Method of manufacturing a component and thermal management process

a manufacturing method and component technology, applied in the direction of superimposed coating process, machine/engine, turbine, etc., can solve the problems of inadvertent filling of cooling channels, difficult and time-consuming manufacturing cooling channels in components, and complex molds that are often difficult to position relatively

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

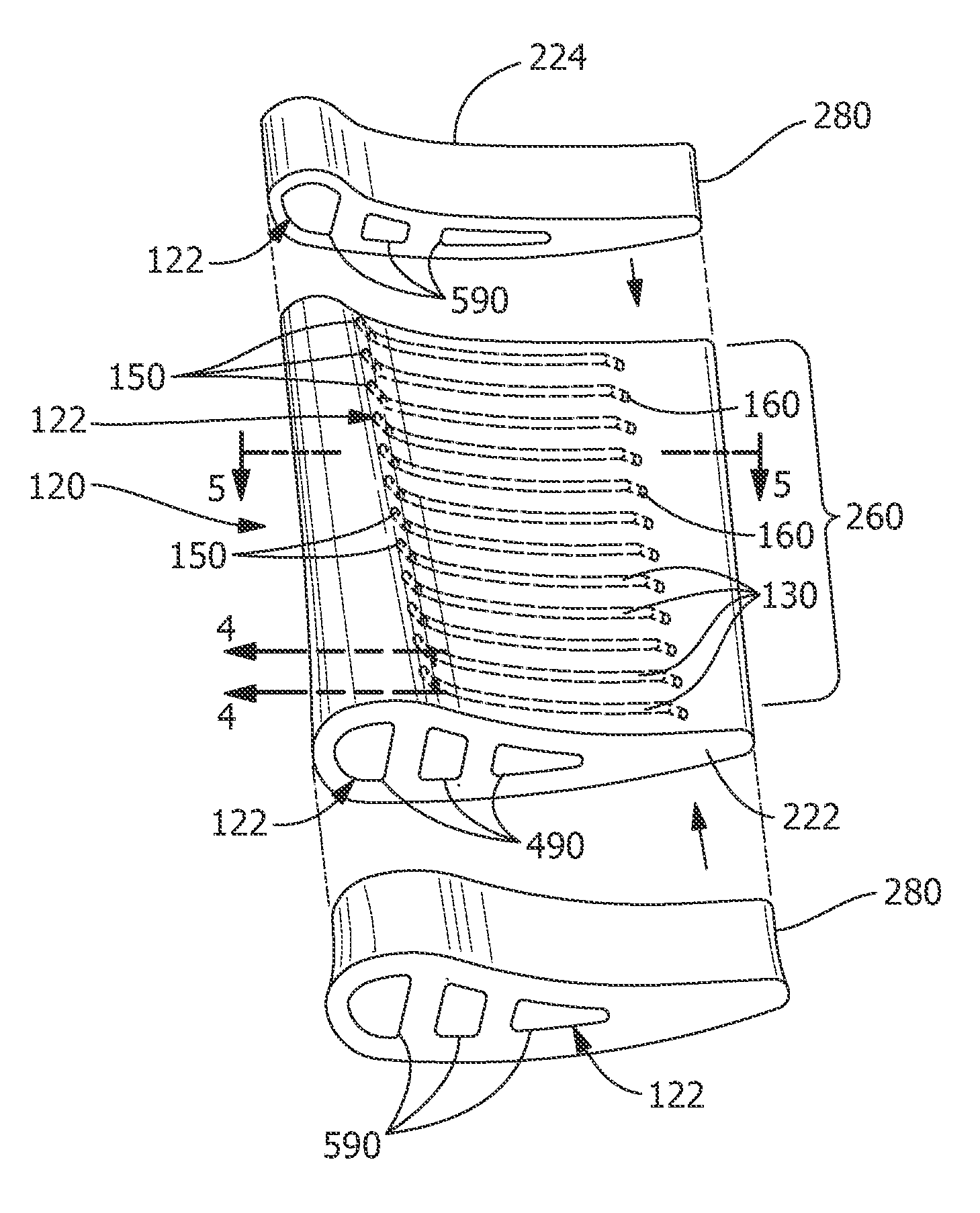

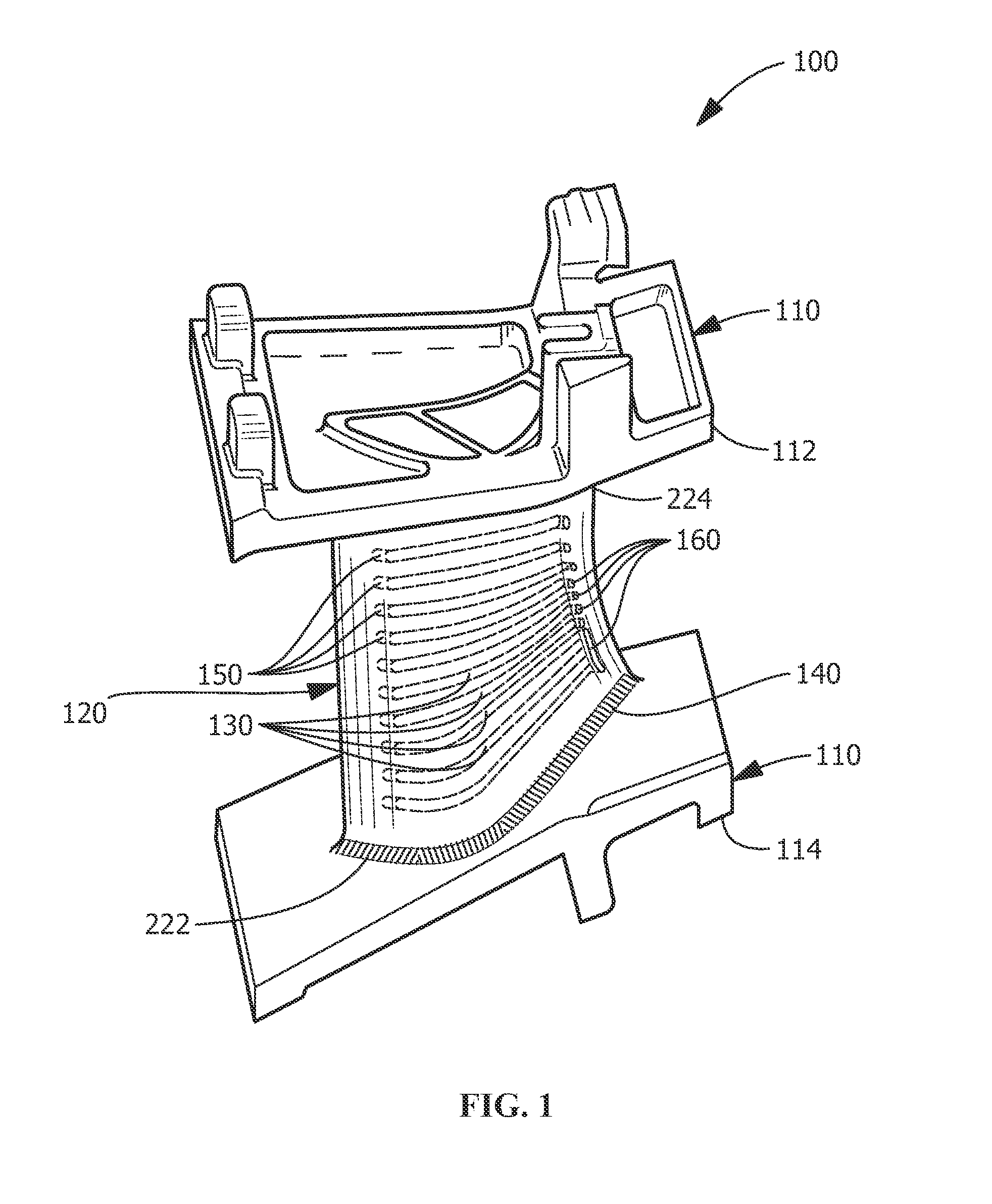

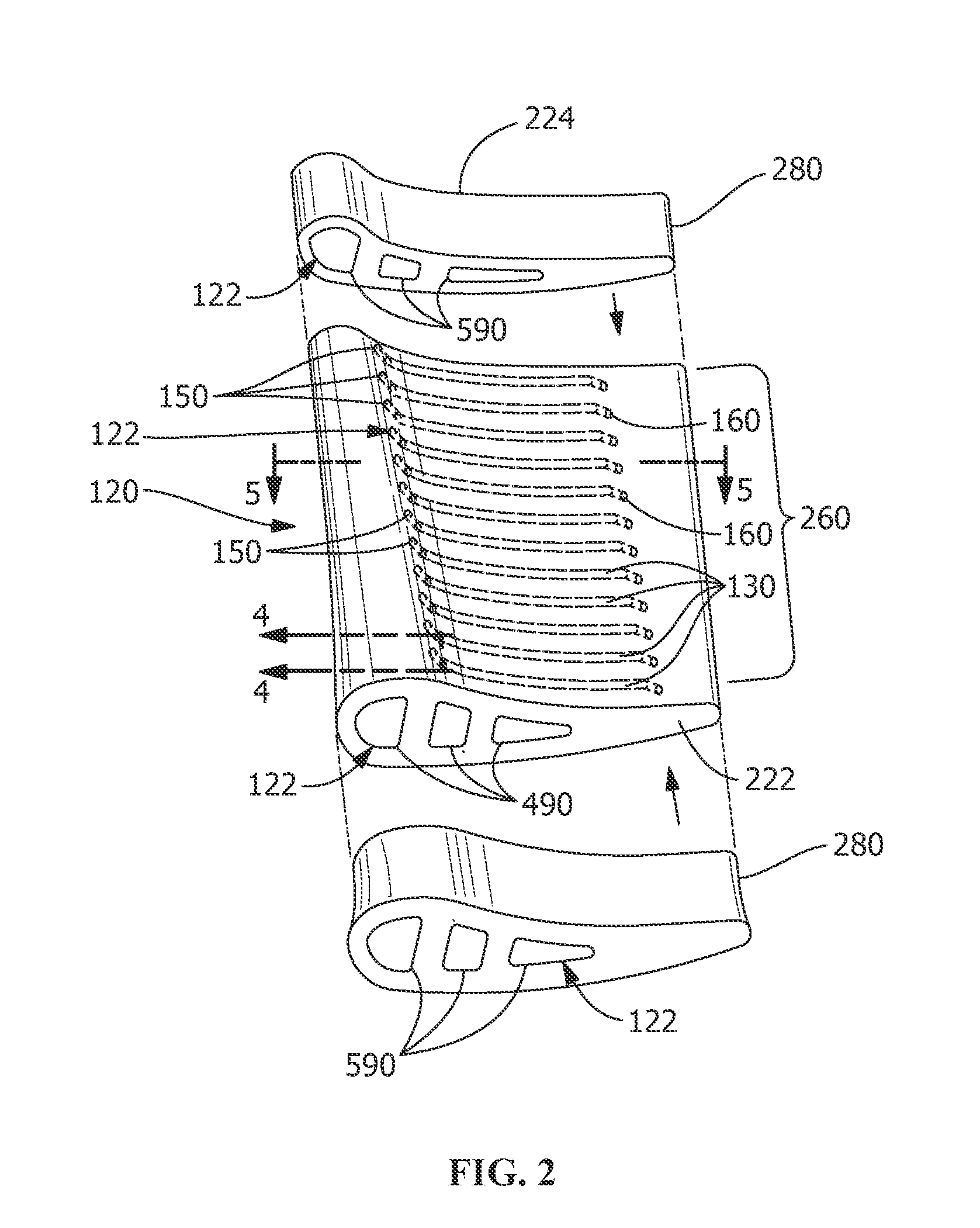

[0017]Provided is a manufacturing process and a thermal management process using the manufactured component. Embodiments of the present disclosure, in comparison to processes and articles that do not include one or more of the features disclosed herein, provide additional cooling and heating, permit cooling in new regions, permit cooling with new materials, permit cooler and / or hotter streams to be directed from flow within turbine components, permit the useful life of turbine components to be extended, permit turbine systems using embodiments of the turbine components to be more efficient, permit turbine components to be manufactured more easily, permit manufacturing of cooling features that previously could not be made, permit manufacturing of components that otherwise cannot be made using traditional manufacturing processes, permit hybrid material construction of turbine components or a combination thereof.

[0018]One or more specific embodiments of the present invention will be de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com