Weatherable tyre tread pattern structure

A tread pattern and tire technology, which is applied in the direction of tire tread/tread pattern, road tires, tire parts, etc., can solve the problems of reduced braking performance, reduced ride feel, and high noise, and achieves improved handling. , the effect of improving drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Hereinafter, the present invention will be described in detail based on the attached example drawings.

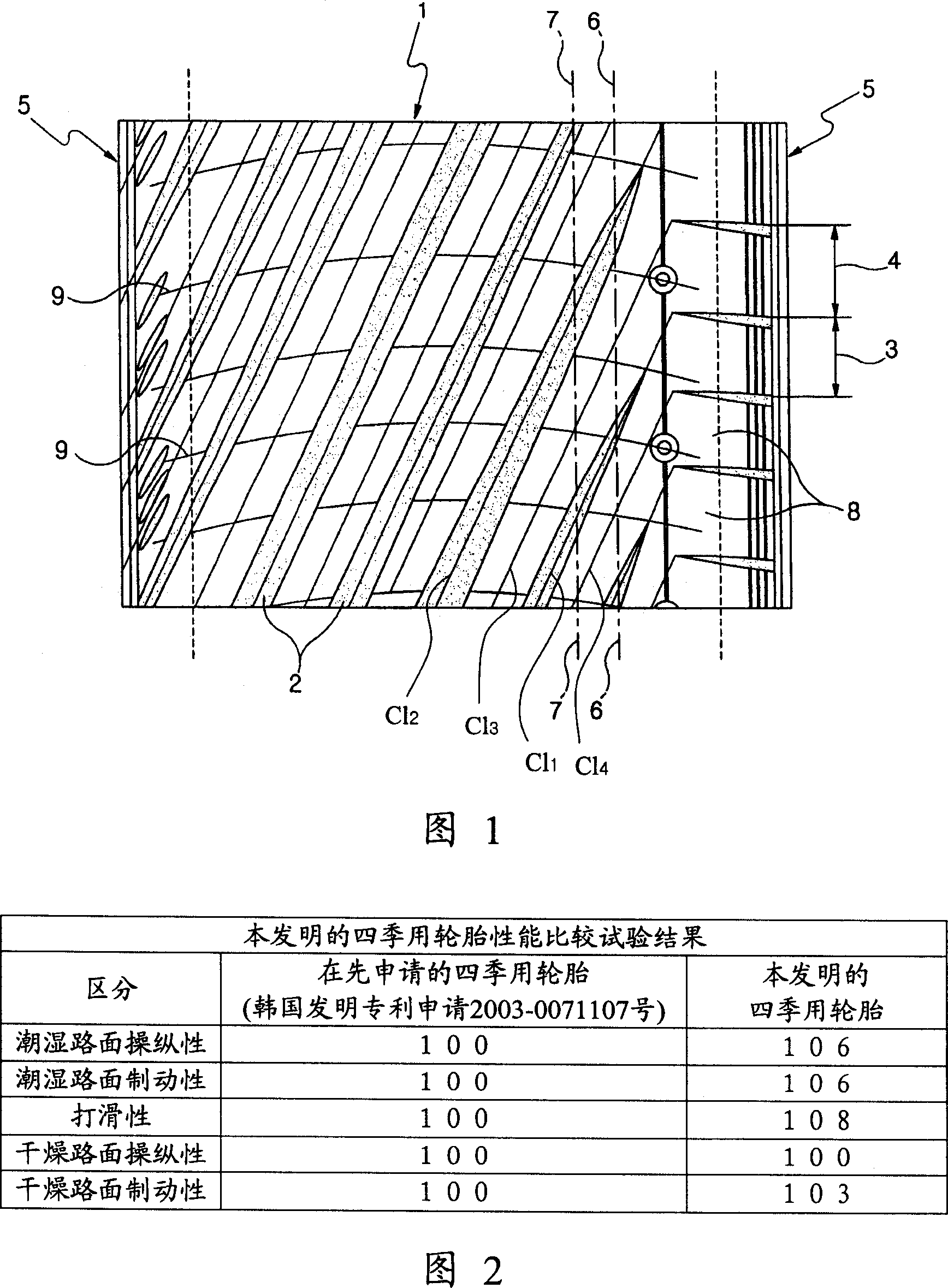

[0010] Fig. 1 shows a top view of the tread pattern structure of a high-performance tire according to the present invention.

[0011] The tread pattern of the present invention includes lateral grooves 2 continuously arranged in the circumferential direction and continuously extending from the inner side to the outer side. The transverse groove is inclined at 20 to 50° with respect to the tire circumferential direction. The width of the transverse groove 2 is set as follows: Let the center line of the transverse groove 2 be Cl 1 , The center lines of the transverse grooves 2 on both sides adjacent to the transverse groove are Cl 2 , Cl 1 With Cl 2 The middle line (the center line between the lines) at 1 / 2 of the width between the lines is Cl 3 , Cl 4 , The centerline Cl of transverse slot 2 1 And the center line between the line Cl 3 , Cl 4 The connecting line in the tir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com