Performance footwear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

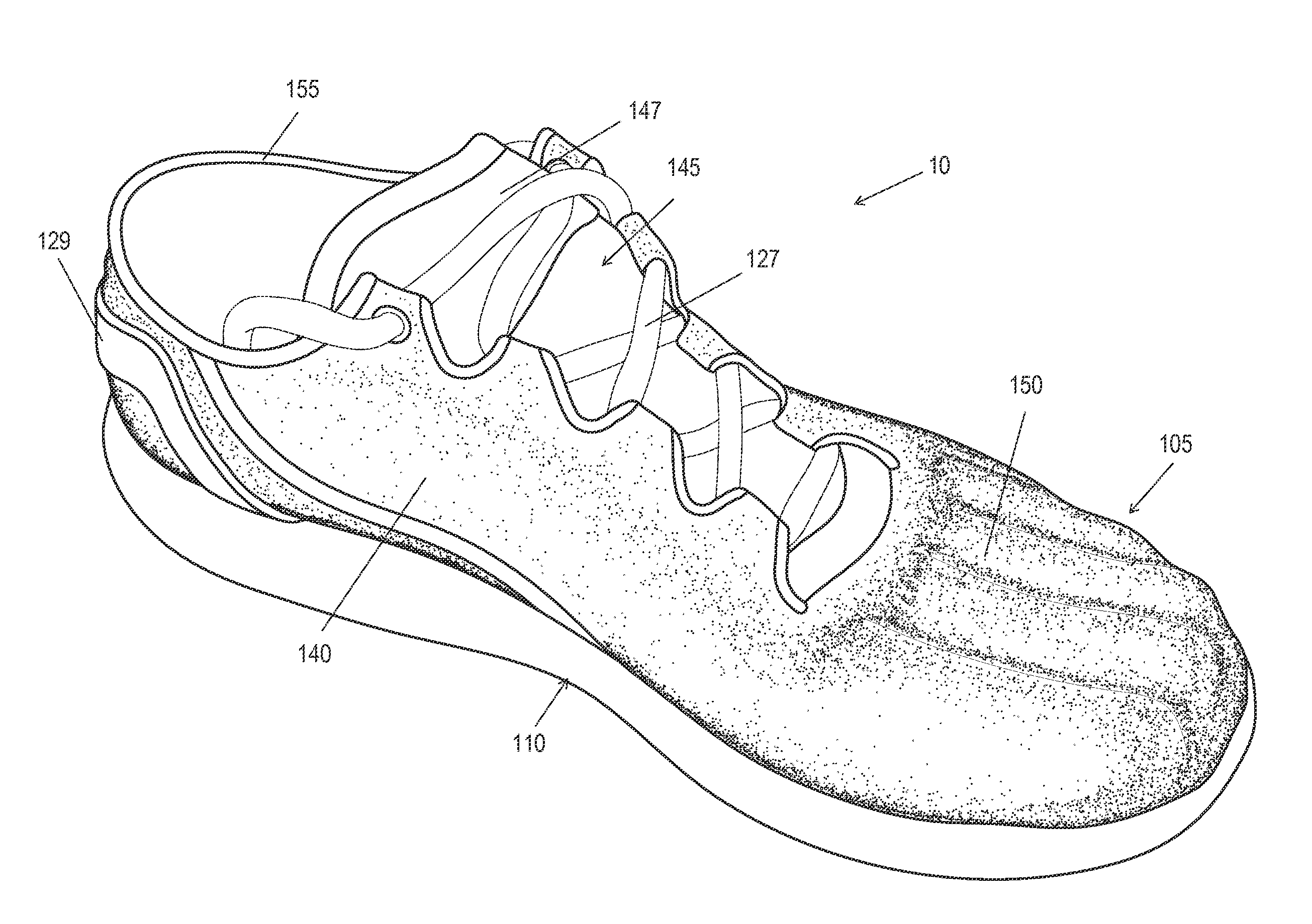

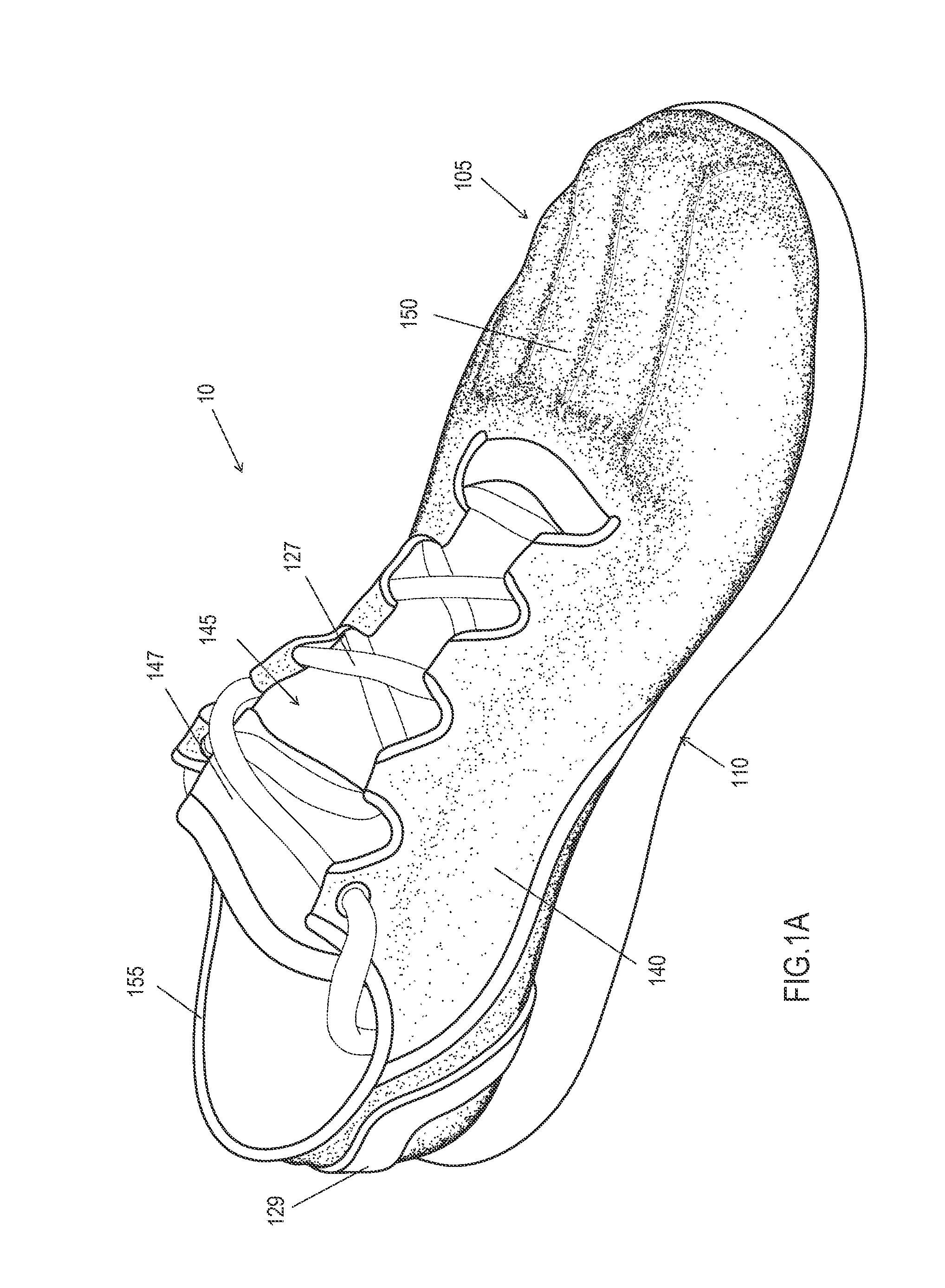

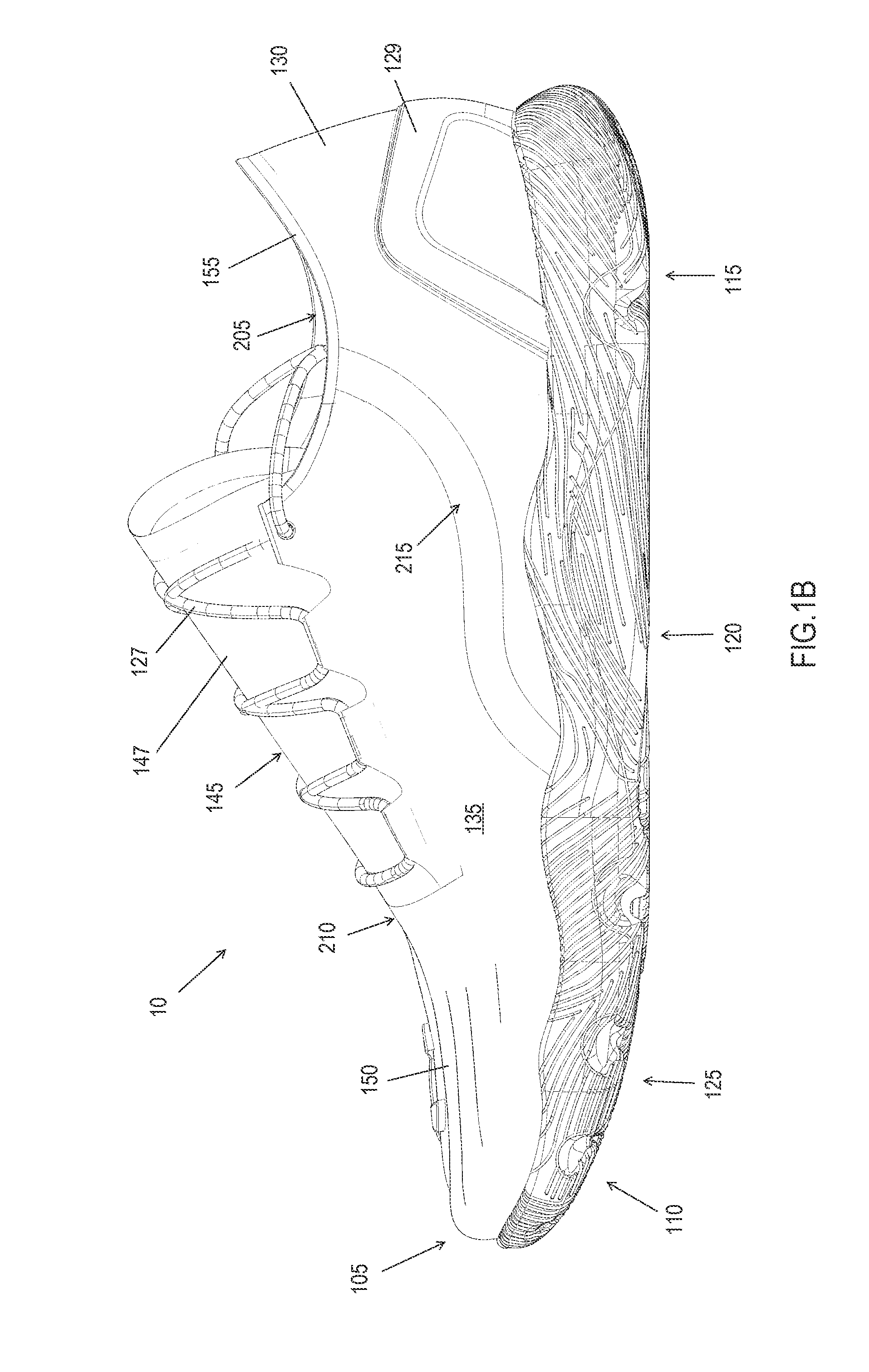

[0024]Turning to FIGS. 1A, 1B, and 1C, an article of footwear 10 in accordance with an embodiment of the present invention includes an upper 105 coupled to (e.g., mounted on) a sole structure 110. The article of footwear 10 defines several regions corresponding with various parts of a foot. Specifically, the footwear 10 defines a rear footwear region 115 generally corresponding with the rear of the foot (e.g., the hindfoot including the heel); an intermediate footwear region 120 disposed forward the rear region and generally corresponding to the midfoot (e.g., the arched, instep, and ball areas of the foot); and a forward footwear region 125 disposed forward of intermediate region and generally corresponding to the forefoot (e.g., the toes of the foot). The article of footwear 10 may further include a fastener 127 (e.g., a shoe lace) and a heel counter 129 (discussed in greater detail below).

[0025]The upper 105 includes a heel 130, a lateral side 135, a medial side 140, an instep 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com