Device for producing shock-absorbing inflatable package and method for filling it

a technology for inflatable packages and packaging, applied in the field of bags blank, can solve the problems of increasing costs, unable to afford the impact-protecting package of the method and device providing the package, etc., and achieve the effect of less shock-absorbing

Inactive Publication Date: 2014-05-15

PRONOVA

View PDF45 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Such a wrapping of products with a gas-filled package structure is a manual and time-consuming operation, which therefore also becomes costly.

In addition, this type of package structure requires large transport vehicles by the fact that the structure is gas-filled.

These disclosed methods and devices for providing a package do not afford a package having impact-protecting effect for goods packed in such a way.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

second embodiment

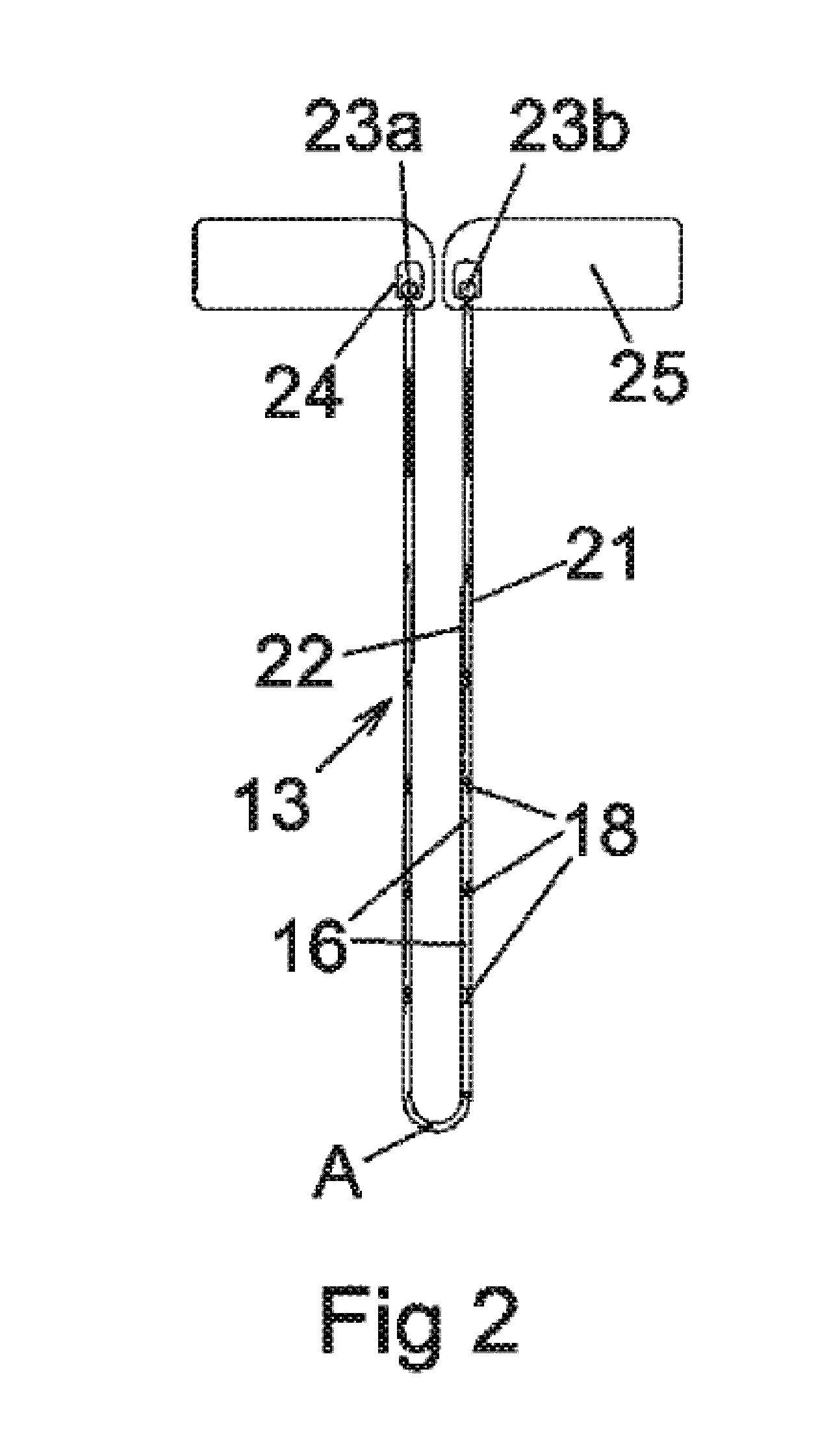

[0040]FIG. 2 shows a section through a bag blank mounted in holder means according to the invention.

third embodiment

[0041]FIG. 3 shows a section through a bag blank mounted in holder means according to the invention.

fourth embodiment

[0042]FIG. 4 shows a section through a bag blank mounted on holder means according to the invention.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

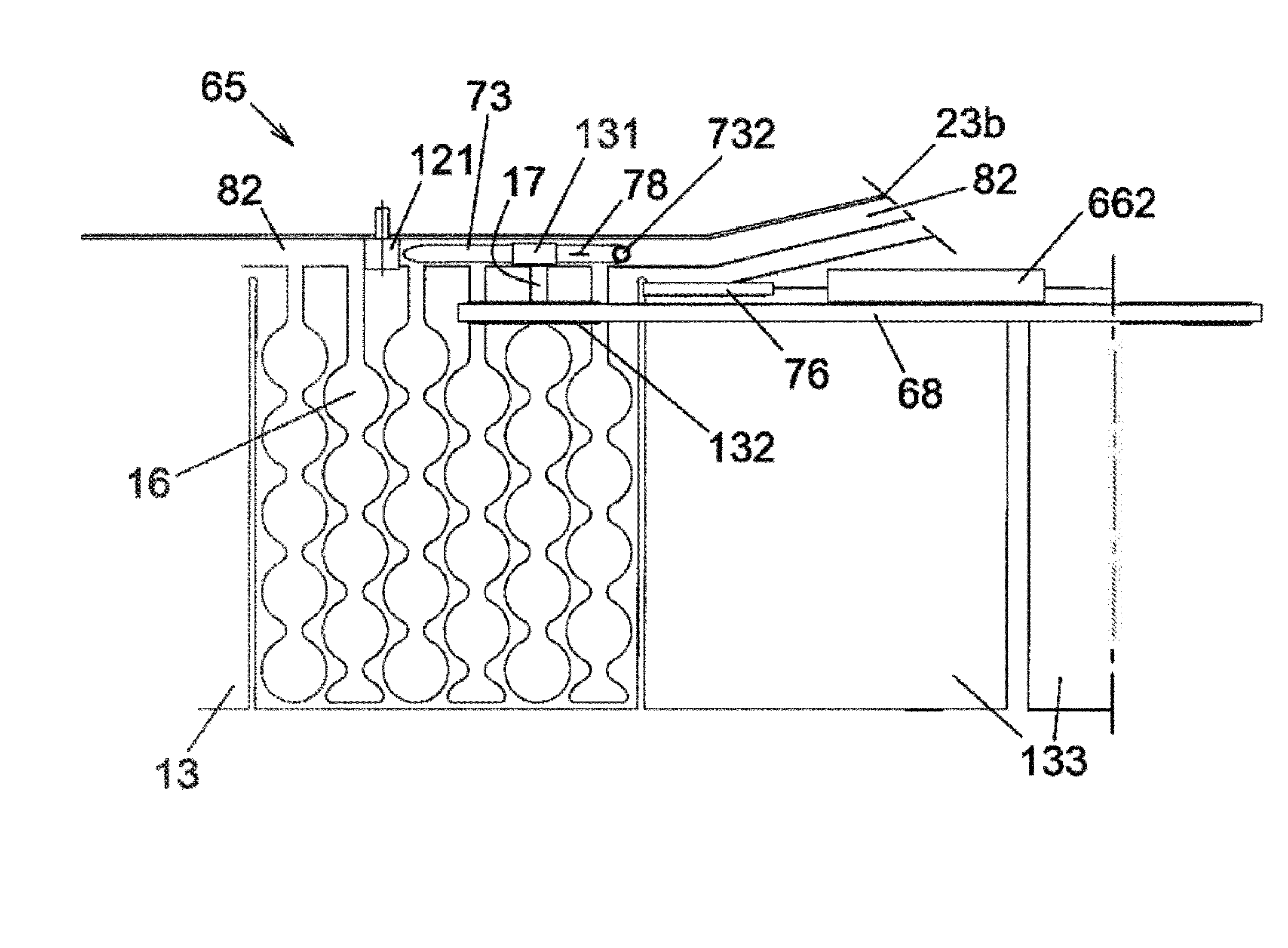

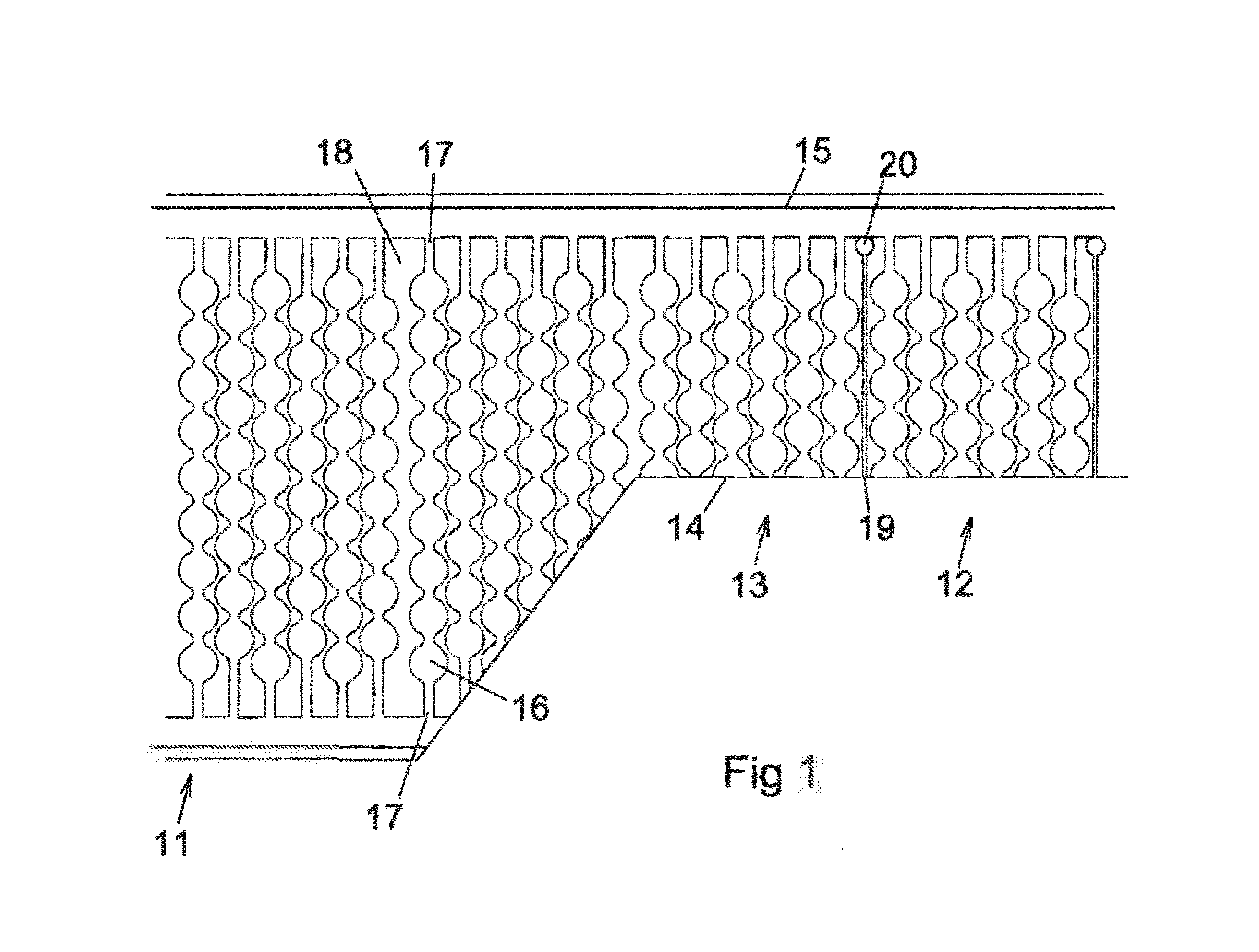

Bag blank (13) comprising an inflatable package blank (11) on a running web, which package blank (11) comprises a semi-finished product consisting of a first plane plastic sheeting (21) and a second plane plastic sheeting (22), which plastic sheetings abut with their plane surfaces against each other and are interconnected by welds (18) so that a series of delimited transverse chambers (16) is formed between the two plastic sheetings (21,22) across the surface of the entire package blank (11), this semi-finished product being folded or welded together along a longitudinal centre line (14) so that its two long sides are parallel and face in the same direction, and that a first longitudinal suspension arrangement (15, 23a, 43a) is connected to the edge along the first long side of the package blank (11) or the bag blank (13), and that a second longitudinal suspension arrangement (23b, 43b) is applied at the edge along the second long side of the package blank (11) or the bag blank (13), as well that the bag blank (13) is provided with transverse full-penetration weldings (18) having a length that has been terminated a distance from the longitudinal suspension arrangements.

Description

TECHNICAL FIELD[0001]The present invention relates to a bag blank, which is formed of an inflatable package blank and a method and a device to pack products using such a bag blank. These package blanks are formed with a plurality of channels, which can be gas-filled and closed to obtain a shock-absorbing gas cushion, preferably air cushion, around the packed product or products.BACKGROUND OF THE INVENTION[0002]The background of the invention is seen in the published patent application US 201010251665, which shows a machine for the inflation and sealing of an inflatable structure. Said structure is provided with double layers of a plastic film, which layers are welded in such a way that the structure forms transverse bubble-like channels, which can be gas-filled and welded together longitudinally to obtain a shock-absorbing gas-filled package structure consisting of a plurality of gas occlusions oriented in the cross-direction of the structure. The mentioned patent application shows,...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B65B43/12

CPCB65B43/123B31D5/0073B65B23/00B65B43/267B65B55/20B65B9/08B65D75/48B65D81/03B31D2205/0005

Inventor JOHAN, JOSTLER

Owner PRONOVA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com