Steam turbine system with steam turbine clutch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

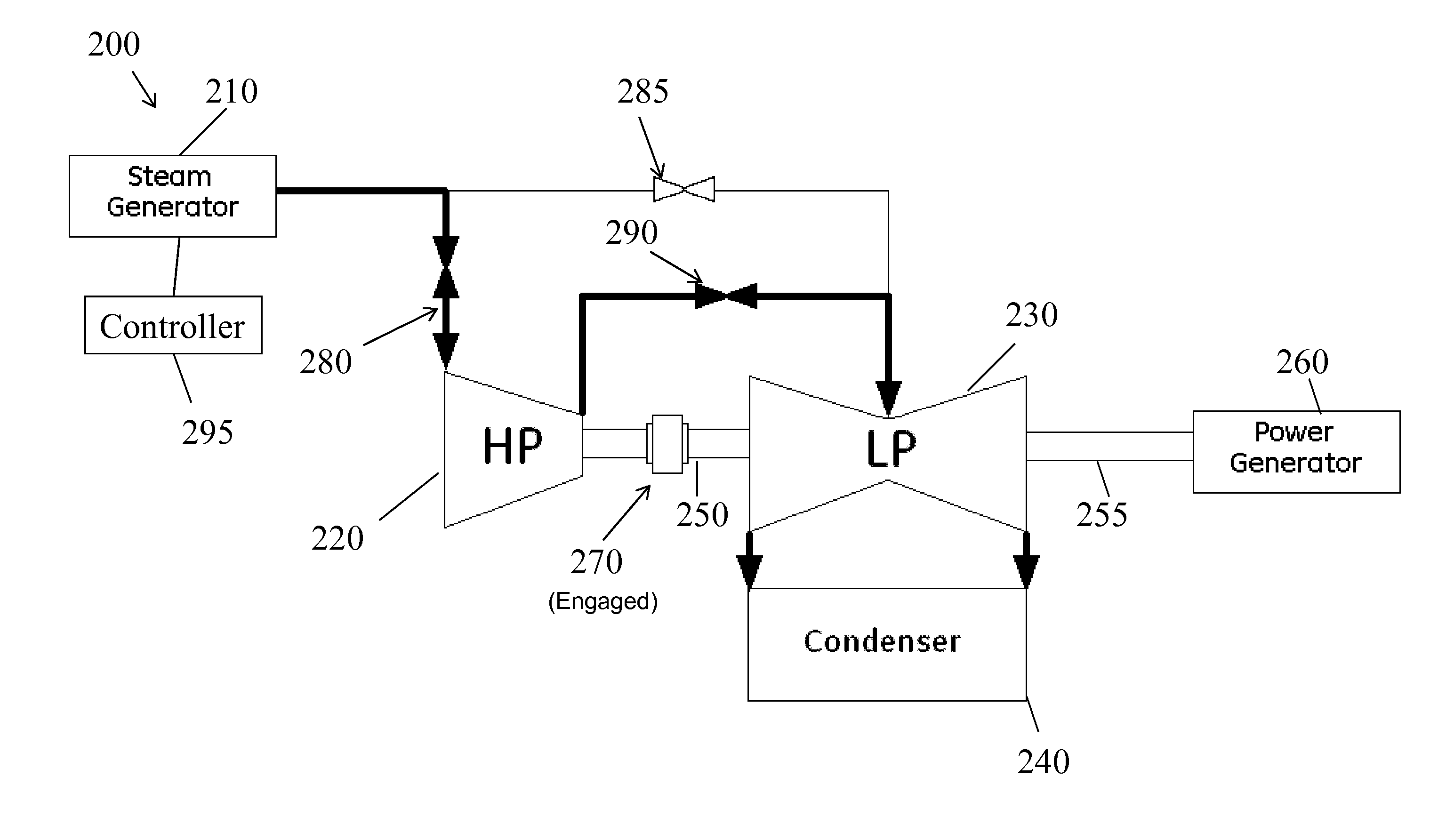

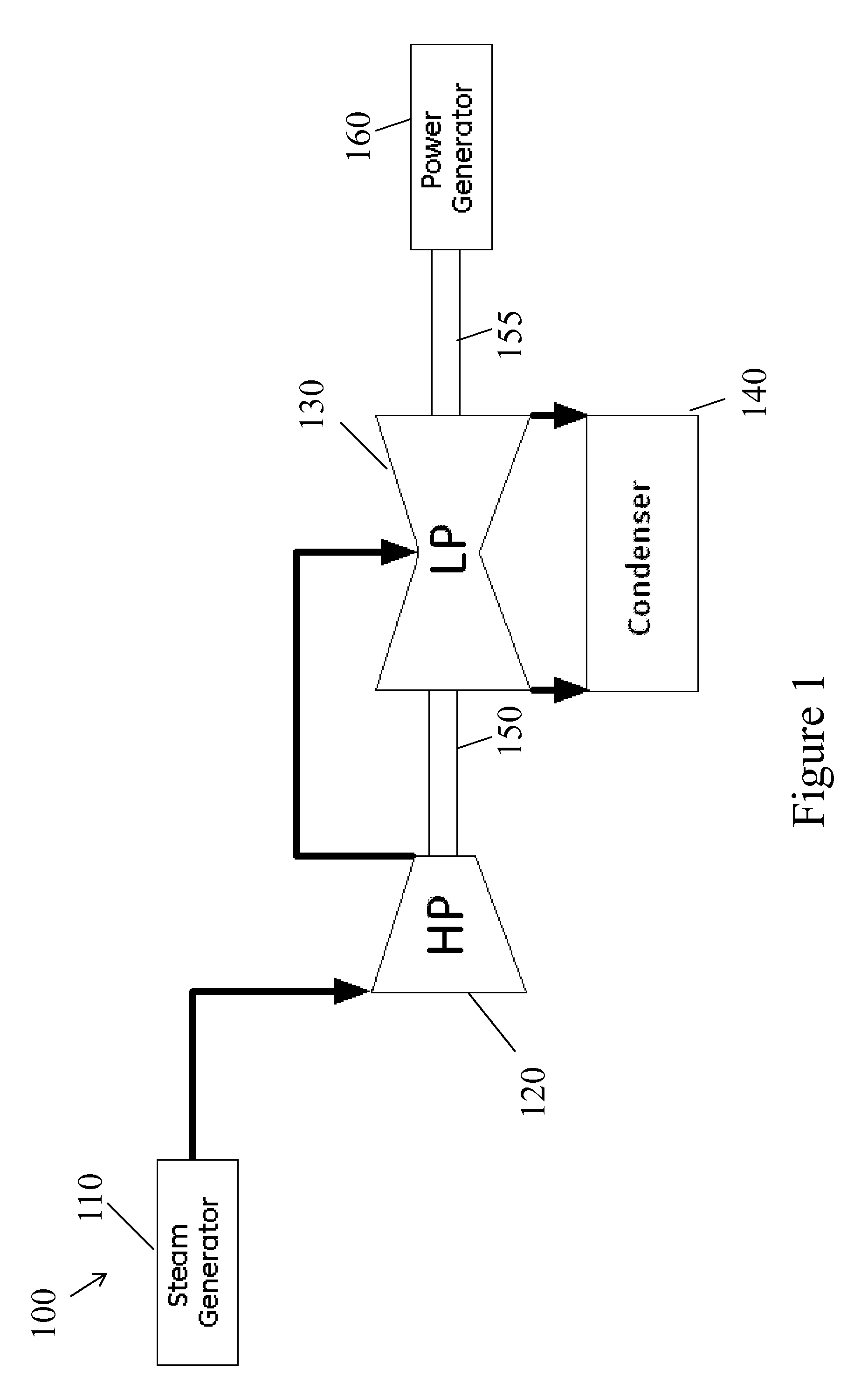

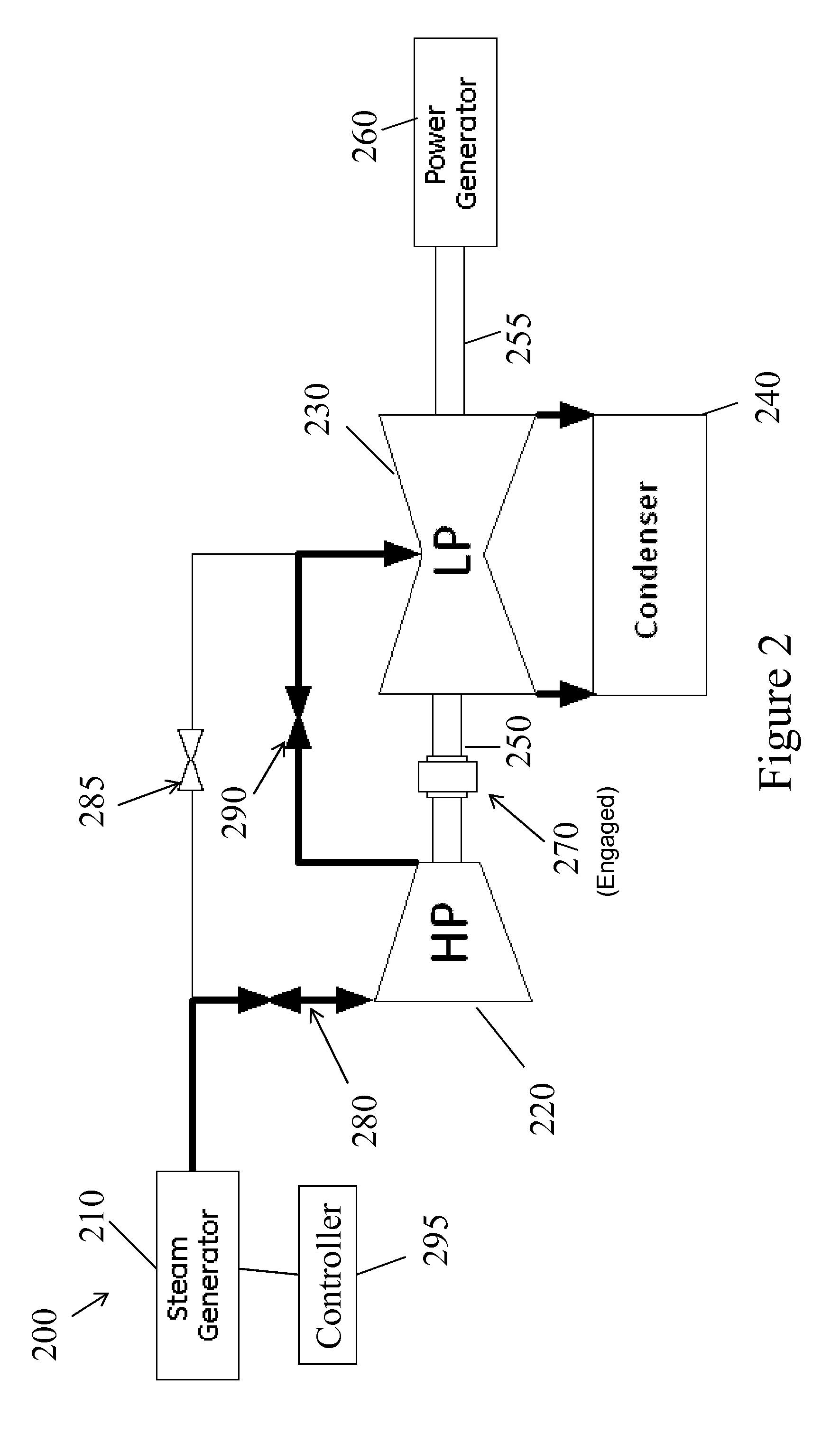

[0012]Disclosed herein is a steam turbine system including a steam turbine clutching device for disengaging a high pressure section from a power generator during low energy supply operation. Turning to FIG. 1, in the prior art, a steam generator 110 would provide steam to a high pressure section 120 of steam turbine system 100. The steam would expand within high pressure section 120 and exhaust from high pressure section 120 and would then pass to low pressure section 130. In low pressure section 130, the steam would again expand, exhausting to the condenser 140. During this operation, a first portion of a drive shaft 150 from high pressure section 120 and a second portion of the drive shaft 155 from low pressure section 130 would always provide shaft power to a power generator 160.

[0013]Still referring to FIG. 1, with both the first and second portions of the drive shafts 150 and 155 constantly supplying shaft power to power generator 160, high pressure section 120 and low pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com