Tray-shaped packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

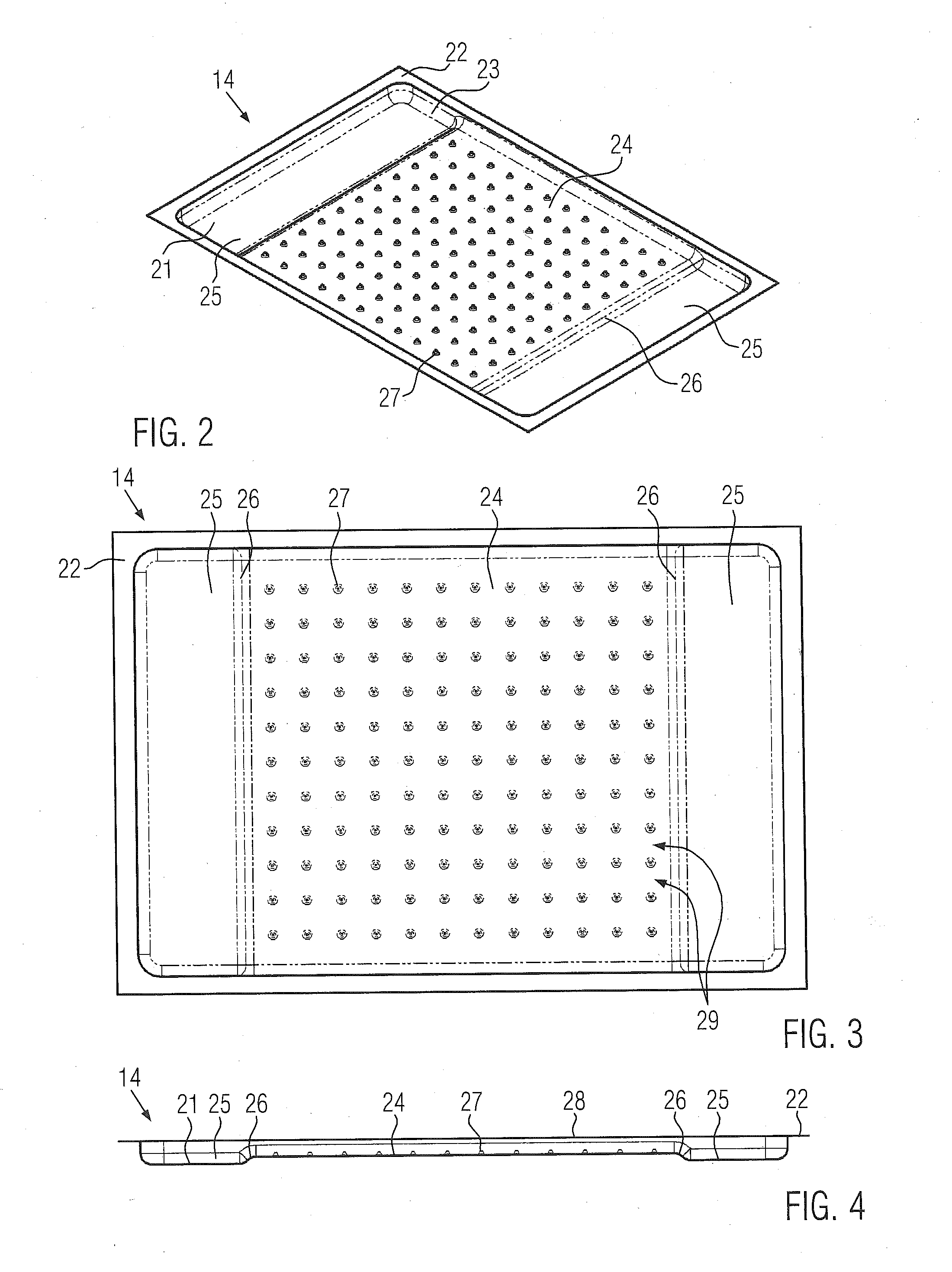

[0047]In contrast to the first embodiment, however, the elevations 27 are now pyramid-shaped. The pyramidal elevations 27 are arranged in a matrix pattern. Again, a step 26 is present between the central support section 24 and each of the collecting sections 25, such that each collecting section 25 entirely has a larger depth relative to the margin 22 than the support section 24.

[0048]FIG. 6 shows a top view of the tray-shaped packaging 14 of FIG. 5. FIG. 7 shows a lateral view of the packaging 14 of FIG. 5. FIG. 7 allows appreciating in particular the pyramid shape of the elevations 27.

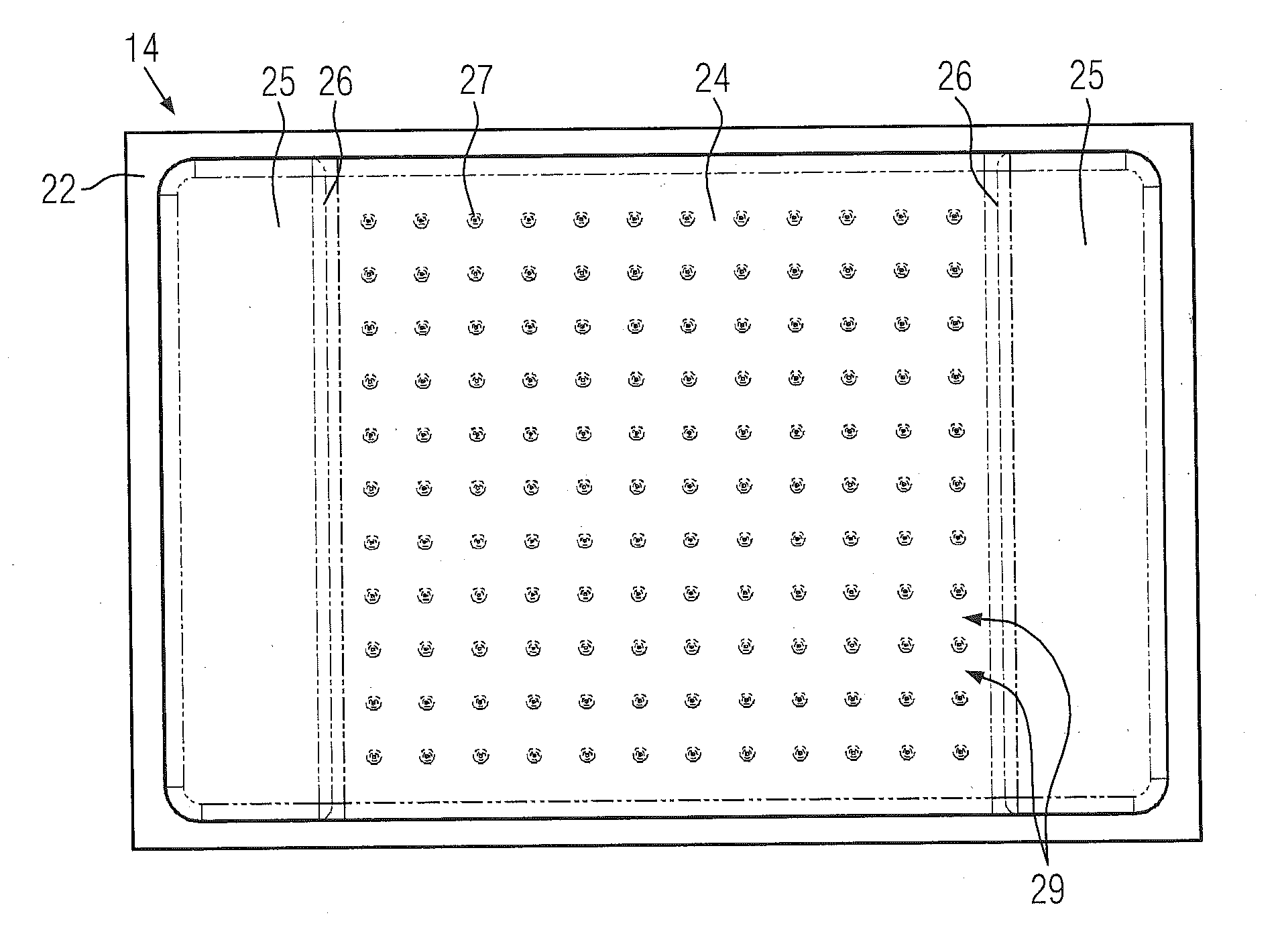

[0049]In each of the embodiments of the packaging 14 according to FIG. 2 or 5, drainage channels 29 are provided between the elevations 27 (cf. FIGS. 3 and 6). These drainage channels 29 are configured to lead excess grease or liquid dripping from the product towards one of the collecting sections 25.

[0050]Further, FIGS. 4 and 7 show that the tray-shaped packaging 14 may rest stably on the two collec...

third embodiment

[0051]FIG. 8 shows a tray-shaped packaging 14 according to the present invention. This embodiment is similar to the embodiment shown in FIG. 5, except for lacking a step between the central support section 24 and the two lateral collection sections 25. Rather, the bottom of the support section 24 has a convex shape on its side facing the interior of the packaging 14. The elevations 27 on the support section 24 are again pyramid-shaped. However, the size of the elevations 27 is smaller in the center and larger in the periphery of the support section 24. This ensures that the peaks 30 of all elevations 27 are arranged in a common plane (P), which is represented by a dashed line. In the present embodiment, this plane is planar, but it could alternatively be curved.

[0052]FIG. 8 shows that the packaging 14 rests on a support surface 31, such as an oven tray.

[0053]FIGS. 9a to 9d show different embodiments of the elevations 27, which can be provided on the support section 24. In FIG. 9a, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com