Method and Apparatus for Completion of Heavy Oil Unconsolidated Sand Reservoirs

a technology of unconsolidated sand and methods, applied in the direction of fluid removal, artificial islands, underwater structures, etc., can solve the problems of low success, overbalance of methods, and low success, and achieve enhanced connection, low impact, and high permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]As a preliminary matter, it should be noted that in this document (including the claims) directional terms, such as “above”, “below”, “upper”, “lower”, etc., are used for convenience in referring to the accompanying drawings. Additionally, it is to be understood that the various embodiments of the invention described herein may be utilized in various orientations, such as inclined, inverted, horizontal, vertical, etc., without departing from the principles of the invention.

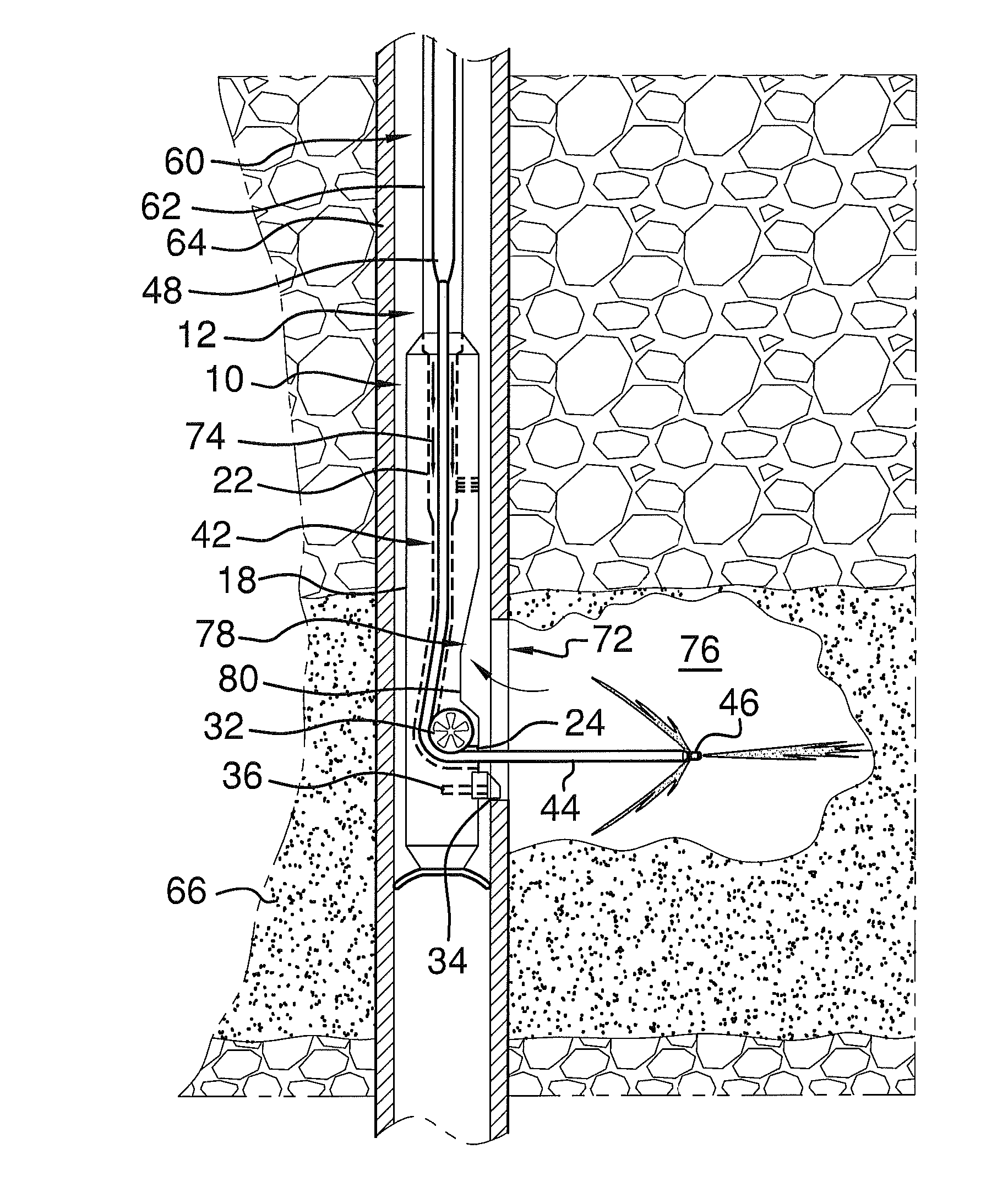

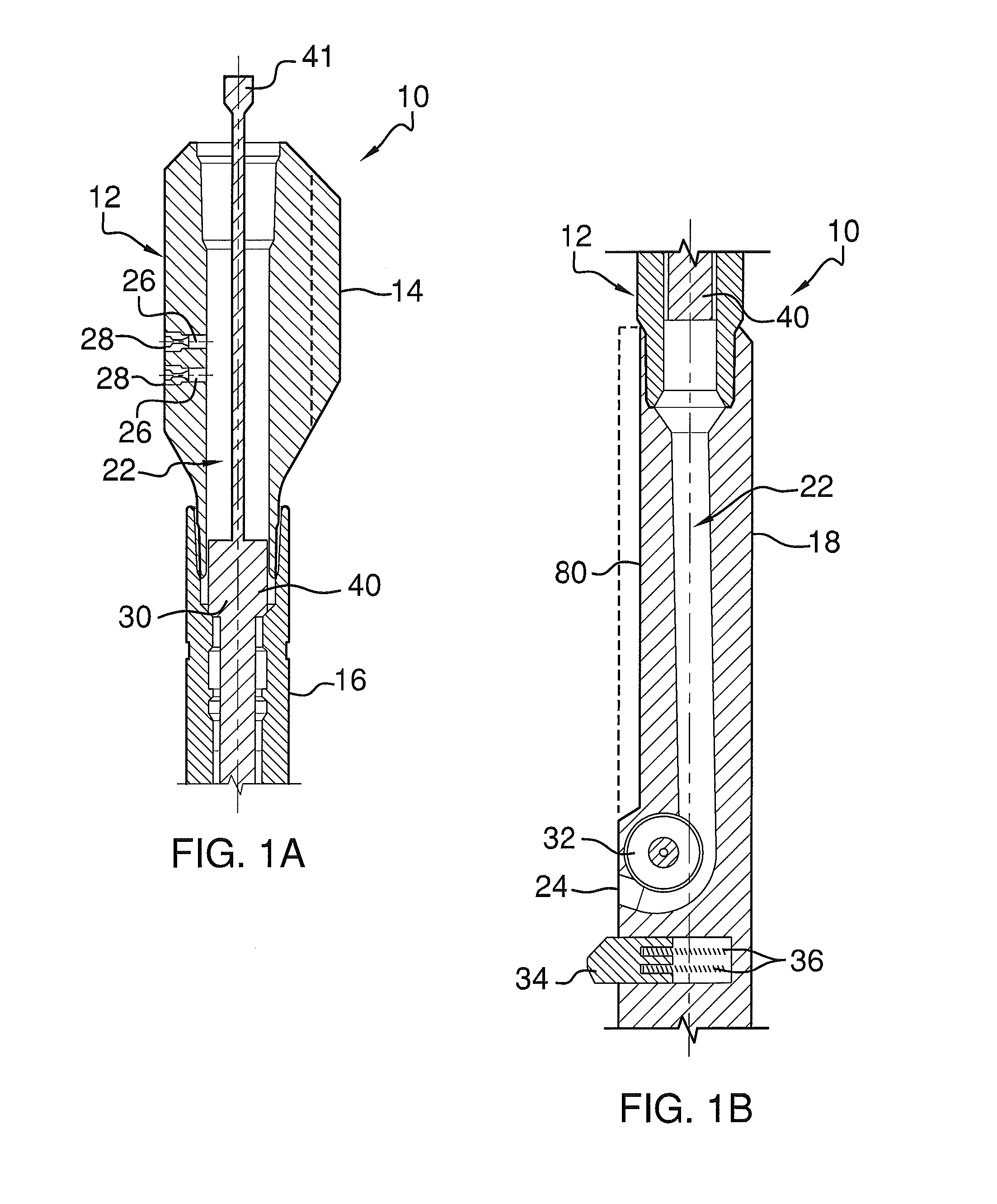

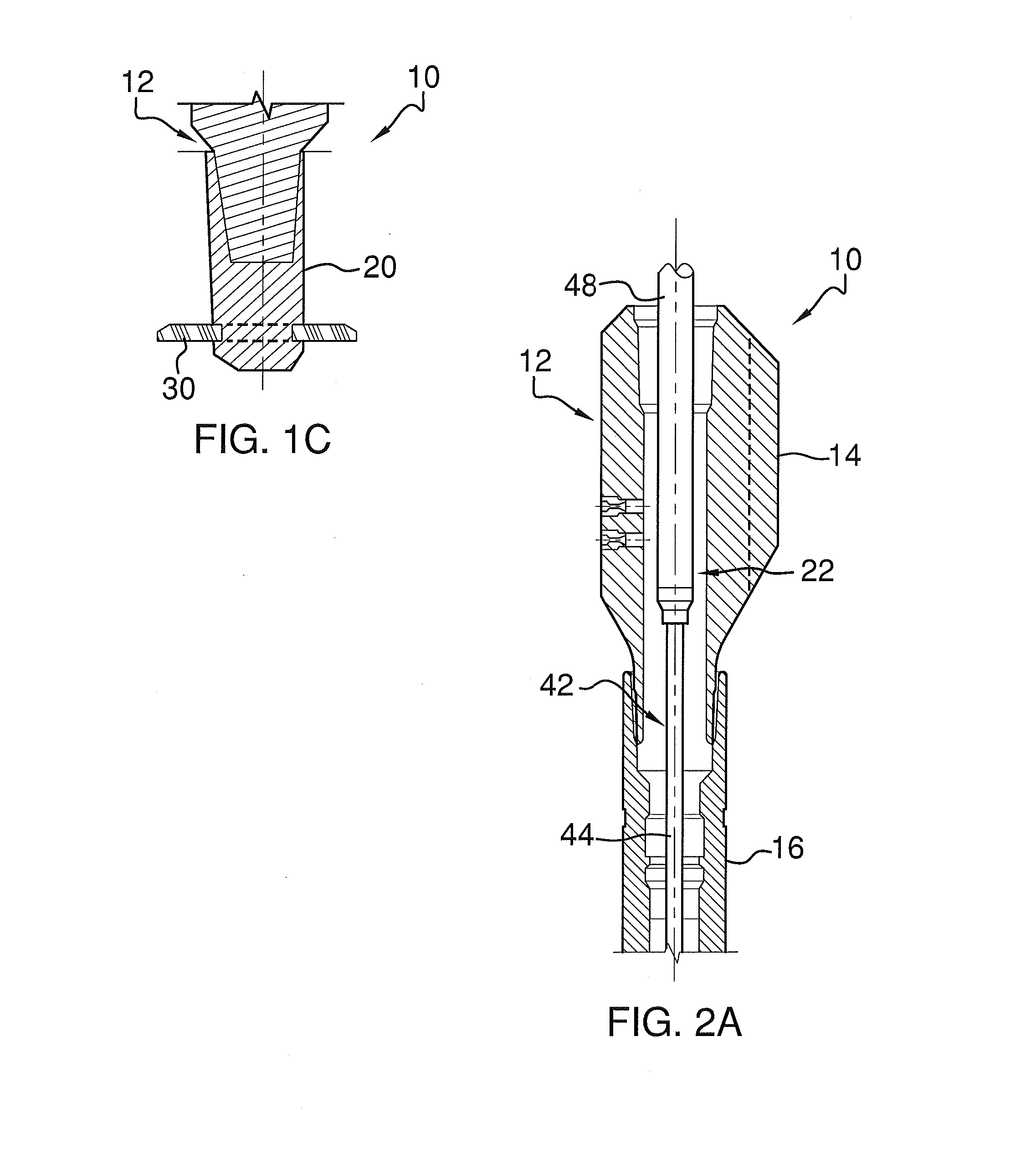

[0035]Representatively illustrated in FIGS. 1A-C is a well casing perforation tool and formation boring tool 10 in accordance with an embodiment of the invention. Tool 10 is shown in a well casing perforation configuration and includes a tool body 12 having an abrasive jet perforation sub 14, a landing nipple 16, a jetting shoe 18 and a wiper sub 20 each disposed coaxially and in series from the abrasive jet perforation sub to the wiper sub. Body 12 further includes an internal axial flow passage 22 extendin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com