Stackable artcle-packaging container

a packaging container and artcle technology, applied in packaging foodstuffs, packaged goods types, transportation and packaging, etc., can solve the problems of difficult difficult to one-piece mold lids with containers, and unenvironmental protection, so as to prevent the opening of containers, safe storage of fragile objects, and easy opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]One preferred embodiment of the present invention will now be described in detail with reference to the accompanying drawings.

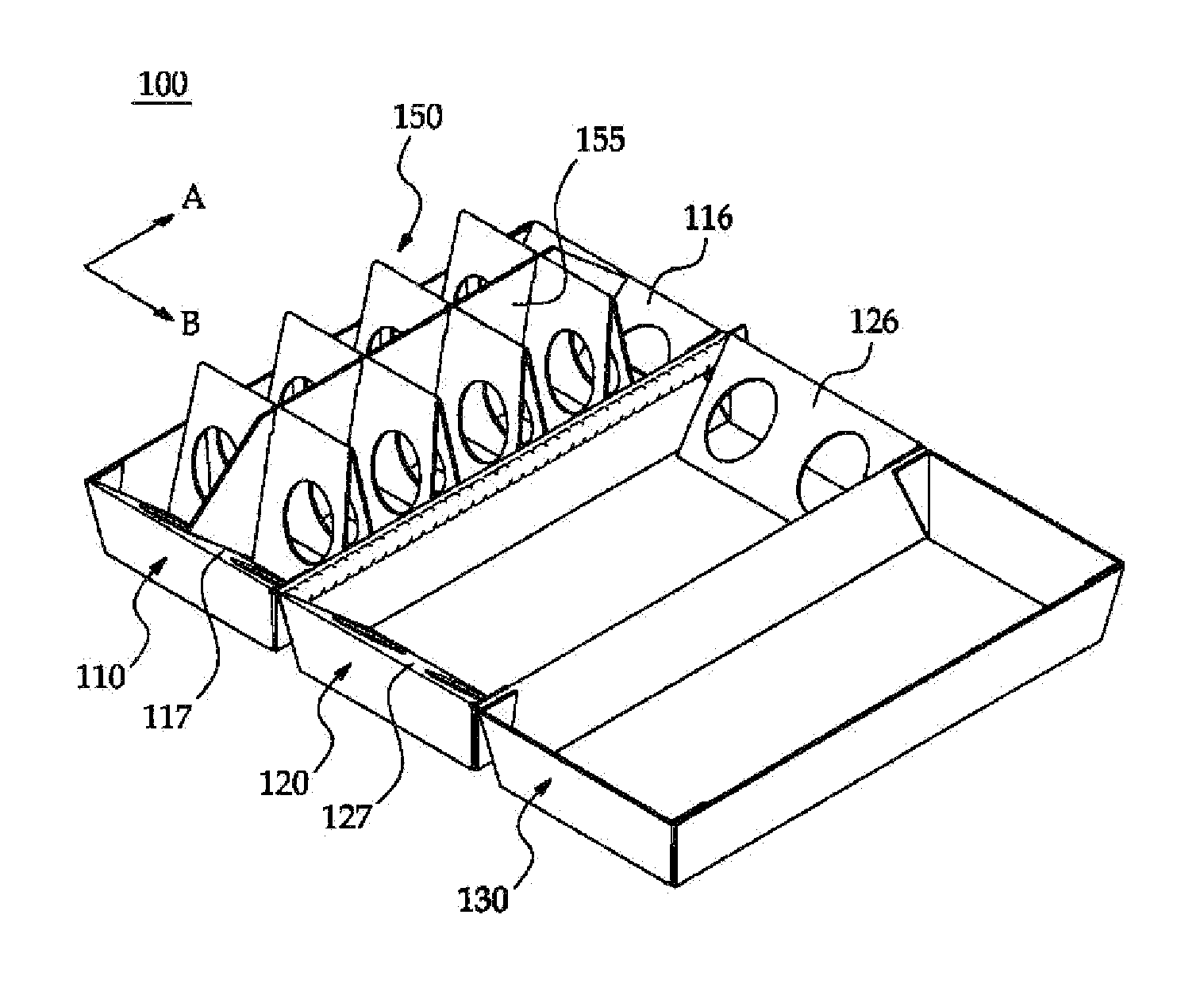

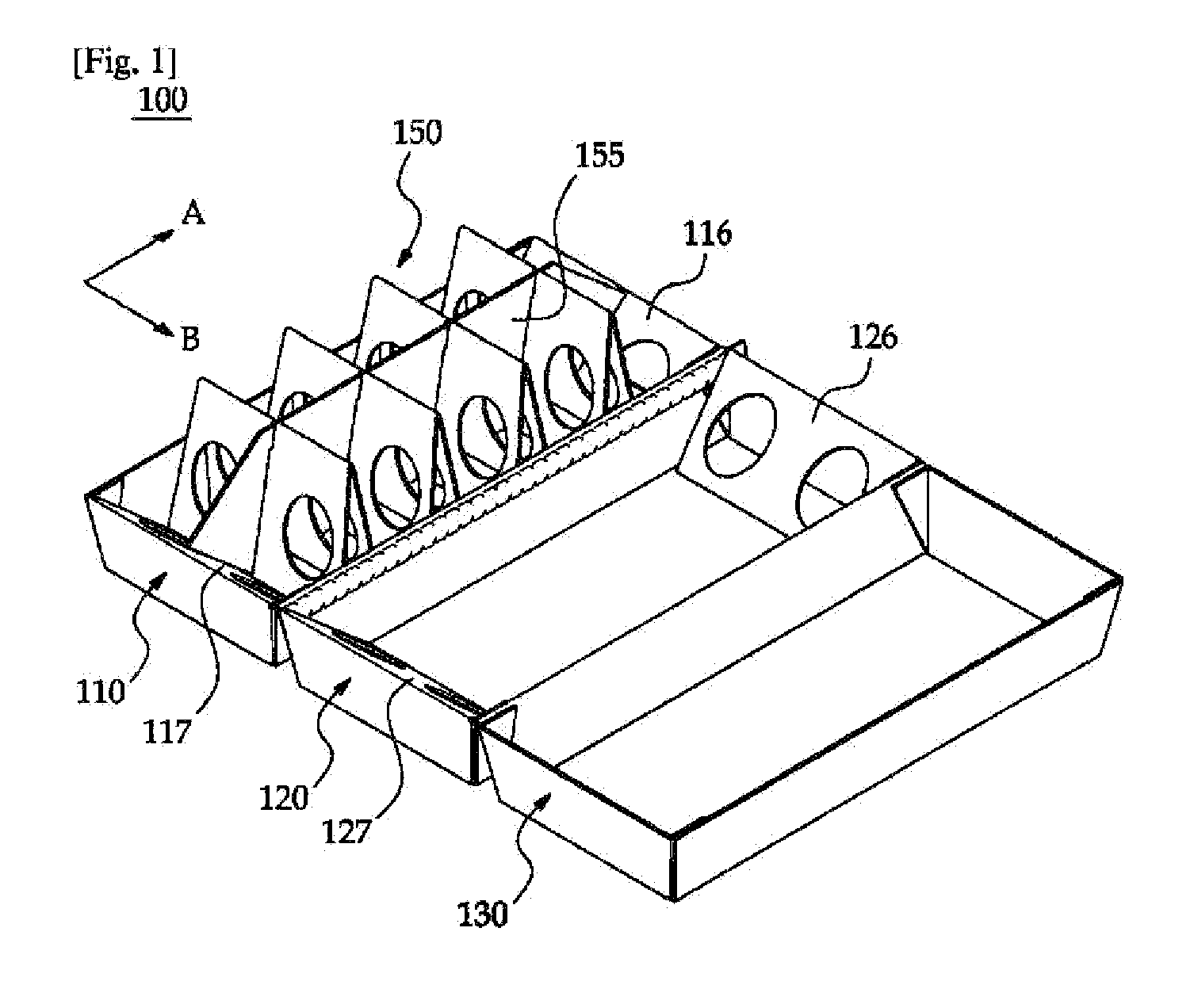

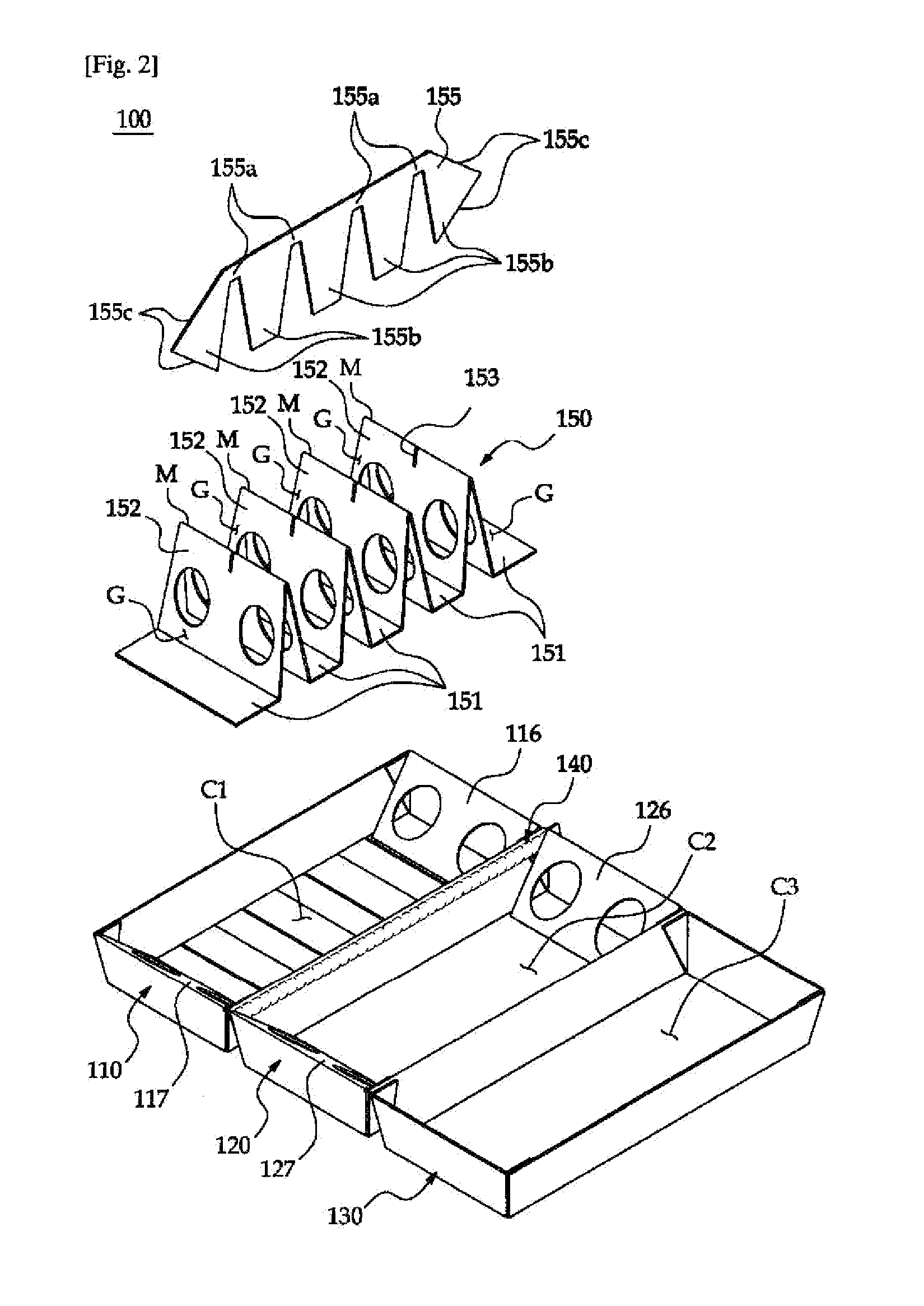

[0041]FIG. 1 is a perspective view showing a stackable article-packaging container according to one embodiment of the present invention. FIG. 2 is an exploded perspective view of the container shown in FIG. 1. FIG. 3 is a developed view of an accommodating unit, a lid unit and a locking unit of the container shown in FIG. 2. FIG. 4 is a developed view of a corrugated insertion unit of the container shown in FIG. 2. For the sake of convenience in description, the direction indicated by an arrow A in FIG. 1 will be referred to as a corrugation arrangement direction. The direction indicated by an arrow B in FIG. 1 will be referred to as a corrugation width direction.

[0042]Referring to FIG. 1, the stackable article-packaging container 100 according to the present invention is designed to accommodate, e.g., eggs. However, the use of the container 100 is not ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com