Rack assembly

a rack and assembly technology, applied in the field of rack assembly, can solve the problems of difficult to easily install racks in the office, difficult to carry heavy loads, difficult to disassemble racks, etc., and achieve the effect of reducing the amount of transportation space, easy disassembly and assembly, and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

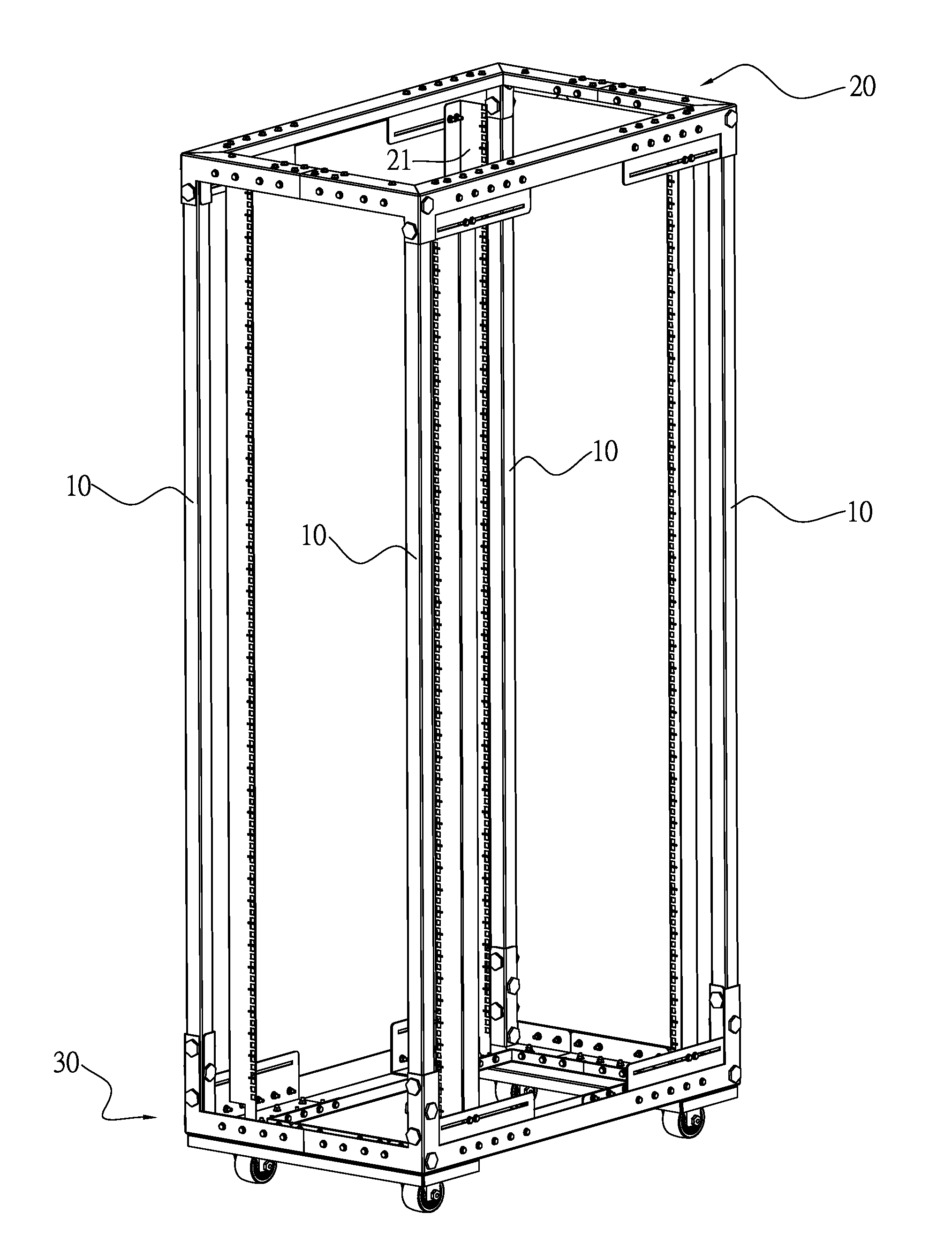

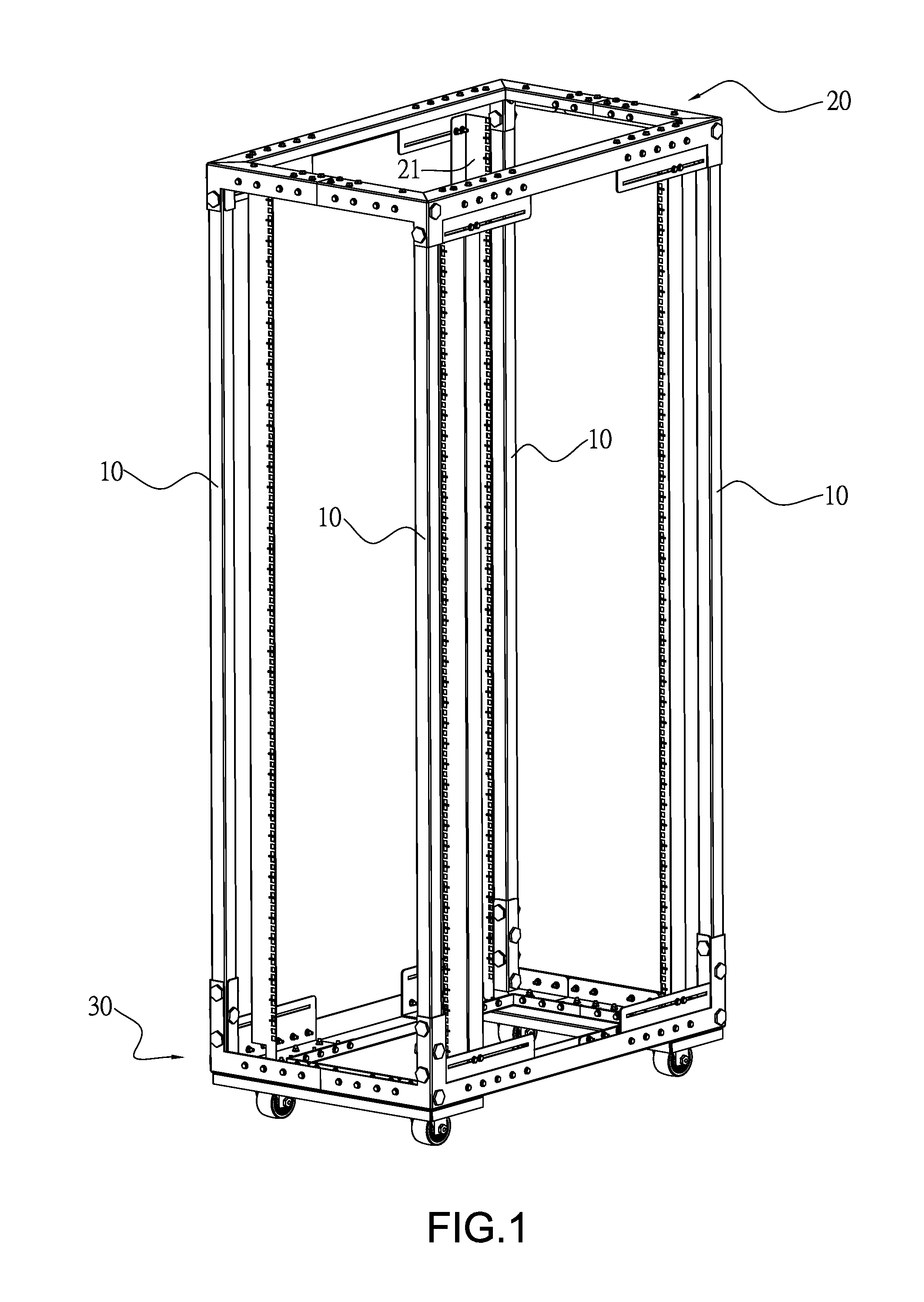

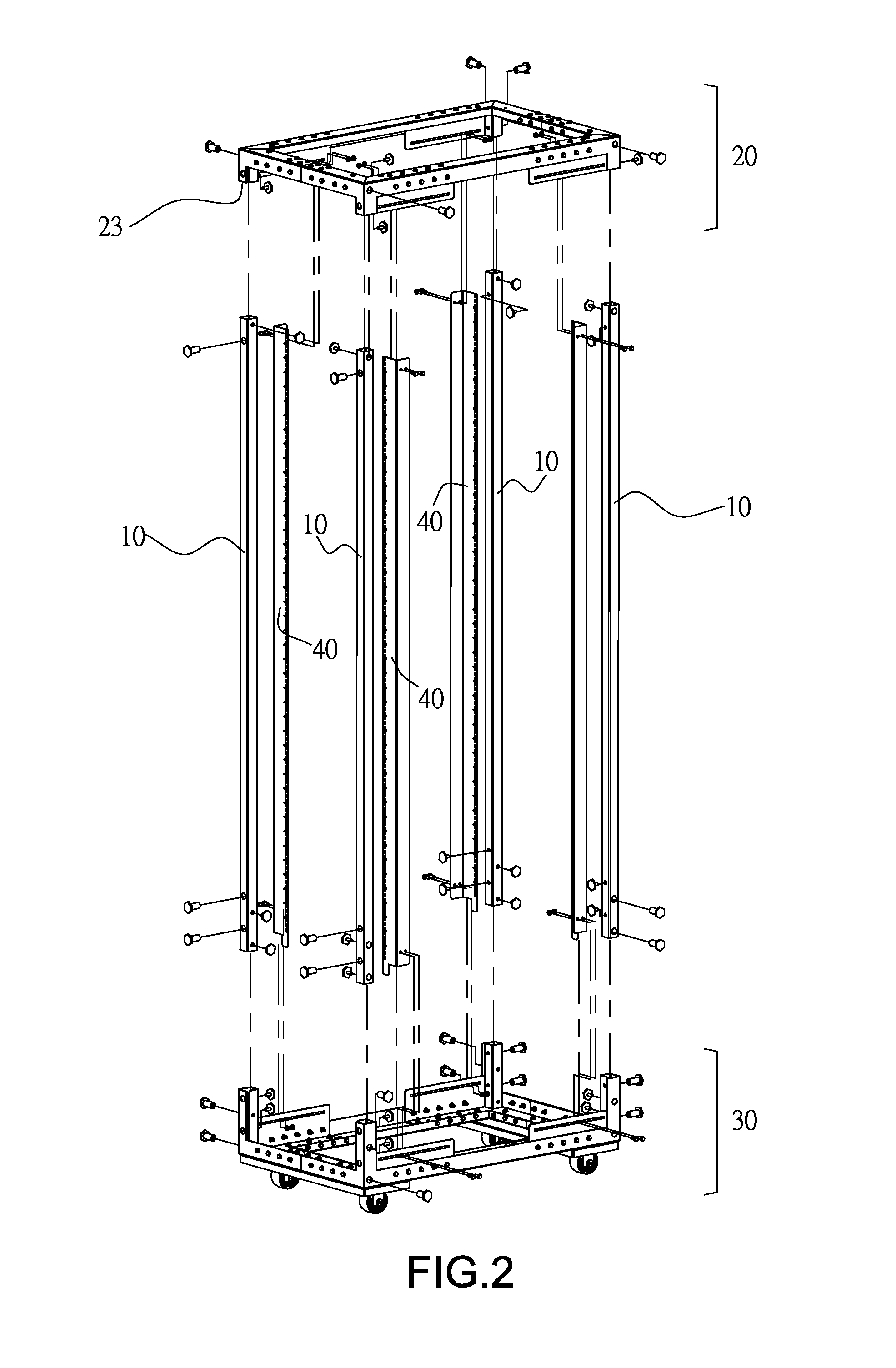

[0030]Referring to FIGS. 1 and 2, the rack assembly of the present invention comprises four columns 10, a top frame module 20 and a bottom frame module 30, so as to reduce the room required when in transportation and the ability for management of load is also increased.

[0031]As shown in FIGS. 2 to 5, the top frame module 20 comprises a top frame 21, a top connection unit 22 and at least four top fixing slots 23. The top connection unit 22 has multiple top connection parts 221 which are connected to the inside of the top frame 21. The at least four top fixing slots 23 each are formed by connections of the top frame 21 and the top connection parts 221, and the four columns 10 have their respective four first ends inserted into the at least four top fixing slots 23. Each of the four columns 10 and each of the at least four top fixing slots 23 are secured by at least one top locking unit T1 so as to secure the relative position between the column 10 and the top fixing slot 23. The top f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com