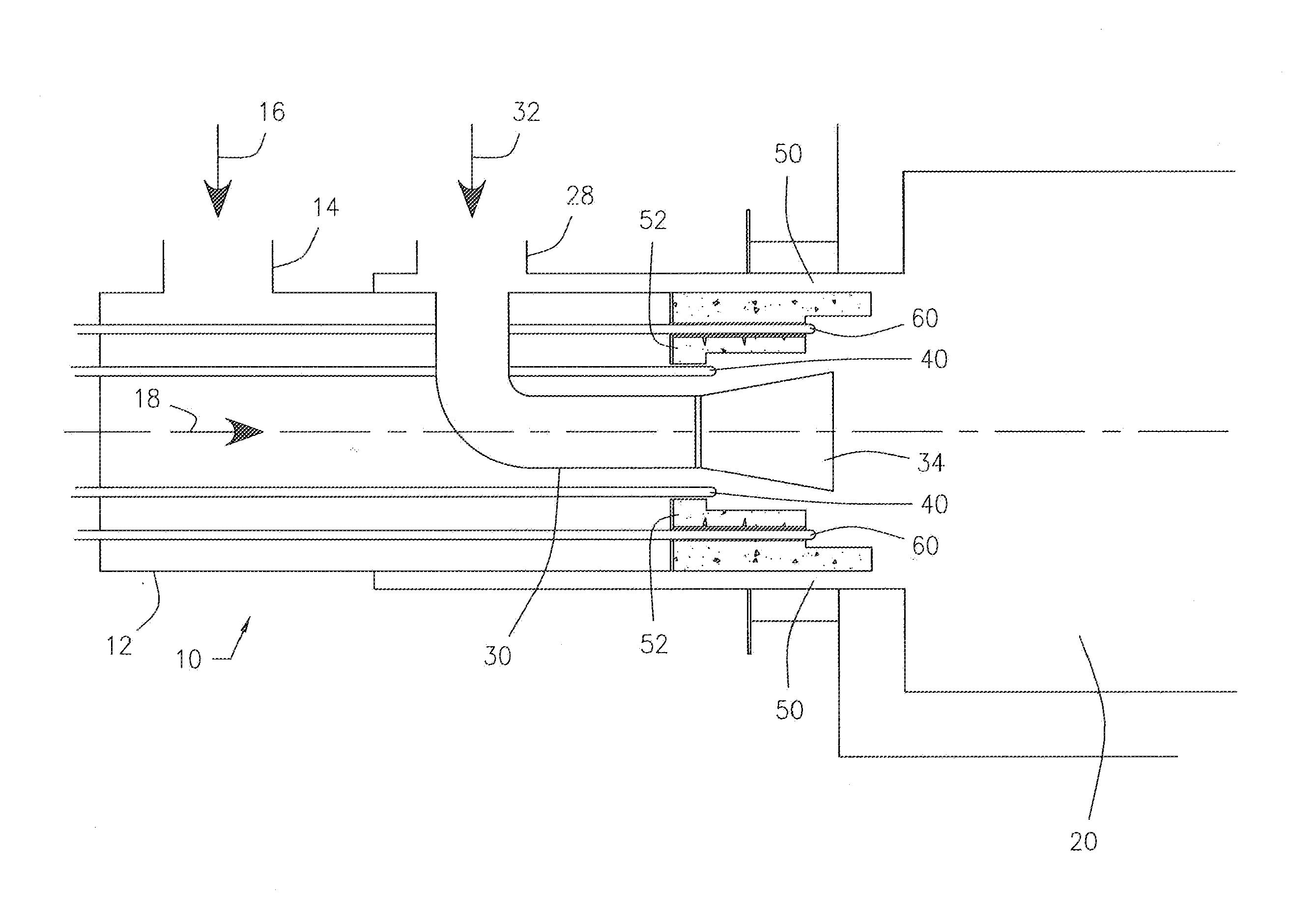

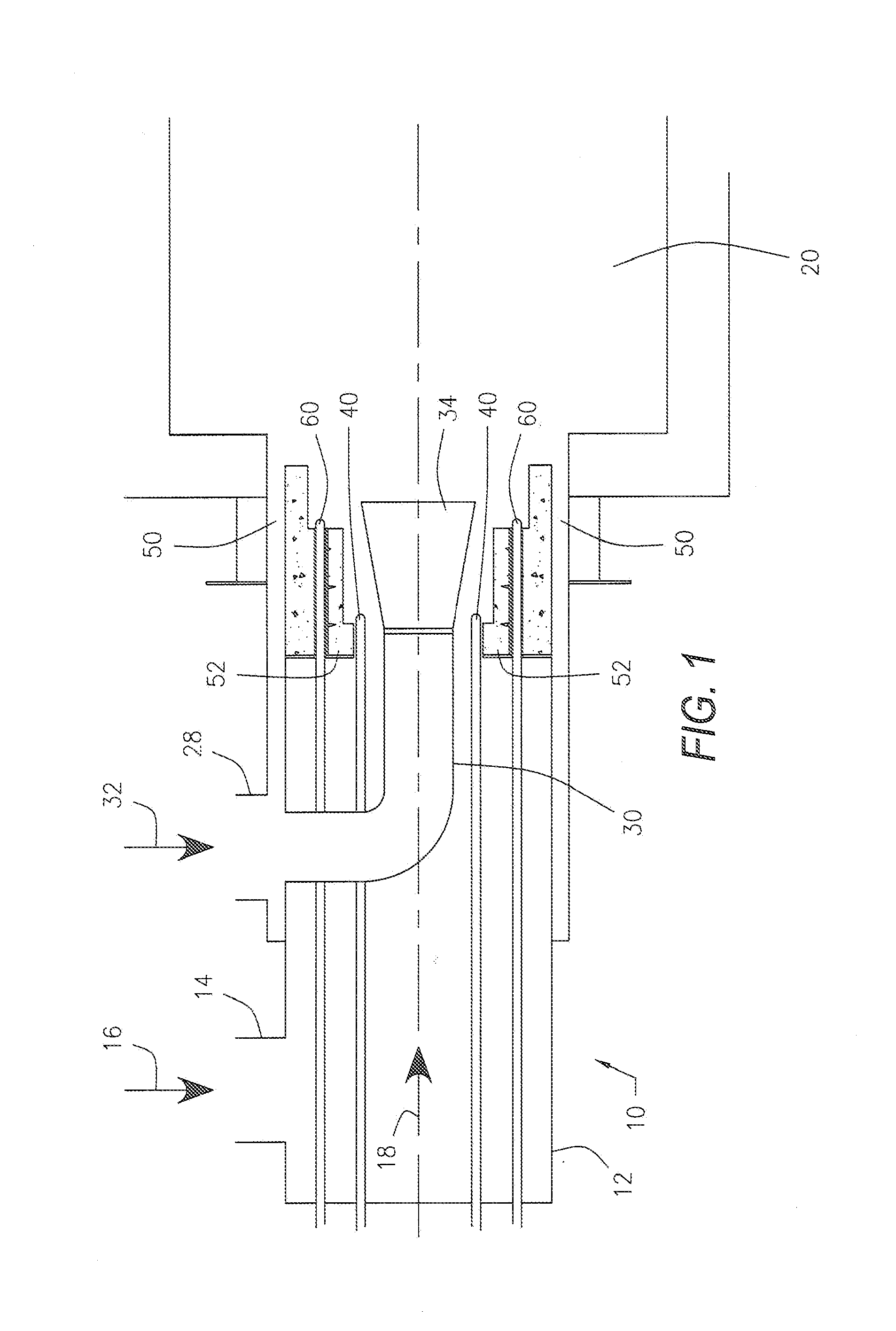

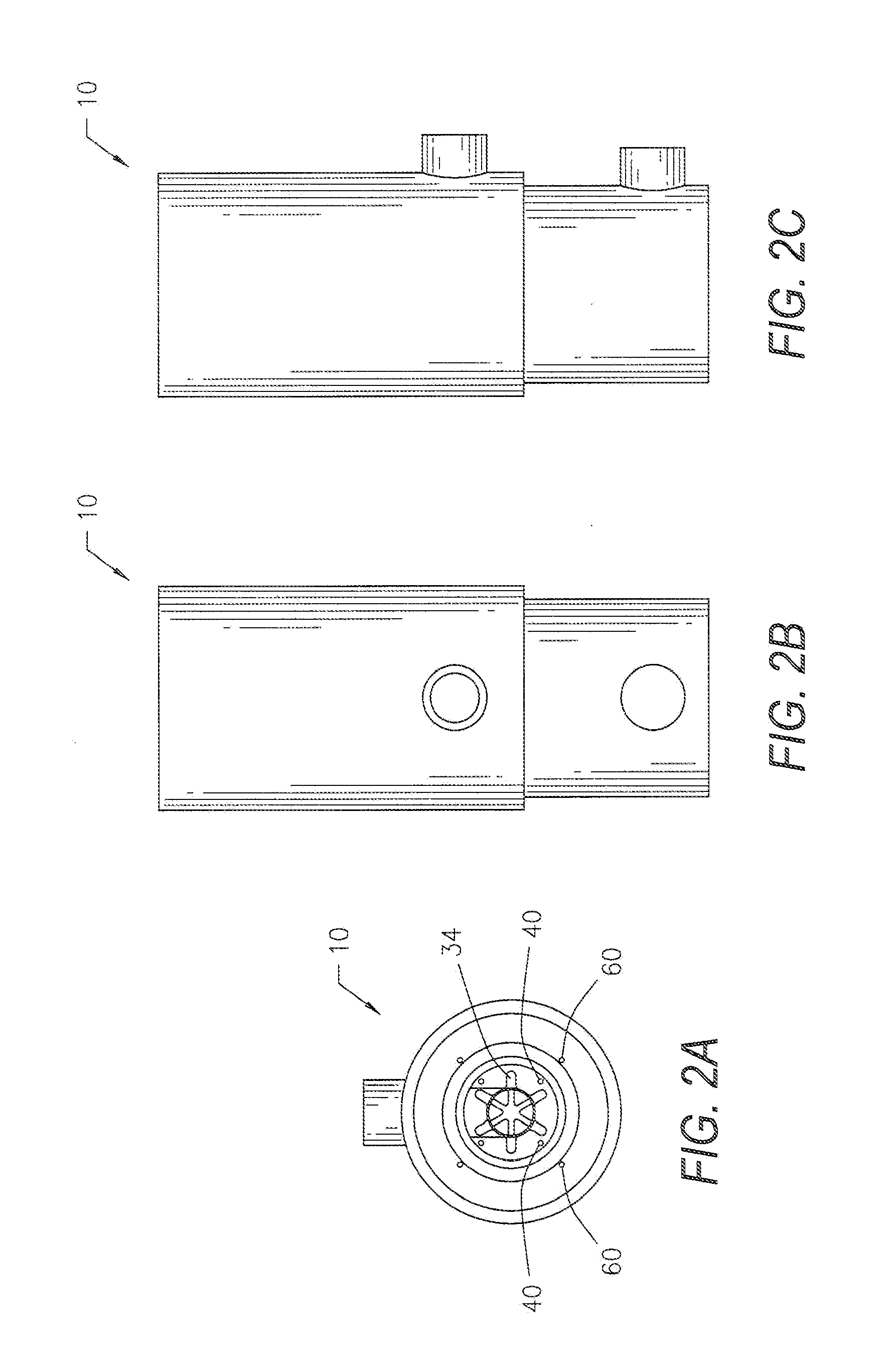

[0039]FIG. 6 discloses an alternate preferred embodiment 70 of the burner apparatus 10. The arrangement is similar to that in FIGS. 1 through 5 with the exception of the introduction of the secondary fuel gas and secondary tail gas or waste gas in conjunction with an alternate arrangement of refractory tile 62. In the alternate embodiment shown in FIG. 6, the secondary fuel gas delivered through secondary fuel gas line 60 mixes with the secondary tail gas or waste gas through secondary waste gas pipe or pipes 50 and then simultaneously mixes with the combustion air, primary fuel gas and primary waste gas.

embodiment 80

[0040]FIG. 7 illustrates a further, alternate preferred embodiment 80 of the present invention. The alternate embodiment shown in FIG. 7 is similar to the arrangement of the foregoing with the exception of the secondary fuel gas and secondary waste gas introduction in conjunction with a further alternate arrangement of refractory tile 72. In the alternate embodiment shown in FIG. 7, the secondary tail gas or waste gas delivered through secondary waste pipe 50 fully or partially mixes with the secondary fuel gas delivered through secondary fuel gas line 60 prior to or before mixing with the combustion air, primary fuel gas through primary fuel gas line 40 and primary waste gas from the primary waste gas pipe or pipes 30. The arrangement disclosed in FIG. 7 will tend to minimize NOx emissions.

[0041]Whereas, the devices and methods have been described in relation to the drawings and claims, it should be understood that other and further modifications, apart from those shown or suggeste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap