Fluid displacement system using gerotor pump

a gerotor pump and fluid displacement technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of significant power waste, impaired ability of centrifugal pumps to handle fluids, and unsatisfactory flow rates from wells, and achieve high viscosity hydrocarbons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

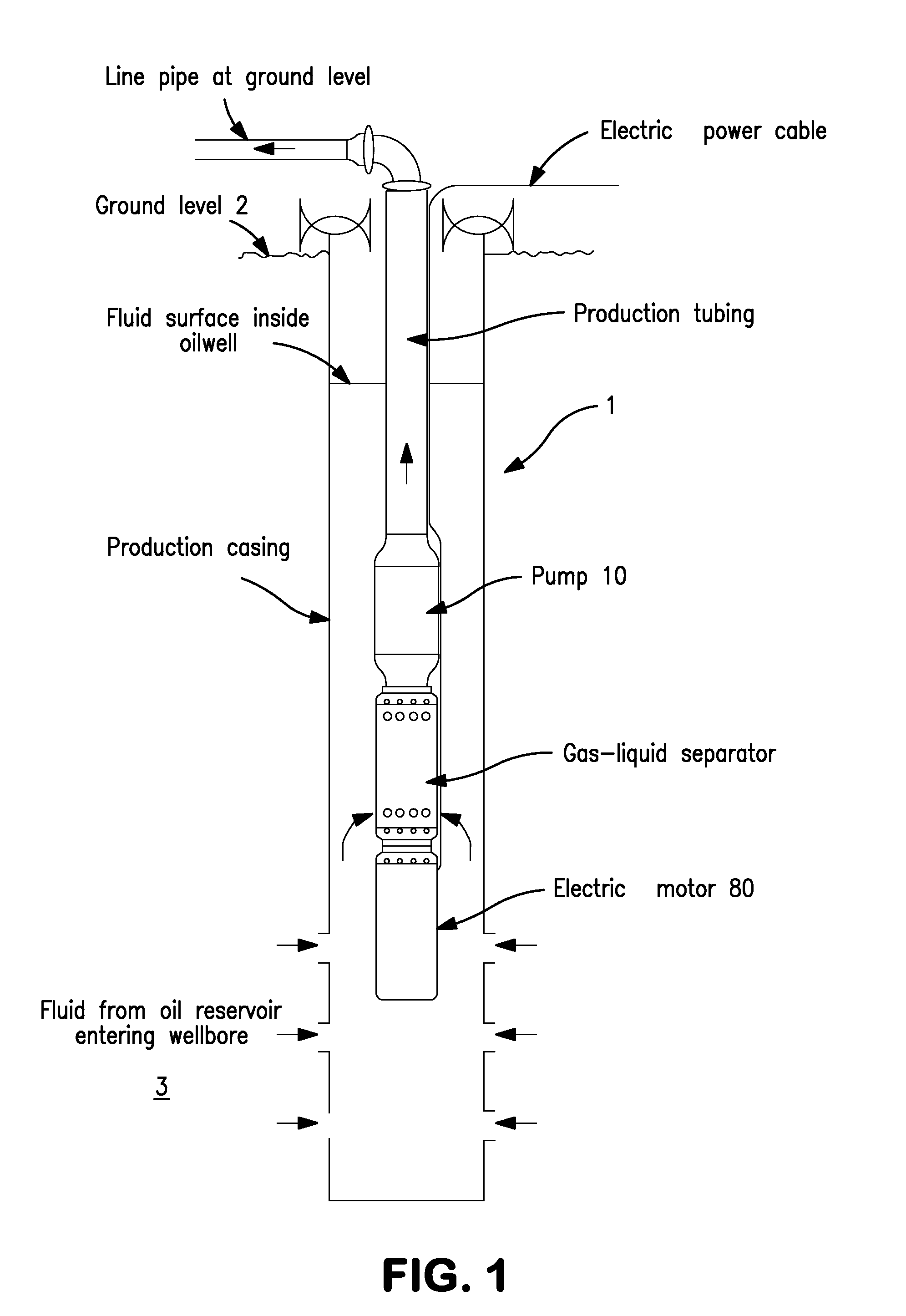

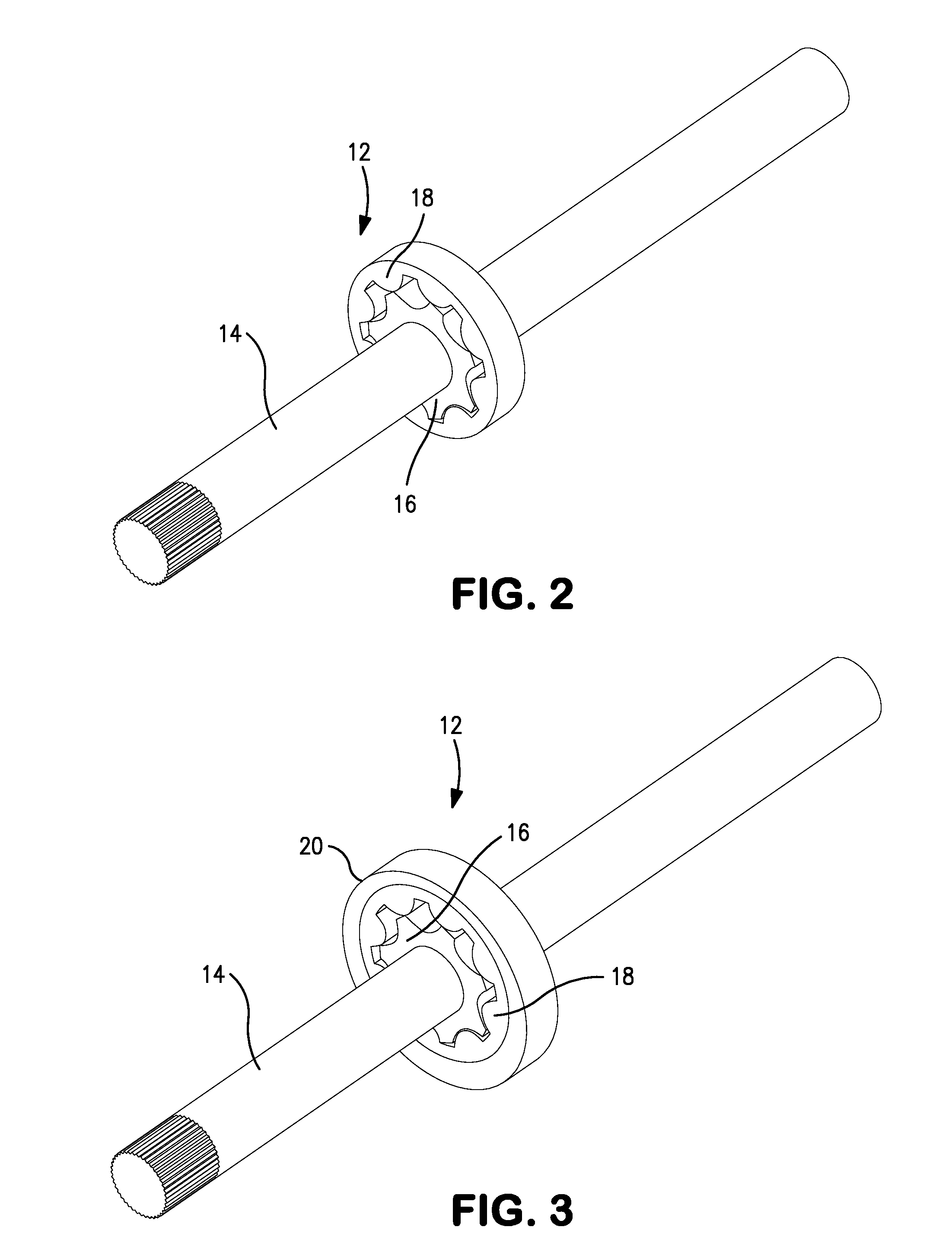

[0023]The invention relates to a fluid displacement system and method which utilizes gerotor pumps to improve pumping flow rates of heavy and extra heavy crude oils from subterranean wells.

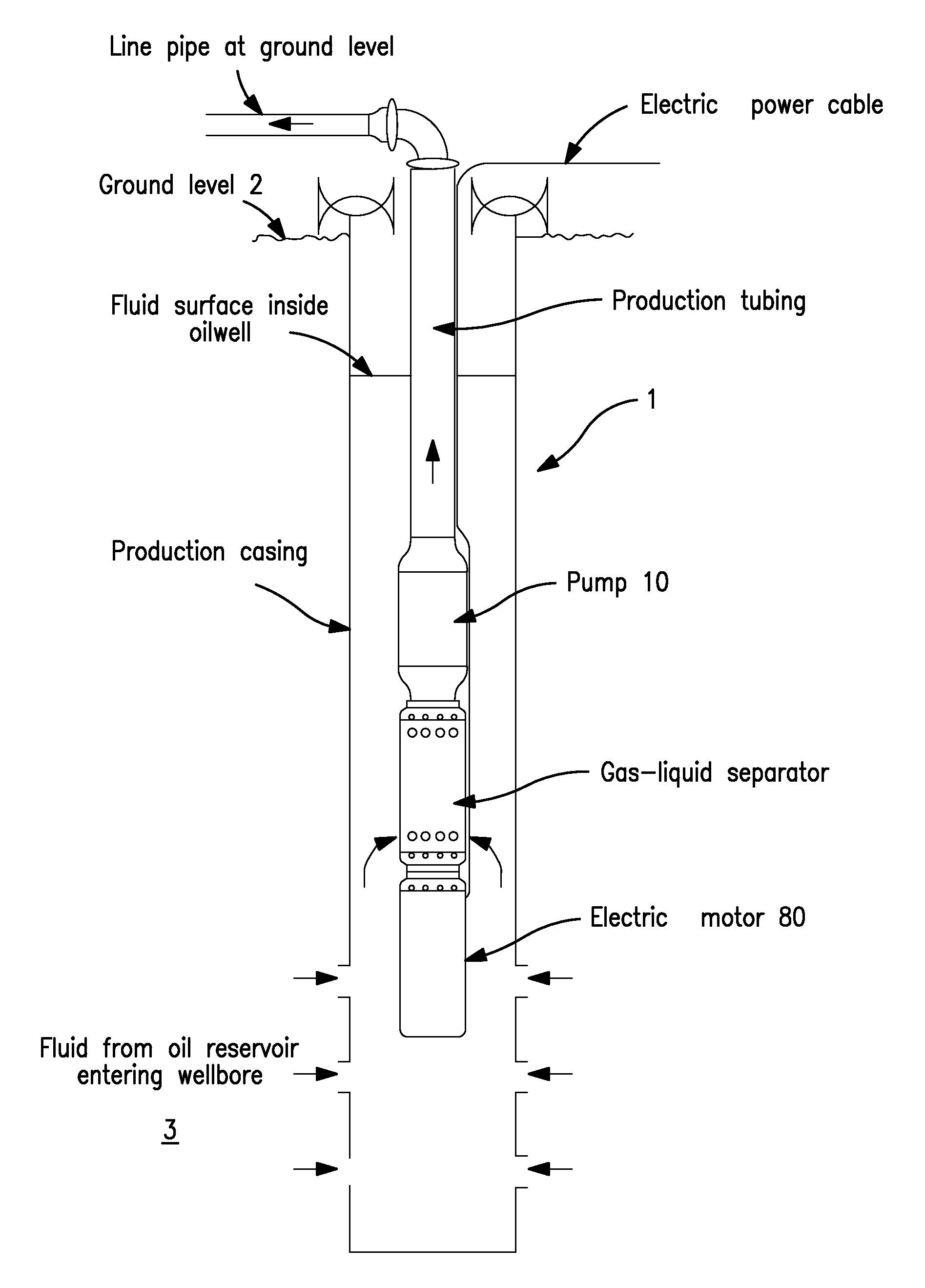

[0024]FIG. 1 illustrates a subterranean well 1 extending from the surface 2 to a subterranean formation 3. Formation 3 is typically a permeable formation containing fluids within the void space of the formation, and it is desired to produce these fluids from the formation 3 through well 1 to surface 2.

[0025]While useful with a variety of potential different applications, the present invention is particularly well suited for use in producing heavy and extra heavy crude oils such as the heavy crude oil contained in the Orinoco Oil Belt. A typical hydrocarbon from this belt has a viscosity of about 1,000 cP at reservoir temperature (130-140° F.), and this type of fluid is very difficult to pump utilizing conventional sucker-rod pumps, progressing cavity pumps and the like.

[0026]In accordance with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com