Process for forming a high loft, nonwoven web exhibiting excellent recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

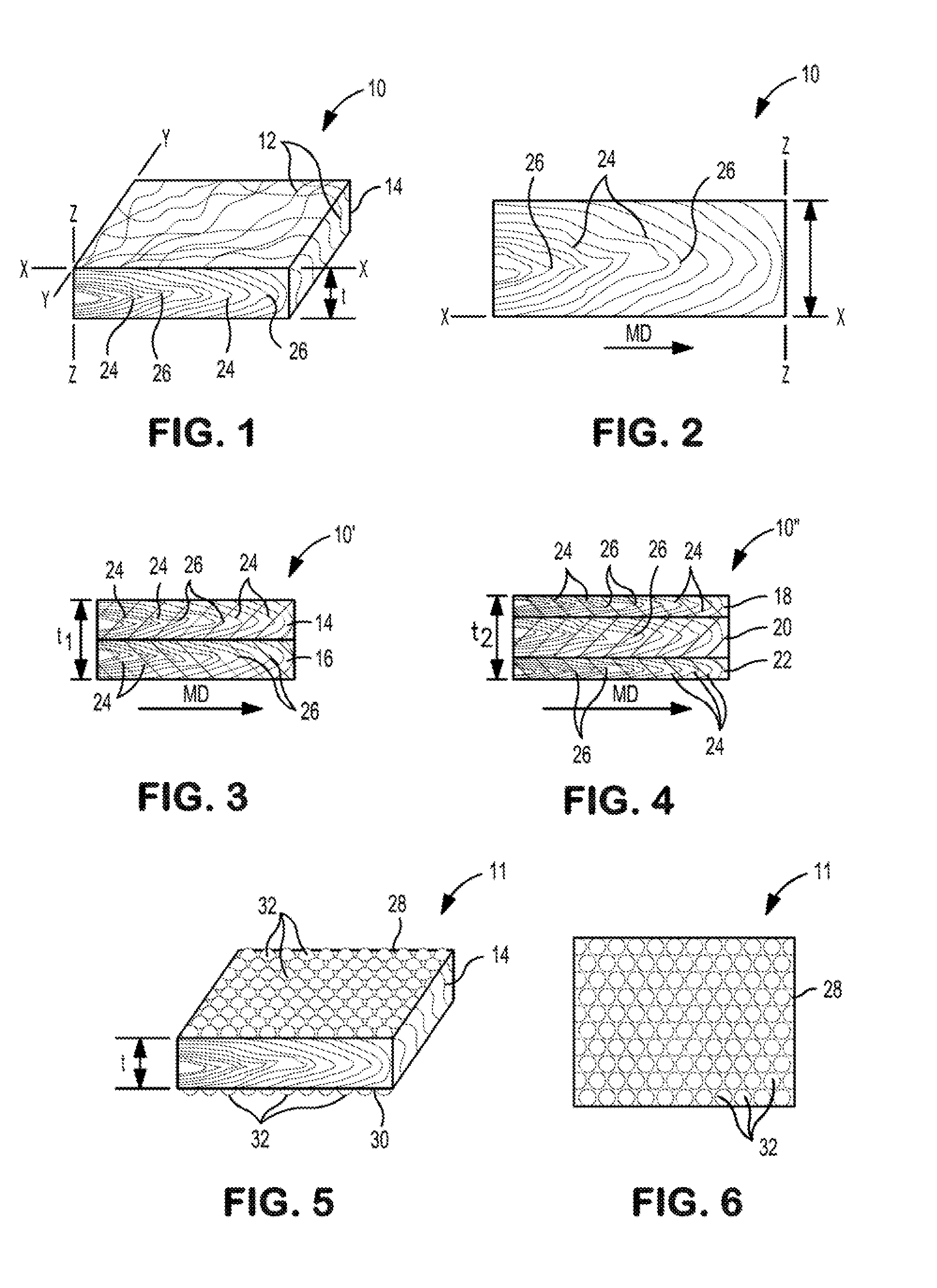

[0097]In this example, the effects of the collector type on the high loft, nonwoven web properties were looked at. Sample 1 and 2 showed a big difference in thickness or caliper of the nonwoven web. The big difference is mainly due to collecting the spun fibers on a flat belt versus collecting them between two rotating drums having a nip gap of 2.5 cm. The dual drum collection system increased the thickness by 1,500% although both samples have the same mass per unit area. Sample 3 showed that by thermally bonding the high loft, nonwoven sample #2, one could enhance the recovery properties by 26%. Such enhancement will greatly increase the thermal insulation and acoustical properties of a web. With the proper tuning of the fiber formation conditions and the bonding conditions, the compression and recovery properties can be greatly enhanced, see Table 1 below.

TABLE 1Table (1): Effect of Collector type on polypropylene high loft nonwoven samplesNipBasisPercentPercentDCD,Collectorgap,we...

example 2

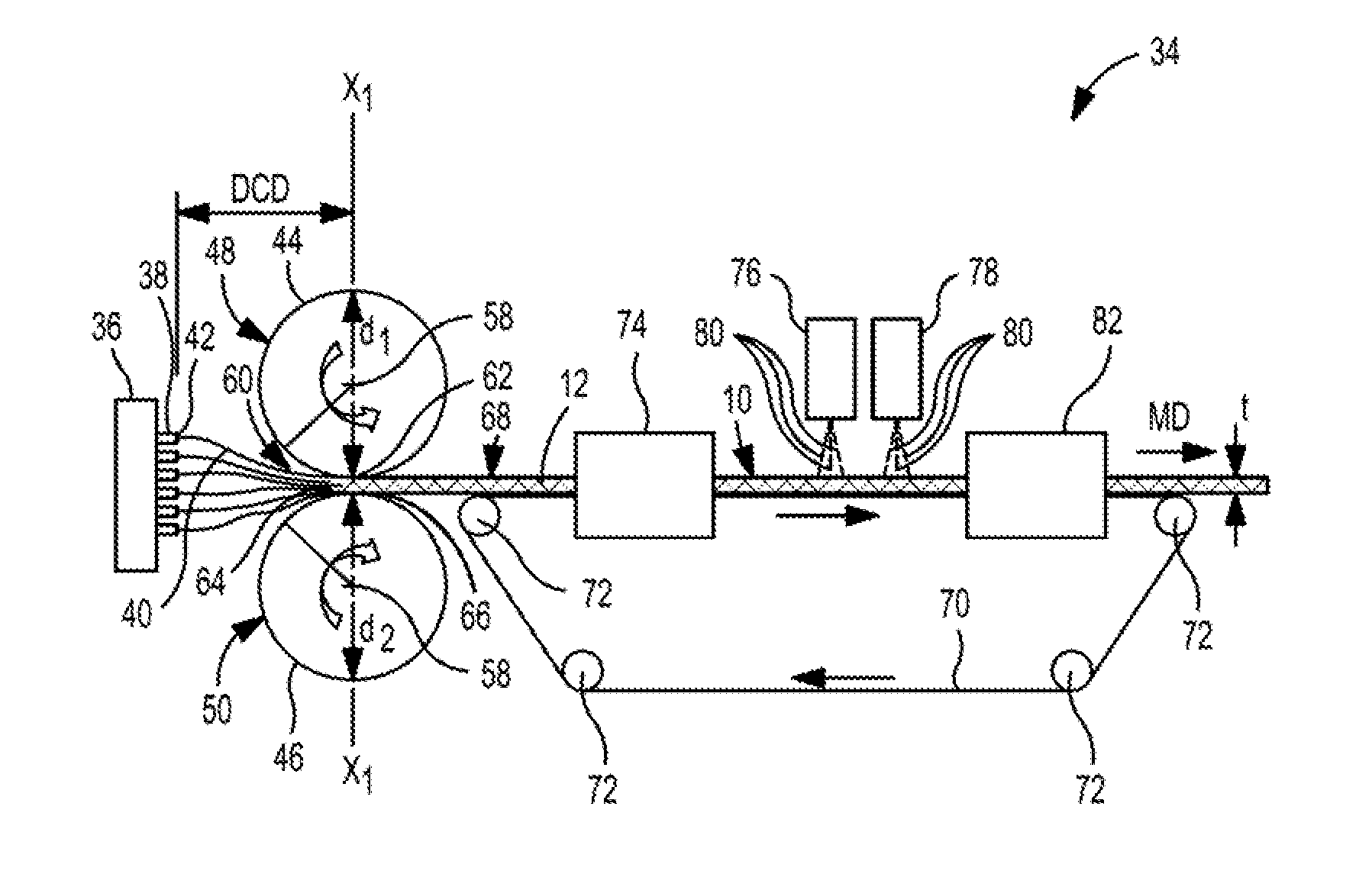

[0098]In this example, the effect of the Die-to-Collector Distance (DCD) on the compression-recovery properties of the high loft nonwoven web samples were looked at. The meltblown filaments were collected at a distance close to the die, where they are very tacky. This action created fiber to fiber bonding in the high loft, nonwoven web samples between the first and second rotatable drums and avoided the need for additional downstream bonding. This might work on equipment operating at a low polymer throughput to produce a high loft, nonwoven web with a basis weight of less than about 150 g / m2. However, when the polymer throughput and the basis weight increases, the blowing air causes the filaments to fly around and they prevent being captured on the first and second rotatable drums because of the difficult air management at a closer Die-to-Collector Distance (DCD). Samples 2 and 3 were collector at a DCD distance of 45 cm from the die face. Samples 4 and 5 were collected at a DCD dis...

example 3

[0099]In this example, the effect that basis weight had on the compression-recovery properties of the high loft, nonwoven web samples were looked at. As shown in Table 3, by increasing the mass per unit area, the compressibility decreased which is obvious because of the larger nonwoven mass passing between the nip of the first and second rotatable drums. It was also noticed that by increasing the basis weight, the percent recovery after compression also increased, which may be due to the larger number of fiber-to-fiber bonds that were created. Collecting the fibers of samples 6 and 7 at a closer Die-to-Collector Distance (DCD) was not successful on the pilot scale because of the difficult air management and the larger mass of filaments that blocked the way in front the blowing attenuation air.

TABLE 3Table (3): Effect of Basis Weight on polypropylene high loft nonwovensNipBasisPercentPercentDCD,Collectorgap,weight,Thickness,compressionRecoverySample(cm)type(cm)Bonding(g / m2)(mm)(%)(%)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com