3 dimensionally woven footwear

a 3 dimensional, woven technology, applied in the field of footwear, can solve the problems of limited esthetics, large number of separate operations, and large waste in the process, and achieve the effect of maintaining support and integrity of the upper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

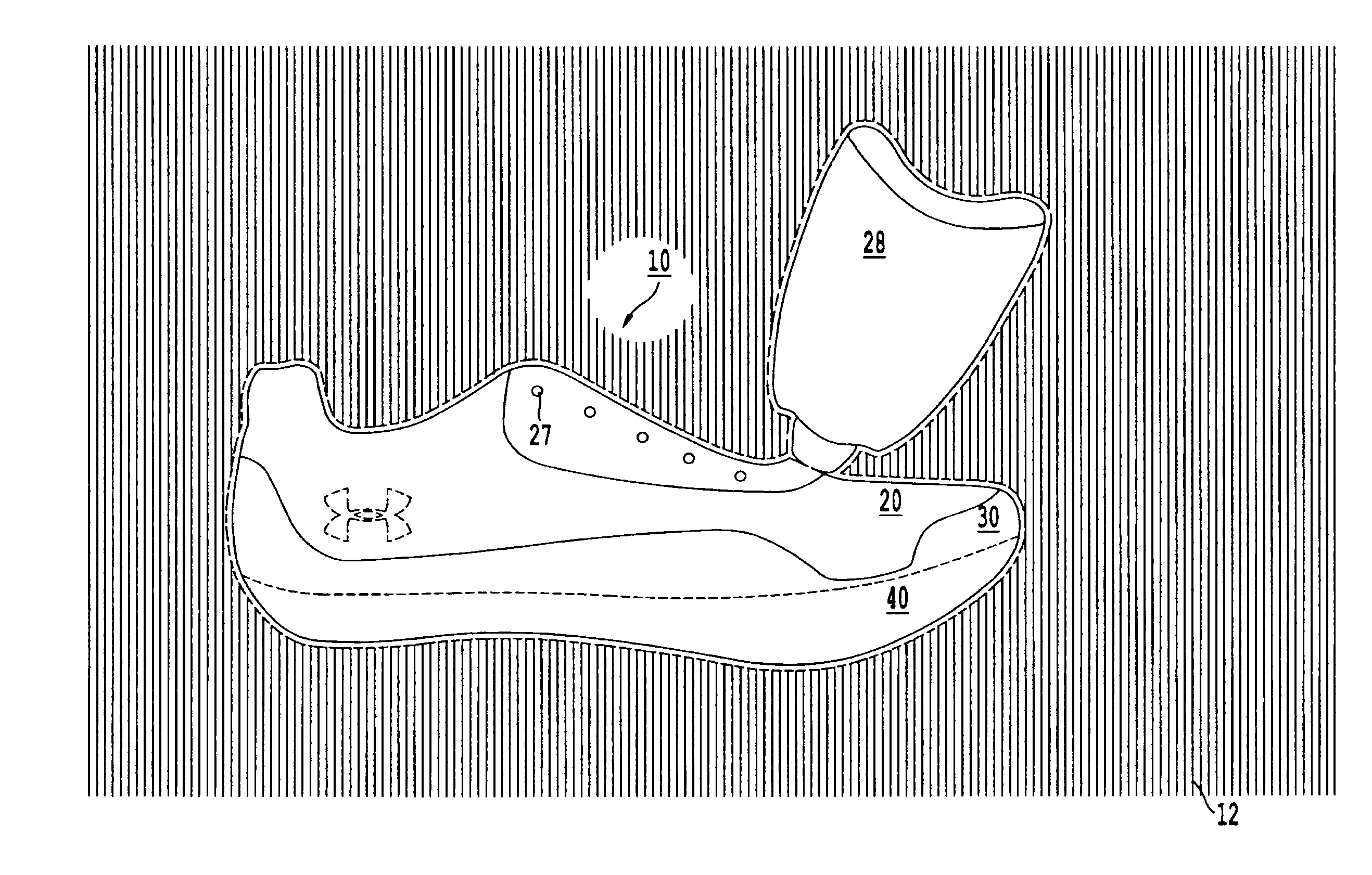

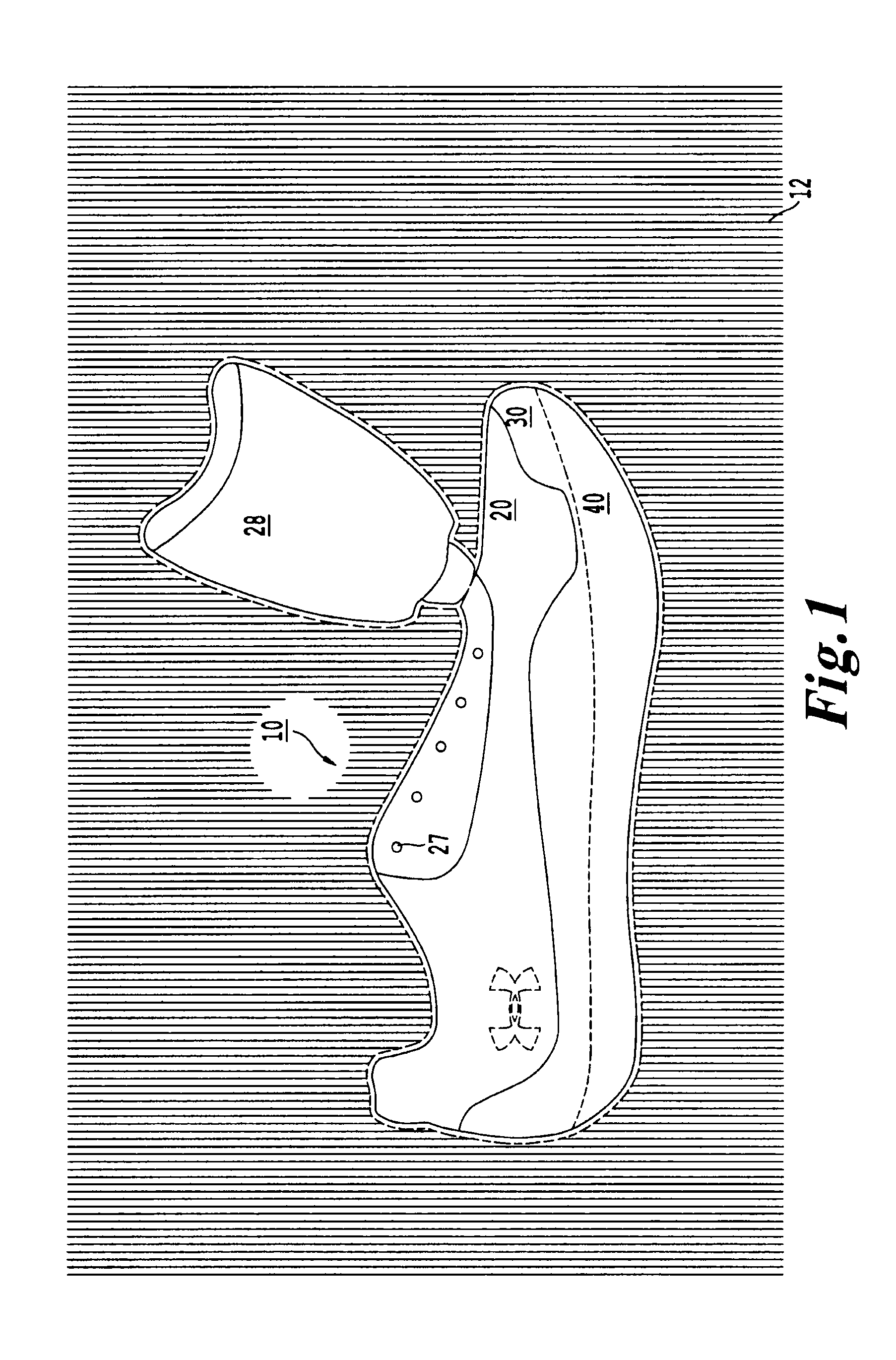

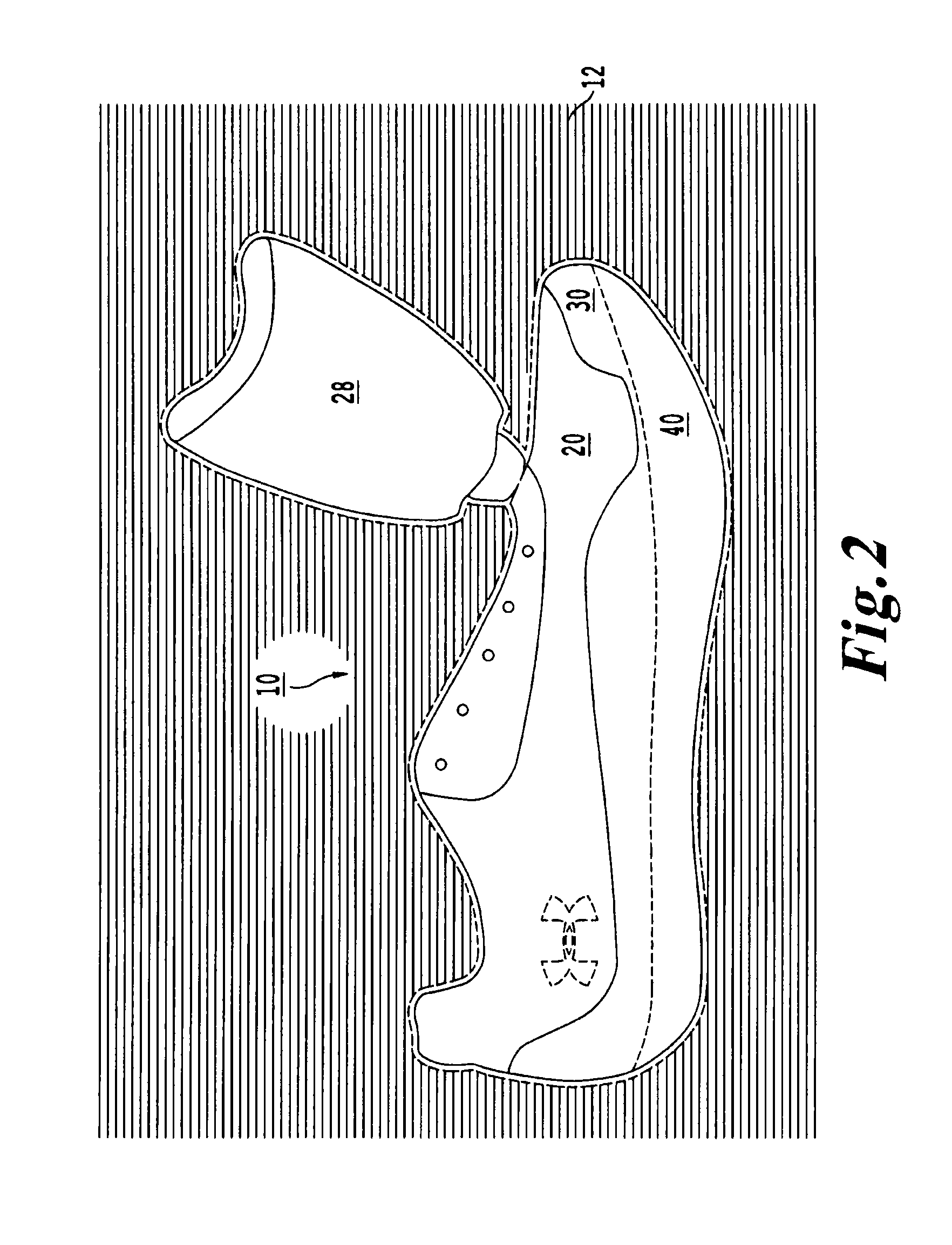

[0054]The present invention relates to a shoe component formed by 3-dimensional weaving, a shoe incorporating at least one 3-dimensionally woven shoe component, a shoe upper formed entirely from 3-dimensional weaving, a unitary structure comprising an upper and a midsole where the entire unitary structure is formed by 3-dimensional weaving, and a shoe comprising the unitary structure, as well as a shoe formed entirely by 3-dimensional weaving, including upper and entire sole.

[0055]Central to the present invention is the technique of 3-dimensional weaving. 3-dimensional weaving is a technique for creating a textile product by utilizing a three dimensional Cartesian coordinate system as the infrastructure for weaving simultaneous independent fabric layers in conjunction with weaving connectors between and among the layers. The 3-dimensional weaving technique is described in detail in U.S. Pat. Nos. 7,836,917 and 7,836,918, the entire contents of each of which are hereby incorporated b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com