Gas supply device for a vacuum processing chamber, method of gas supplying and switching

a vacuum processing chamber and gas supply device technology, applied in water supply installation, process and machine control, instruments, etc., can solve the problems of increasing production cost, waste of processing gas, and continuous delivery of process gas, so as to reduce processing time, reduce production cost, and reduce the effect of reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0030]FIG. 3 shows a gas supply device for a vacuum processing chamber of the present invention. In this embodiment, the gas supply device is used in semiconductor equipment for the application of TSV process. TSV process requires rapid switching between etching step and deposition step.

[0031]The gas supply device includes six gas switches and six reactant gas sources. The outputs of the gas supply device are connected to two vacuum processing chambers or two processing stations in one vacuum processing chamber.

[0032]In this embodiment, the outputs of gas supply device are connected to two vacuum processing chambers, which are the first vacuum processing chamber 307 and the second vacuum processing chamber 308.

[0033]The six reactant gas sources are the first reactant gas source 301, the second reactant gas source 302, the third reactant gas source 303, the fourth reactant gas source 304, the fifth reactant gas source 305 and the sixth reactant gas source 306.

[0034]The outputs of the...

second embodiment

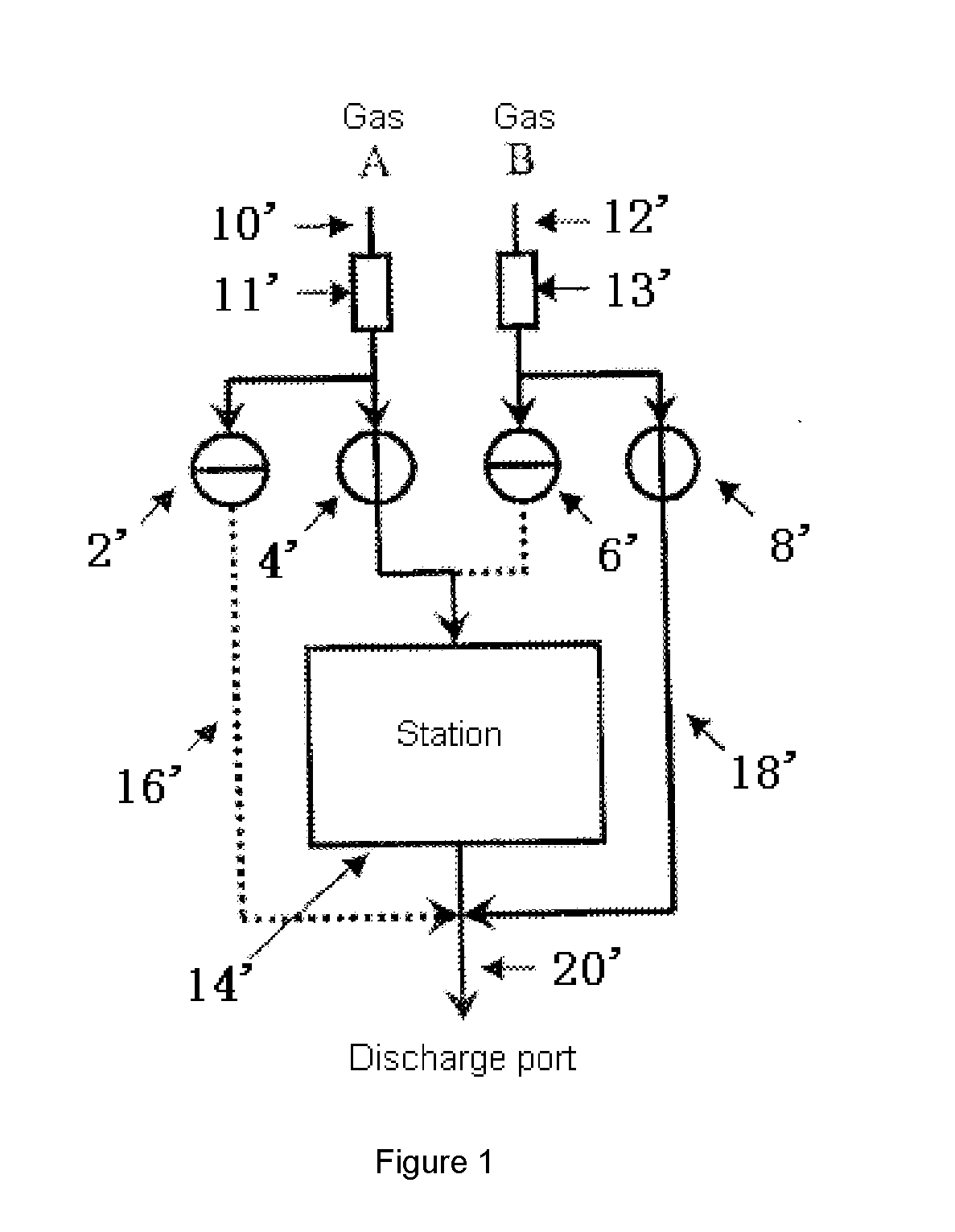

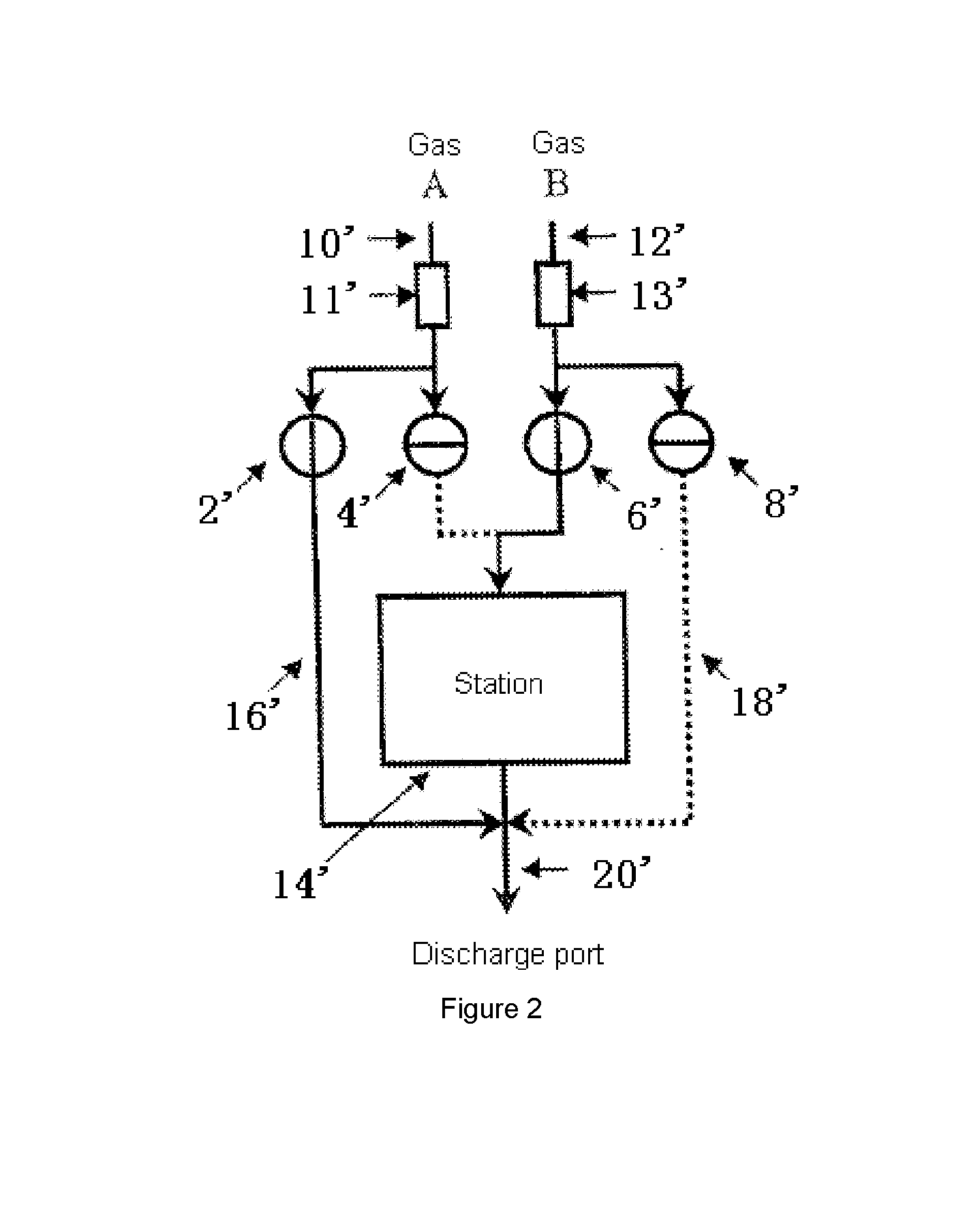

[0073]FIG. 4 shows a gas supply device for a vacuum processing chamber.

[0074]The gas supply device supplies alternatively two types of reactant gases into two vacuum processing chambers. The two types of reactant gases are etching reactant gas and deposition reactant gas, respectively.

[0075]In this embodiment, the gas supply device is used to provide alternatively two types of reactant gases into two vacuum processing chambers, which are etching reactant gas and deposition reactant gas, respectively.

[0076]It should be noted that, the present invention is not limited to the above description. The gas supply device of the present invention can also be applied to provide reactant gases to two processing stations in one vacuum processing chamber. In addition, the gas supply device provides at least two types of reactant gases to at least two vacuum processing chambers or two processing stations in one vacuum processing chamber. However, the technicians in this field should understand th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| switching time | aaaaa | aaaaa |

| switching time | aaaaa | aaaaa |

| process time t1 | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap