Tool dust control attachment

a technology of dust control and tool, which is applied in the direction of vehicle maintenance, cleaning equipment, vehicle cleaning, etc., can solve the problems of creating dust and debris, rotary grinders, and large amounts of fine dus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

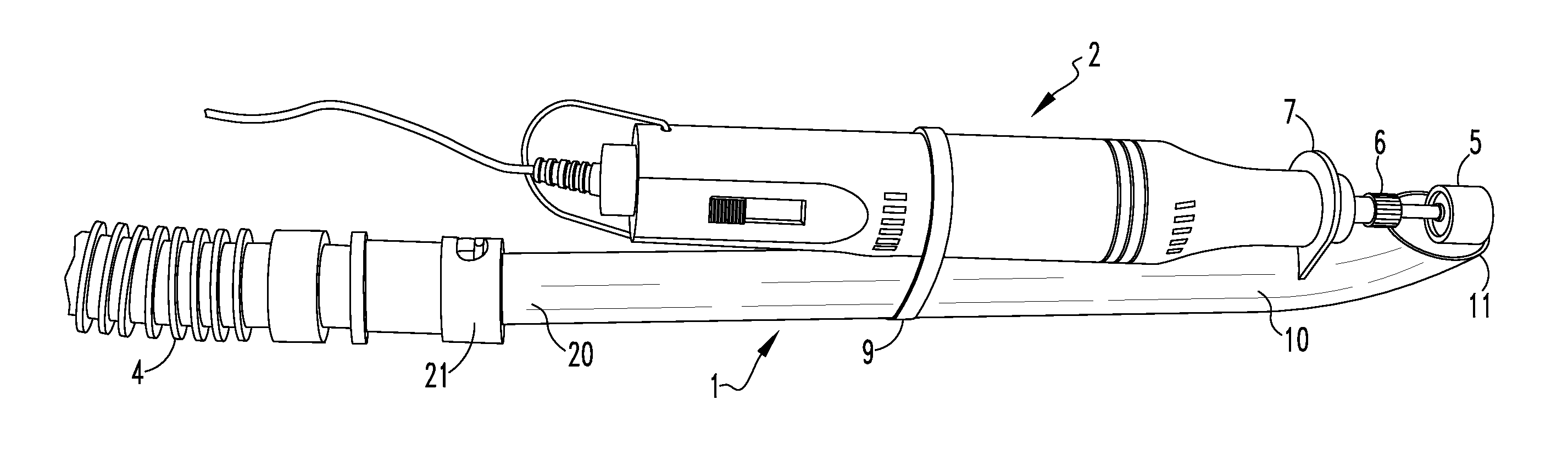

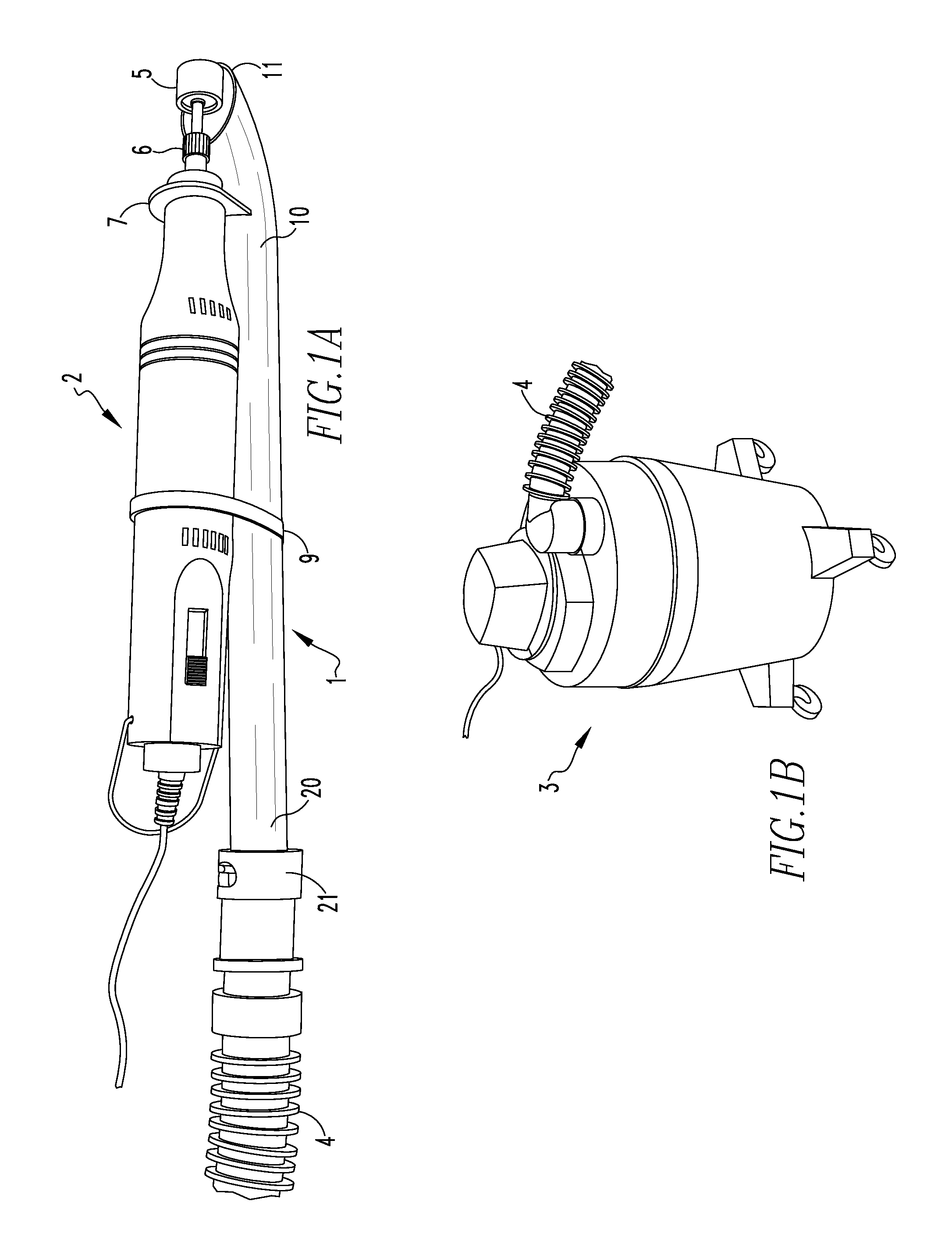

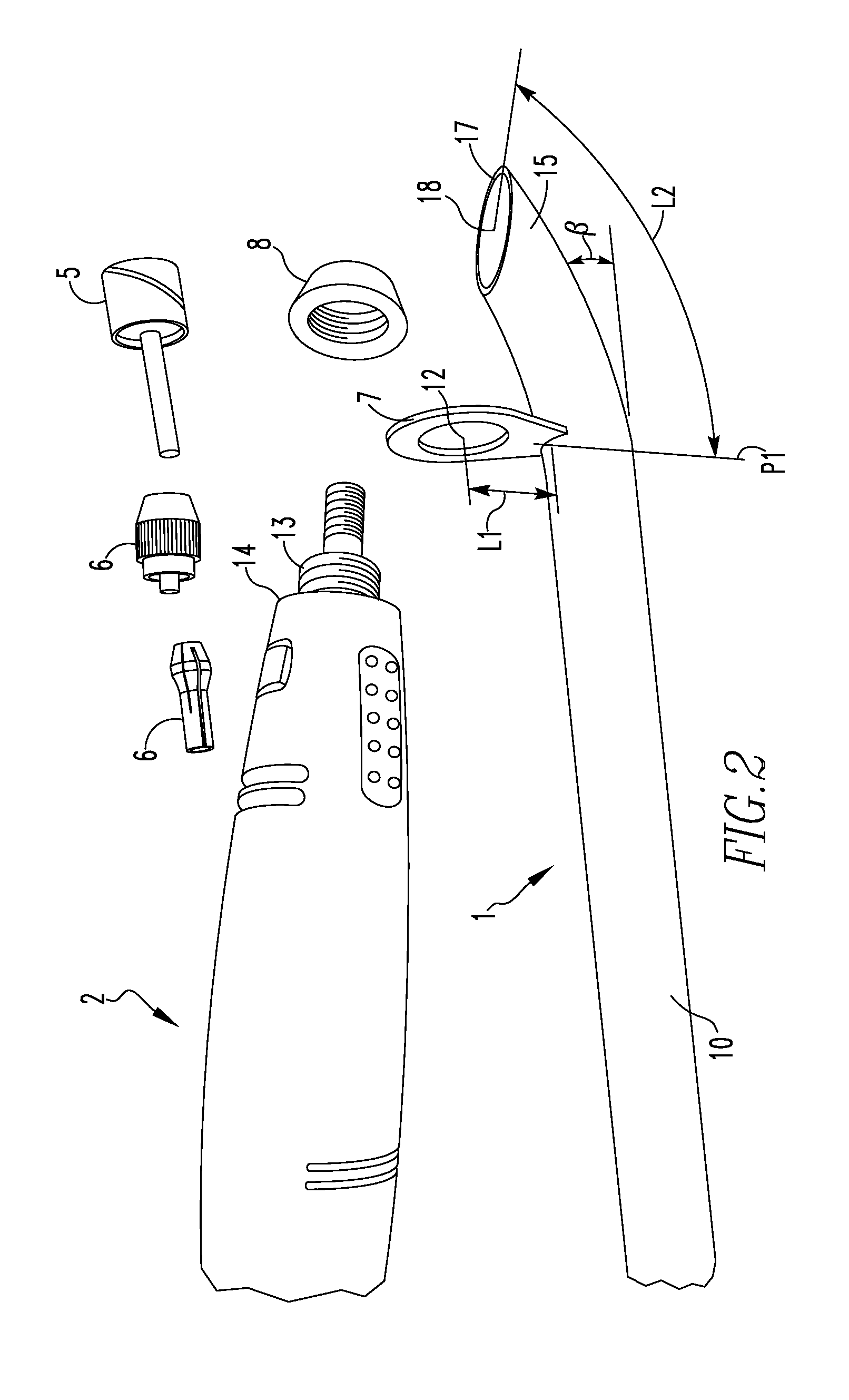

[0016]The tool dust control attachment 1 is comprised of a tube 10 having a first end 15 and a second end 20. There are openings 18 and 19 at each end of tube 10 to allow passage of dust through the tube. The attachment 1 further has a mounting tab 7, which is used to secure the too dust control attachment 1 to grinder 2. At the first end 15 of the attachment 1 is an opening 18 adapted to collect dust dispersed by the grinding bit 5 of the rotary tool 2. The second end 20 of the tube 10 is adapted to connect to a source of vacuum, embodied as an electric vacuum cleaner 3 as shown in FIG. 1B. As seen in FIG. 1A, hose 4 fluidly connects the tool dust control device 1 to the vacuum cleaner 3 at vacuum connection 21.

[0017]Though the invention is described being assembled to a rotary grinder 2, it is not to be limited to only being compatible with a rotary grinder 2. The tool dust control attachment can be adapted to routers, oscillating multi-tools, or any other tool that creates dust. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com