Engine suspension structure for two-wheeled motor vehicle

A technology for motorized two-wheeled vehicles and engines, which is applied to motor vehicles, motorcycles, bicycles, etc., can solve problems such as weight increase, and achieve the effects of improving support rigidity, reducing costs, and improving exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Hereinafter, preferred embodiments of the present invention will be described in detail based on the drawings.

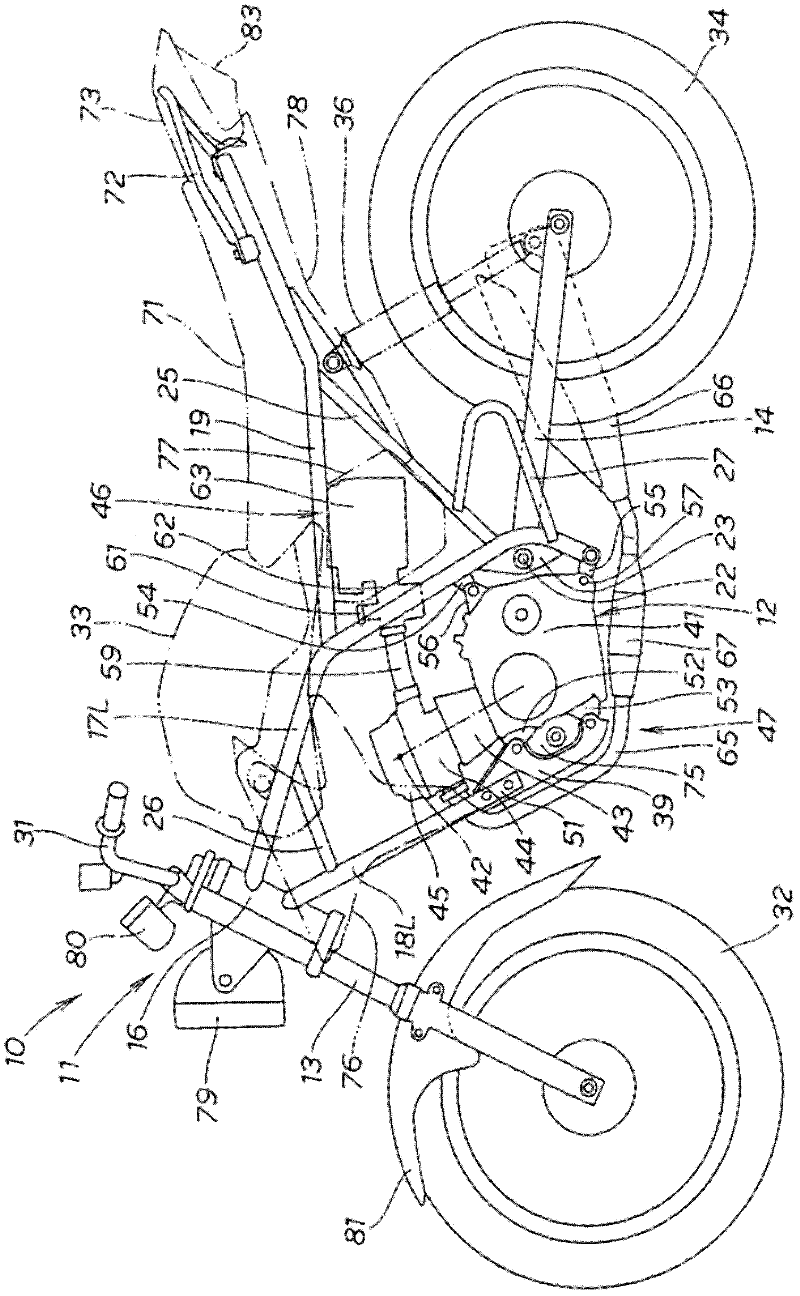

[0040] figure 1 The illustrated motorcycle 10 has: an engine 12 arranged at the central portion of the vehicle frame 11, a front fork 13 manipulably supported on the front end of the vehicle frame 11, and a front fork 13 supported swingably up and down at the rear lower portion of the vehicle frame 11. The left and right rocking arms 14.

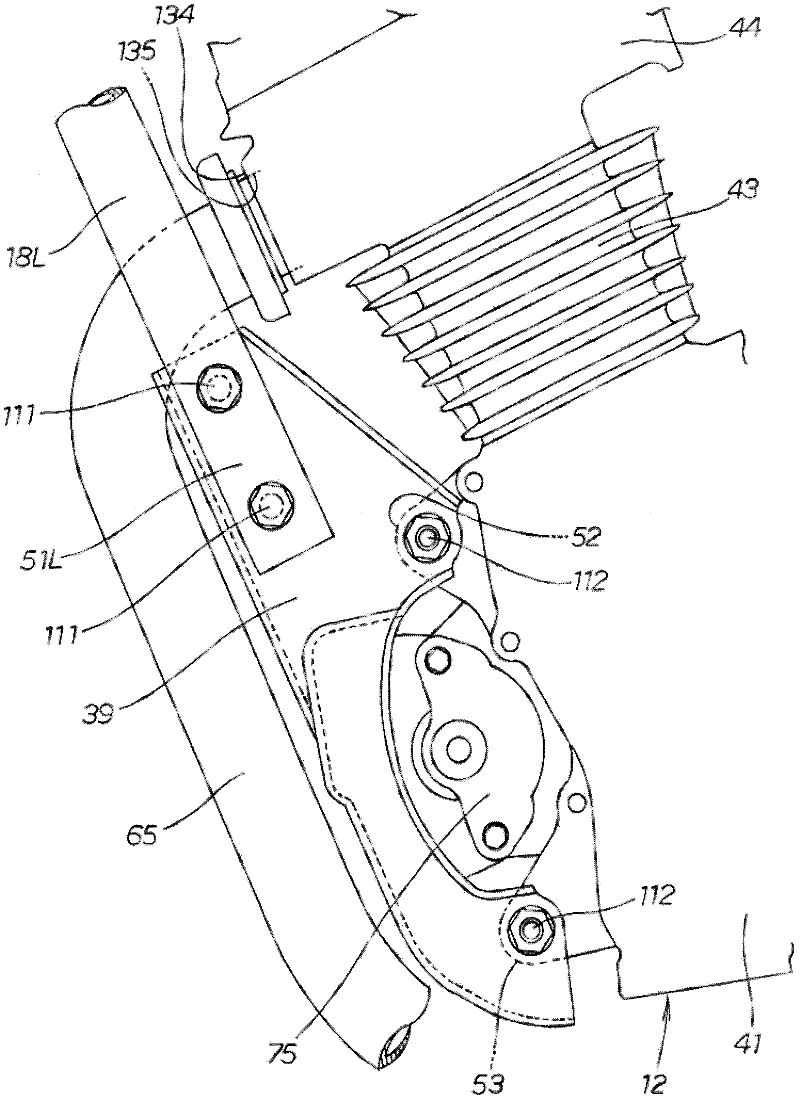

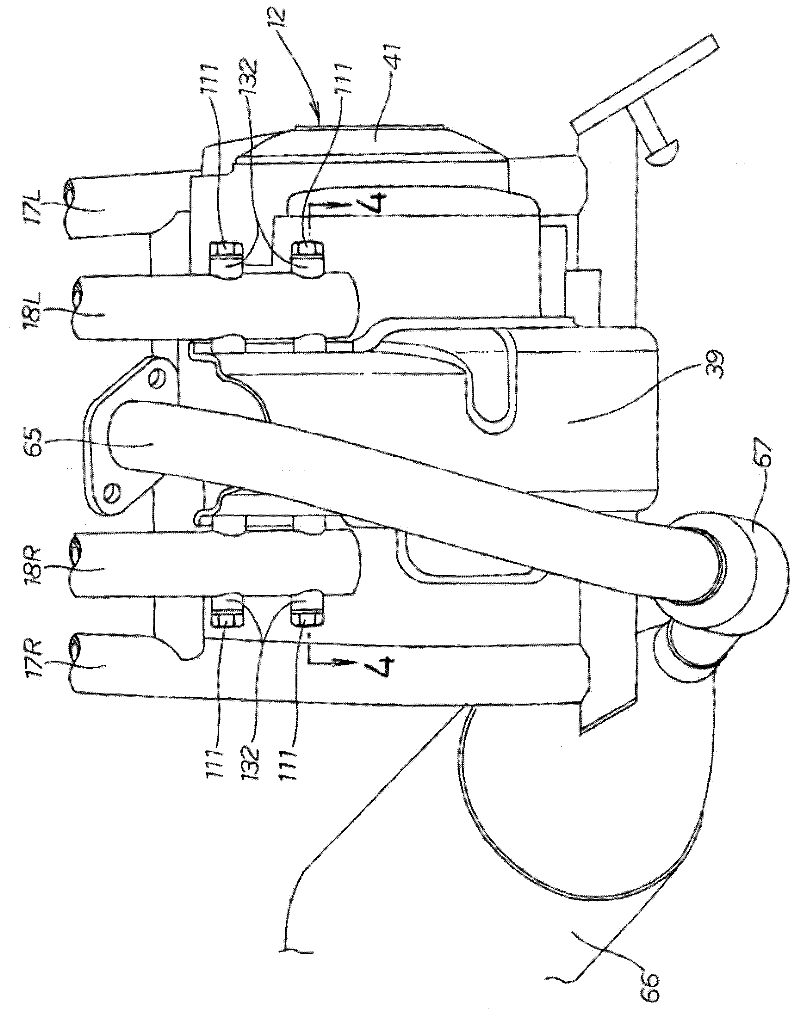

[0041] The frame 11 has left and right main frames 17L, 17R ( image 3 ); the left and right down frames 18L, 18R ( image 3 ), and the front end of the down frame 18L, 18R is mounted on the head pipe 16 below the left and right main frames 17L, 17R; The left and right sub-frames 25 between the respective rear lower parts of the main frame 17 and the respective intermediate parts of the left and right seat rails 19.

[0042] The left and right pivot plates 23 are provided on the lower portions of the left and right main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com