Turbine blade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037]In all figures, identical features are provided with identical reference signs.

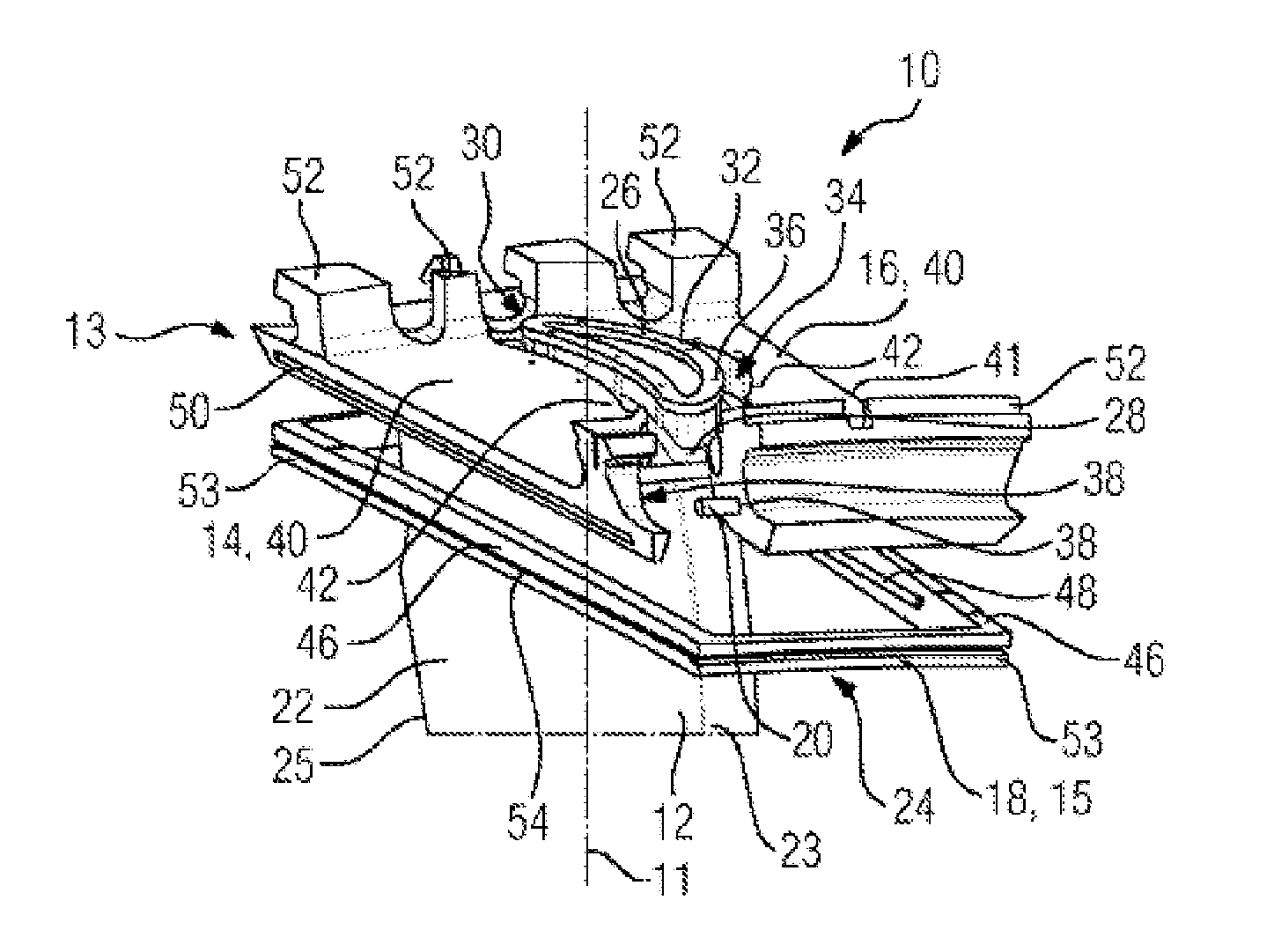

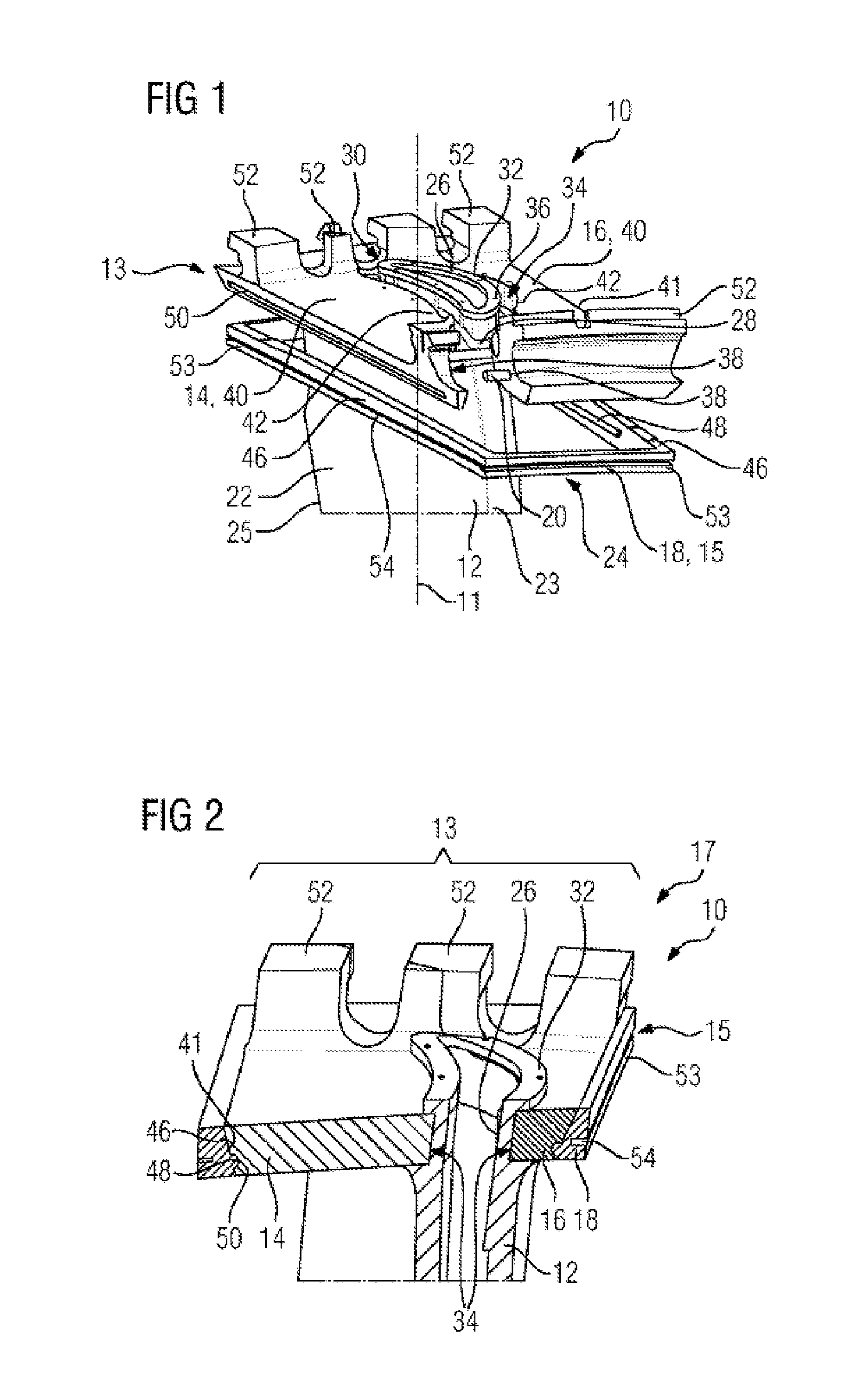

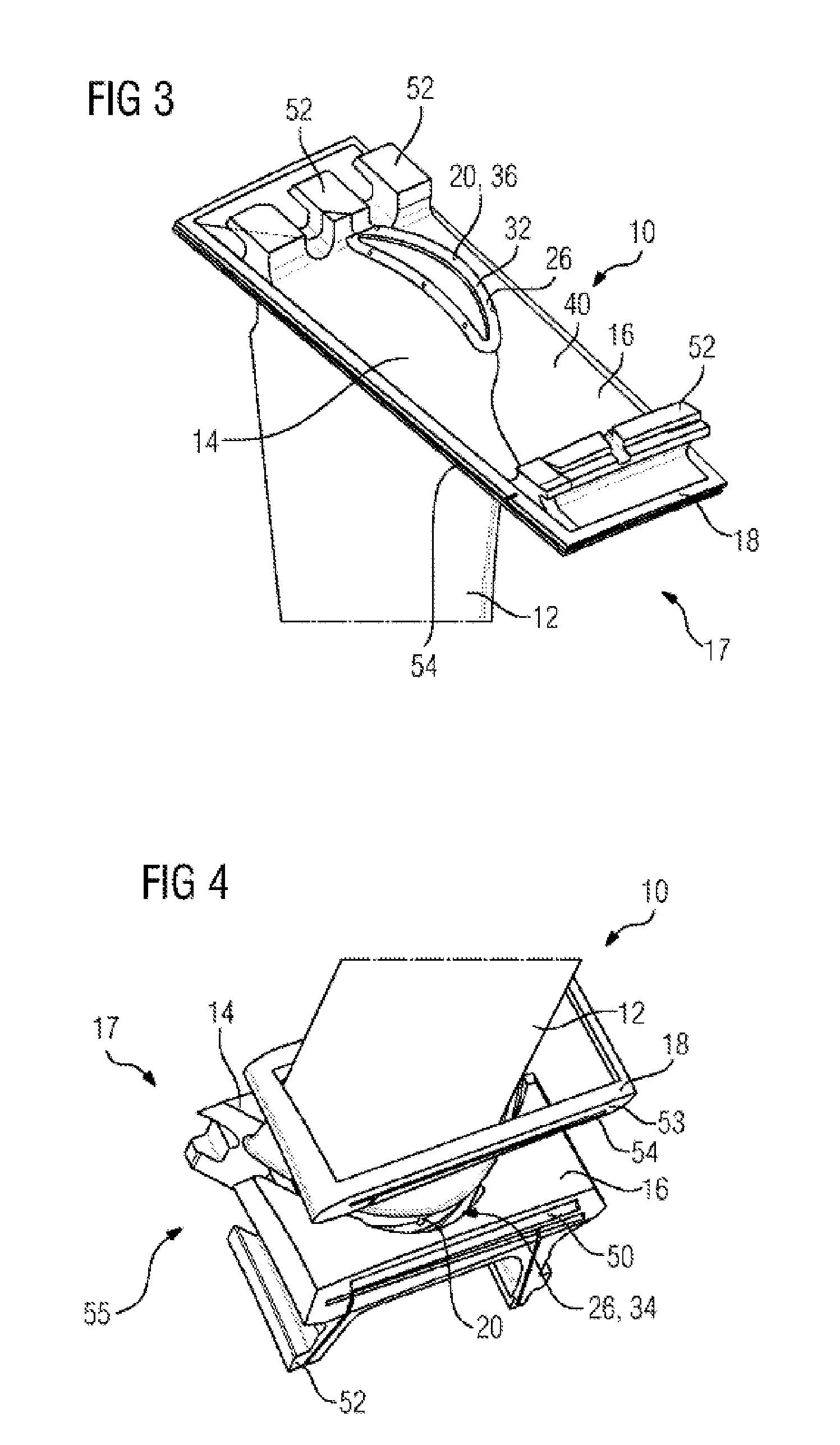

[0038]FIG. 1 shows part of a turbine blade 10 in the manner of an exploded drawing. The turbine blade 10 is of modular configuration and, according to this exemplary embodiment, therefore comprises as separately manufactured components a blade airfoil 12, two platform elements 14, 16 and a platform frame 18 and a plurality of bolts 20 connecting these to one another.

[0039]Moreover, the turbine blade 10 comprises a virtual longitudinal axis 11.

[0040]The blade airfoil 12 is curved aerodynamically and has, as is known, a pressure side 22 and a suction side 24. The pressure side 22 and the suction side 24 connect at a leading edge 23 and at a trailing edge 25. During designated use within a turbomachine, a working medium flows from the leading edge 23 to the trailing edge 25.

[0041]At the upper end, shown in FIG. 1, of the blade airfoil 12, there is provided a projection 26 which is formed in one piece w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com