Multi-facet light engine

a light engine and facet technology, applied in the field of multi-facet light engines, can solve the problems of reducing efficiency, adding additional optical elements, adding cost and complexity to the lighting assembly,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

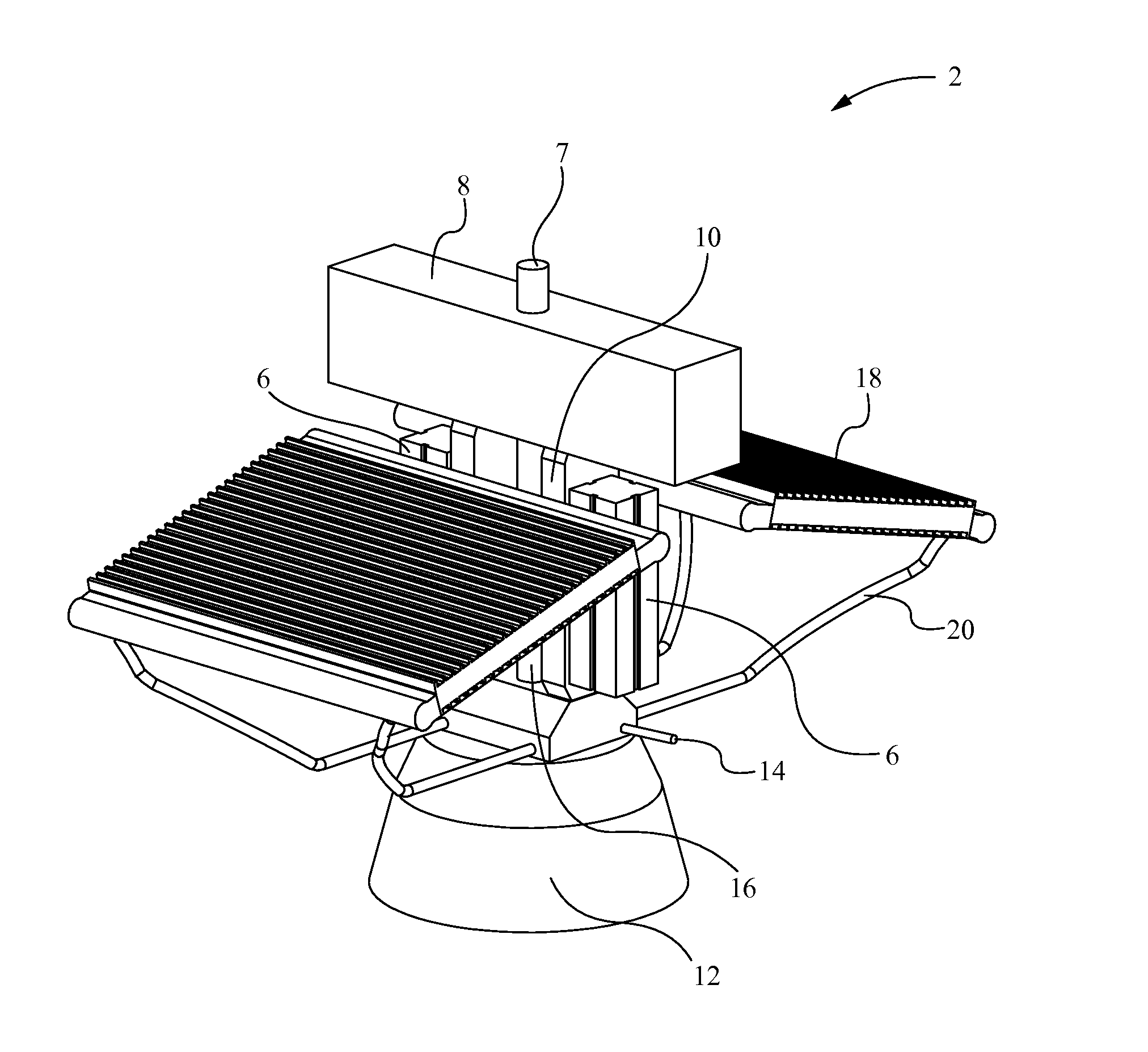

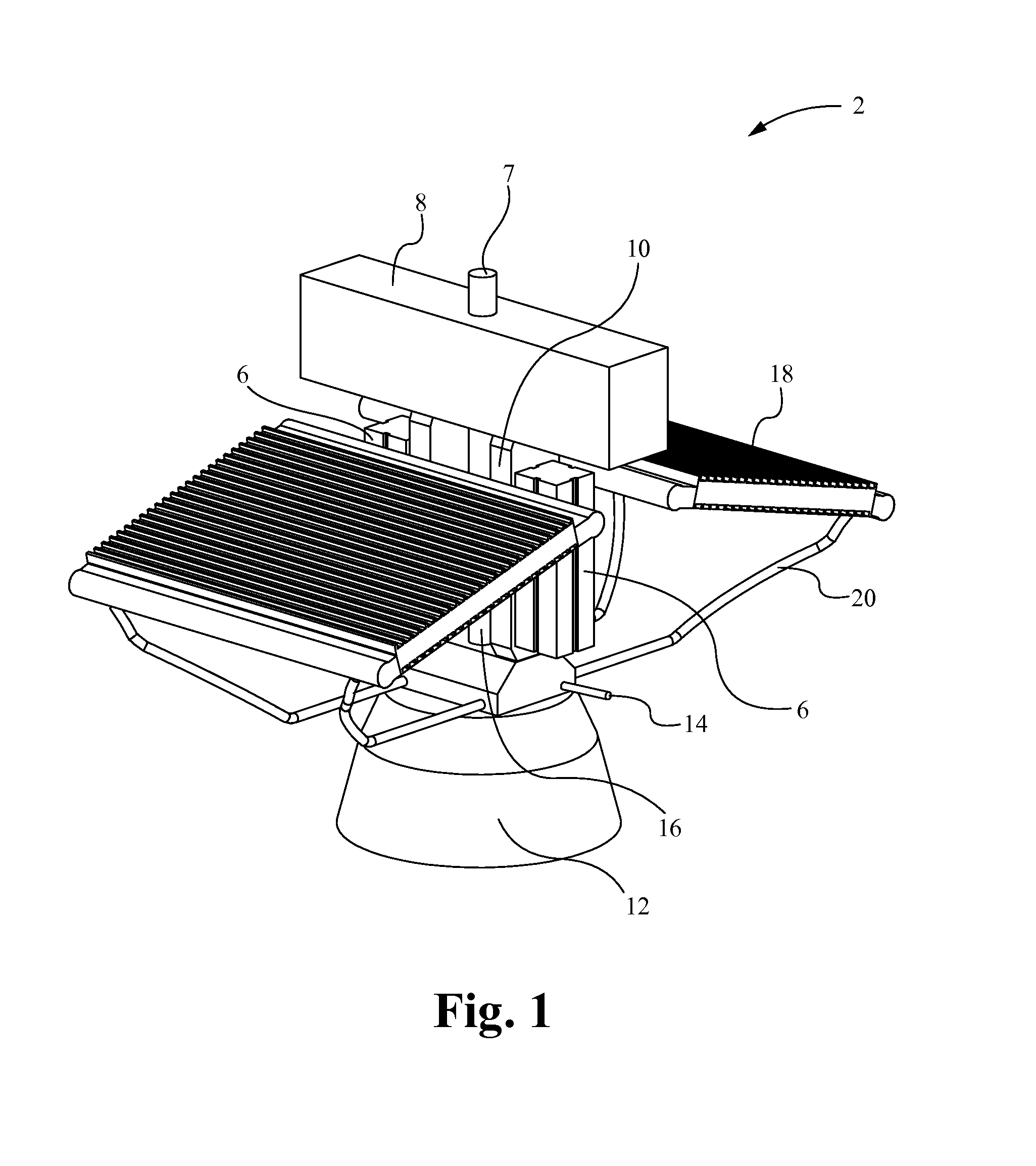

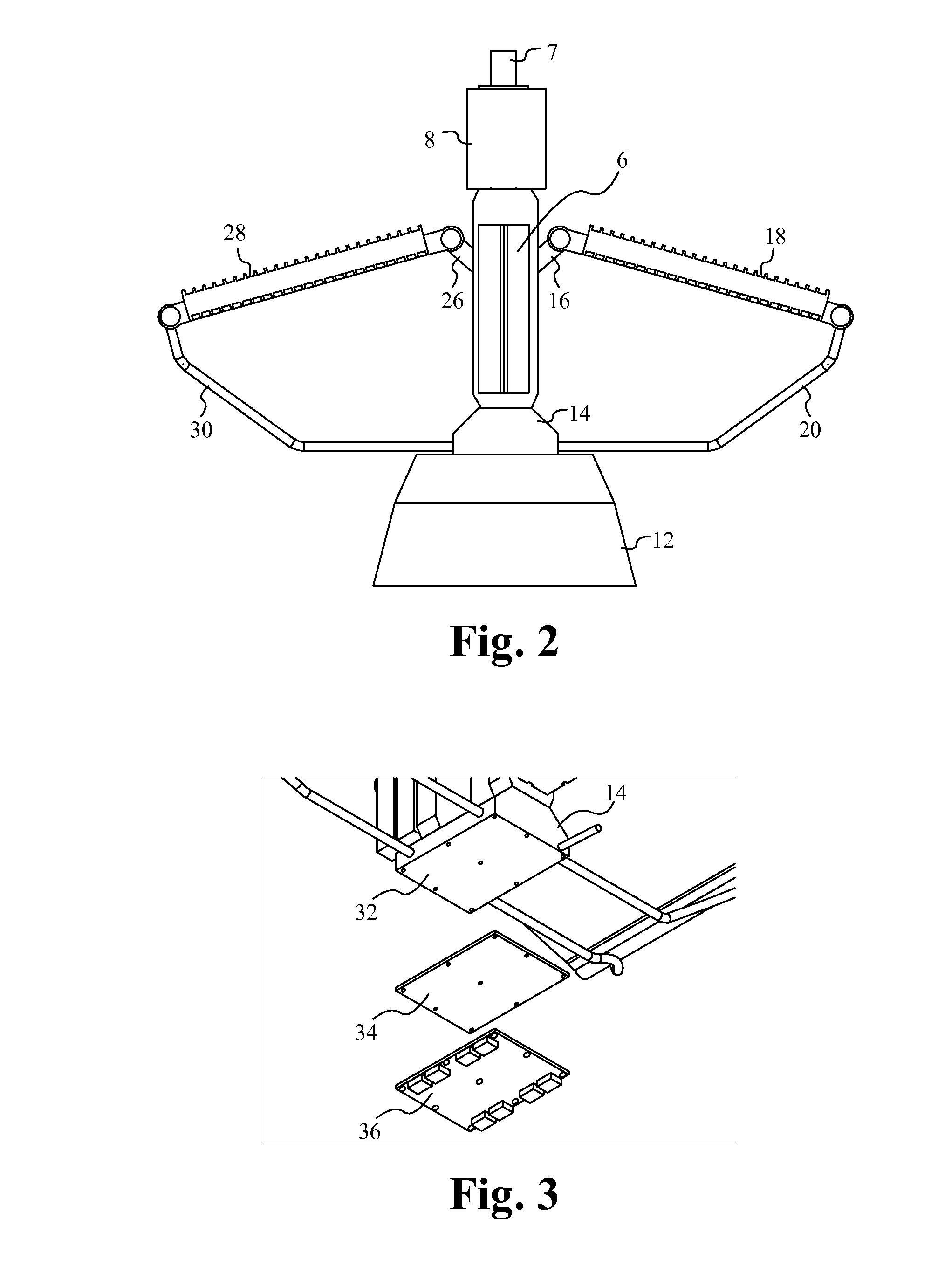

[0021]Embodiments of the present application are directed to a lighting assembly. Those of ordinary skill in the art will realize that the following detailed description of the lighting assembly is illustrative only and is not intended to be in any way limiting. Other embodiments of the lighting assembly will readily suggest themselves to such skilled persons having the benefit of this disclosure.

[0022]Reference will now be made in detail to implementations of the lighting assembly as illustrated in the accompanying drawings. The same reference indicators will be used throughout the drawings and the following detailed description to refer to the same or like parts. In the interest of clarity, not all of the routine features of the implementations described herein are shown and described. It will, of course, be appreciated that in the development of any such actual implementation, numerous implementation-specific decisions must be made in order to achieve the developer's specific goa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com