Multi-stage shock absorber

a shock absorber and multi-stage technology, applied in the field of shock absorbers, can solve the problems of jarring impact, shock absorber bottom out, and limited effectiveness of known jounce control systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

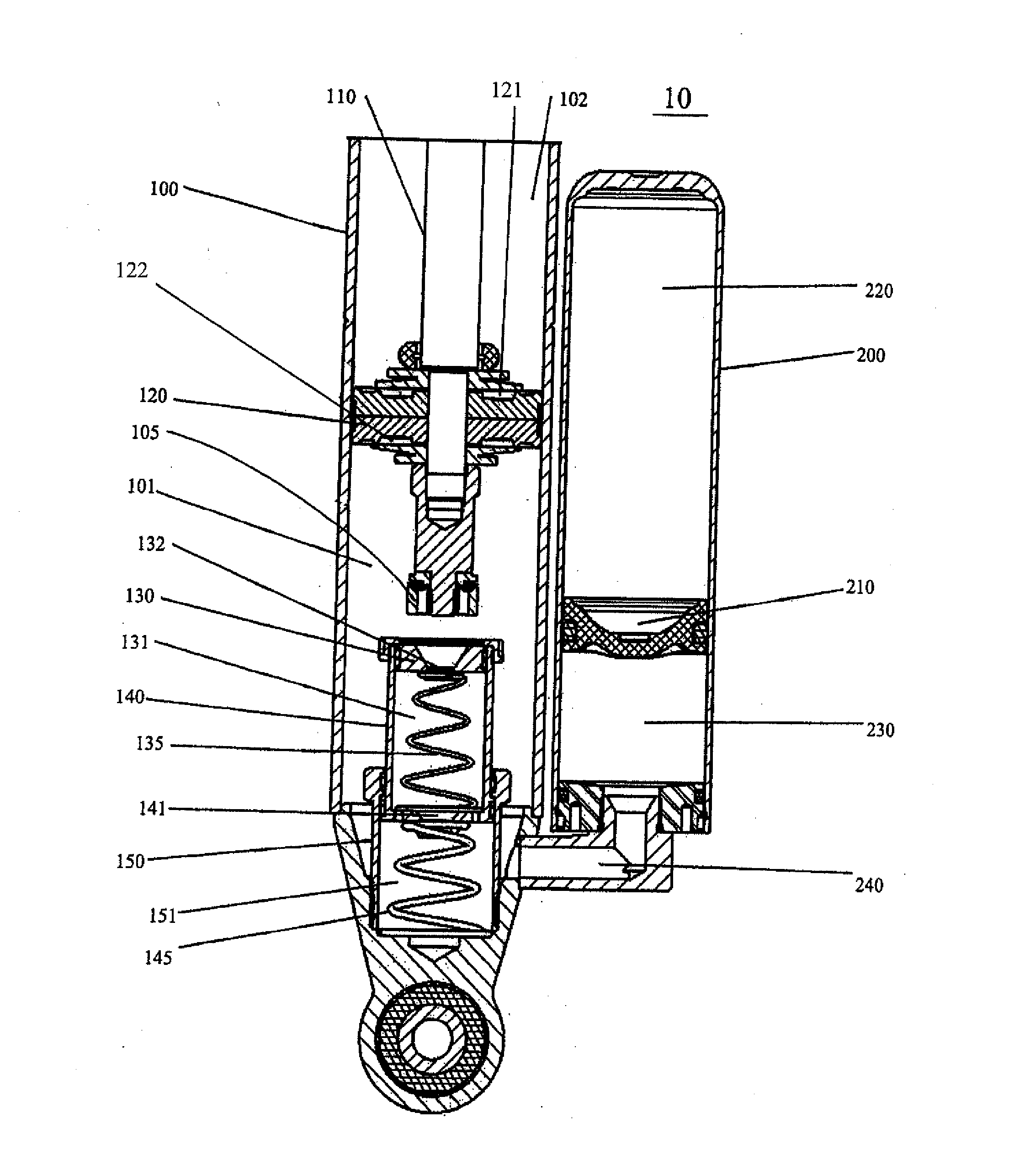

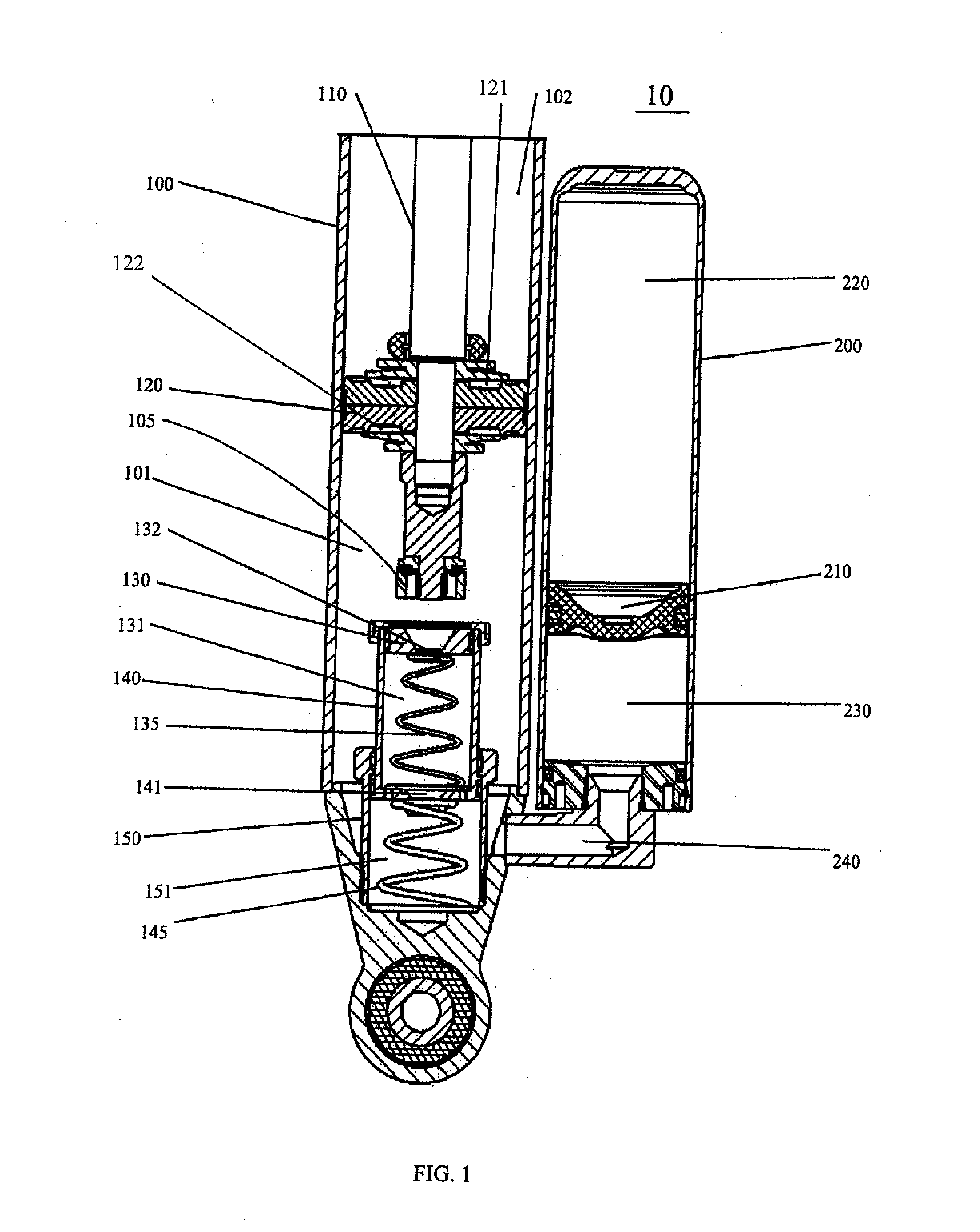

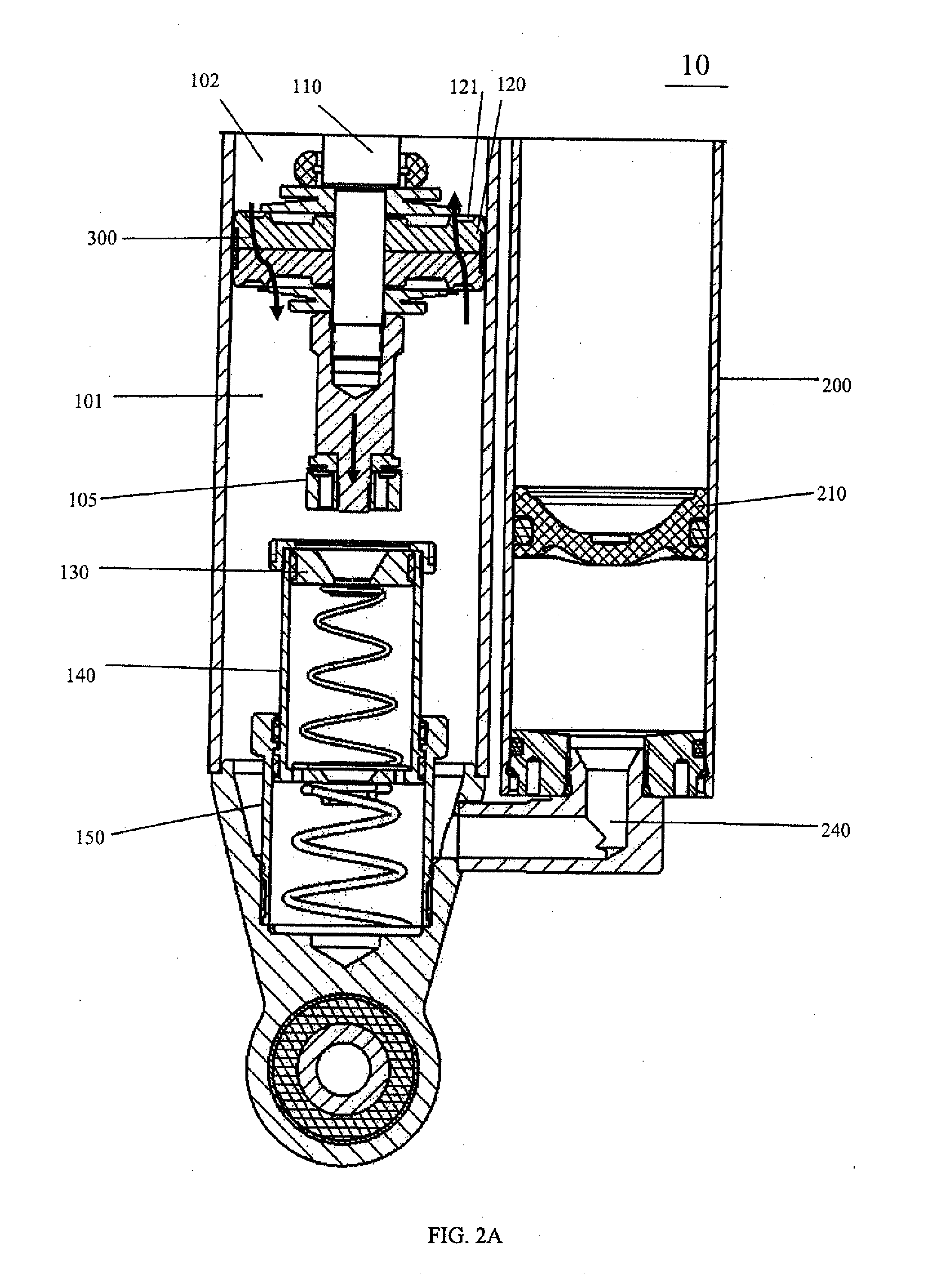

[0020]The invention is directed to a shock absorber advantageously for use with a vehicle suspension. The shock absorber increases the damping force when there is significant travel of the vehicle suspension. In particular, as the suspension reaches a bottoming out condition during compression, the damping force of the shock absorber increases. The present invention provides unique and novel mechanisms for increasing the damping force depending on the position of the shock absorber during compression so as to significantly reduce or avoid a bottoming out condition. As discussed below, the shock absorber of the present invention sequentially increases the damping force using a multi-stage jounce control configuration.

[0021]For the purposes of promoting an understanding of the principles of the invention, reference will now be made to the embodiment illustrated in the drawings and specific language will be used to describe the same. It will nevertheless be understood that no limitatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com