Touch panel inspecting apparatus

a technology for touch panel inspection and apparatus, which is applied in the direction of instruments, error detection/correction, computing, etc., can solve the problems of considerable degradation in inspection efficiency and the inability of inspection devices to fill a need, and achieve the effect of improving inspection efficiency and easy and flexible force chang

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

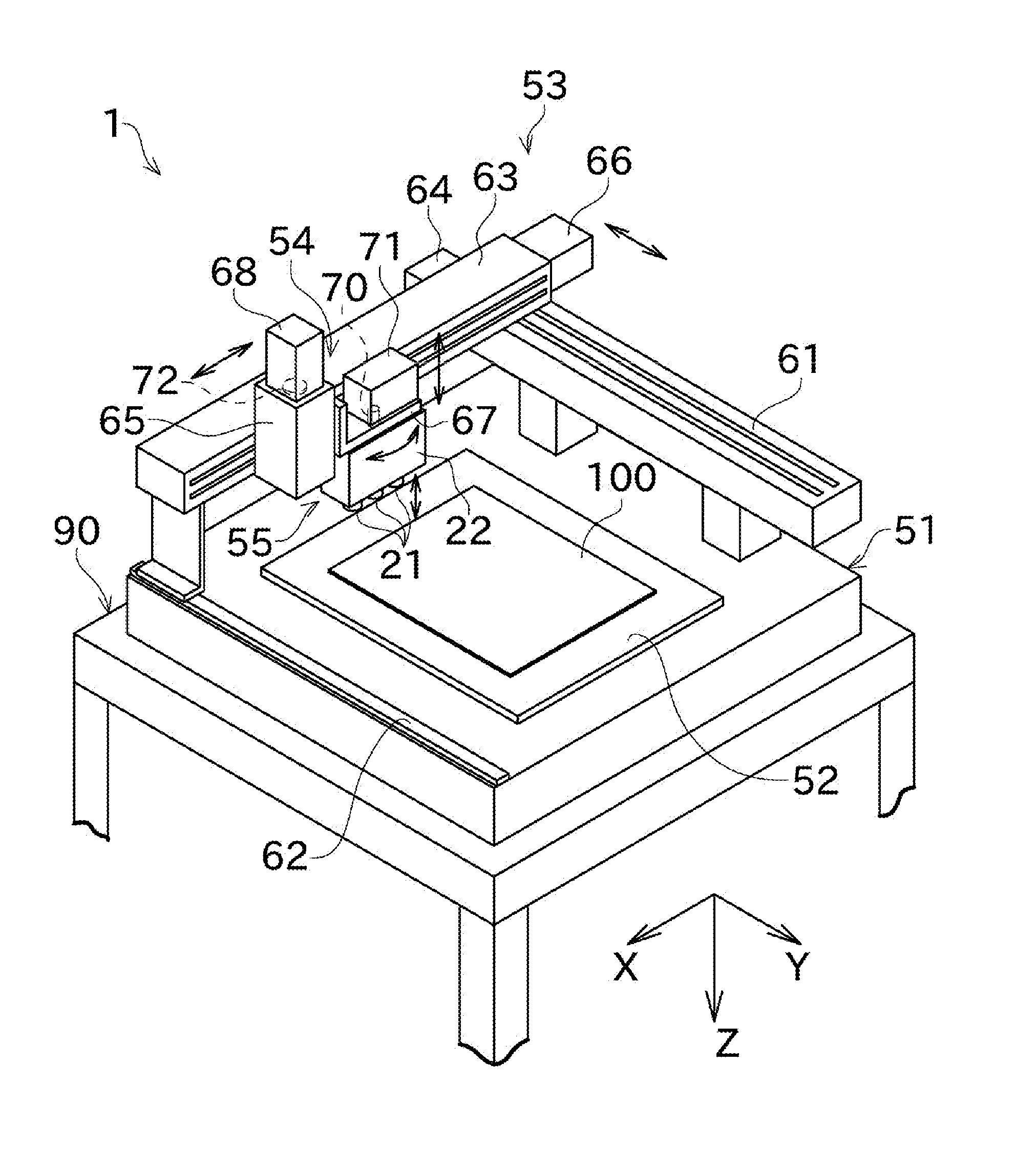

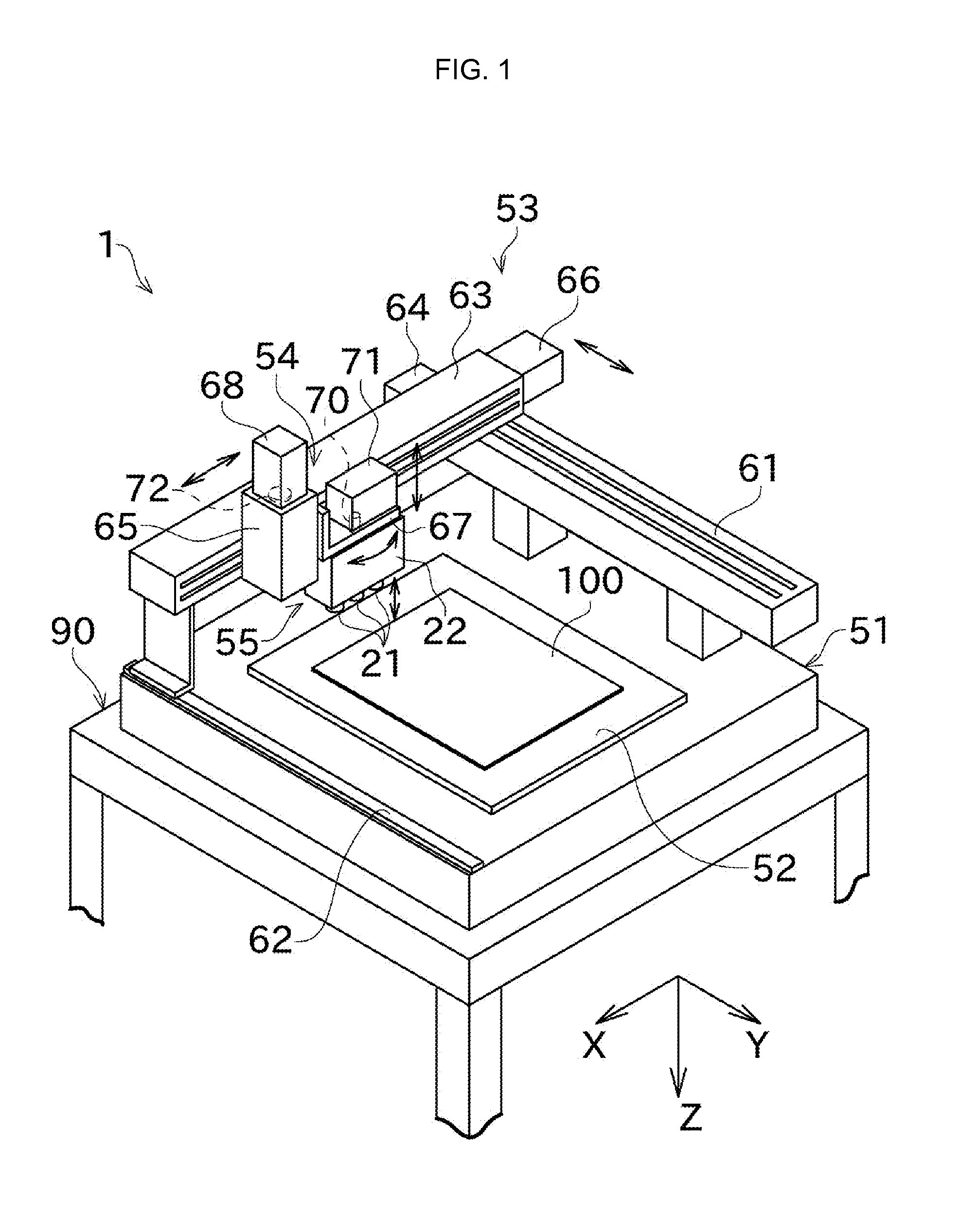

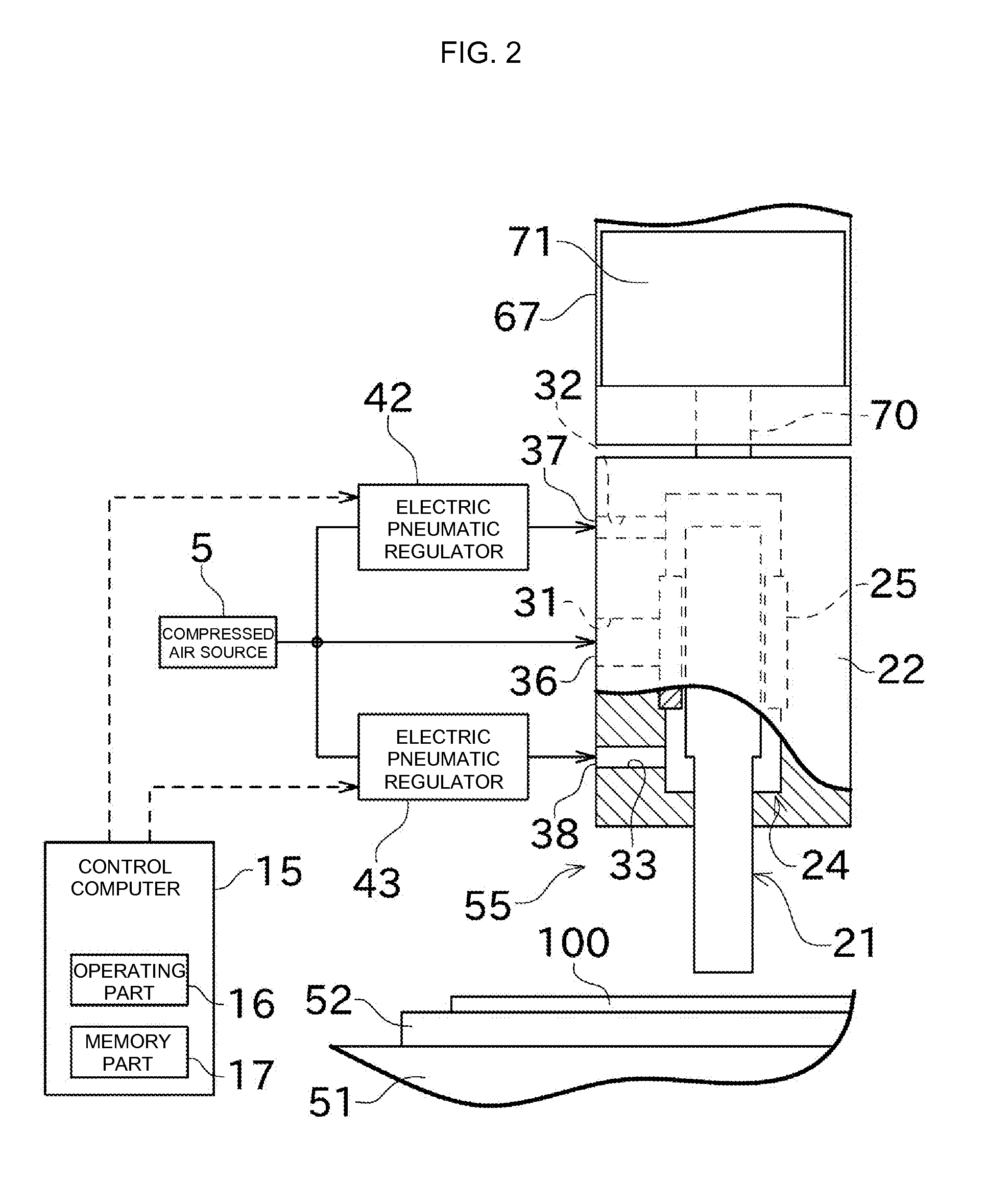

[0031]Various embodiments of the disclosure will be described below with reference to the drawings. FIG. 1 is a schematic perspective view illustrating an overall configuration of a touch panel inspecting apparatus 1 according to an exemplary embodiment.

[0032]The touch panel inspecting apparatus 1 illustrated in FIG. 1 is mounted on a horizontal workbench 90 in active use. The touch panel inspecting apparatus 1 includes a base 51, a workpiece holder (a holding part) 52, an X-Y movement mechanism 53, a Z movement mechanism 54, and a pseudo finger mechanism 55.

[0033]The base 51 has a horizontal upper surface, and an X axis and a Y axis which are orthogonal to each other are defined in a plane parallel with the horizontal upper surface. Moreover, a Z axis is defined in a direction perpendicular to the X-Y plane.

[0034]The workpiece holder (the holding part) 52 is fixed onto the upper surface of the base 51. The workpiece holder 52 has a horizontal flat plate shape. The workpiece holder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com