Extension tool

a technology of extension tool and extension rod, which is applied in the field of extension tools, can solve the problems of time-consuming and potentially dangerous procedures, and none of the prior art patents have solved the needs of the art, and achieve the effect of facilitating slidable displacement and preventing slidable displacement of the second pol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

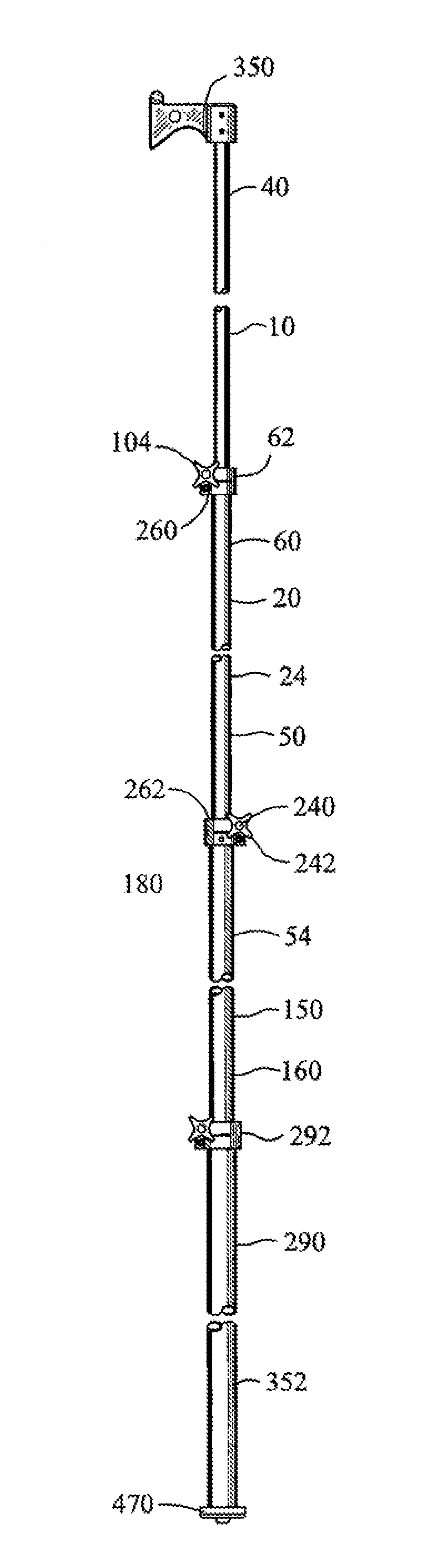

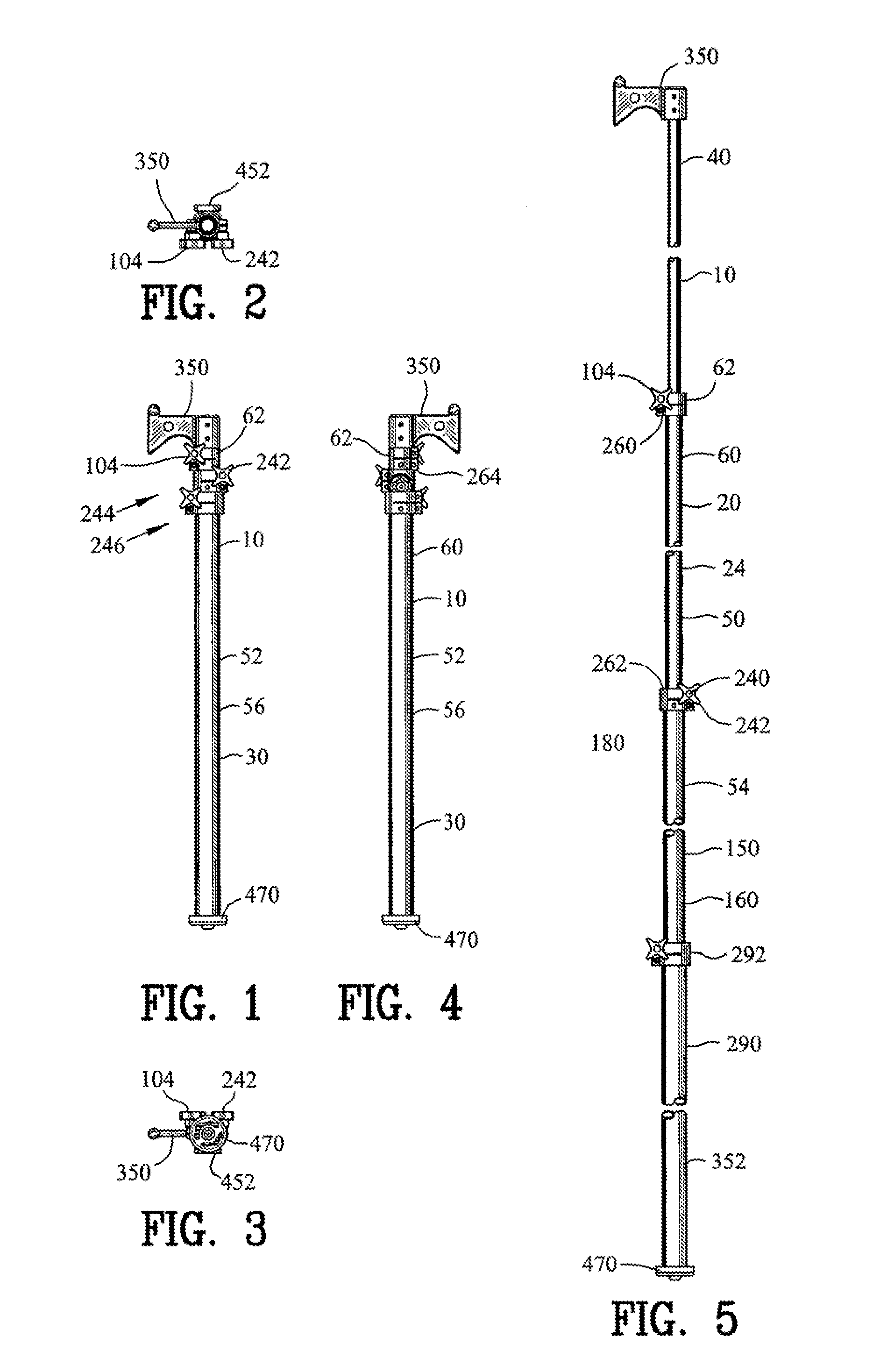

[0076]FIGS. 1-45 are various views of an extension tool 10. The extension tool 10 may be utilized for engaging a railroad car 300 as shown in FIGS. 25-33, however the extension tool 10 may be utilized as a support between two objects, for distancing an object from another object, or for applying a force upon an object that is distanced from another object.

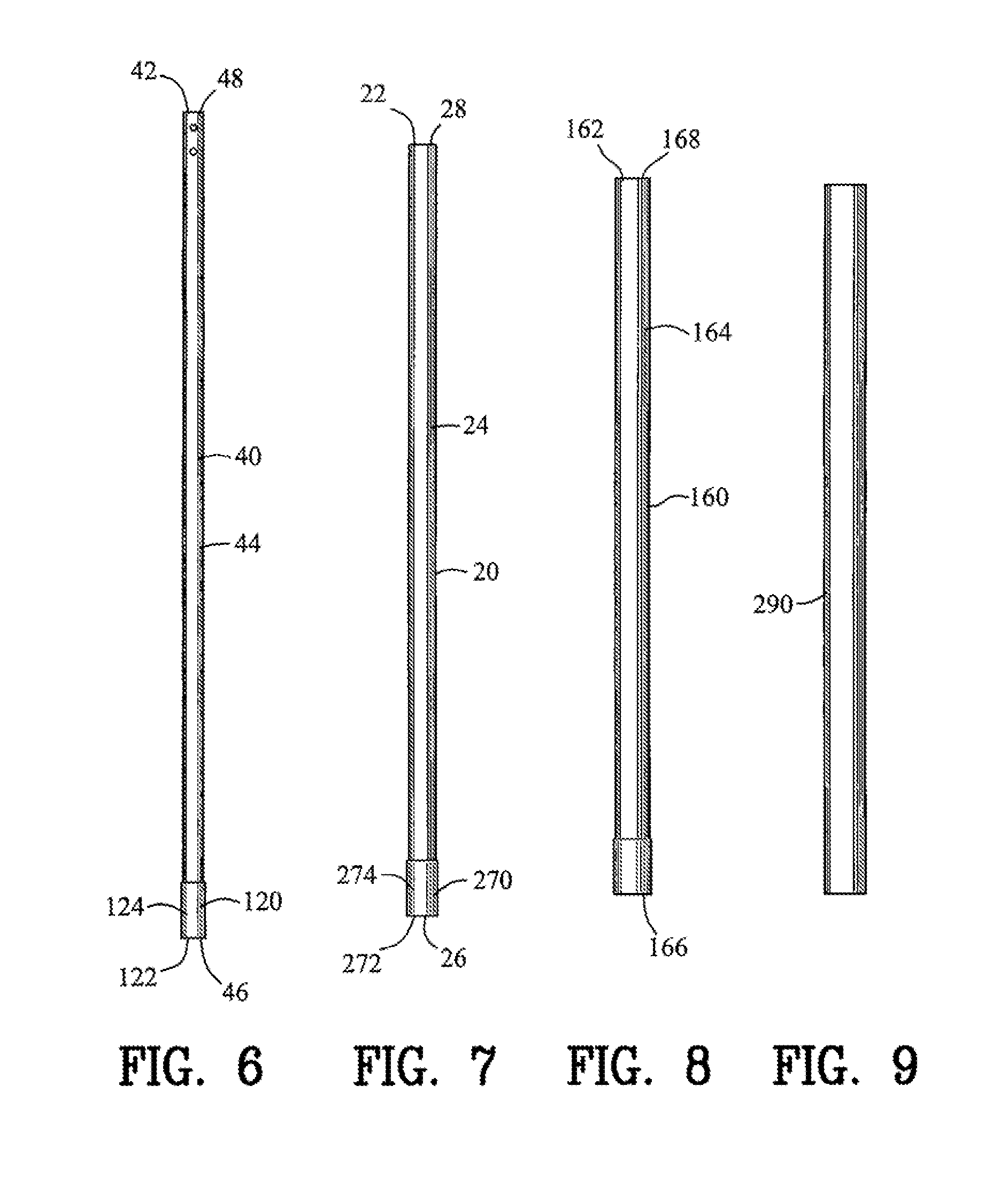

[0077]As best shown in FIGS. 1-24, the extension tool 10 comprises a first pole 20 defining a first interior bore 22 and a first exterior surface 24 with the first pole extending between a first end 26 and a second end 28. A second pole 40 defines a second interior bore 42 and a second exterior surface 44 with the second pole 40 extending between a first end 46 and a second end 48. The second pole 40 is partially disposed in the first pole 20 for defining a variable overall tool length 60. As the second pole 40 is withdrawn from the first pole 20, the variable overall tool length 60 increases as best shown in FIGS. 5, 7, 25, 29, 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com