Canister

a canister and canister technology, applied in the field of canisters, can solve the problems of contaminating infant formula and formula on the hands of users, utensils are limited in size, utensils are difficult to remove, etc., and achieve the effect of adding rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

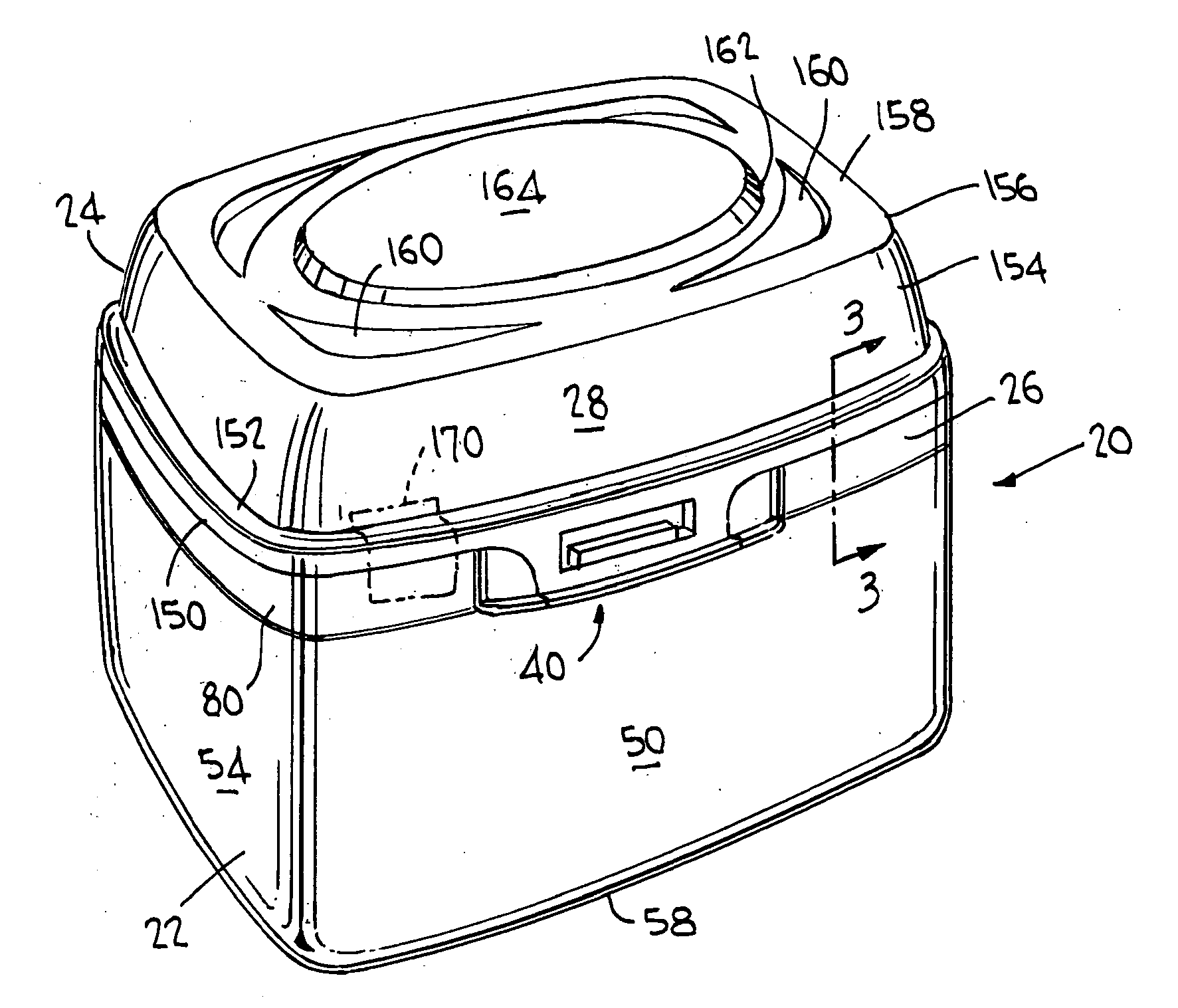

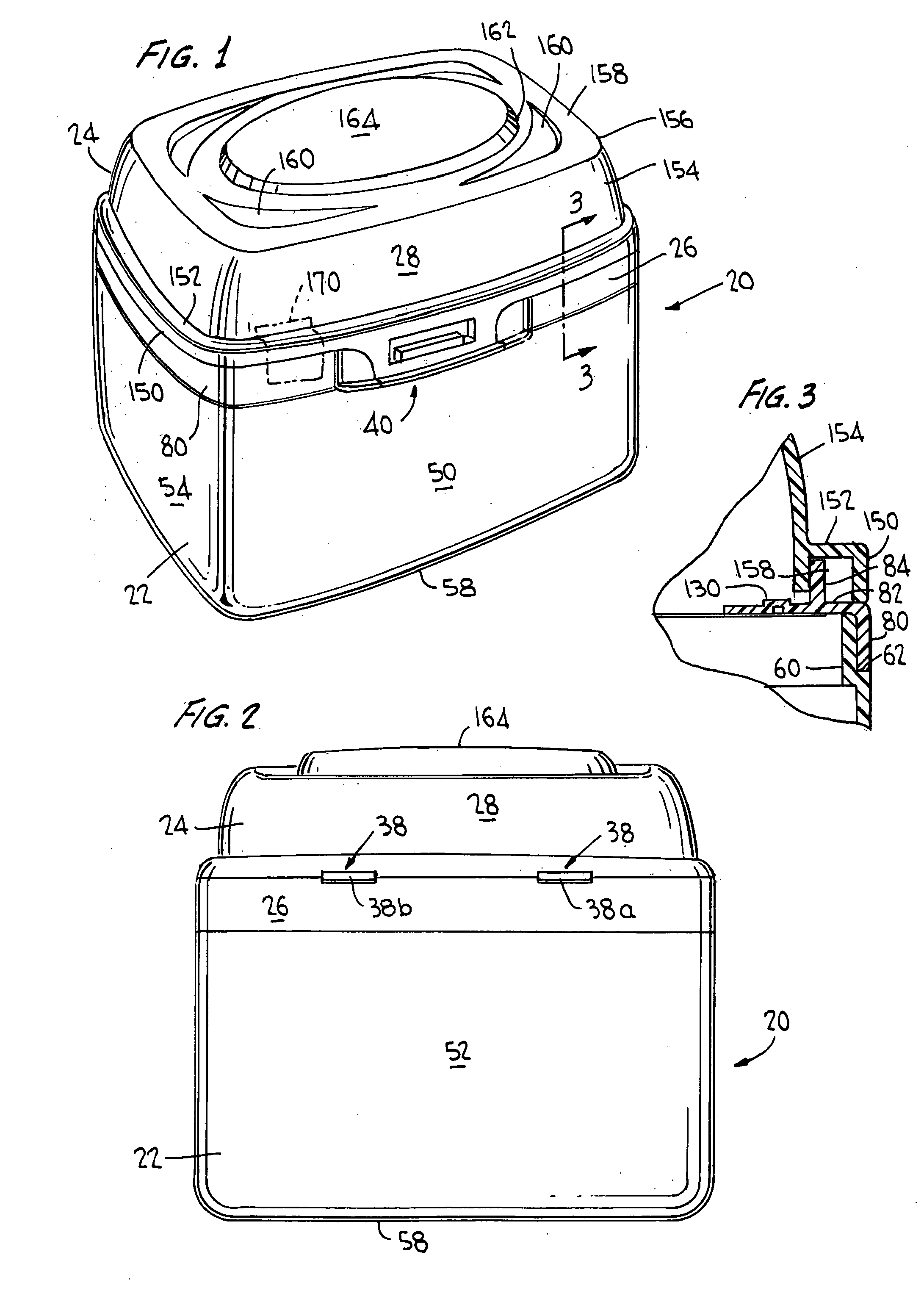

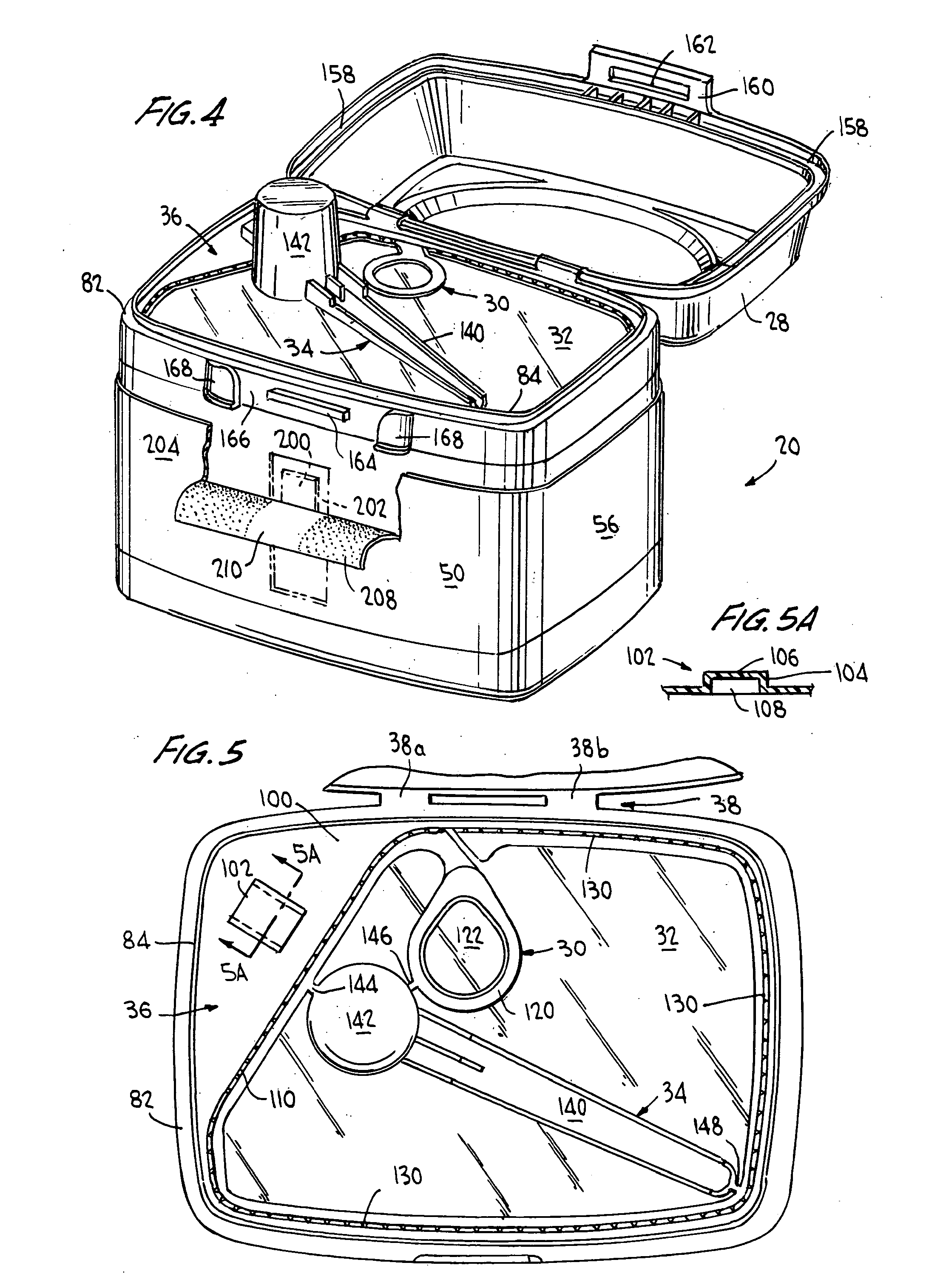

[0049]Preferred embodiments of the canister invention are illustrated in FIGS. 1-28. It is understood that the invention is not limited to these preferred embodiments. One primary useful function of the canister invention is for packaging and dispensing infant formula. The invention will, therefore, be illustrated with reference to packaging and dispensing infant formula. However, it is understood by those skilled in the art that the invention is not so limited and that other materials may be packaged and dispensed from the canister of the invention including, for example, other powder or pulverized materials such as coffee, cereal, etc.

[0050]The canister of the invention as illustrated, for example, in FIGS. 1, 13 and 20 show preferred embodiments having a generally rectangular configuration. Again, it will be understood by those skilled in the art that other shaped canisters may be useful without departing from the scope of the invention, including square, round or other shaped ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com