Power steering pump and water pump assembly

a technology of power steering pump and water pump, which is applied in the direction of machines/engines, liquid fuel engines, transportation and packaging, etc., can solve the problems of increasing labor and time required to replace a defective pump, and the pump must be separated, so as to achieve convenient separation and less deflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

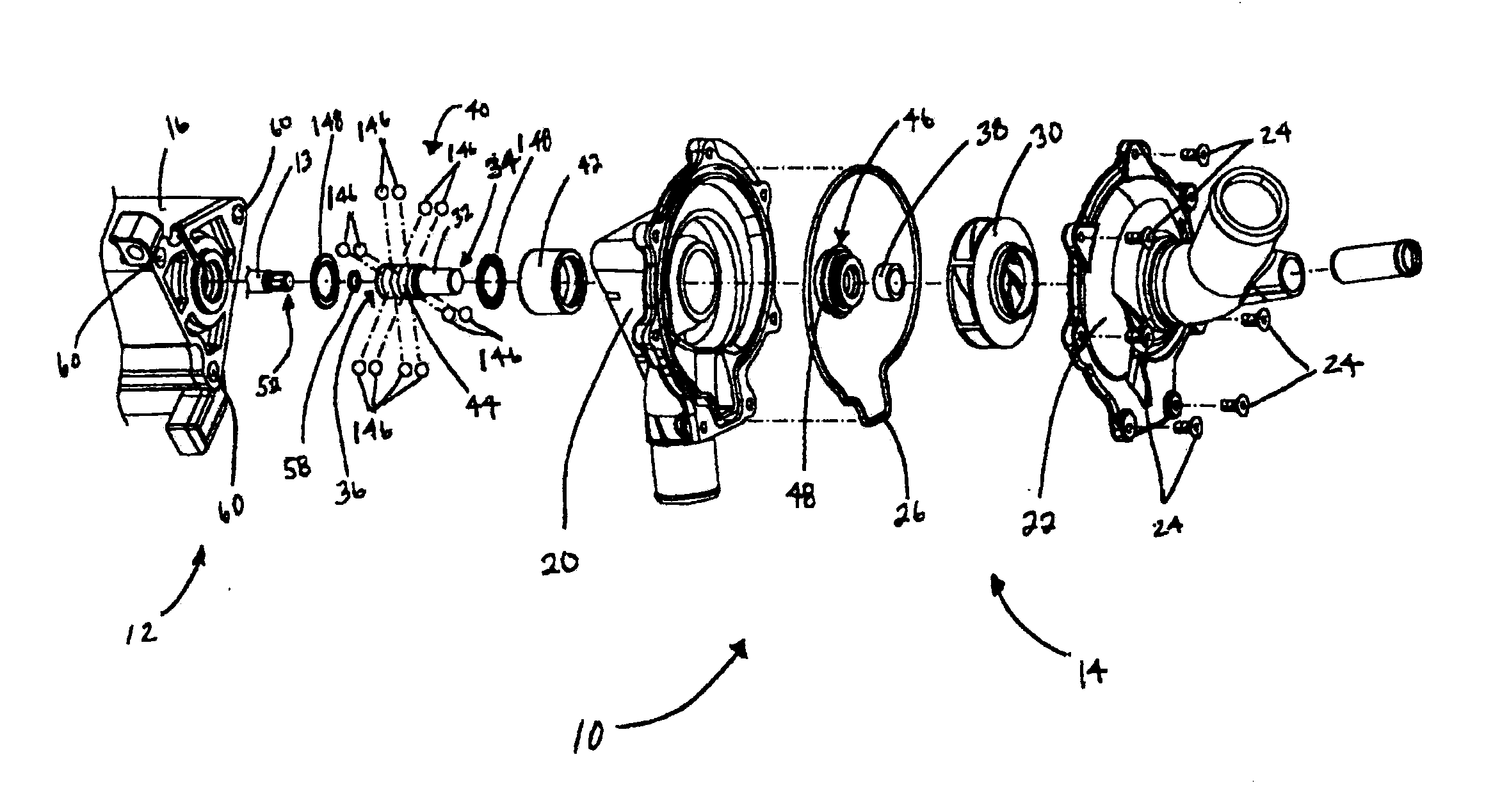

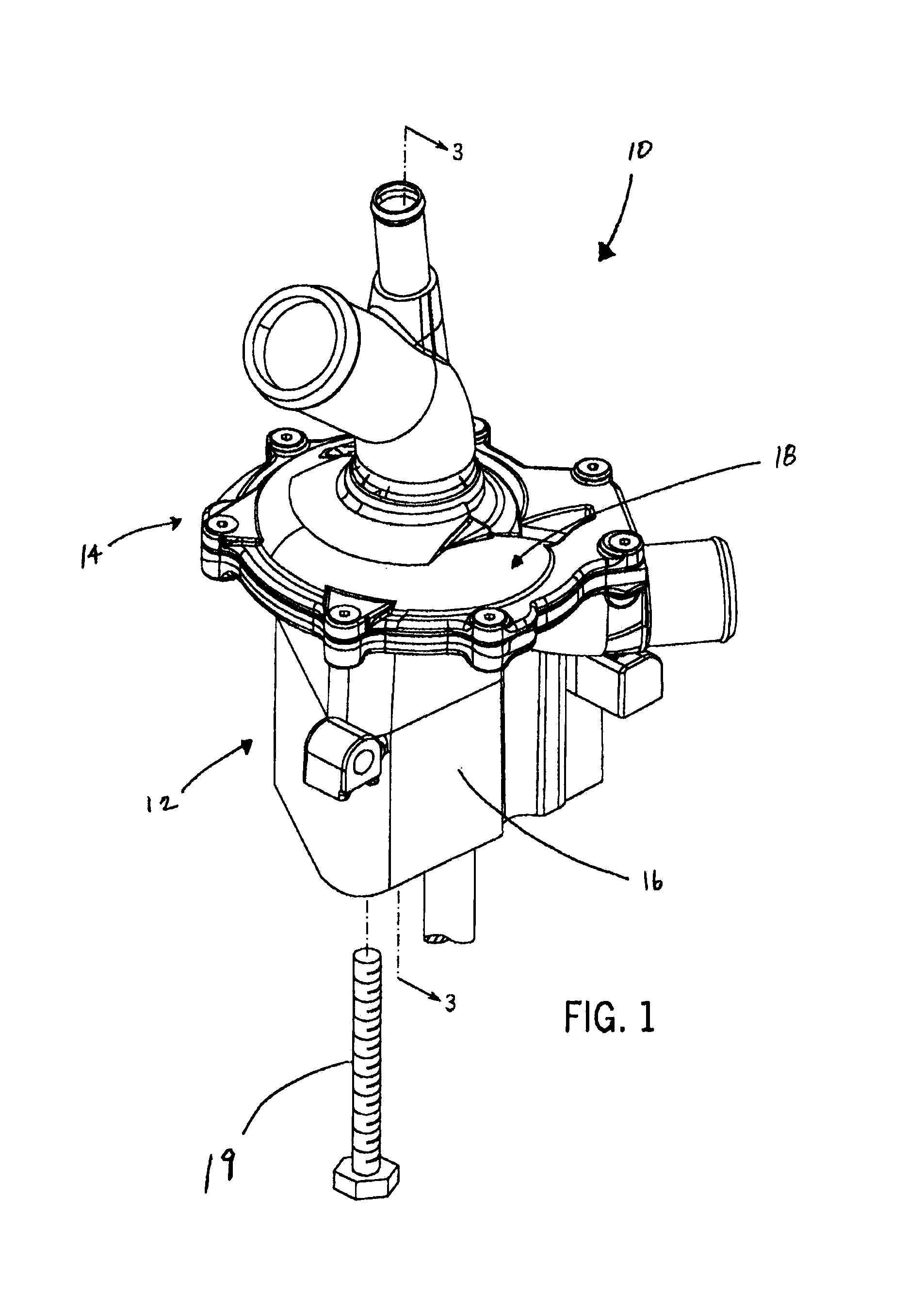

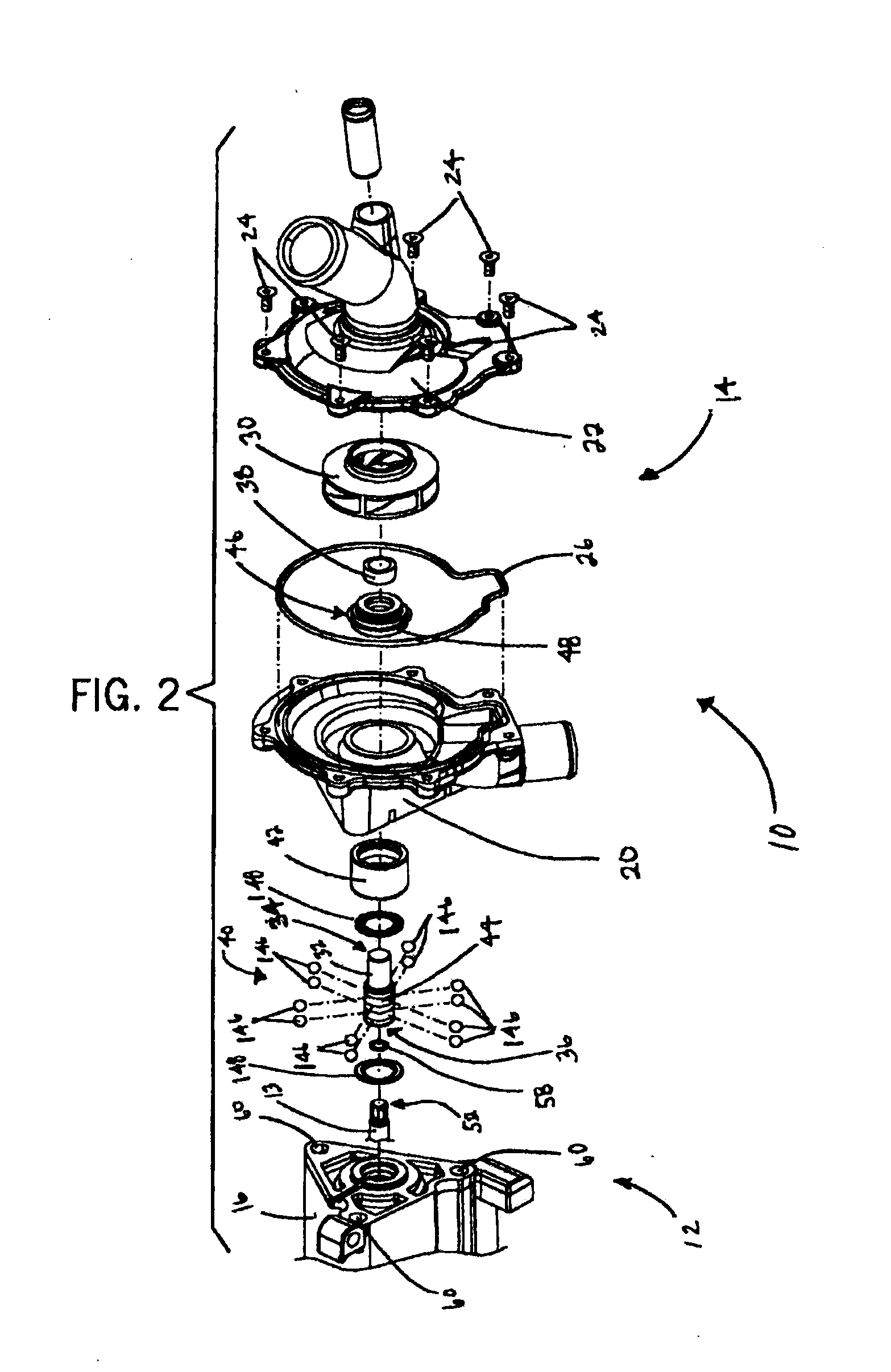

[0020]Referring to FIGS. 1-4, a power steering pump and water pump assembly 10 is shown. The assembly 10 includes a power steering pump 12 and a water pump 14. The power steering pump 12 includes a housing 16 and the water pump 14 has a housing 18 as well. The power steering pump 12 housing 16 is assembled to the water pump 14 housing 18 through fasteners 19 (only one shown in FIG. 1 for clarity). As shown in FIG. 2, the power steering pump 12 includes a rotatable shaft 13. The rotatable shaft 13 is driven by an engine (not shown) to pressurize and distribute power steering fluid as known to one skilled in the art. The power steering pump 12 shaft 13 drives the water pump 14.

[0021]As shown in FIG. 2, the water pump 14 housing 18 is constructed of a pair of mating housing parts 20, 22. The housing parts 20, 22 are fastened together with a series of fasteners 24. A gasket 26 is placed between the two mating housing parts 20, 22 to seal the connection of the two housing parts 20, 22 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| torque | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com