Auxiliary equipment for use with drilling apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

DETAILED DESCRIPTION OF THE DRAWINGS

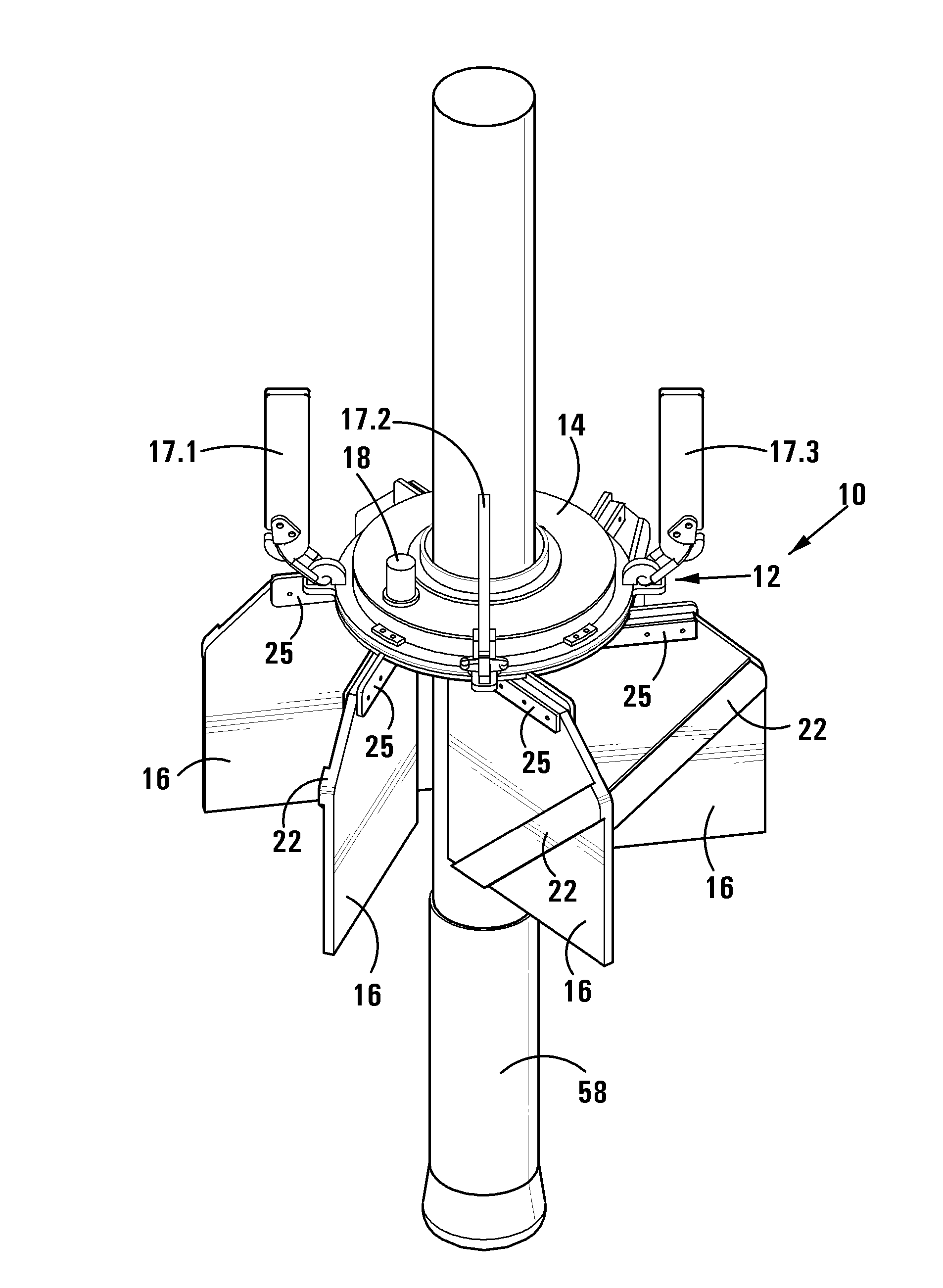

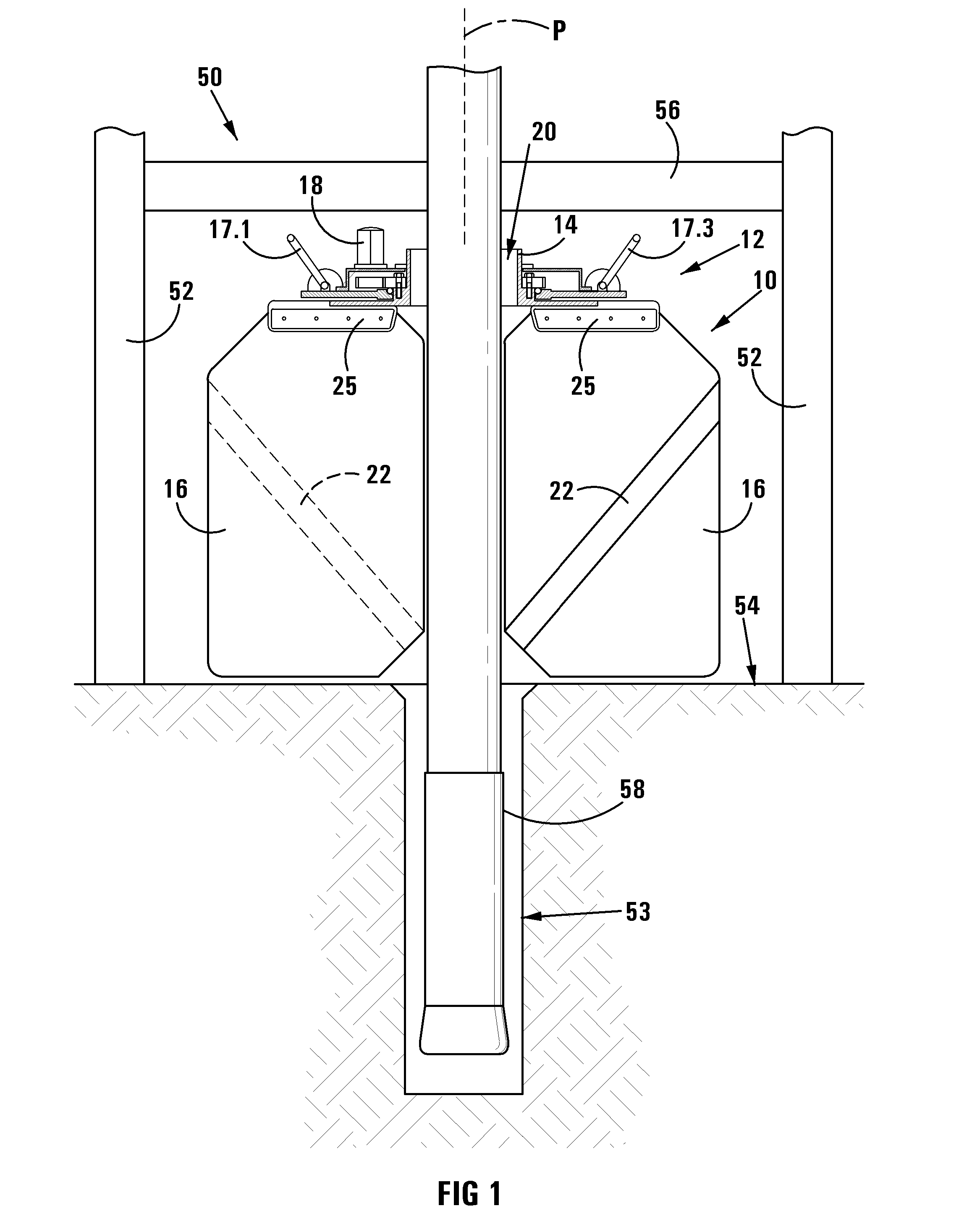

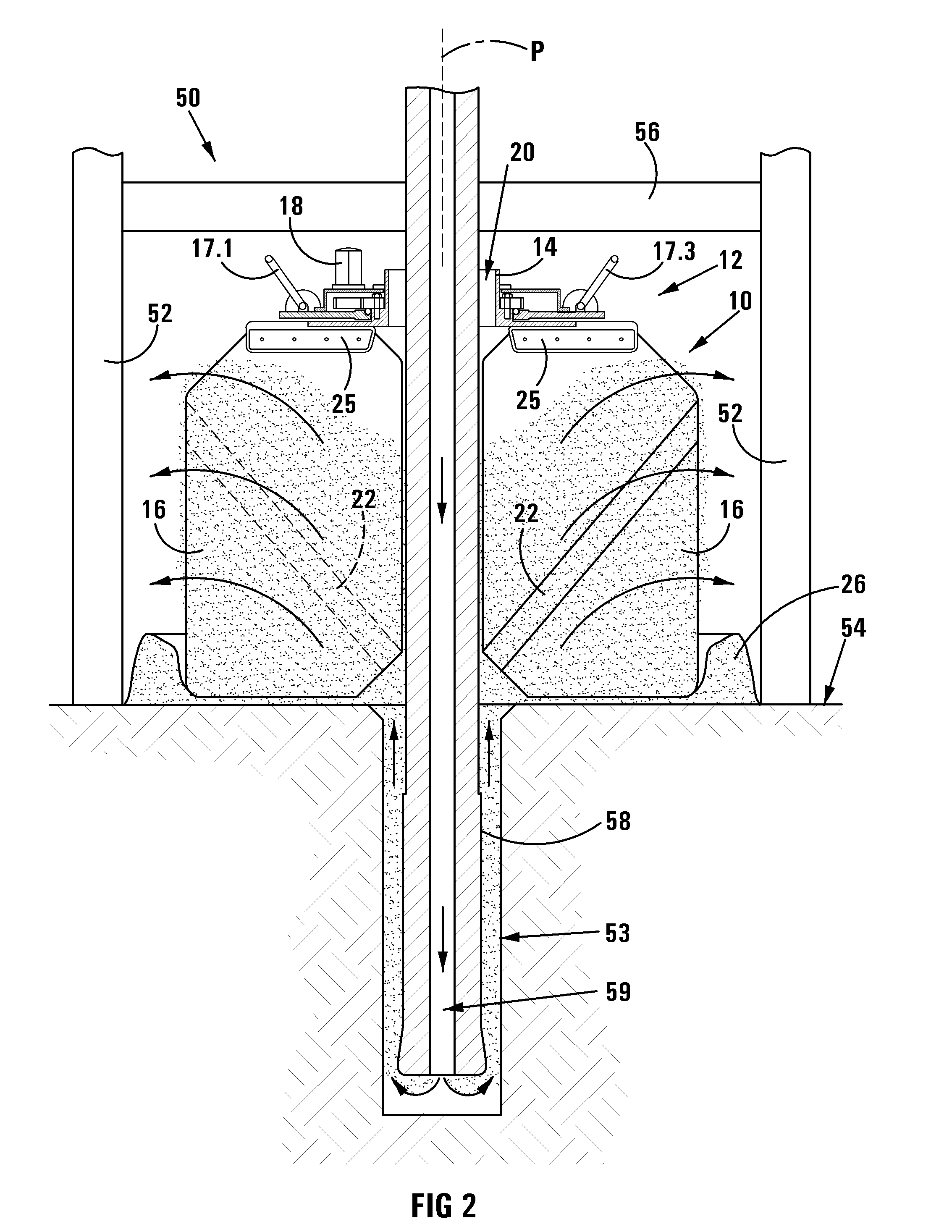

[0024]Referring to the drawings, an auxiliary working apparatus for use with a drilling apparatus for drilling holes into the ground, in accordance with the invention, is designated generally by the reference numeral 10. The auxiliary working apparatus 10 comprises, broadly, an auxiliary support structure 12 including a hub 14, a number of vanes 16 mounted to the hub and a hydraulic motor 18 for driving the hub.

[0025]The auxiliary working apparatus 10 is configured for use with a drilling apparatus designated by the reference numeral 50, for drilling holes into the ground. The drilling apparatus 50 generally includes a support structure comprising a number of upright support columns 52 which are located on a ground surface 54 and a platform 56 which is supported in a horizontal configuration by the support columns in an arrangement wherein the platform forms a barrier at a spaced location above the ground. The drilling apparatus further includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com