Method for perishable food or item in a container with a container storage technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

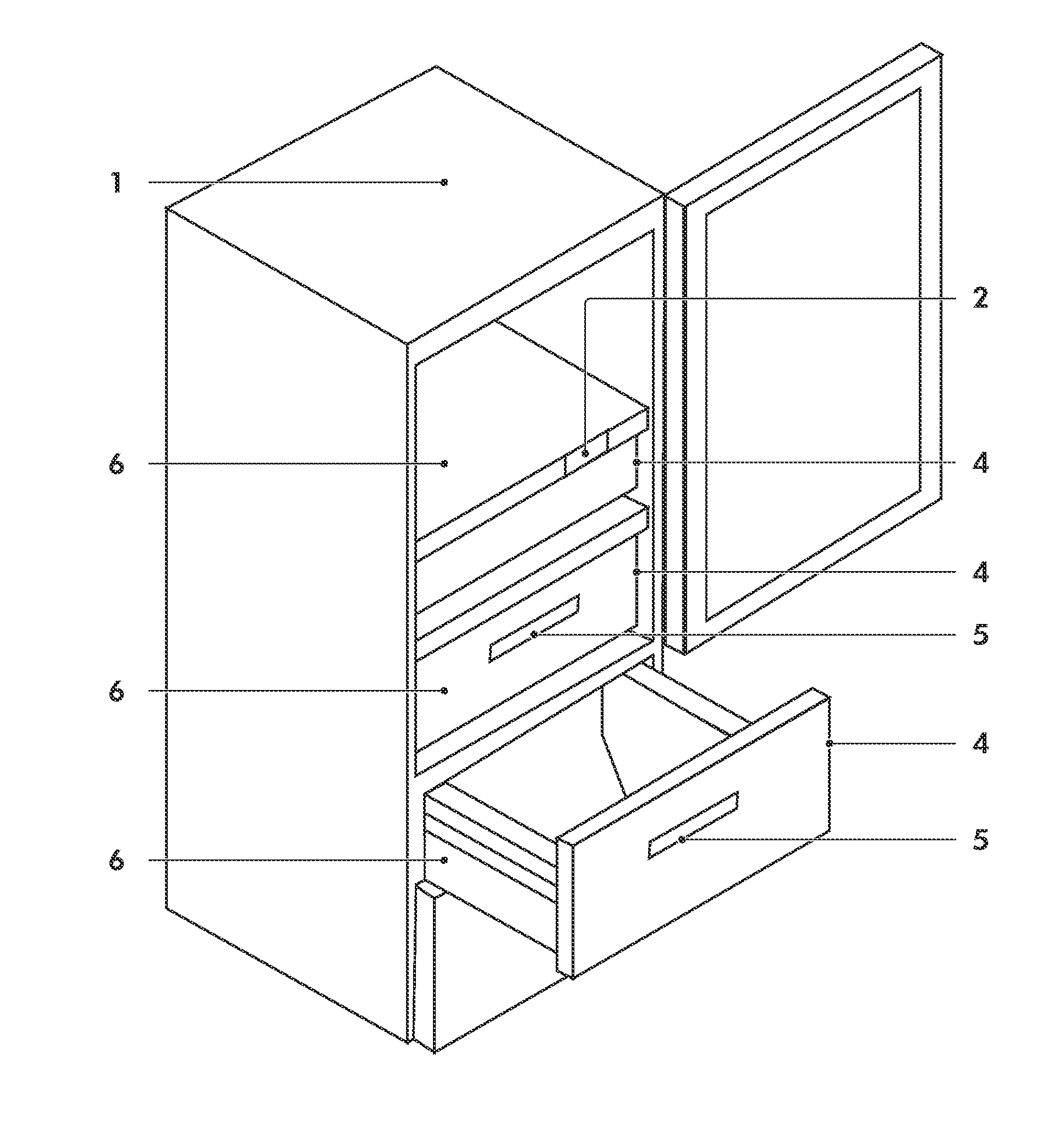

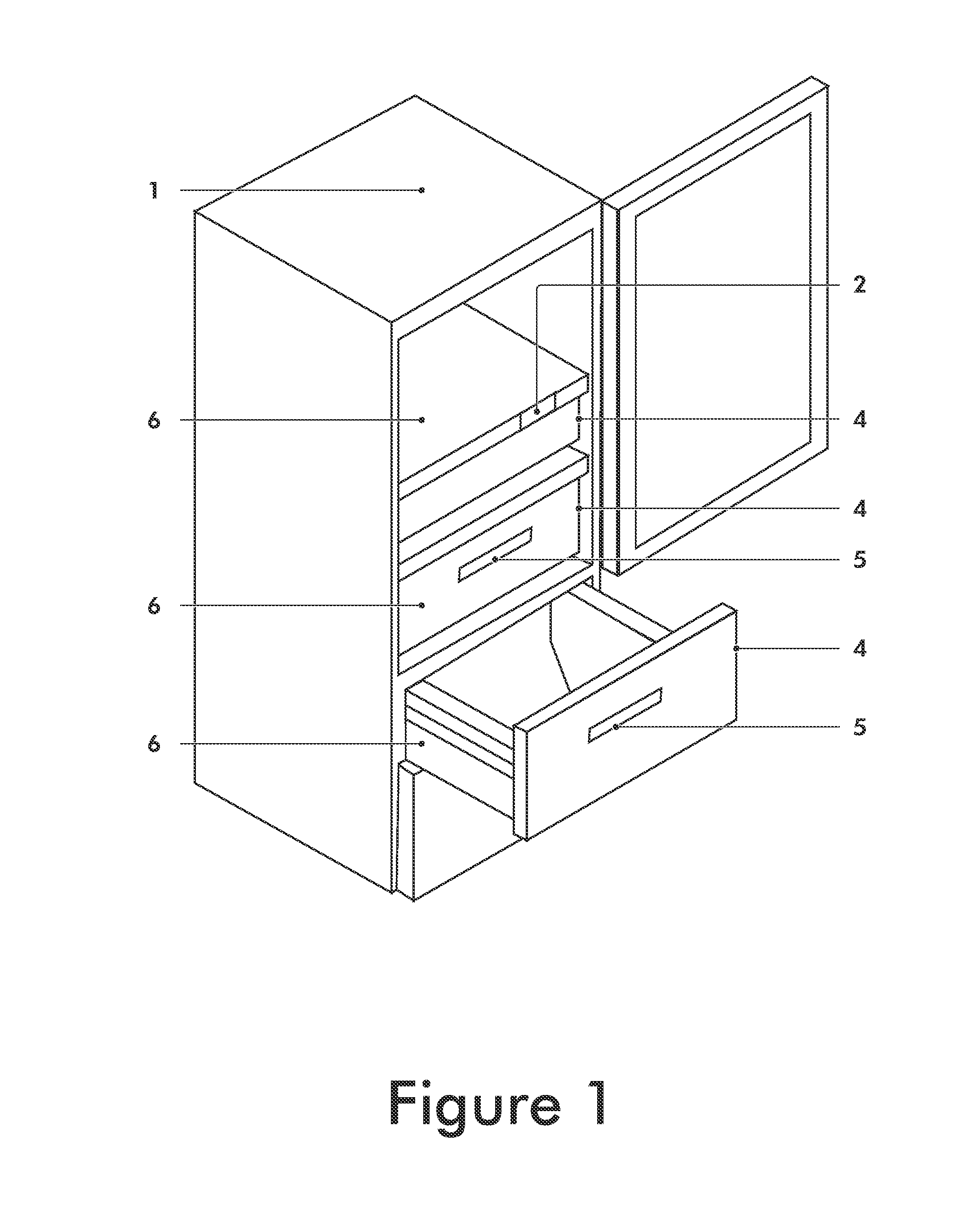

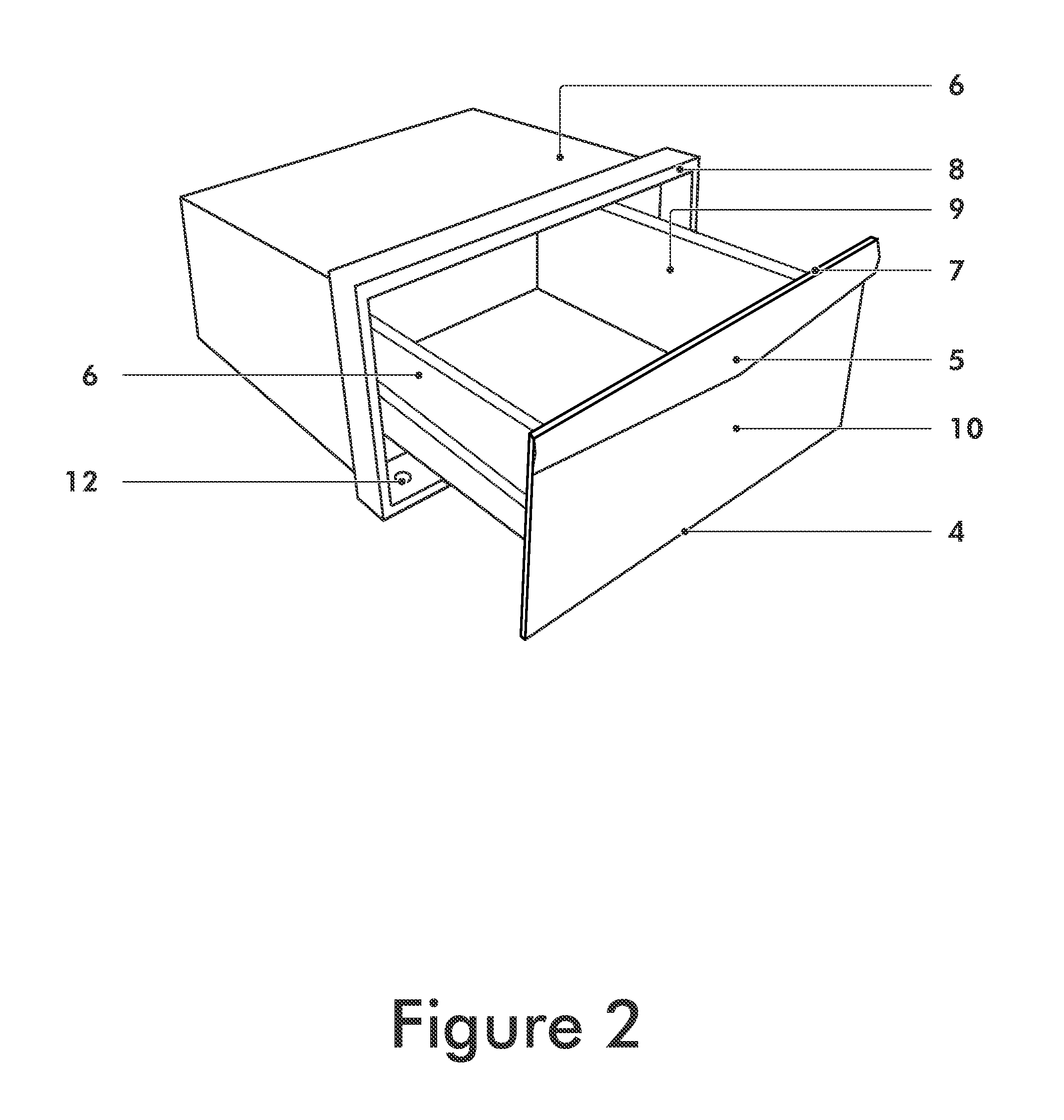

[0106]The invention will now be described with reference to the attached non-limiting Figures. In a preferred embodiment and as described herein, a vacuum storage system can comprise any of the following such as, a housing (1) shown in FIG. 1, in which at least one sealable modular compartment (6) can be disposed with at least one or more containers disposed therein. A compartment (6) can also be removably disposed inside a housing. Physically removed from and in communication with the interior of a compartment is a pump to create vacuum, pressure and other environments inside said compartment and containers disposed therein. A control system (2), which can include a display panel, microprocessor (CPU) and memory device, as well as, operating system controls, as shown in FIG. 4, can selectively or automatically activate and deactivate a pump and place said pump in either a vacuum or pressure mode or function. Further, said pump can function in a vacuum or pressure mode and can pump,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com