Central compressor variable refrigerant flow air conditioning sysytem

a technology of air conditioning and compressor, which is applied in the direction of refrigeration components, lighting and heating apparatus, heating types, etc., can solve the problems of limited prior art refrigerant piping lengths and severe curtailment of prior art applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

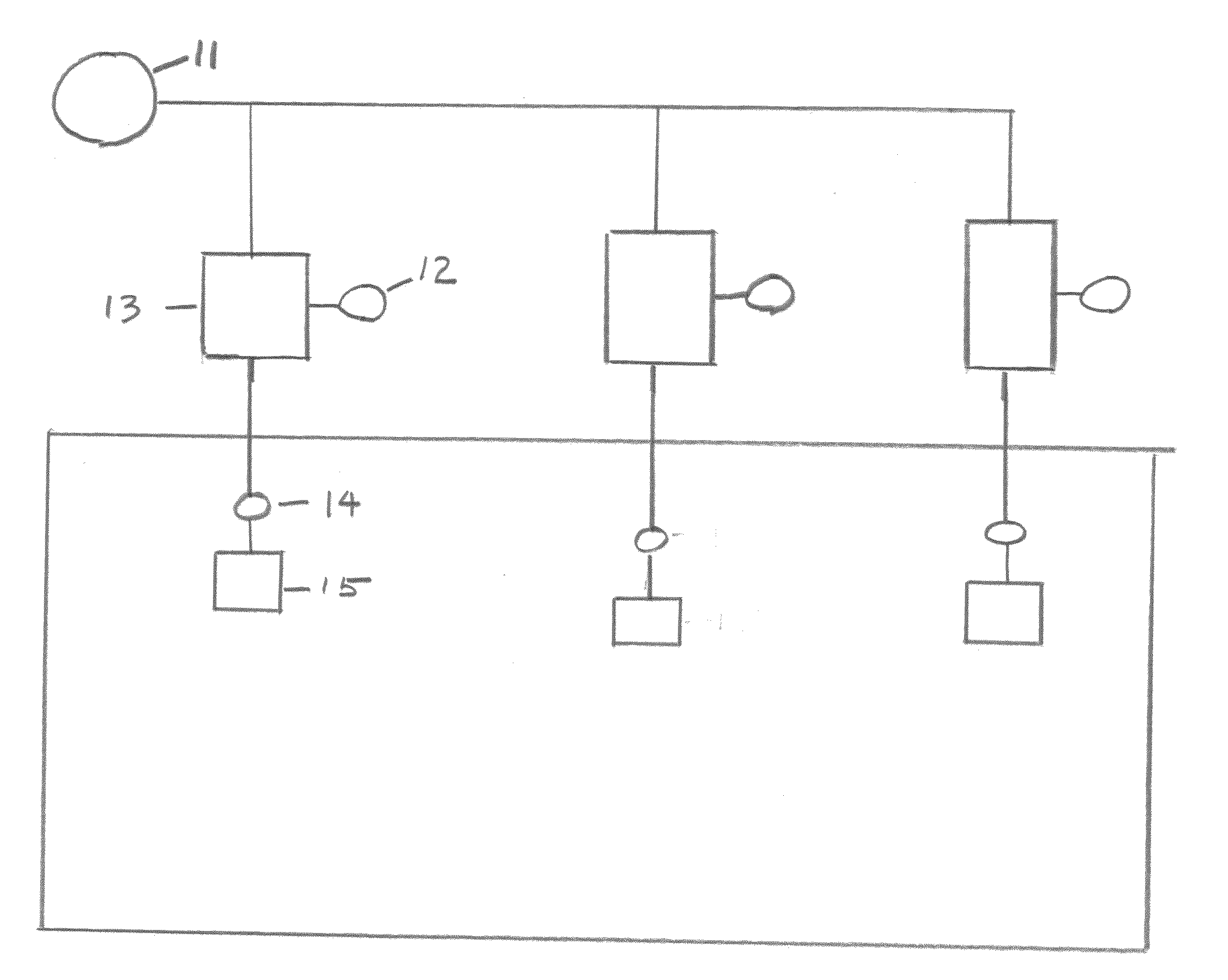

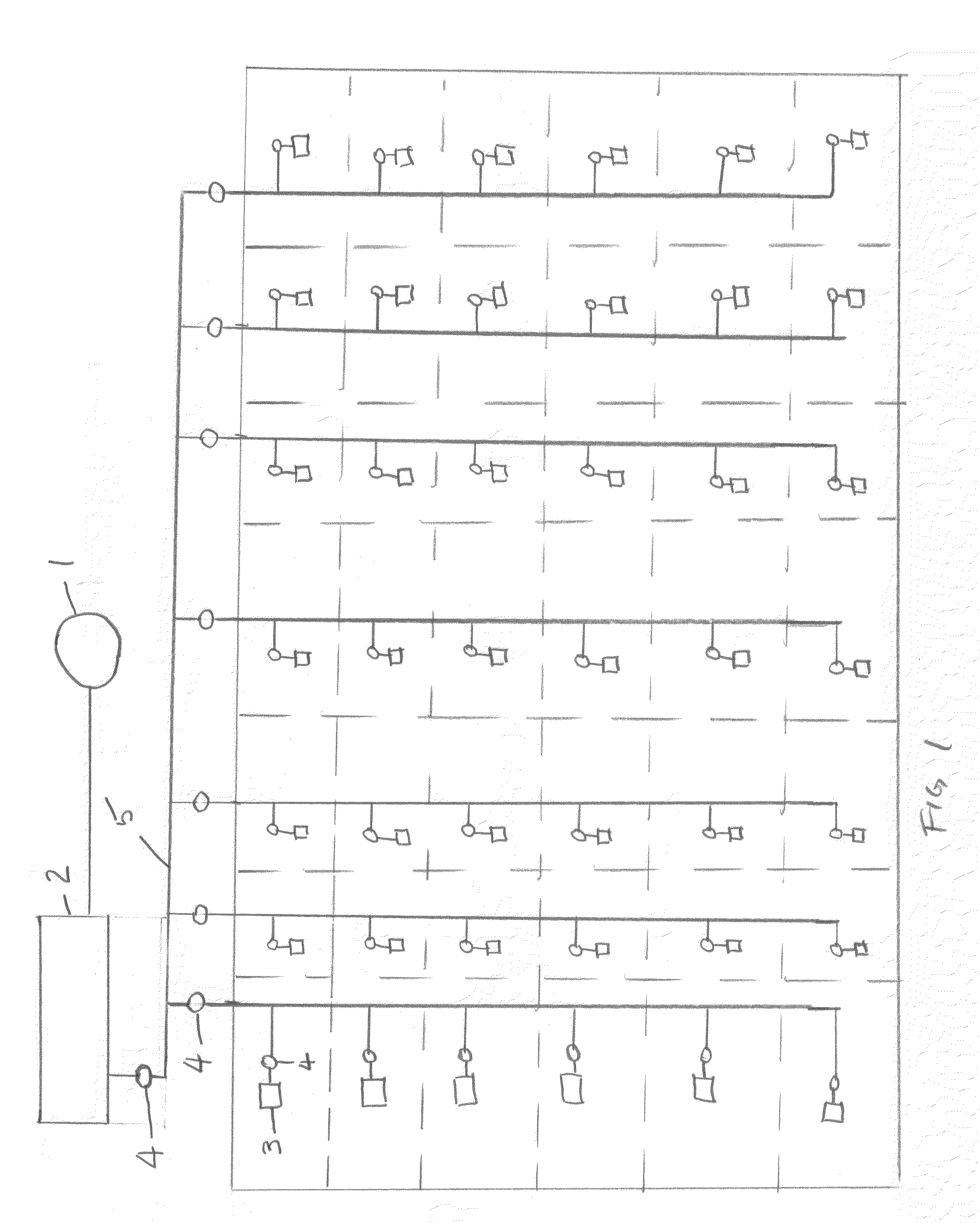

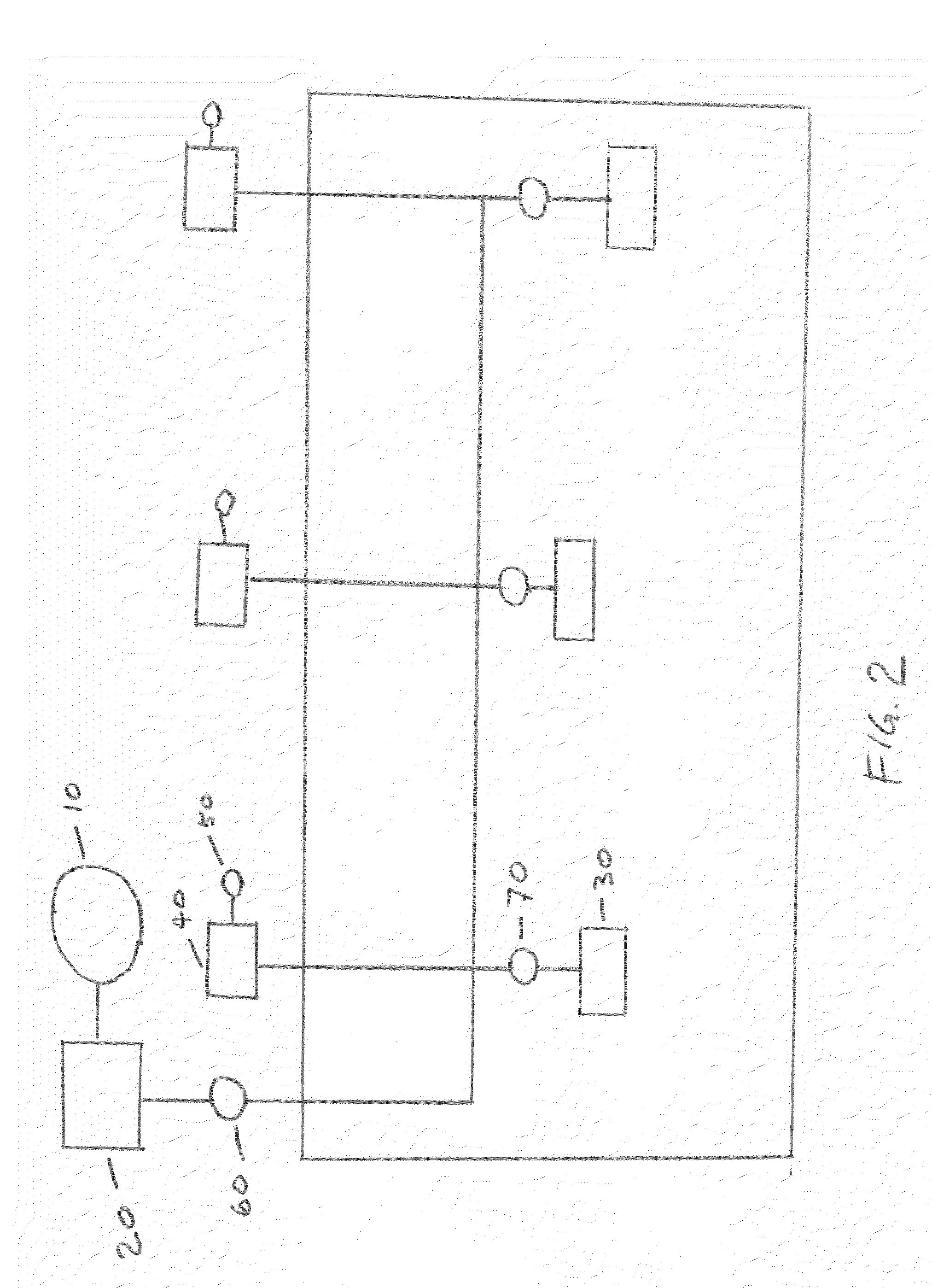

[0023]FIG. 1 sets out an overall schematic view of the present application. Central station compressor 1 consists of magnetic levitation bearing types requiring no entrained oil in the refrigerant fluid. It compresses the oil free refrigerant and delivers it to a central condenser package 2 for removal of heat from the refrigerant. Thereafter the refrigerant travels to the various evaporators 3 which are placed in the building space at locations where heat is to be removed from the space.

[0024]Expansion valves 4 are disposed at appropriate locations upstream of the various evaporators 3.

[0025]By controlling the refrigerant flow to each evaporator 3, using an electronic control / flow control system (not shown), the amount of cooling can be carefully and specifically regulated at each cooling location.

[0026]By virtue of the present invention, the distances in the spans of the refrigerant piping are no longer limited in particular due to the absence of entrained oil in the refrigerant l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com