Stand-up bag of a weldable foil for holding pourable contents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

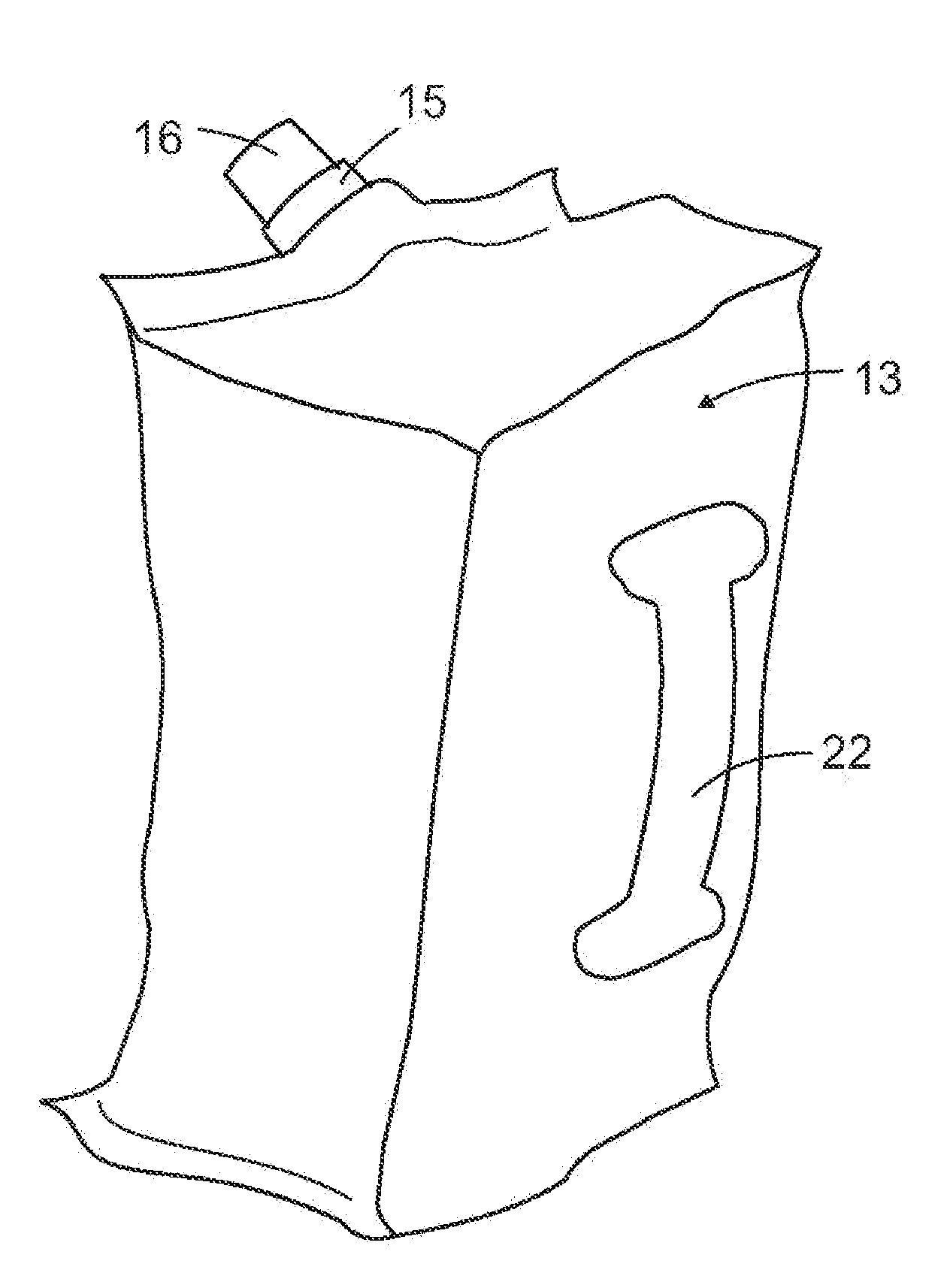

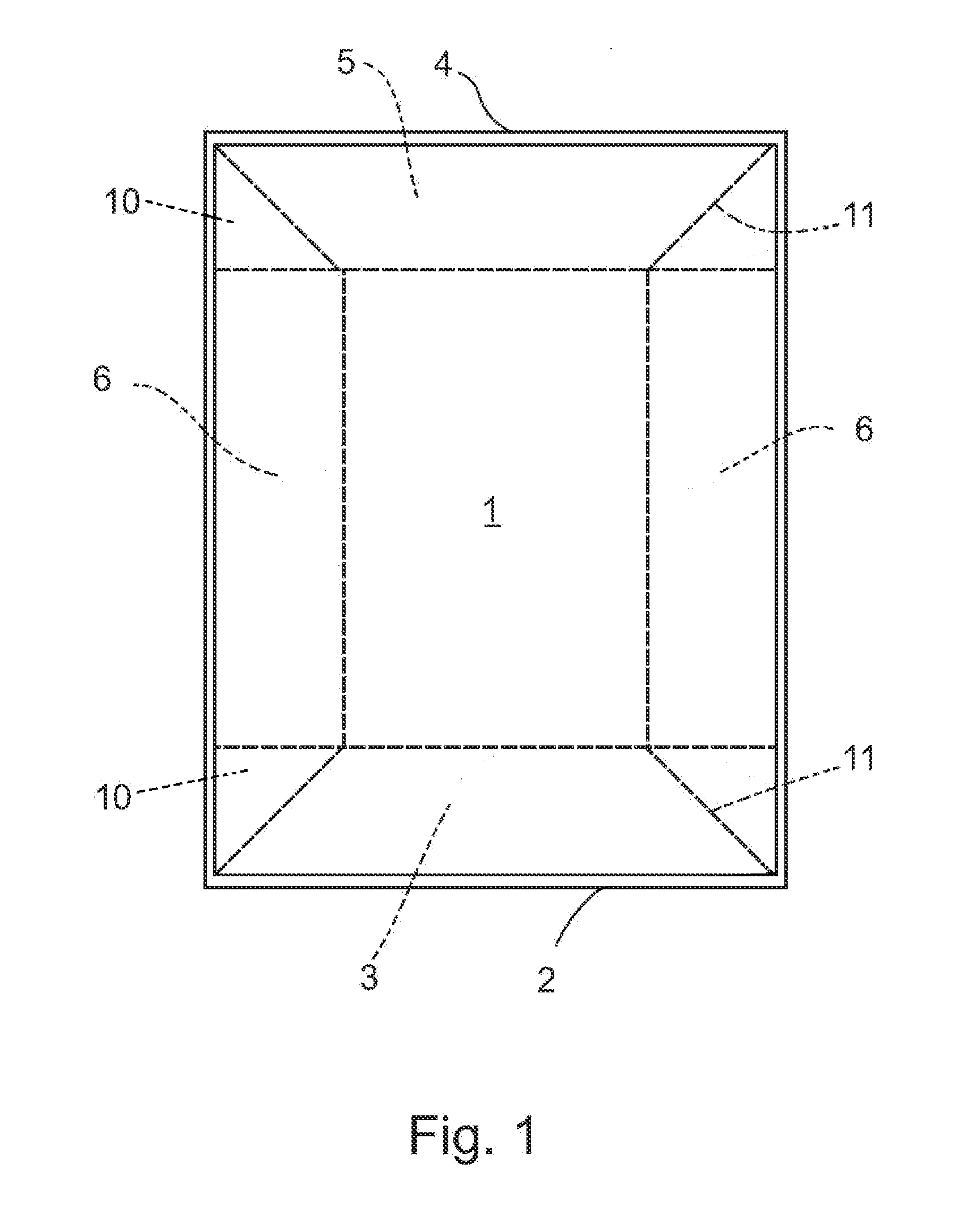

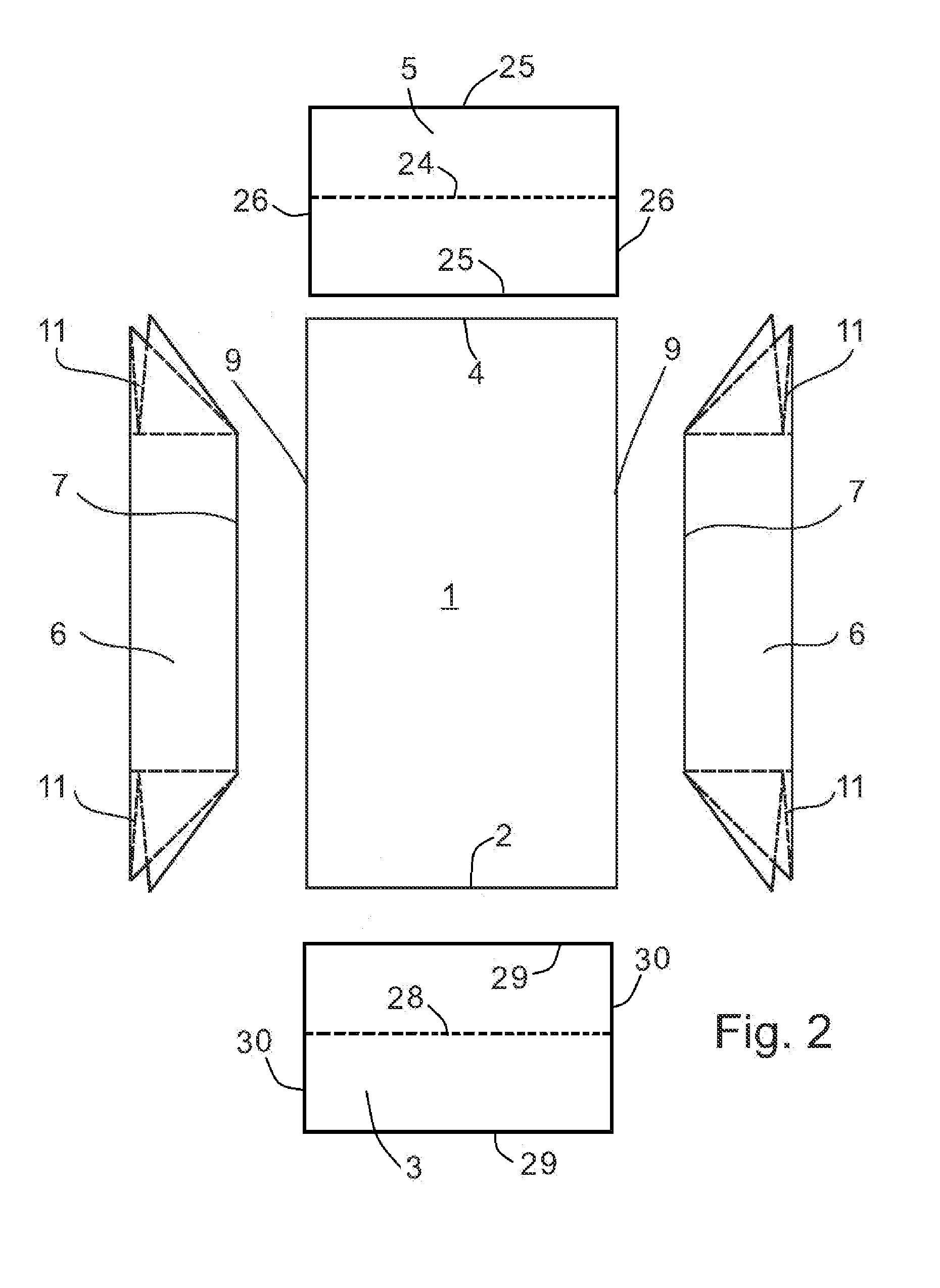

[0029]A stand-up bag 13 made of a thermoplastic weldable film is fabricated to lie flat when empty as shown in FIG. 1. When filled with a liquid, a pasty material, or particles it assumes a generally parallepipedal shape as shown in FIG. 5. This bag 13 has as shown also in FIG. 2 rectangular front and back face panels 1 each with two long vertical side edges 9 and two shorter horizontal bottom and top edges 2 and 4. A rectangular top panel 5 has parallel long front and back edges 25 that are joined by is welds to the top edges 4 and a rectangular floor panel 3 has parallel long front and back edges 29 welded to the bottom edges 2. The panels 5 and 3 have respective central creases 24 and 28 parallel to the respective edges 25 and 29 that divide them each into two identical rectangular flaps.

[0030]As also shown in FIGS. 3 and 4, rectangular side gusset panels 6 having short straight upper and lower edges 31 and long straight vertical side edges 32 are subdivided by a central crease 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weldability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com