Atomizer component, battery component and electronic cigarette

a technology of electronic cigarettes and atomizers, applied in the field of electronic cigarettes, can solve the problems of low manufacturing efficiency, harm to human body, and affecting the quality of atomizers,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

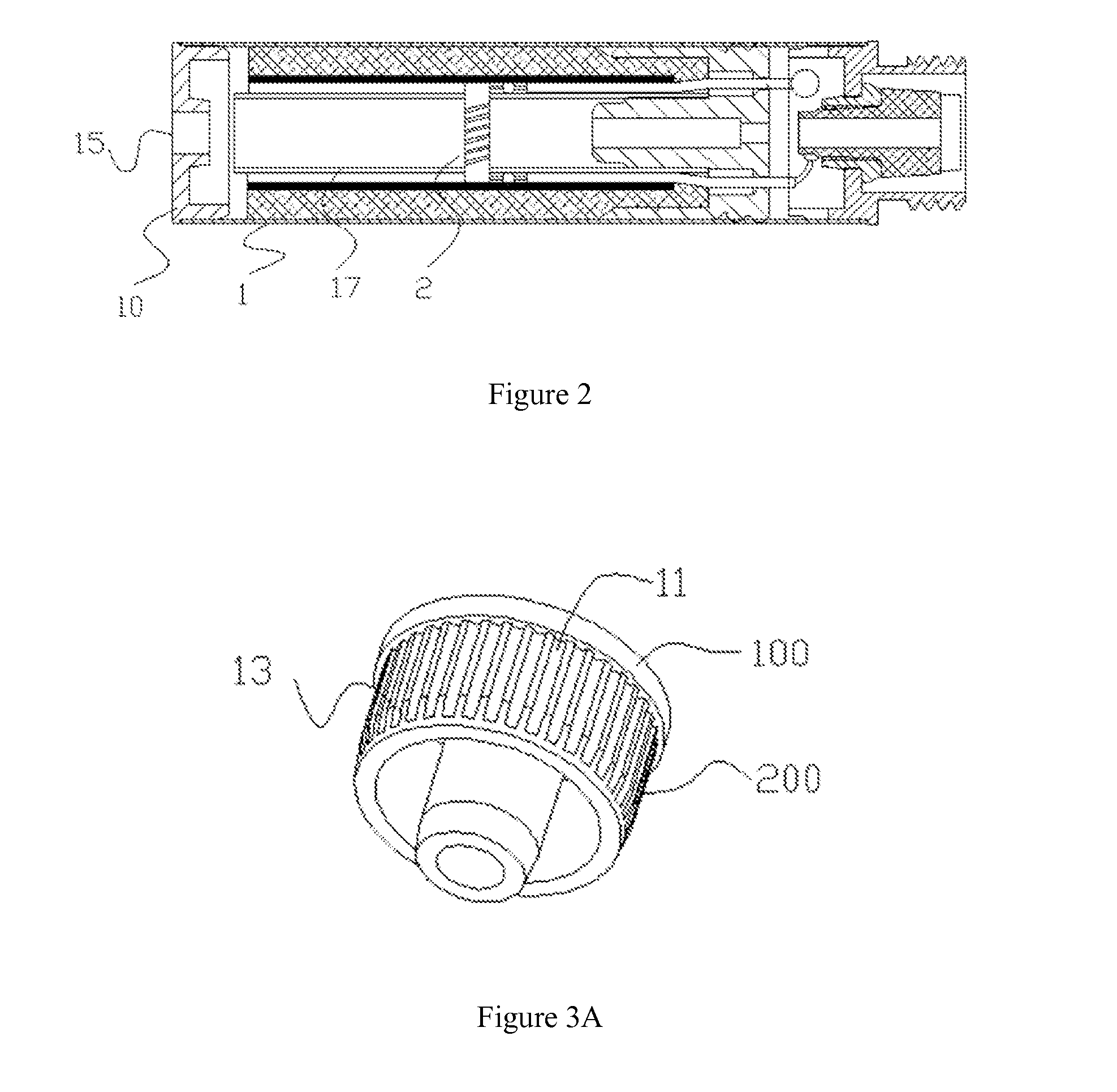

[0046]The specific structure of the end cover 10 is shown in FIG. 3A which shows the atomizer component.

[0047]The end cover 10 comprises a body 100 and a joint part 200 that axially extends away from an edge of the body 100. The knurl configuration is defined on the outer surface of the circumferential side wall of the joint part 200.

[0048]The knurl configuration comprises several first grooves 11, the first grooves 11 extend from the body 100 towards one end of the joint part 200 and form a first preset angle with respect to the axis of the joint part 200. The several first grooves 11 form a straight knurl configuration or a twill knurl configuration. The first preset angle is an angle between the central axis of the joint part 200 and the projection that a first groove 11 is projected on to any surface that comprises the central axis of the joint part 200.

[0049]In the embodiment, the first groove 11 is a curved groove or a rectangular groove. The distances between any two adjacent...

second embodiment

[0051]Referring to FIG. 3B, the atomizer component is shown.

[0052]The knurl configuration comprises several first grooves 11 and several second grooves 12. The first grooves 11 extend from the body 100 towards one end of the joint part 200 and form a first preset angle with respect to the axis of the joint part 200. The second grooves 12 extend from the body 100 towards one end of the joint part 200 and form a second preset angle with respect to the first grooves 11. The several first grooves 11 and second grooves 12 are intersected to form a netlike knurl configuration. The first preset angle is an angle between the central axis of the joint part 200 and the projection that a first groove 11 is projected on to any surface that comprises the central axis of the joint part 200, and the second preset angle is an angle between the projection that the first groove 11 is projected on above surface and the projection that a corresponding second groove 12 is projected on to above surface. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com