Cistern Assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

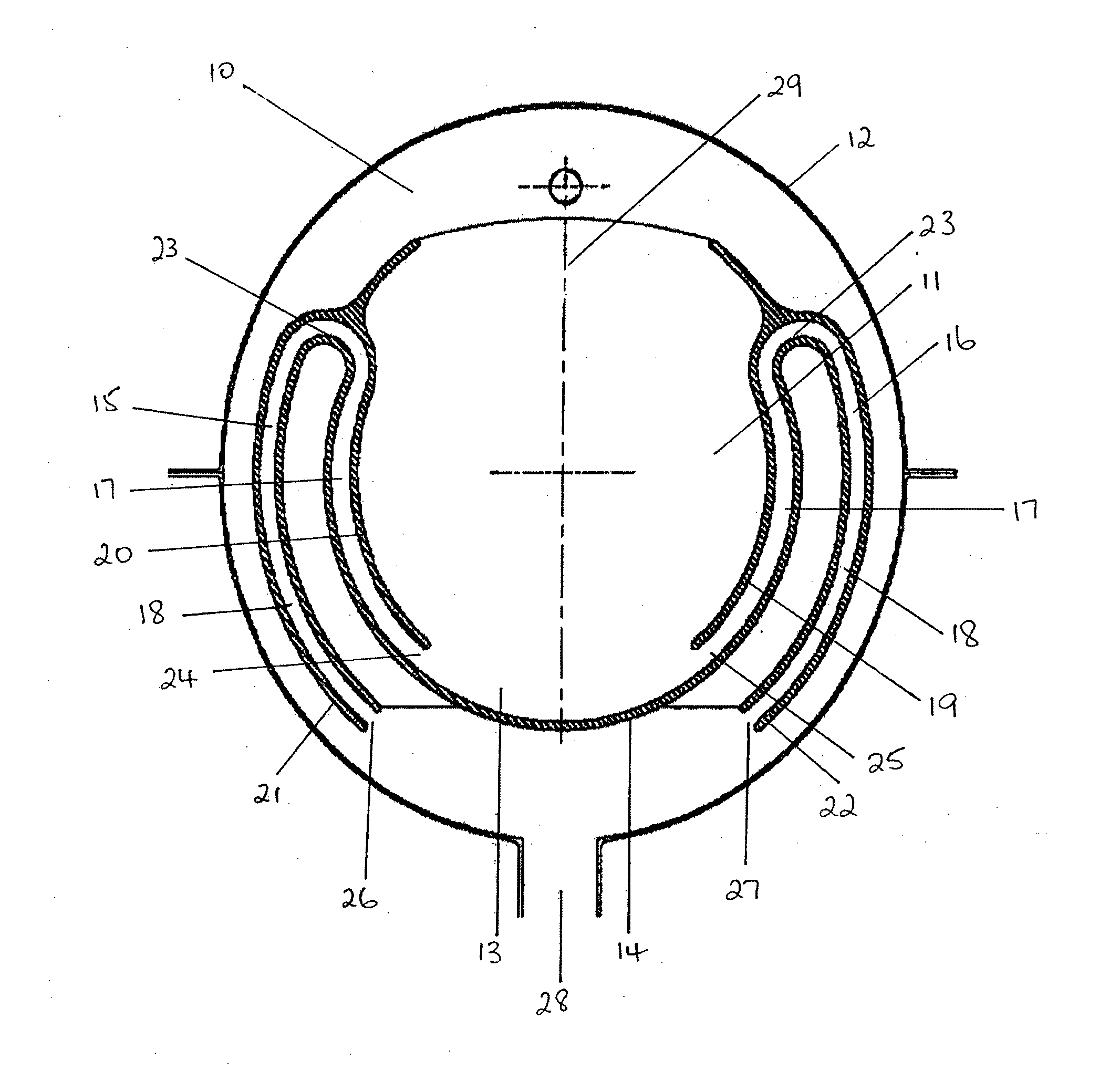

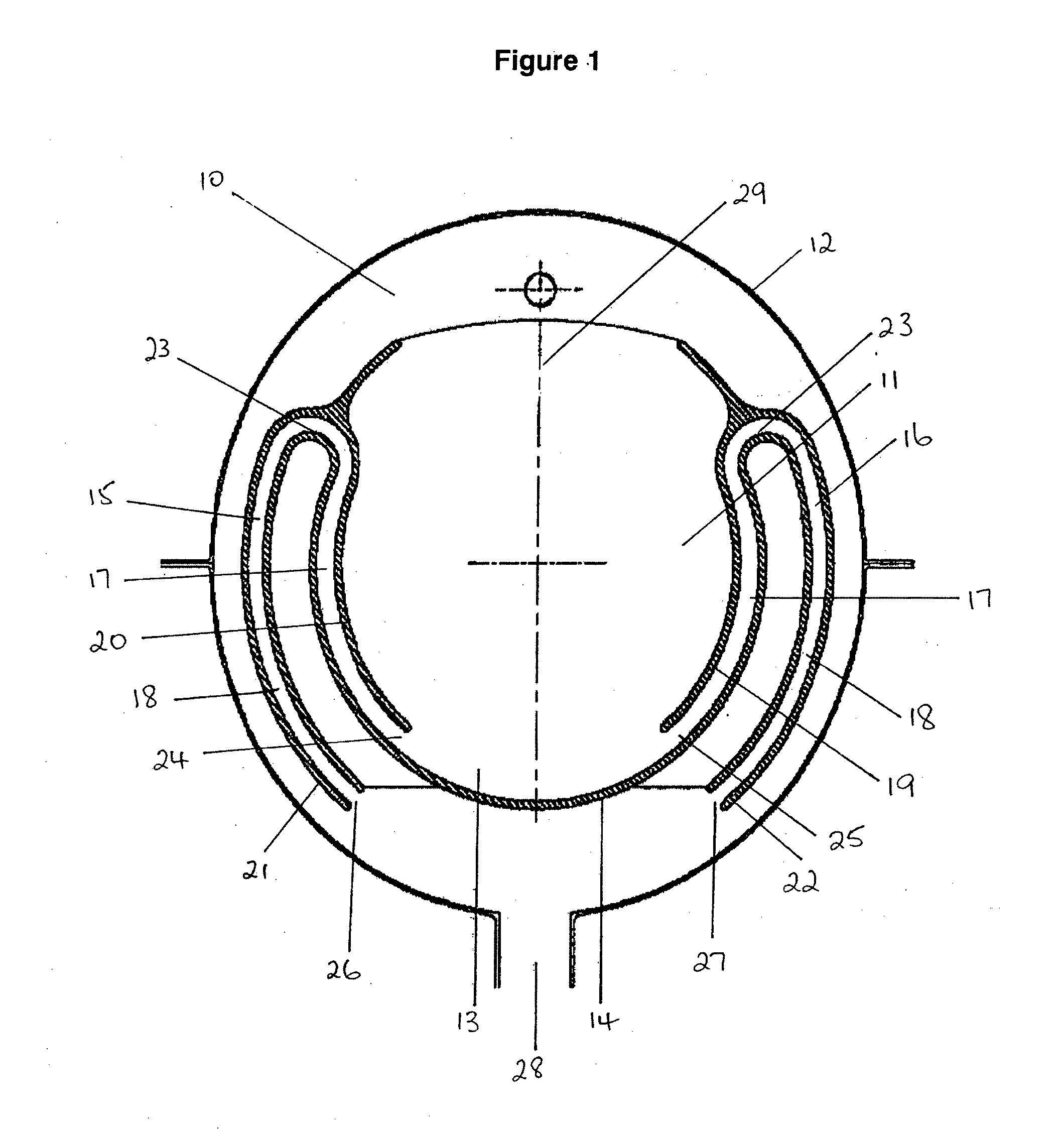

[0143]With reference to FIGS. 3A-3D there is shown a cistern assembly 30 comprising a basin forming a cistern member 31 in a cistern housing 12 and actuation means (not shown). The cistern assembly 30 is similar to that described for cistern assembly 10, except that the basin forming the cistern member 31 has a substantially flat or substantially convex portion that is substantially symmetrical about the vertical axis of the cistern member.

[0144]FIG. 3A shows the base wall32 of the basin forming the cistern member 31 is flattened and is symmetrically positioned about the vertical axis of the cistern member.

[0145]FIG. 3B shows the base wall 33 of the basin forming the cistern member 31 forming an inwardly protruding V-shape symmetrically positioned about the vertical axis of the cistern member.

[0146]FIG. 3C shows the base wall 34 of the basin forming the cistern member 31 forming an inwardly protruding ramp shape symmetrically positioned about the vertical axis of the cistern member....

third embodiment

[0151]FIGS. 5A, 5B, 6A and 6B illustrate a basin forming a cistern member 41. FIGS. 5A and 5B show a basin forming a cistern member 41. Cistern member 41 is intended for use with a cistern housing and actuation means (not shown) to form a cistern assembly 40 according to the present invention. The cistern member 41 is similar to cistern member 11, except that the basin forming the cistern member 41 has a substantially wedge shaped recess section 42 located in the back wall or in the front wall, or in both the back wall and front wall, of the basin of the cistern member 41. The, or each, wedge shaped recess 42 is substantially symmetrical about the vertical axis of symmetry 29 of the cistern member 41 when the cistern member is in the equilibrium position. The, or each, wedge shaped recess 42 has an apex 43 to provide a recessed pivot point for the cistern member 41 to rest on in the cistern housing.

[0152]Because the front to back dimension of the cistern member 41 is smaller behind ...

fourth embodiment

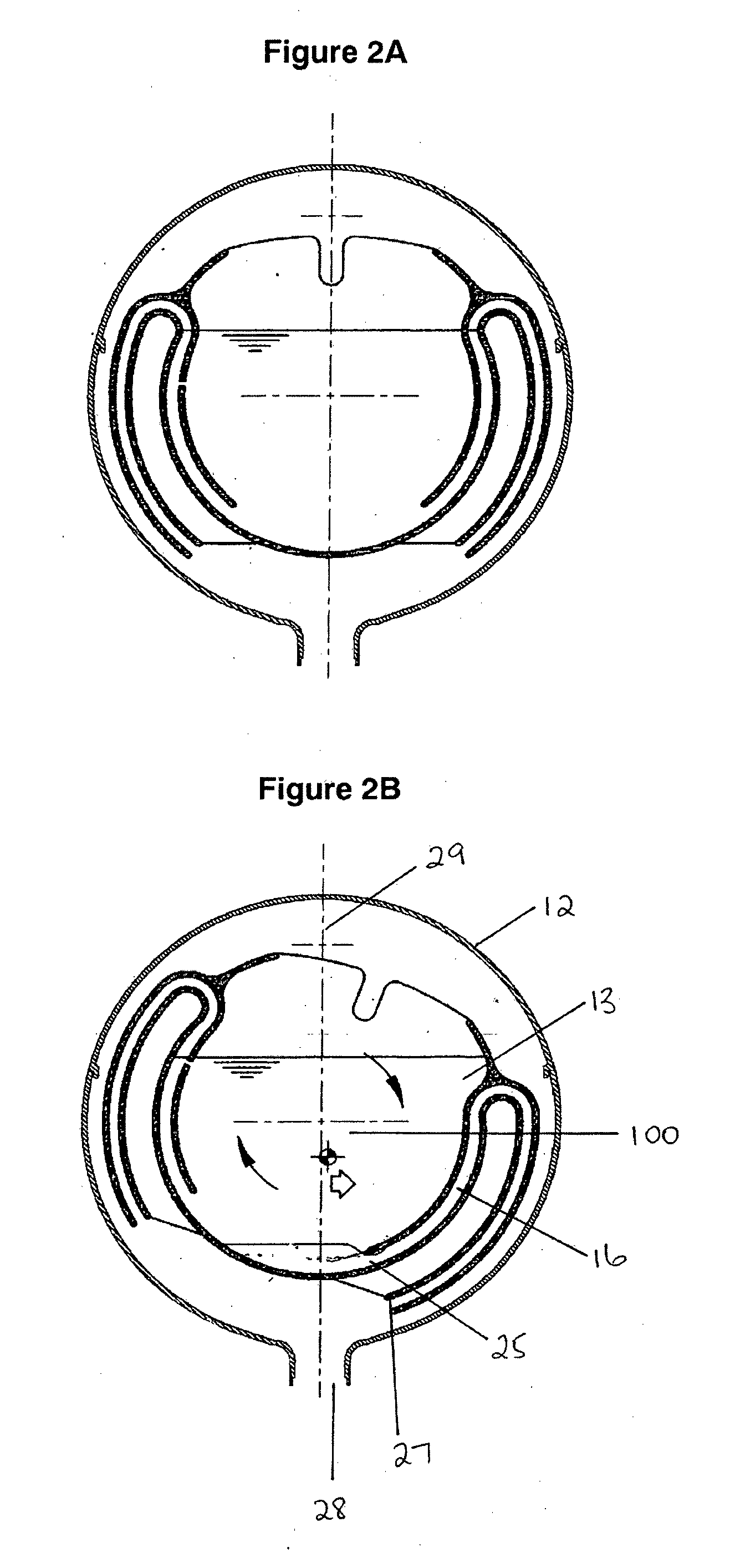

[0153]With reference to FIG. 7, there is shown the present invention. FIG. 7 shows a cistern assembly 50 comprising a basin forming a cistern member 11 in a cistern housing 12 and magnetic actuation means 52-56. The cistern assembly 50 is similar to that described in cistern assembly 10, but the pivoting is initiated by magnetic actuation means provided by an arrangement of permanent magnets 52-56 associated with the cistern housing 12 and the cistern member 11.

[0154]The partial cross sectional views in FIGS. 8A-8E show the upper section of a cistern assembly 60 representing further embodiments of the present invention. Cistern assembly 60 comprises a cistern housing 12, and magnetic actuation means and a basin forming a cistern member 61. The basin forming the cistern member 61 is similar to any of those described in the above-mentioned Figures. In one embodiment the cistern member 61 is similar to that described by cistern member 11 in FIG. 1. In further embodiments the cistern me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com