Rotor pivoting system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

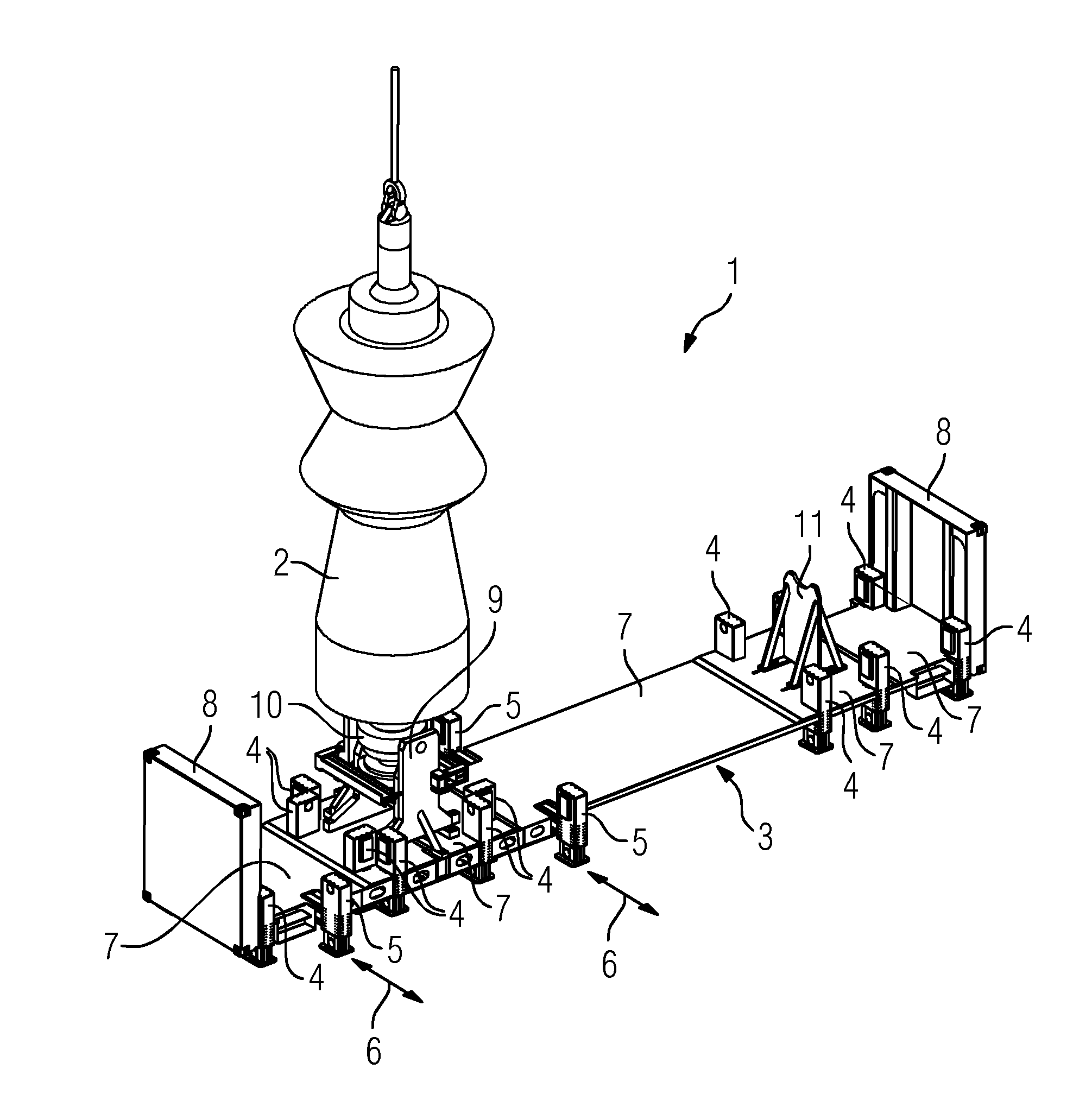

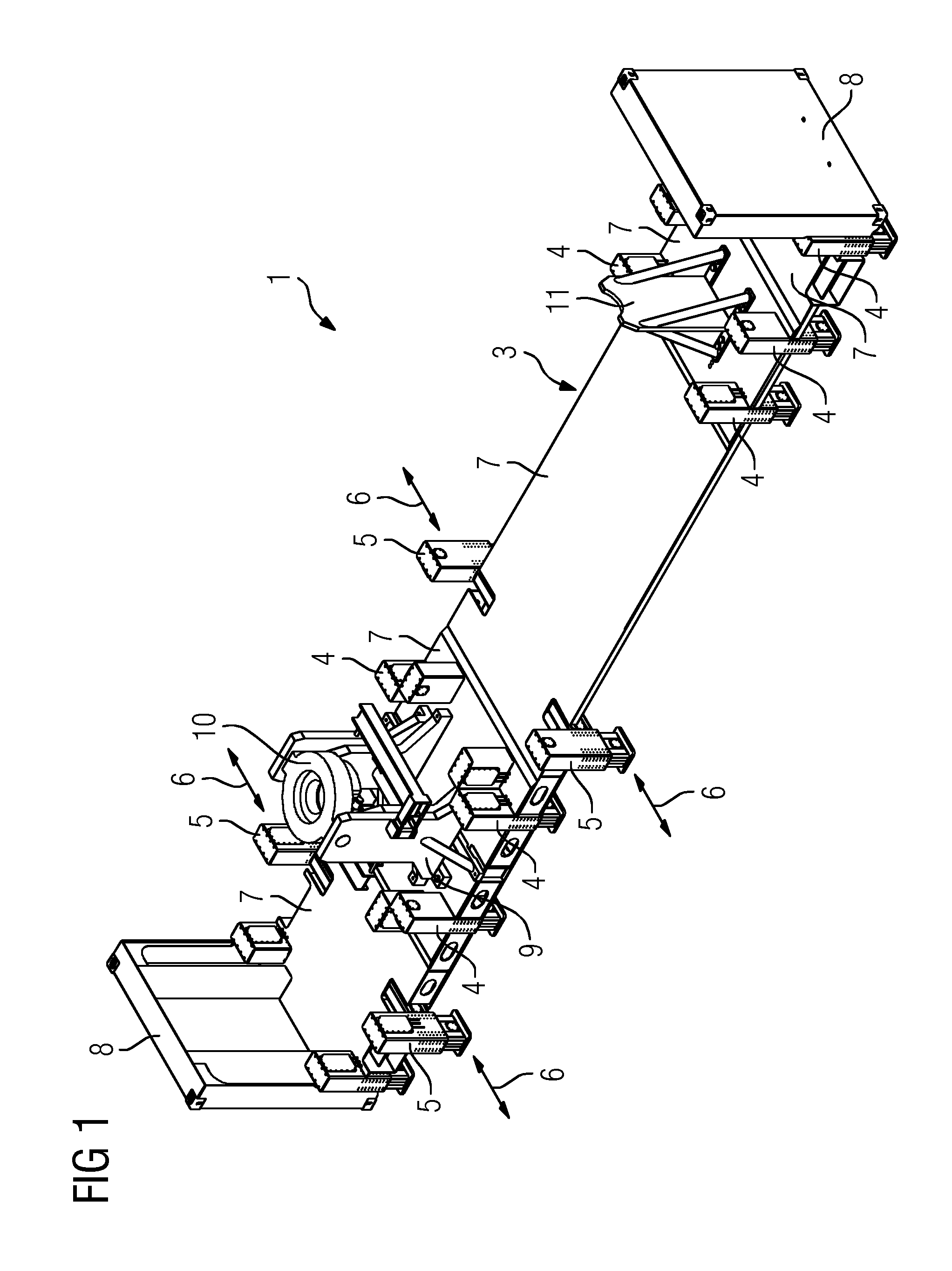

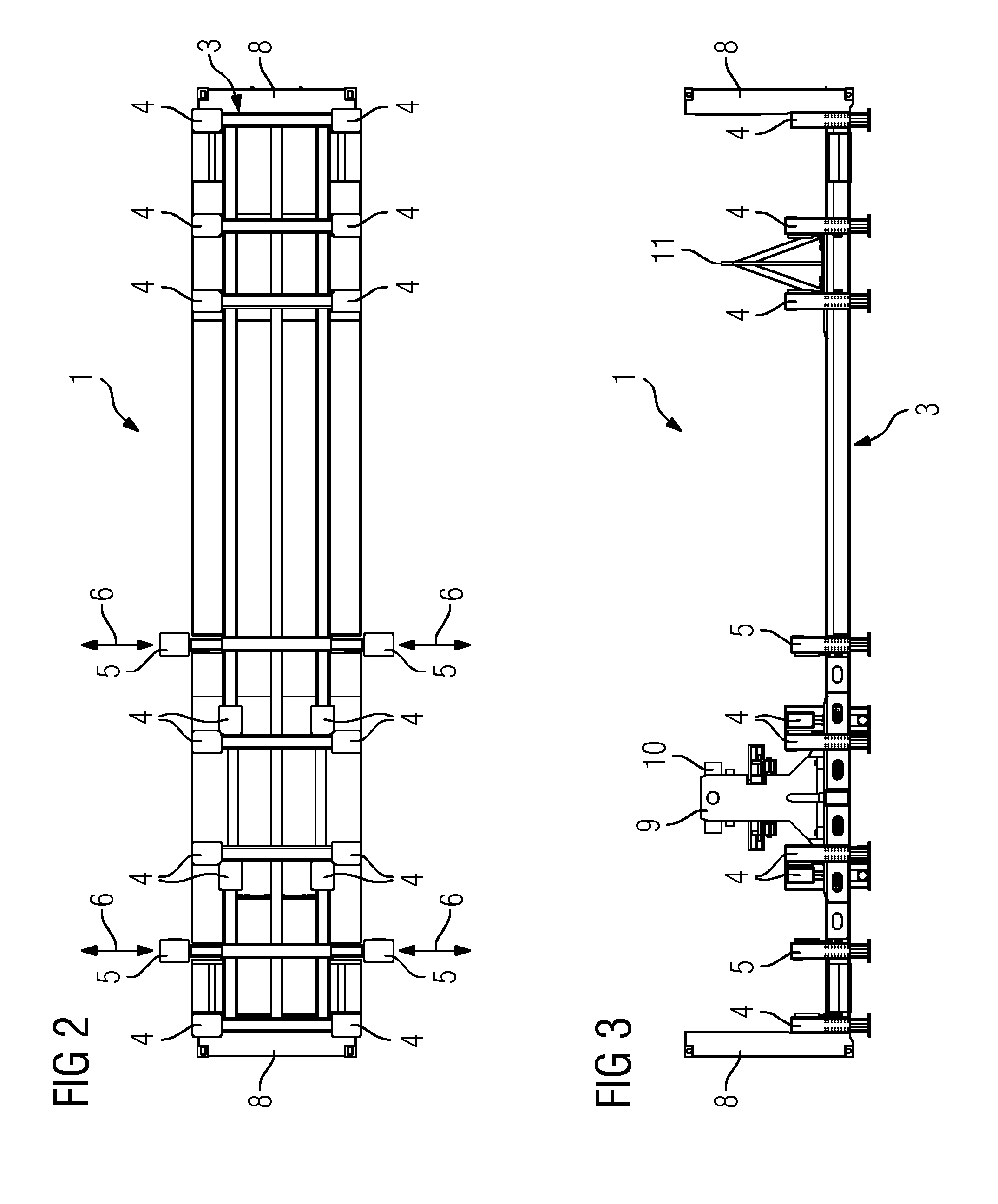

[0033]The Figures show a rotor pivoting system 1 according to an embodiment of the present invention, which serves for setting rotors upright, for example for setting a gas turbine rotor 2 upright. The rotor pivoting system 1 comprises a heavy-duty stand 3 which is provided with a multiplicity of vertically extendable supporting feet 4 and 5. Moreover, the supporting feet 5 are extendable horizontally in the direction of the arrows 6, in order, if required, to improve the steadiness of the heavy-duty stand 3. In this case, actuation of the supporting feet 4 and 5 takes place hydraulically, although, of course, alternative actuation variants will also be envisaged. The heavy-duty stand 3, may, for example, be a steel stand. A plurality of floorboards 7, which define a walk-on plane, are held on the stand. The heavy-duty stand has end walls 8 on its end faces. The dimensions of those walls are selected to correspond essentially to those of the end walls of a standard container, in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com