Motor-driven compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

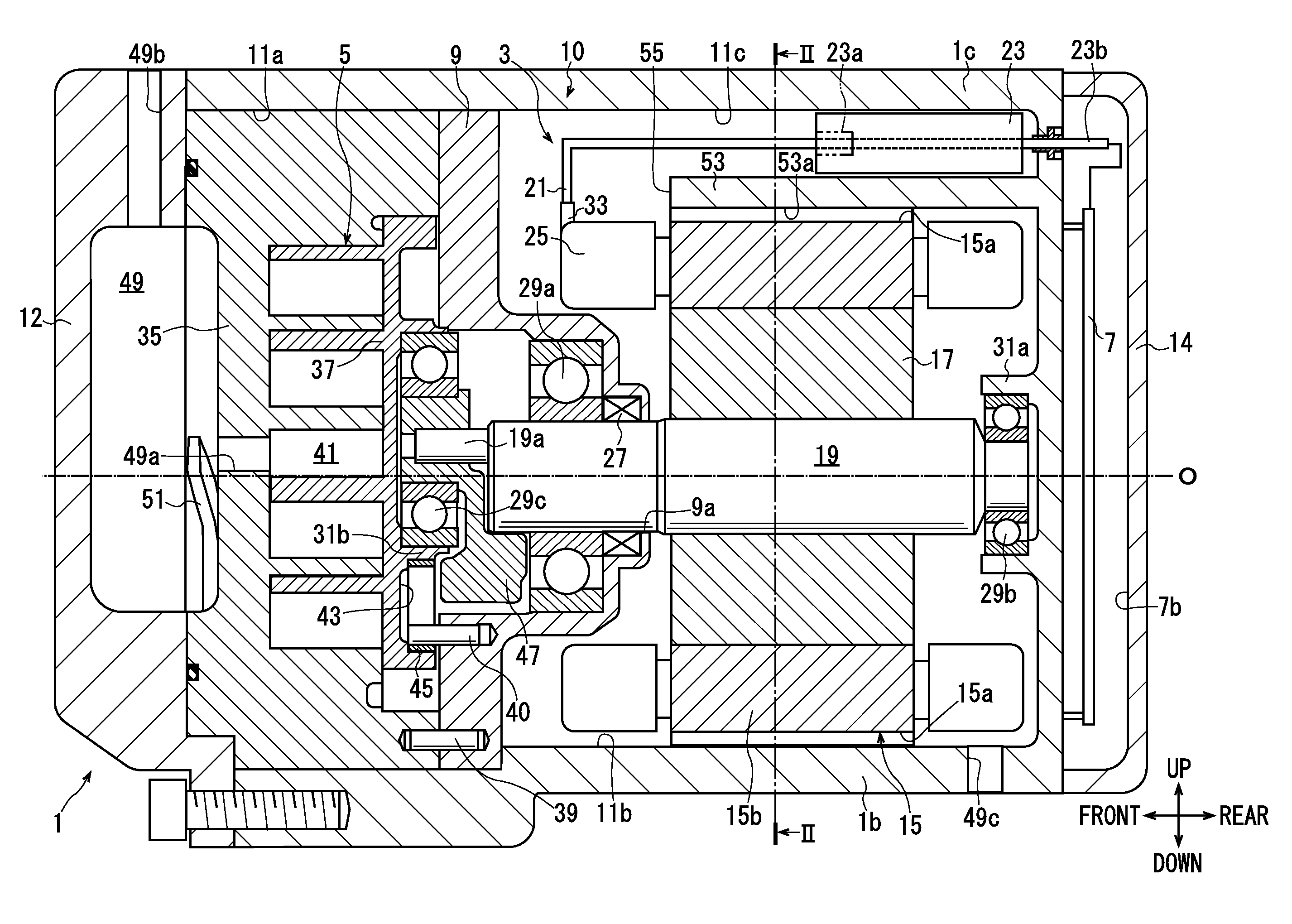

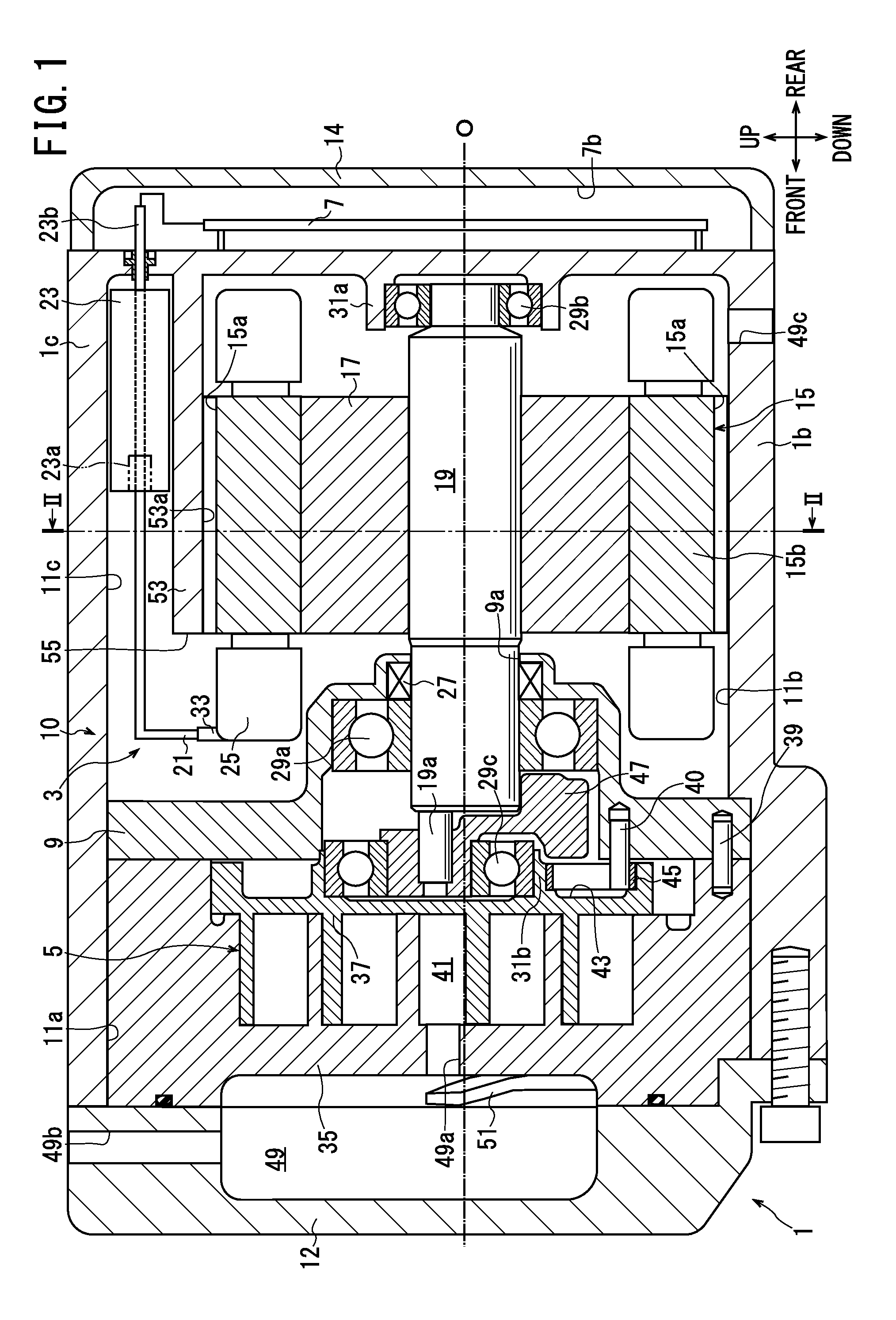

[0016]A compressor of embodiment 1 is used in an air-conditioning apparatus that is mounted on a hybrid vehicle and performs temperature control of a vehicle interior. As shown in FIG. 1, the compressor includes a housing 1, an electric driving mechanism 3, a compression mechanism 5 and a motor drive circuit 7.

[0017]The housing 1 is formed of a main housing 10, an end housing 12 and a cover 14. The main housing 10 is in a bottomed cylindrical shape. The end housing 12 is located at a front of the main housing 10 to close an opening of the main housing 10. The cover 14 is fixed to a rear end of the main housing 10.

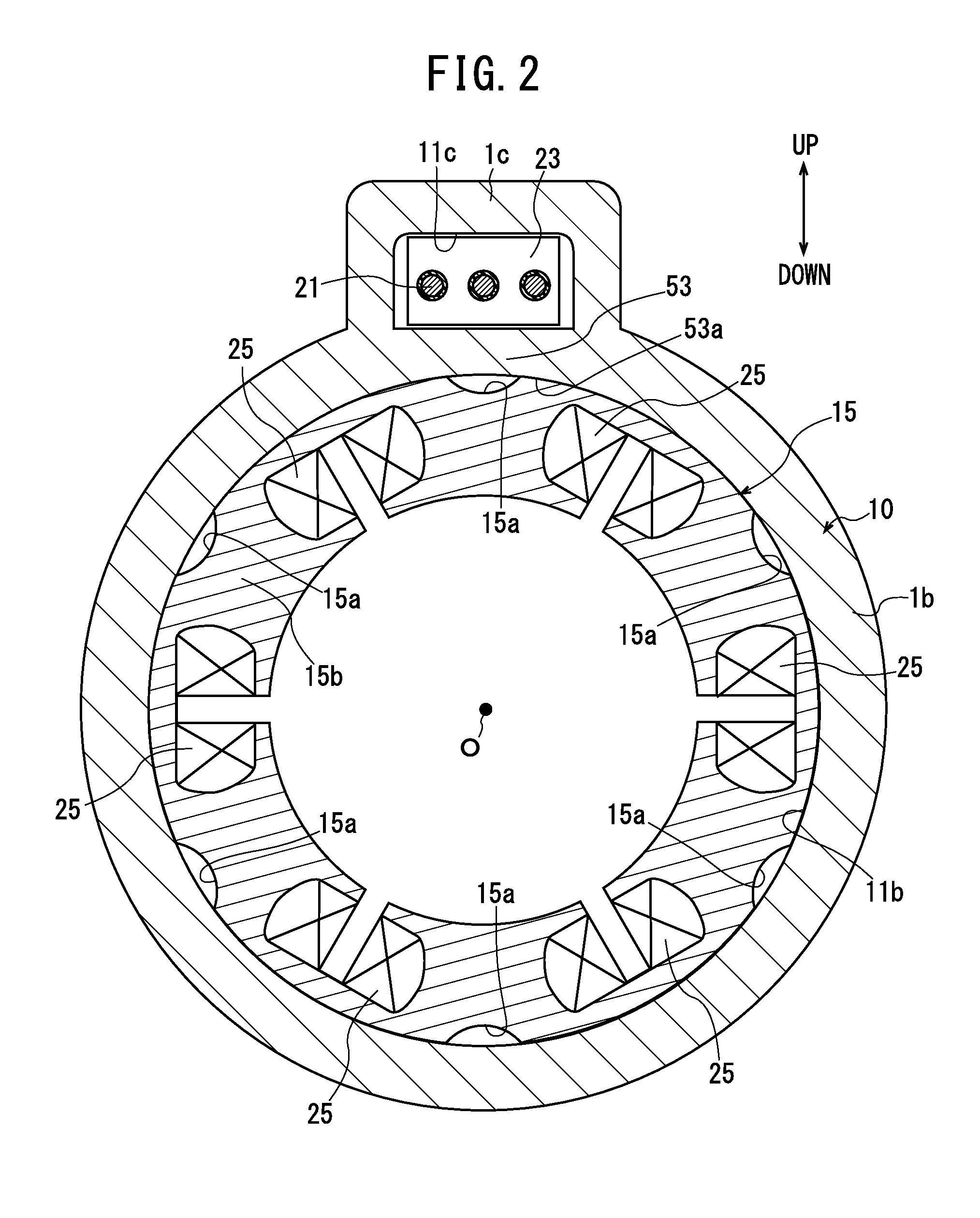

[0018]In the main housing 10, a fixed block 9 is supported. A front portion of the housing 1 is configured by a front portion of the main housing 10 that is located forward of the fixed block 9, and the end housing 12. In the front portion, a compression mechanism accommodation chamber 11a is formed. In the compression mechanism accommodation chamber 11a, the compression me...

embodiment 2

[0037]As shown in FIG. 3, in a compressor of embodiment 2, a slit 57 that extends in an axial direction is formed in a partition wall 54. The slit 57 allows the stator accommodation chamber 11b and the cluster block accommodation chamber 11c to communicate with each other.

[0038]Further, the cluster block 23 is fixed to the stator core 15b via a fitting member 59 of a resin. The fitting member 59 is located in the slit 57.

[0039]Further, in this compressor, a plurality of refrigerant channels 61 are formed in the inner circumferential surface of the main body portion 1b. The slit 57 and the respective refrigerant channels 61 are spaced equiangularly from one another in a circumferential direction of the main body portion 1b. Further, the slit 57 and the respective refrigerant channels 61 are formed to have widths equal to one another in the circumferential direction of the main body portion 1b. The other configuration is similar to that of embodiment 1.

[0040]In this compressor, by ins...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap